What Is Industry 4.0 Technology?

Industry 4.0, also known as the Fourth Industrial Revolution, is all about making business smarter and more automated. Where the Third Industrial Revolution focused on switching mechanical and analog processes to digital ones, the Fourth Industrial Revolution focuses on deepening the impact of our digital technologies by making our machines more self-sufficient, able to “talk” to one another, and to consider massive amounts of data in ways that humans simply can’t—all in the name of efficiency and growth. Industry 4.0 technology represents a foundational shift in how businesses operate, as fundamental as the change from steam power to electricity in the Second Industrial Revolution.

Want to learn more? Read our complete guide on Industry 4.0.

How is Industry 4.0 Technology Impacting the Manufacturing Industry?

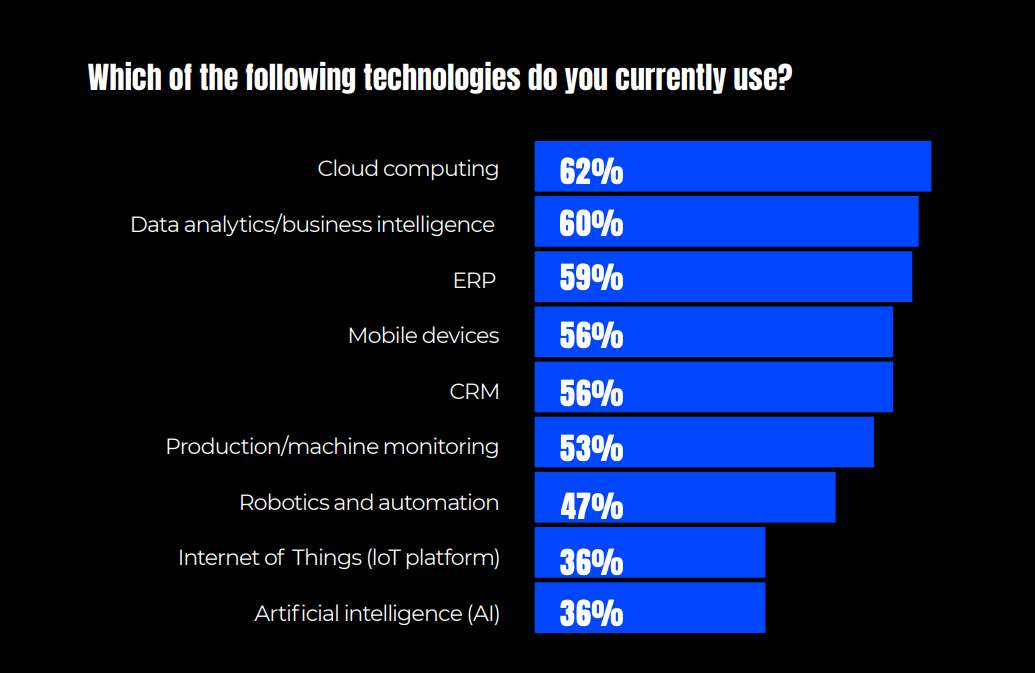

In manufacturing, Industry 4.0 has widespread repercussions. It’s used to leverage operational efficiency, refine demand forecasting, break down data silos, engage in predictive maintenance, offer workers boosts to safety and virtual training, and more. Industry 4.0, as part of a wider concept termed digital transformation, spans manufacturing from planning to delivery, with solutions for deep analytics, shop floor data sensors, smart warehouses, simulated changes, plus product and asset tracking.

For manufacturers, Industry 4.0 technologies help to bridge the gap between what were once separate processes to a more transparent, visible view across the entire organization, with plenty of actionable insights.

10 Real-World Industry 4.0 Technologies with Examples

Below are the top digital transformation technologies brought about by Industry 4.0. Feel free to select any of them to jump to a particular section:

- Big Data & Analytics

- Autonomous Robots

- Simulation/Digital Twins

- Horizontal and Vertical Systems

- Industrial IoT (IIoT)

- Cybersecurity Technology

- The Cloud

- Additive Manufacturing

- Artificial Intelligence

- Augmented Reality

1. Big Data & Analytics

Big Data is exactly what it sounds like—massive amounts of data. Mountains of stats and numbers so huge that humans and teams could spend years sifting through it manually and still not derive a lot of real value. With machines in the driving seat, it’s a whole different story. Using today’s advanced computing capabilities, those huge streams of pure, unadulterated data can be transformed into accurate, actionable insights that can drive decision-making for manufacturing leaders. Data sources can include everything from IoT sensors on factory floors and lighting systems to sales data or supply chain-related factors like the weather and political climate.

Big data underpins much of the other technology of Industry 4.0. The more data is used, the greater the level of effectiveness.

