What is Lean Manufacturing?

Lean manufacturing is a philosophy founded on a strategic approach to continuous improvement and sustainability through the holistic elimination of waste and inefficiencies throughout an organization.

Lean manufacturing is more than following a set of rules—rather, it is a philosophical approach that requires changing the pervasive mindset within an organization towards one of learning, innovation, and agility. An important set of ideals to this philosophy is the Toyota Production System (TPS), a set of guiding principles that influence many Lean organizations today. Some concepts, by name, that you might see in a Lean organization are: measurable everything, KPIs, visualization of data; value stream mapping; and a demand-based, “pull” approach to manufacturing.

Jump to a section:

A Brief History of Lean Manufacturing

The development of Lean manufacturing can be traced through history, even before the birth of TPS. While humans naturally desire to improve systems to be more efficient, Frederick Taylor wrote early accounts and Lean production (although not yet known by that name), releasing Principles of Scientific Management in 1911. Henry Ford is commonly referenced as the true starting point of Lean, influencing even Toyota’s principles, because his distaste for waste led him to ruthlessly cut inefficiencies from his auto manufacturing business.

Studying methods within these early documents, Taiichi Ohno began to develop the world-renowned manufacturing processes of Toyota and, with them, the TPS. John Krafcik, an MIT alumni that now works at Hyundai, is official originator of the term “lean” as it relates to manufacturing, coining it via an article he released in the late 1980’s outlining how facilities following these sorts of principles performed better both in productivity and quality, as well as an account of how companies could reduce risk while implementing a “Lean” philosophy.

The Five Principles of Lean Manufacturing

The starting point for most organizations that decide to implement a lean manufacturing strategy is with a 5S strategy, a collection of principles that guide a company towards more organized, efficient, and clean spaces throughout, setting the stage for deeper and more complex lean strategy tactics. Here’s what each “S” in 5S stands for:

- Sort: Sort through items and separate that which is needed and often used from that which is never or rarely used. (A red tag system will sometimes be implemented here.)

- Straighten: Every item should have a home that workers can visit to retrieve the item as well as return it when they’re done. Tools and other items should always be ready and easy to use, arranged in a way that employees can easily find them thanks to clear, simple identification. (Shadow boards are a frequent tool here.)

- Shine: Beyond the tidying that occurs in the first and second S’s, shining is cleaning regularly so other lean standards can be upheld and so defects aren’t missed under inches of dust and grime. This step can also include preventive and predictive maintenance.

- Standardize: Implement standard processes for tasks. This could be a standard method of reviewing and assessing your 5S strategy, a method to clock in and out, or a specific way to perform any other function in the business. SOPs are one method of standardization.

- Sustain: Ensure the sustainability of your 5S strategy through regular review and reassessment as well as continue to uphold commitments made within the current strategy to achieve the slow, steady, continuous improvements that are a foundation of 5S, lean, and Kaizen.

- Safety: Some standards are adding safety as an additional S, creating a 6S strategy, because safety can so heavily impact each of the previous five as well as create inefficiencies of its own.

8 Wastes of Lean Manufacturing

Eliminating waste from the process of manufacturing—whether time, material, or labor—is a high priority, foundational task within a lean manufacturing strategy. There are eight standardized, defined forms of waste that manufacturers can examine that lead to a comprehensive view of where the organization is losing profits to inefficiencies.

We previously covered the eight wastes of lean manufacturing in an in-depth article, but below is a summarized version.

- Defects: When something isn’t working right, there is waste, and there is loss of profit. Poor quality or inconsistent products, poor machine repair, inaccuracies in inventory levels, and even a lack of documentation can all qualify as defects.

- Excess Processing: This occurs when processes move too slowly or are too cumbersome to be efficient, i.e. they are a hindrance to progress rather than a necessity. This involves things like slow approval processes, excess reporting, duplicate data, etc.

- Overproduction: Too much product and not enough need immediately results in waste. If customer needs aren’t clear or forecasting data is inaccurate, among a host of other issues, then overproduction can lead to waste in time, material, and labor alike.

