Smart Industry has said, "Industry 4.0 should boost production flexibility, enabling a facility to rapidly adapt its operations to market changes. For instance, a plant control system could autonomously adjust output based on fluctuating utility prices, thereby optimizing the costs of production."

Industry 4.0 certainly has some amazing benefits and has come a long way over the past few years, but there are still some challenges to overcome. For example, cybersecurity remains a major concern and is one of the largest challenges brought forth by the Fourth Industrial revolution.

Below, we break down the pros and cons of Industry 4.0 to give you insight into what manufacturers and industrial organizations keep in mind when approaching digital transformation initiatives.

The Benefits of Industry 4.0

- Competitive Advantages: Industry 4.0 smart solutions and services offer a wide range of competitive advantages for organizations that are able to successfully launch these new strategies and technologies.

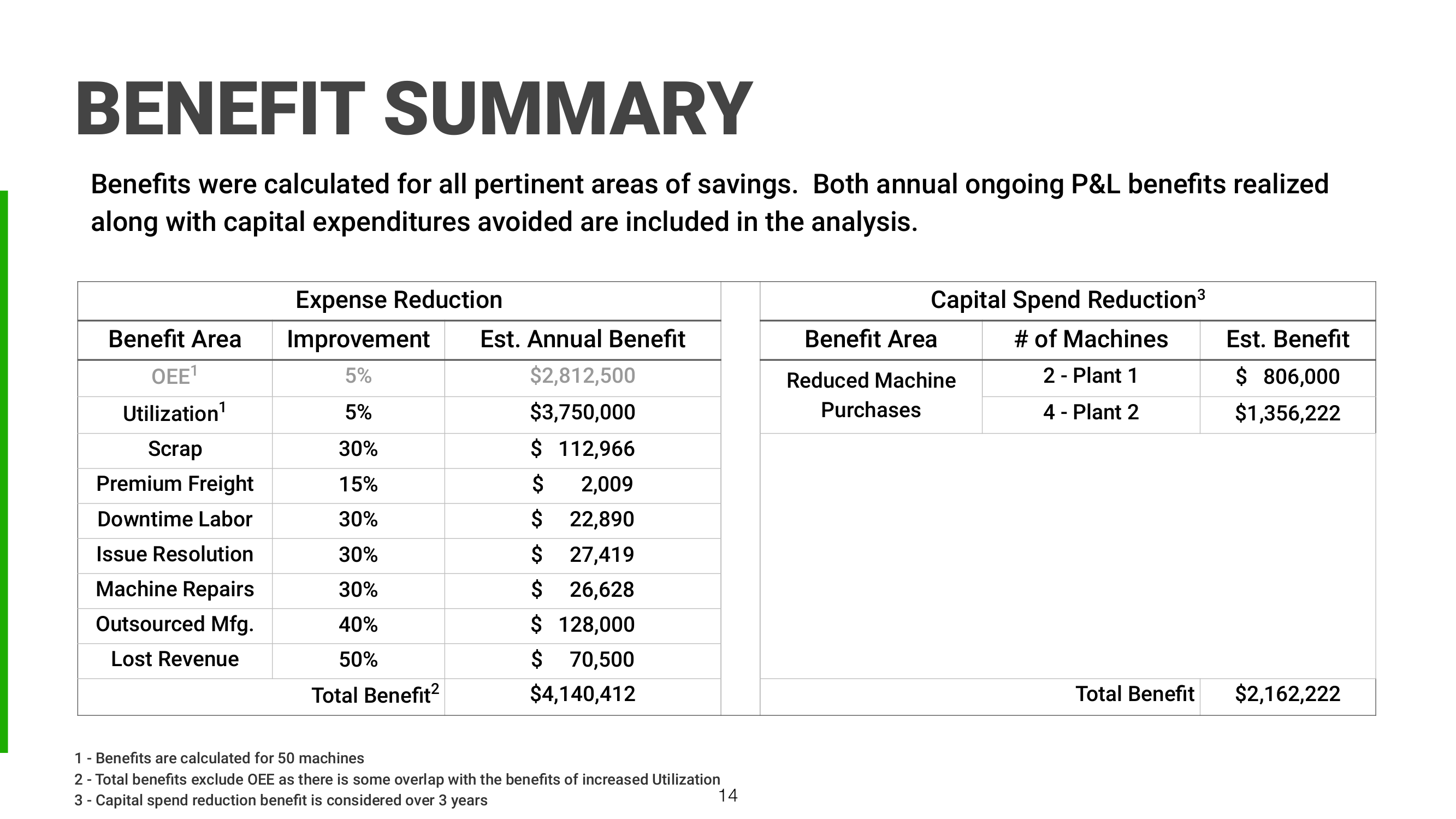

- Increase in Operational Efficiency: The hope for Industry 4.0 is that the next generation of industrial revolution will drive even greater profitability for organizations, as they are able to squeeze greater output from the same resource input.

- Better Products and Services: Whether it be product quality, safety, or customer experiences, Industry 4.0 will drive greater visibility and throughput for operations, allowing them to continue driving value for customers to retain business.