Example of Big Data & Analytics in Manufacturing

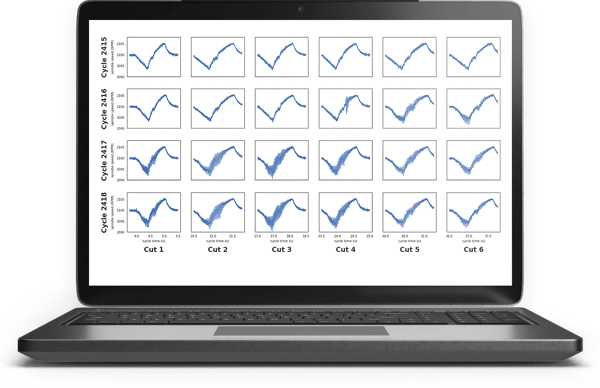

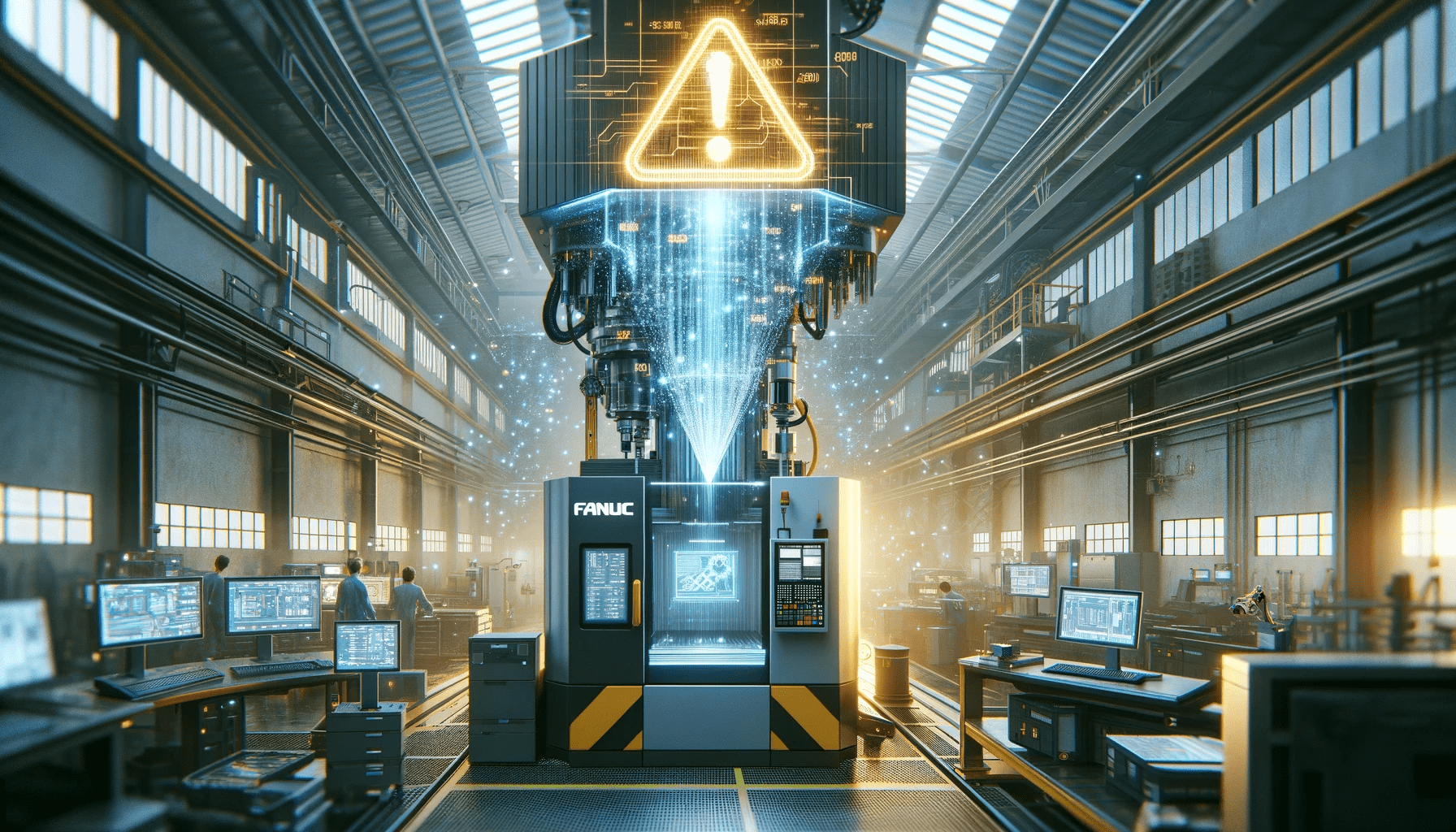

Imagine this: There’s a shop floor somewhere in Wisconsin that has a small sensor (an industrial IoT sensor which we’ll cover in greater depth momentarily) connected to each and every machine in that factory. That sensor is constantly logging and analyzing information both at the sensor site as well as in the Cloud (which we’ll also cover). All the data from this little IoT sensor, including information like how much the machine has been used, is collected and fed into a machine learning algorithm.

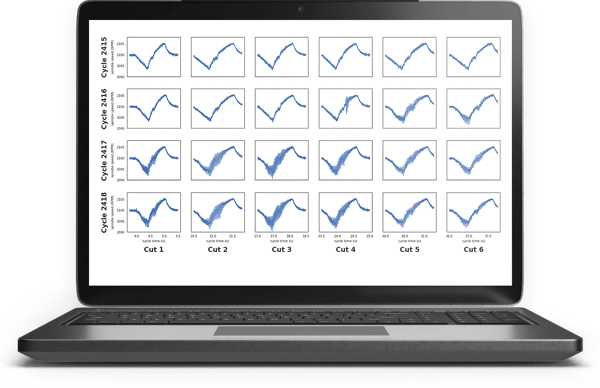

Collected machine data can be analyzed to predict quality defects and extend tool life.