- Waiting: Spending time waiting is called spending for a reason. There are plenty of reasons employees might have to wait around including unplanned downtime, idle equipment, poor process communication, and long setup times.

- Inventory: Safety stock is one place many manufacturers get in trouble with this form of waste. Inaccurate forecasting, overproduction, or poor communication between manufacturing and purchasing can all lead to inventory waste.

- Transportation: If all the things that you need to get to have huge gaps between them, then there is a lot of waste compared to optimizing spaces so that logically-relevant items are closer together. A transportation waste due to a poor factory layout can be a catalyst for other wastes such as waiting.

- Motion: If it gets moved when it really doesn’t need to, that’s waste. “It” here can refer to data, raw materials, people—anything really. Wasted motion comes from bending, squatting, and reaching just as it comes from siloed operations and poor production planning.

- Non-utilized Talent: If employees are undertrained and understimulated, there is waste. Employee talent could be underutilized due to poor management or communication as well as a failure to involve employees in design and development tasks

Benefits of Lean Manufacturing

Lean manufacturing has gained such popularity for a reason—it works. More specifically, it works to reduce inventory overhead, reduce overtime, postpone capital investment, increase throughput, and reduce lead times by an average 99%. Lean manufacturing also results in improved customer service, higher quality, greater innovations, improved stock turns, and obvious boosts to productivity and value-add per person. This offers great financial benefits and supports companies in quickly scaling their operations. Lean strategies also boost agility and competitiveness.

The Benefits of Lean:

- Improve Stock Turns

- Improved Customer Service

- Reduced Waste

- Improved Employee Satisfaction

- Improved Productivity

- Improved Lead Times

- Improved Quality

- Innovation

- Increased Profits

Lean Manufacturing Tools and Techniques

In order to achieve this wide range of benefits, there are tools and techniques for organizations to learn and effectively implement, as well as lean manufacturing software to enable these approaches. There are physical tools like those mentioned above such as red tags and shadow boards. There are also systems, tools, and techniques for lean manufacturing that are more philosophically-linked such as:

Just-In-Time or Just-In-Sequence

This method promotes manufacturing the right amount at the right time—exactly as much as the customer wants when they want it. This reduces inventory waste.

Gemba

This means the real, physical space of work where value happens, like the factory floor. Managers can regularly go on-site to get a close-up understanding of processes and their associated issues, referred to in lean manufacturing as a “Gemba walk.”

Value Stream Mapping

This is a hugely important tool to lean manufacturing, and it refers to a visual representation, like a flow chart, of every single thing in the business that adds value. Waste and inefficiencies become much clearer using this method.

Kaizen

This is the philosophy of continuous improvement that underpins lean manufacturing. Learn more about the benefits of Kaizen in manufacturing.

Bottlenecks

These are places where inefficiencies squeeze productivity to a much slower pace than other items that surround them in their value stream. Reducing inefficiencies here will have a substantial impact, because other aspects of the manufacturing business can already support growth after this process is no longer a limiting factor. It’s “the thing that’s holding you back.”

Kanban

This is a planning system that separates tasks into to-do, doing, and done so manufacturers can focus and manage what’s relevant at the right time. Inventory reduction is one of many benefits of a kanban system.

Continuous Flow

This means keeping production moving at all times with little to no waste or downtime. Continuous flow relies on a manufacturer's ability to examine, evaluate, and improve upon their products and processes.

Armed with these tools and an openness to operate under a new paradigm by making systemic, philosophical changes, manufacturers can create optimized facilities and processes that eliminate waste as well as supercharge their progress and growth potential through lean manufacturing.