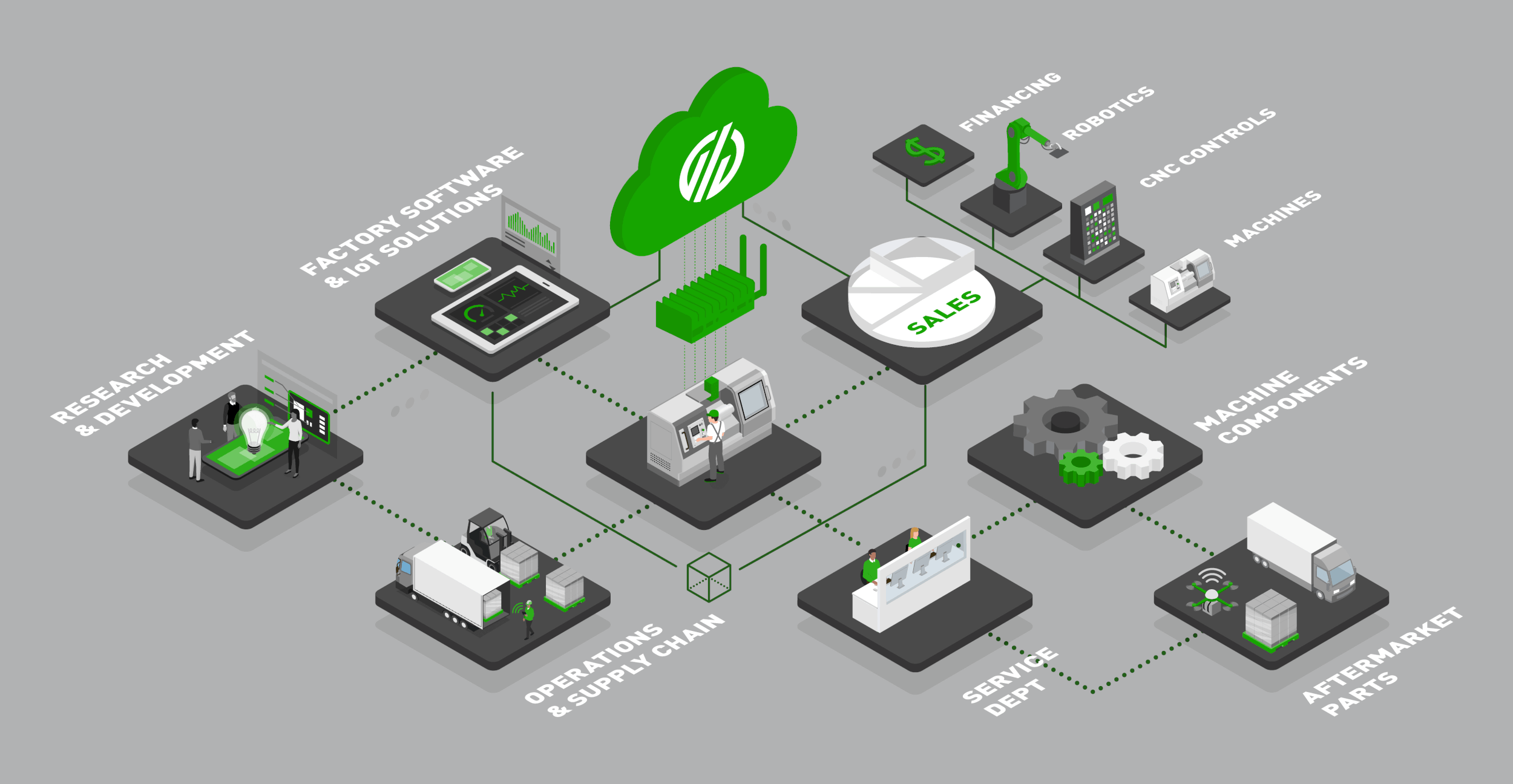

- Growth of Markets and New Markets: With any technological revolution, new services, products, and software will be needed to support the transformation of organizations. This will create entirely new product categories, new jobs, and more.

- Improving Lives Overall: With new technologies, higher profitability, and growth in economies, peoples' lives as a whole generally get better, with income rising, better health solutions, and overall a higher quality of life.

The Downsides of the Fourth Industrial Revolution (4IR)

- High Costs: Not only is technology a major cost to consider, but the expertise in enabling the technology to be implemented. Having the know-how in newer fields like IoT, Augmented Reality, and AI can lead to major budget constraints, not to mention a lack of understanding among all parties involved.

- High Rate of Failure: The difficulty in launching Industry 4.0 initiatives is that there is often a lack of direction when it comes to establishing objectives. They are often cross-functional projects with many stakeholders, which can mean projects can become mired in conflicting goals, and may simply sputter out.

- Cybersecurity: People, products, and equipment is, and will increasingly be, connected to the internet. Although this gives us greater access to data via the cloud, it opens up opportunities for hackers to access networks.

- Need for Highly Skilled Labor: Manufacturing, and industry as a whole, continues to rely on humans to enable production. However, with the move to digitally connected systems, there is a greater need for highly skilled labor, which may unintentionally reduce the need for low-skill labor.

- Industry and Market Disruption: With new technologies available, existing solutions will eventually be phased out. Similar to the Blockbusters of the world, certain industries will be unable to survive what Industry 4.0 brings to market.

Your Next Step

There is a lot to consider as you contemplate what the Fourth Industrial Revolution will bring, and how your organization explores solutions that fit within your business goals. Not only is there a lot to learn about, but there are an innumerable amount of problems to solve and plenty of solutions available in the marketplace.