That algorithm, or formula, spits out results regarding that equipment’s maintenance schedule. It says, “This machine’s belt is likely to break in 2-3 weeks.” With that in mind, maintenance is scheduled in ‘off’ hours within a week and the machine maintains operational effectiveness during all working hours. That’s called “predictive maintenance” and it wouldn’t work at all without big data. Big data helps this factory care for its assets, reduce costs, and limit the risk of downtime.

2. Autonomous Robots

Autonomous robots are self-sufficient machines that can manage their tasks intelligently without the need for a human operator. They quickly and accurately perform repetitive tasks, even if they are complex, while requiring little to no downtime except for maintenance.

Example of Autonomous Robots in Manufacturing

Autonomous robots are used in manufacturing to hold and move heavy items on a production line. This helps to prevent human injury for welding, assembly, and palletization. Autonomous robots can also help with order picking at the warehouse level because they have the ability to quickly analyze and choose the most efficient route to pick items—even for multiple orders. They can also be used for continuous production, because they don’t necessarily need breaks.

3. Simulation / Digital Twins

A digital twin, despite sounding like something ripped out of a sci-fi movie, is the very authentic technology behind creating a simulation of a real-world object, concept, or area within a digital space. It can include a 3D representation of all of the physical assets, operational systems and structures within an entire facility. The use cases for digital twin systems are hugely broad.