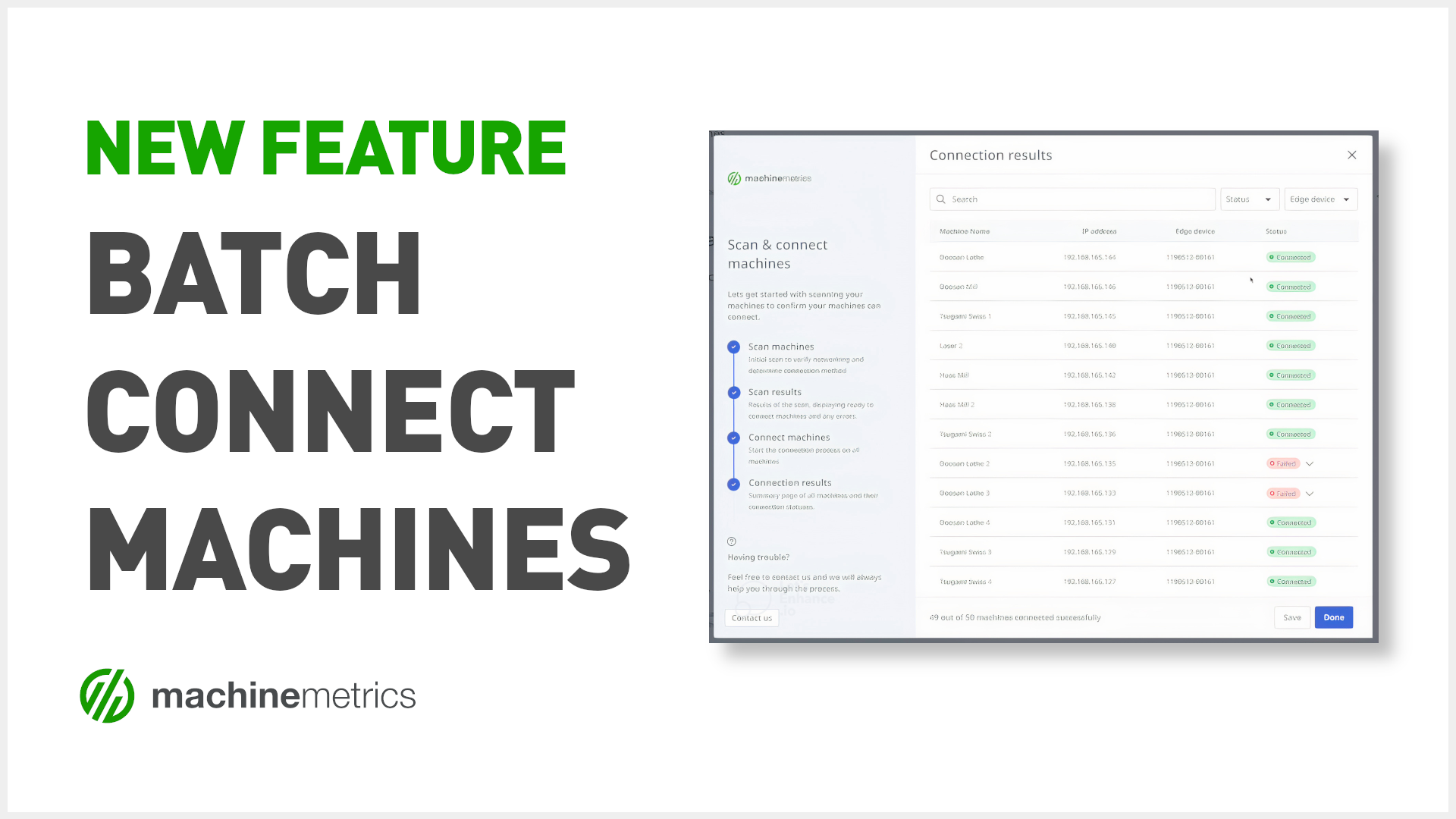

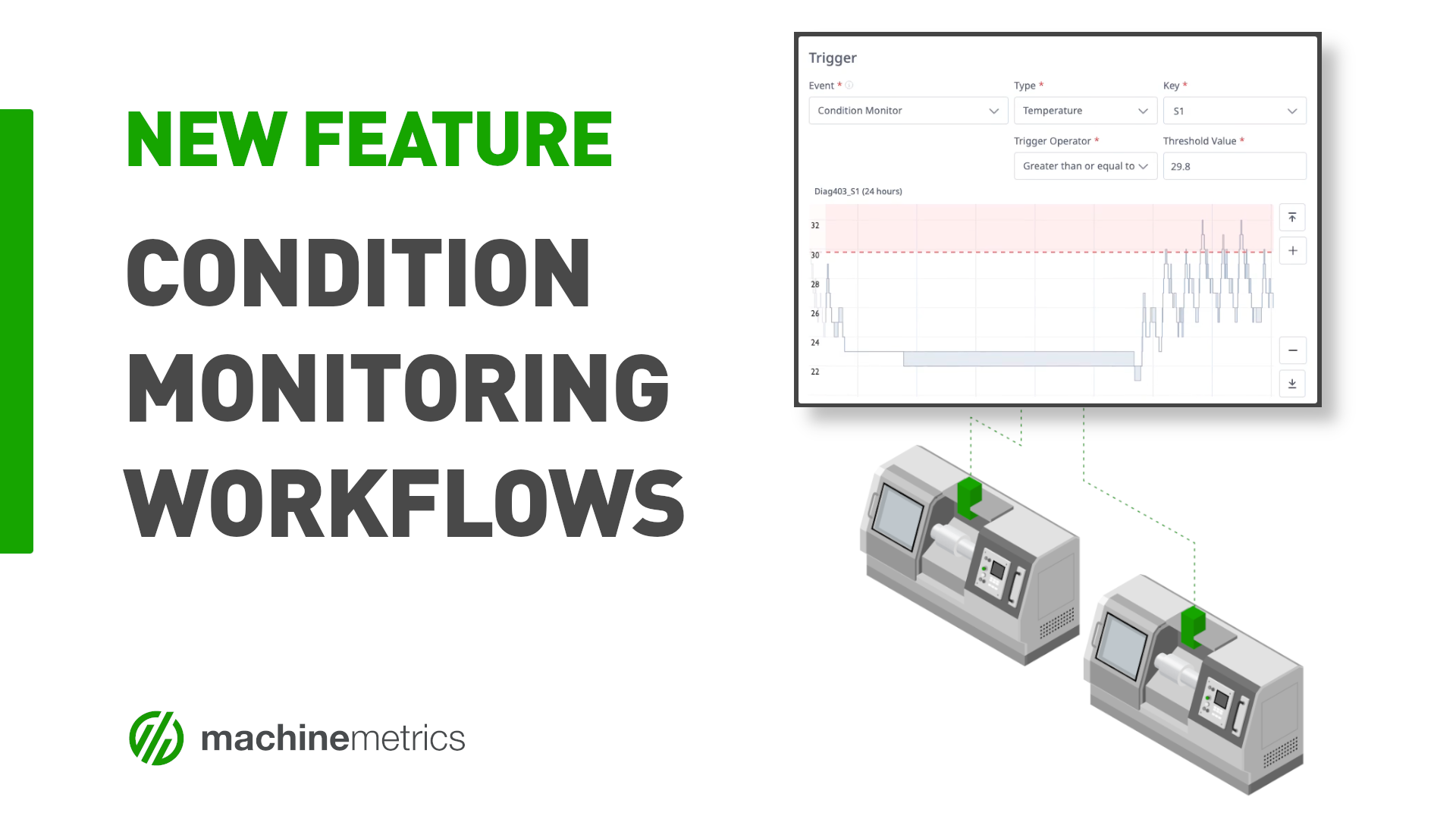

Interested in how an Industrial IoT Platform purpose-built for manufacturers can help drive your continuous improvement initiatives? Get real-time visibility into shop floor performance, track your most important metrics, reduce downtime, and more, all with a plug-and-play solution.

Learn about the MachineMetrics Industrial IoT Platform or book a demo today.

Plug-and-play Machine Connectivity

Comments