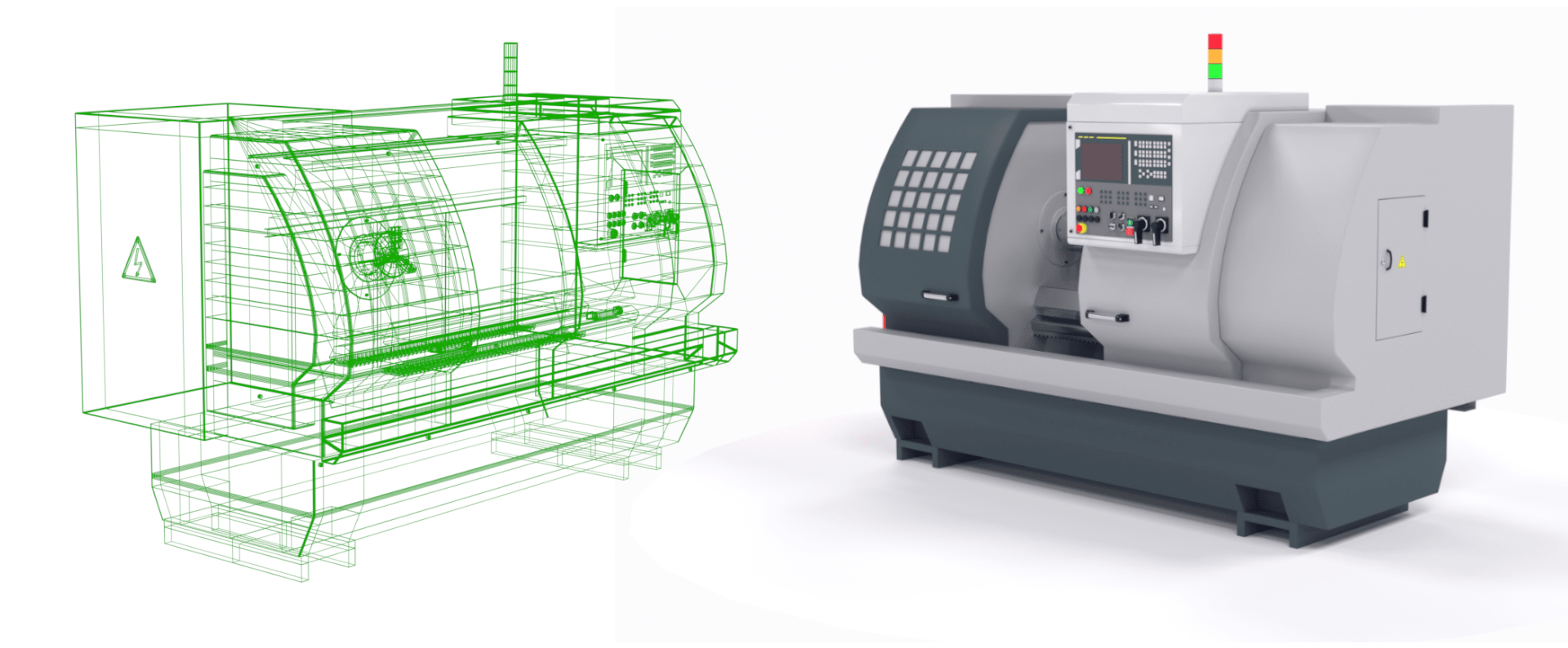

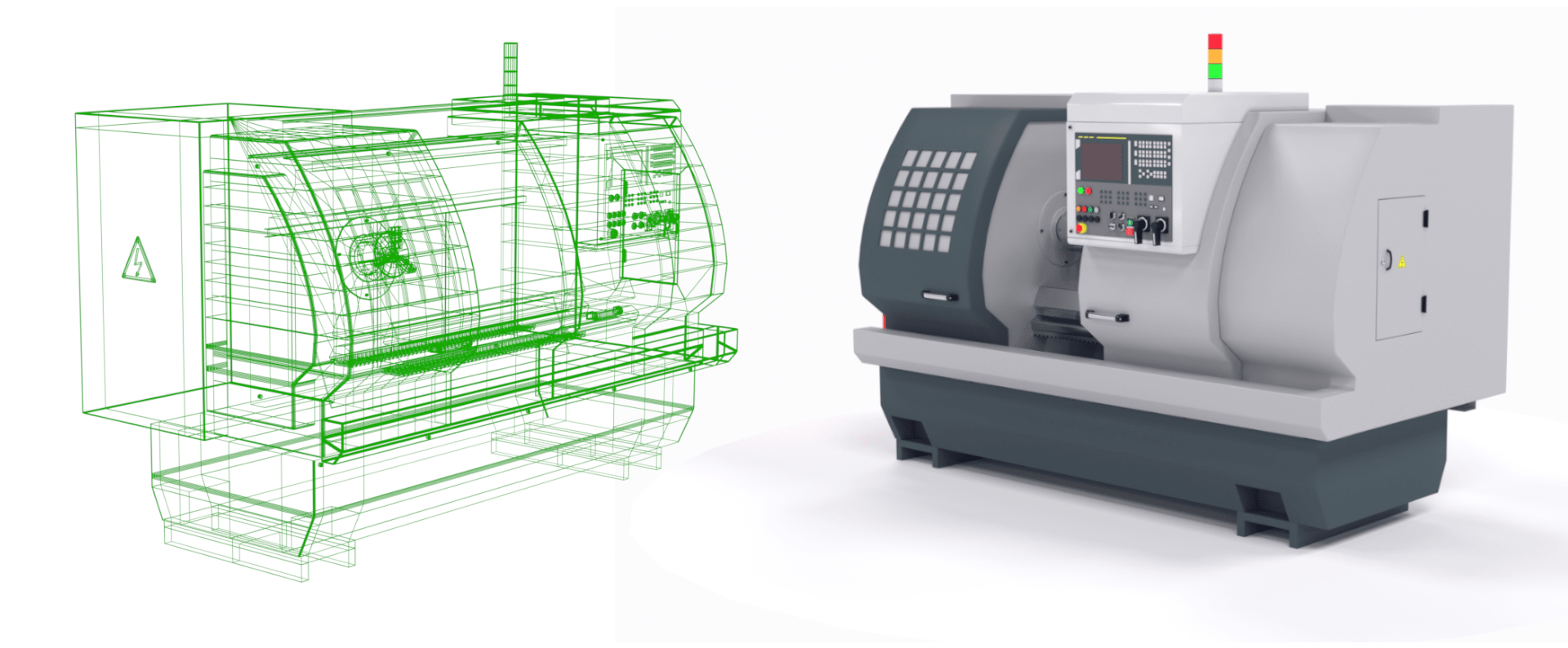

A digital twin of a CNC machine, a sort of 3D model on "steroids".

Example of Simulation / Digital Twins in Manufacturing

Using industrial IoT sensors, a manufacturing company can “see” their entire shop floor in virtual space. They can view the location of every asset, its uptime, and maintenance needs (even those that have not yet arisen). They can even ‘look’ inside of machines which would be dangerous or costly to open in real life.

Using this digital twin and machine learning, manufacturing leaders can predict maintenance tasks and find times to better utilize the equipment to reduce manufacturing bottlenecks. They can train employees at a safe distance before introducing them to the non-simulated machines on the floor and test ideas for operational changes before spending money, time, and energy implementing them.

4. Horizontal and Vertical System Integration

Horizontal and vertical integration has been called the “backbone of Industry 4.0.” The premise of horizontal and vertical system integration is connectedness and visibility. This could mean either within a single organization or outside of it with industry partners. Machines and companies are constantly communicating and sharing data, helping to achieve deeper analysis opportunities, greater transparency, and increased efficiency for all.

Example of Horizontal and Vertical System Integration in Manufacturing

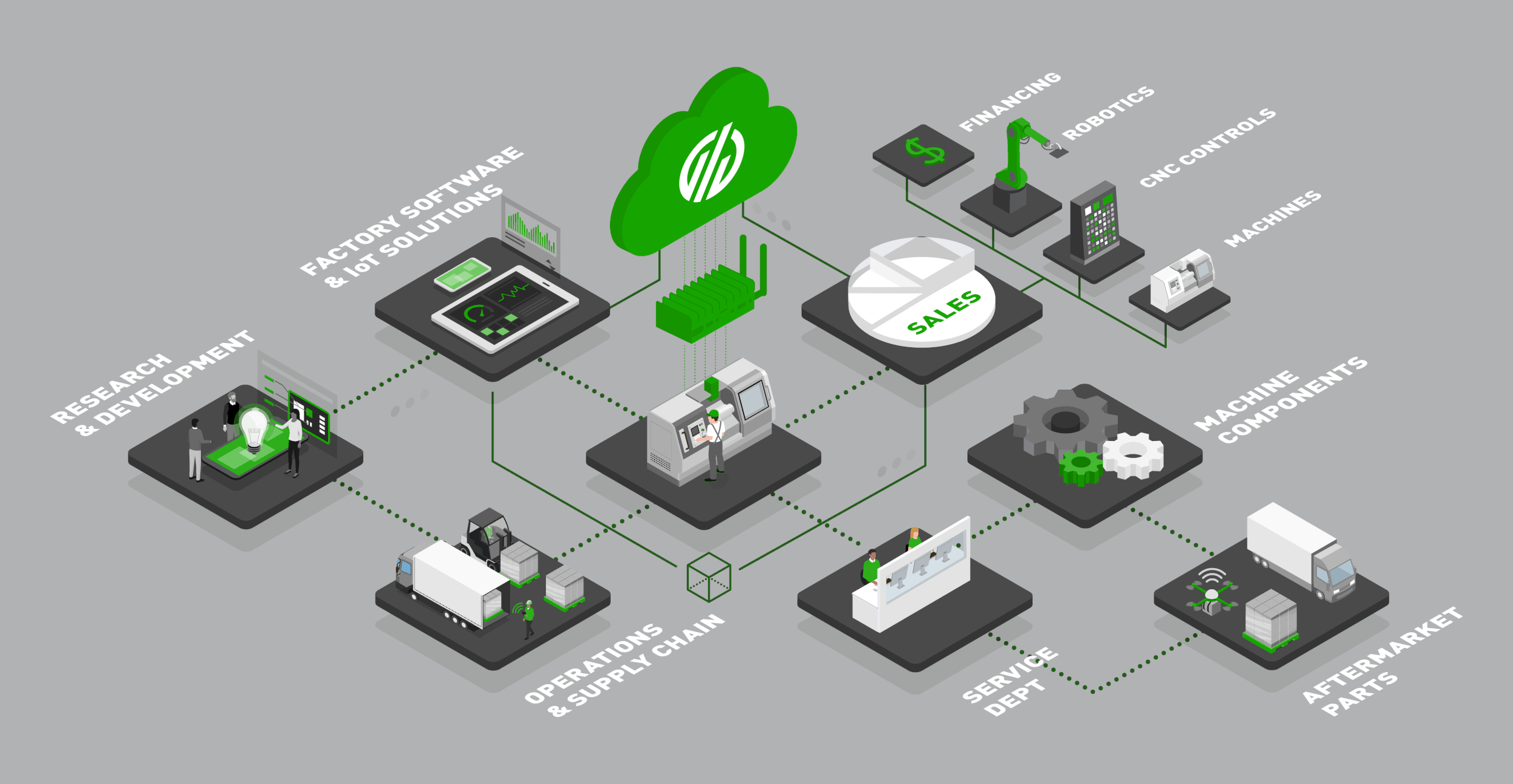

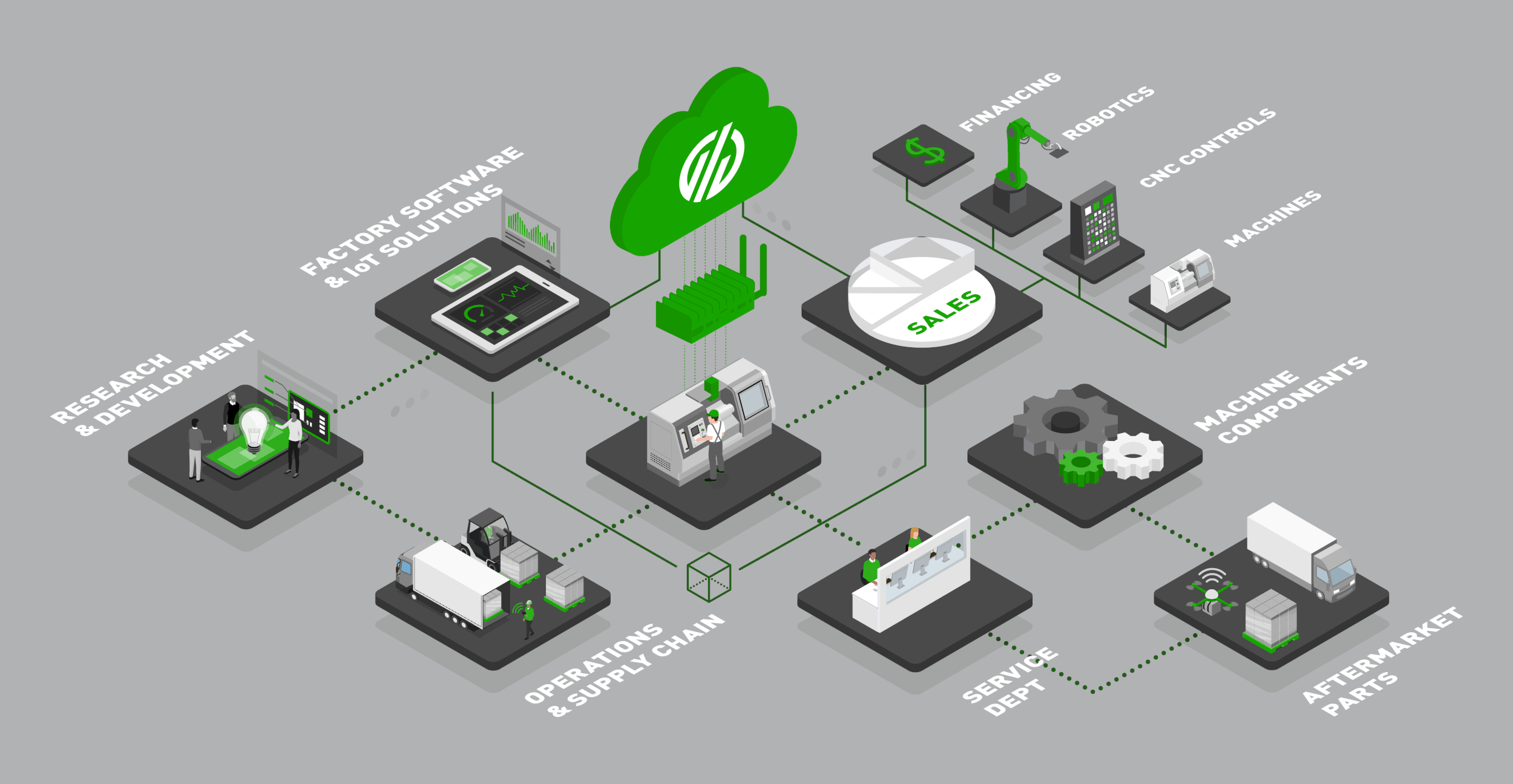

If a company has within it multiple production facilities, horizontal integration can ensure seamless sharing about data issues such as inventory levels and delays. Vertical integration in manufacturing can include breaking down interdepartmental silos so the entire organization works as a unit—from R&D to procurement, and manufacturing to sales and beyond. Everyone shares data, everyone benefits and everyone operates dynamically.

5. Industrial IoT (IIot)

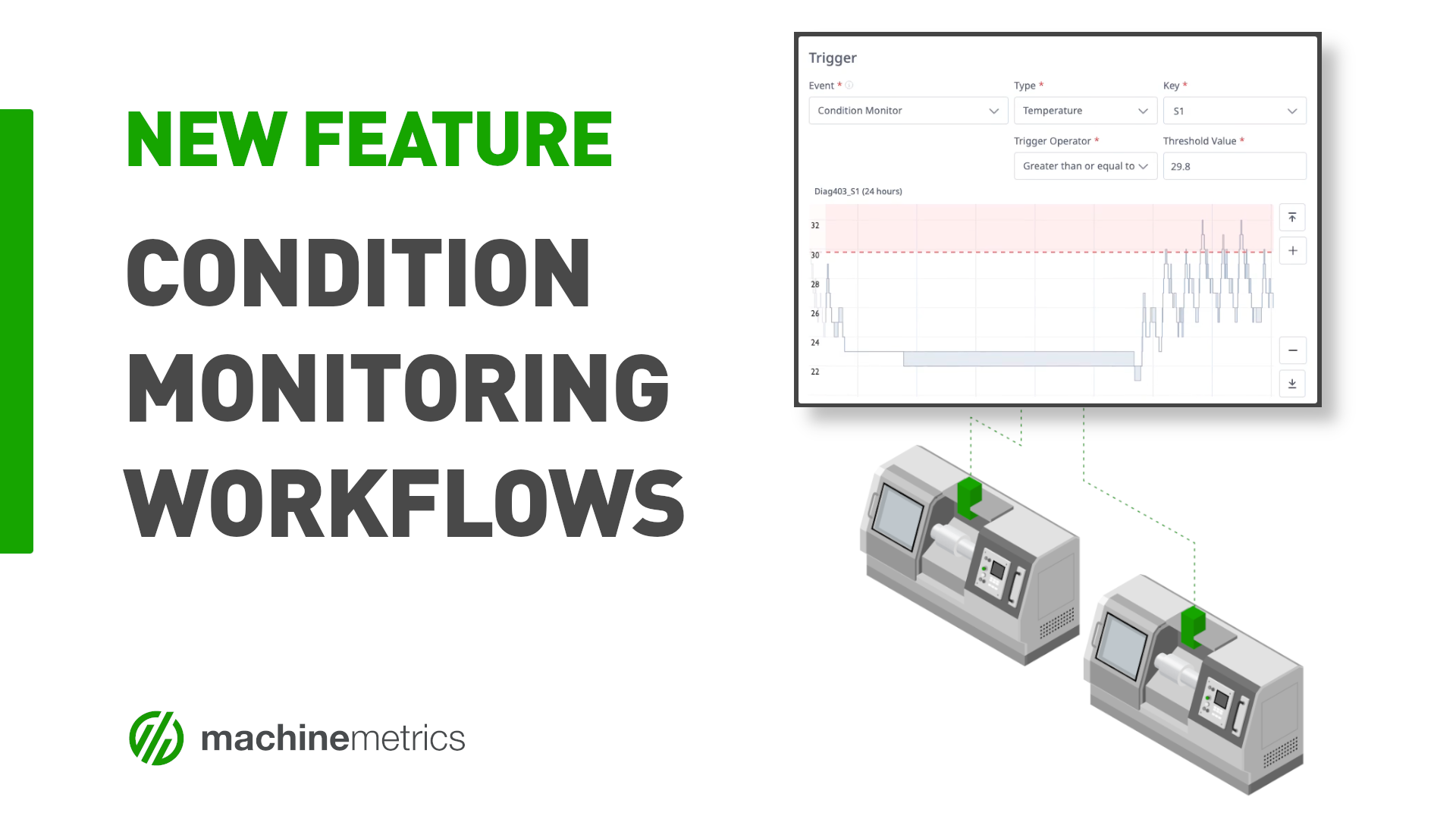

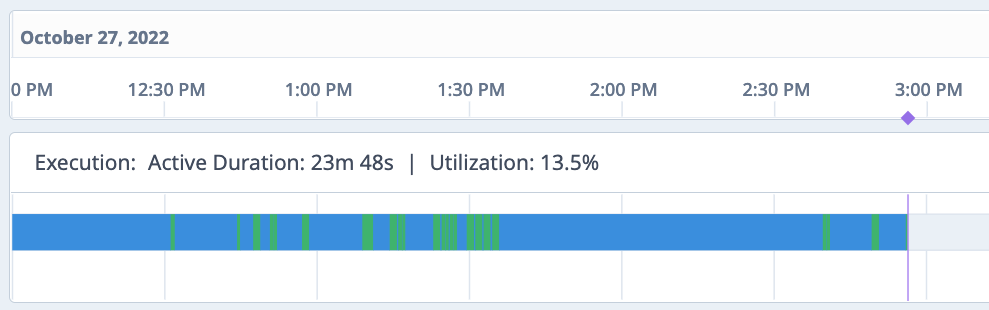

Industrial IoT refers to the deployment of small sensors, sometimes with computing capabilities, that collect and monitor data in real-time throughout businesses. IoT sensors can be deployed in conjunction with basically anything from lights to HVAC (Heating, ventilation, air-conditioning) to factory floor machinery. Industrial IoT is a foundational technology of Industry 4.0. The benefits of connected equipment are tremendous, as it provides insight for better decision making on many levels of the organization.

A fully connected industrial operation leverages Industry 4.0 technology, including IoT, to gain deeper insight into performance.

Example of Industrial IoT (IIoT) in Manufacturing

We’ve already discussed the role of Industrial IoT in predictive maintenance. Another example of IIoT in manufacturing involves breaking bottlenecks and driving massive upticks in production throughput.. If each machine on a production floor has an IoT device connected to it that monitors production efficiency, usage, uptime, etc., then this data can be used in conjunction with a machine learning algorithm. This determines which piece of machinery represents the highest priority bottleneck as well as how to fix it. Does the machine need an upgrade? Does it simply need to be utilized at more points during the day?

Want to See the Platform in Action?

6. Cybersecurity Technology

You can’t have lots of technology involved in every level of your business without some sort of protections in place to keep hackers and other nefarious agents out of your systems. Cybersecurity technology is anything that protects your digital systems from internal and external attack vectors. Modern cybersecurity involves tech such as blockchain or artificial intelligence and can guard new technologies such as industrial IoT devices.

Example of Cybersecurity Technology in Manufacturing

With digitized, smart systems in place, manufacturers without sufficient cybersecurity are exposed to the threat of stolen intellectual property, manufacturing equipment commandeered by saboteurs to create faulty products, ransomware, identity theft, and more. However, manufacturers can mitigate security threats by creating a plan in case they experience a breach, as well as enable protective cybersecurity measures that safeguard their data and equipment, including their IoT systems.

7. The Cloud

The Cloud is a nebulous term that refers to a broad number of connected systems on the internet. Usually, it means a server located offsite from your business. The “Cloud” can be used for software and data that is stored somewhere on the internet (e.g. someone else’s server) instead of on a local machine.

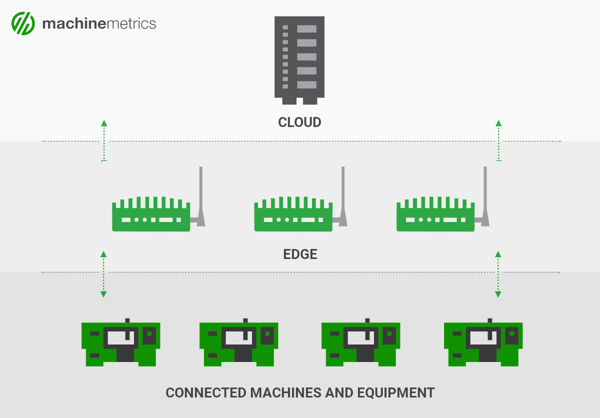

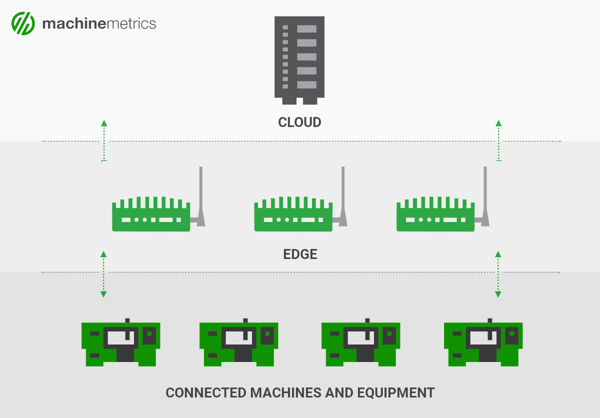

In a complete IoT architecture, manufacturers can leverage both the cloud and the edge to deliver rapid decision making with deep processing power and scalability.

In a complete IoT architecture, manufacturers can leverage both the cloud and the edge to deliver rapid decision making with deep processing power and scalability.

Example of The Cloud in Manufacturing

The Cloud offers a lot of benefits to manufacturers. It can hold vast amounts of sensor data securely with redundancies already in place. It can safely hold customer data. It can be used for computing. Computationally-intensive tasks such as risk modelling using machine learning can be done on the Cloud to reduce overhead costs for high-powered machinery. In recent years, it has also been used for “cloud manufacturing” which can refer to software or true, distributed manufacturing across disparate geographical locations.

8. Additive Manufacturing

Additive manufacturing means creating items layer by layer, adding new material rather than subtracting it. This is compared to the old way of manufacturing (subtractive manufacturing), which covers tasks like cutting and carving wood, etc.

Example of Additive Manufacturing in the Manufacturing Industry

3D printing is a form of additive manufacturing. Mainstream adopters include Adidas which 3D prints shoes, the designs of which were created based on big data.

9. Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning refer to machines which utilize algorithms to process data and reach conclusions that were not programmed into them by human developers. These machines learn from data in order to generate increasingly accurate predictions.

Example of Artificial Intelligence in Manufacturing

Artificial intelligence and machine learning are widely used in manufacturing for demand forecasting and predictive maintenance. Because AI can consider vast arrays of data from sensors and other sources, it is a perfect candidate to anticipate volatile, complex, dynamic situations in near to real time in a way humans cannot. AI works well to forecast and predict market changes for manufacturers.

10. Augmented Reality

Augmented reality includes extra sensory input, usually visual, overlaid onto the actual world. Common examples include Google Glass and the game Pokémon Go.

Example of Augmented Reality in Manufacturing

In manufacturing, augmented reality can be used for worker training and maintenance alike. New employees can learn how to use machinery that could be dangerous in a safe, virtualized environment before entering the factory floor. AR can also be beneficial during maintenance tasks by offering tooltips, repair manuals, and other notations to become readily visible on-site, within the technician’s field of vision. Augmented reality also allows technicians to see inside dangerous and complicated machinery before they open it up, so they know exactly what they’re looking for and what to do before they start.

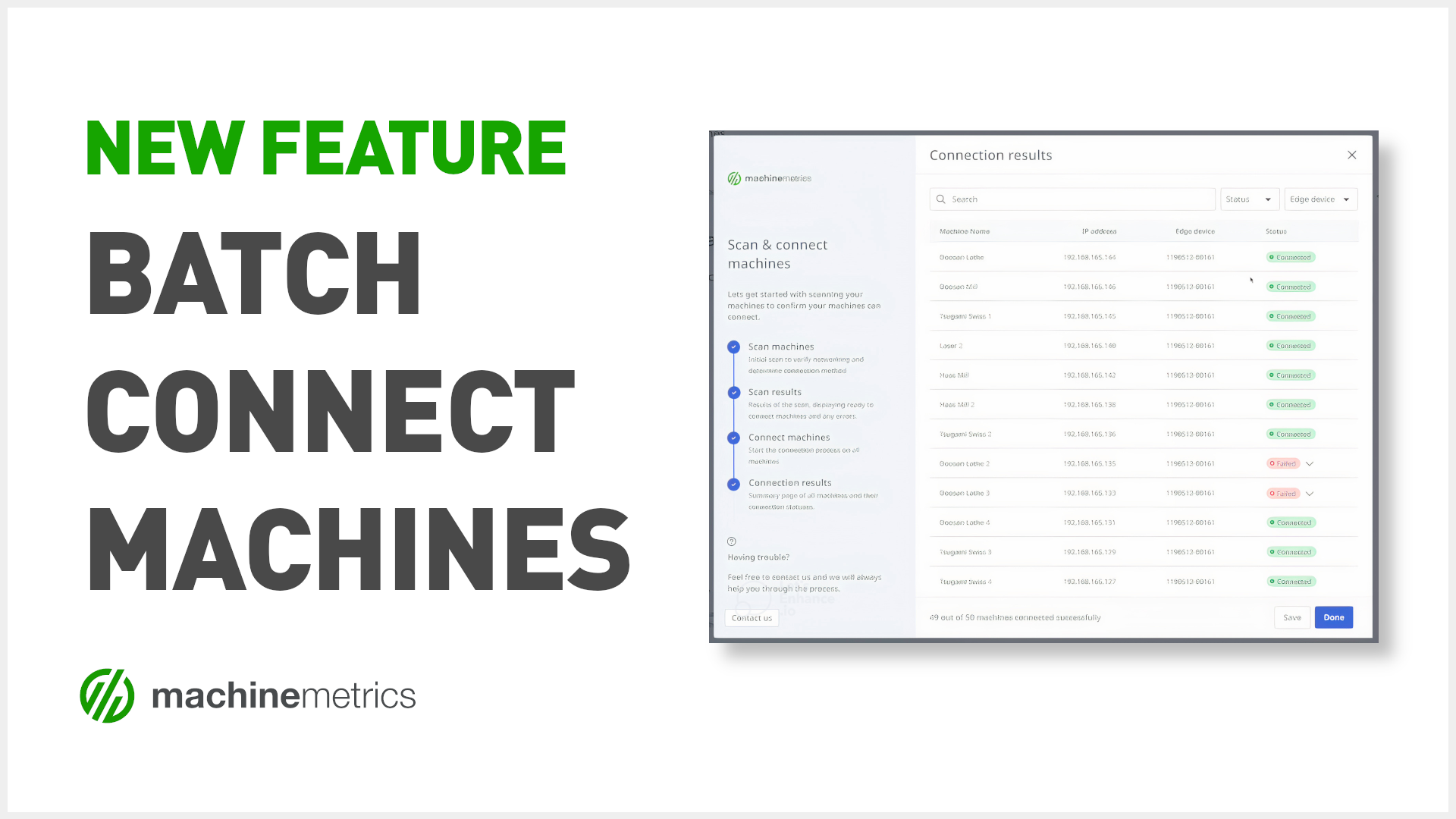

MachineMetrics is accelerating digital factory transformations by providing an intuitive and flexible industrial IoT platform to easily collect and transform data from any piece of manufacturing equipment into powerful, actionable applications.

Right now, hundreds of manufacturers have connected thousands of machines to MachineMetrics across global factories to reduce machine downtime, optimize capacity, and drive increased throughput and profitability for their manufacturing operations.

Ready to connect your shop floor?

Comments