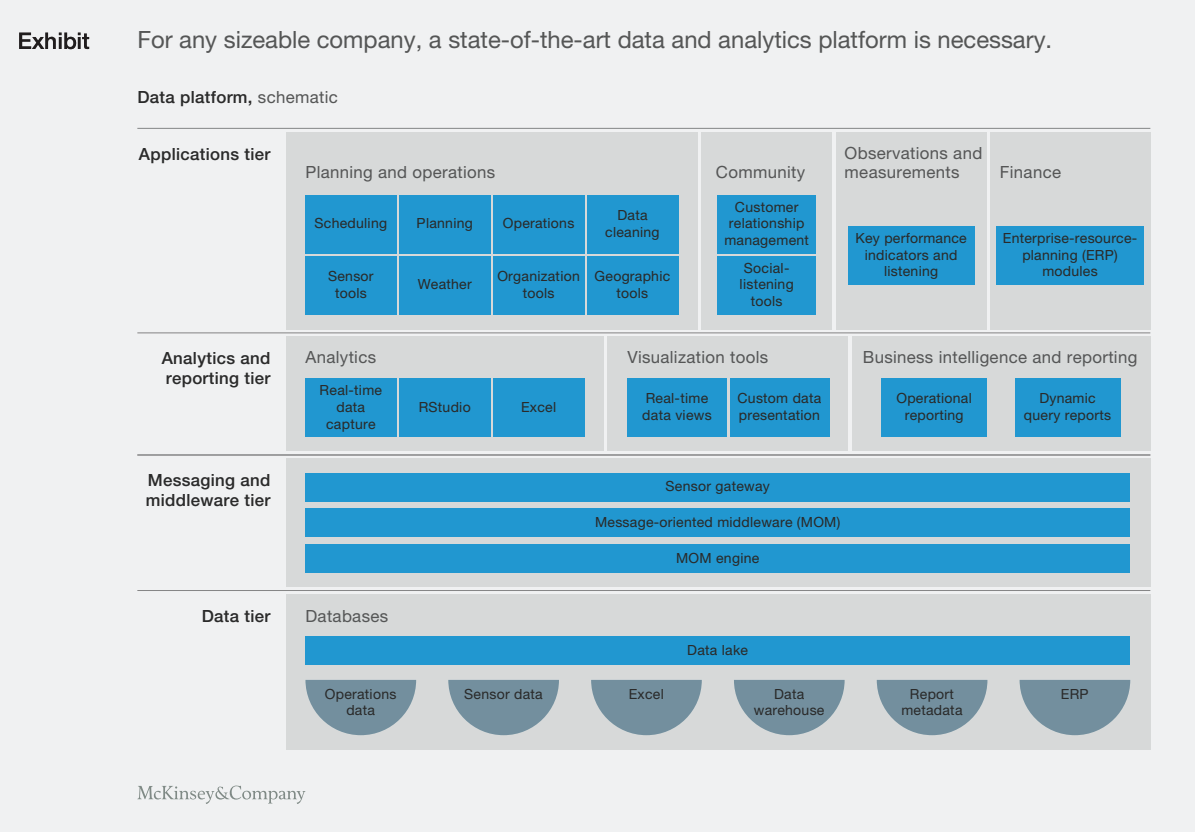

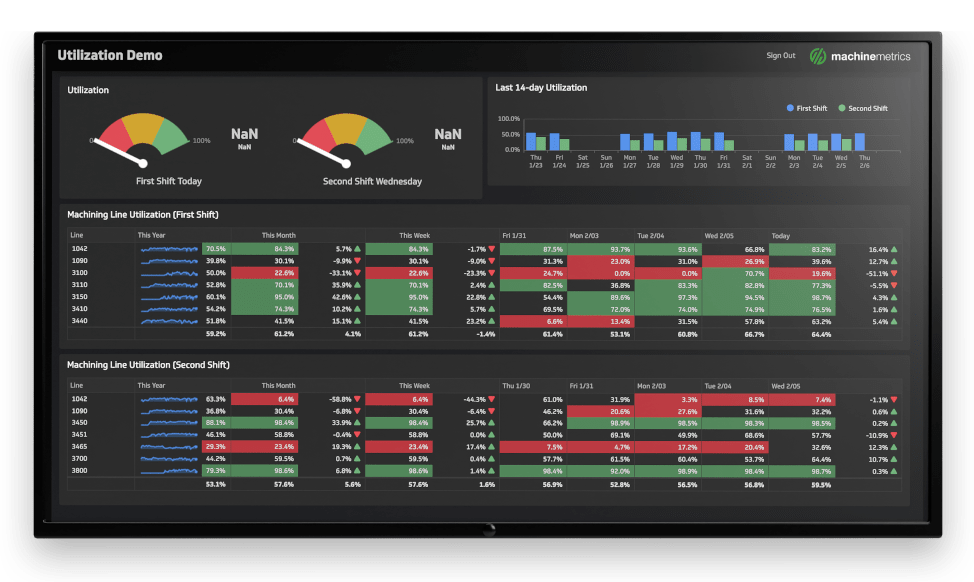

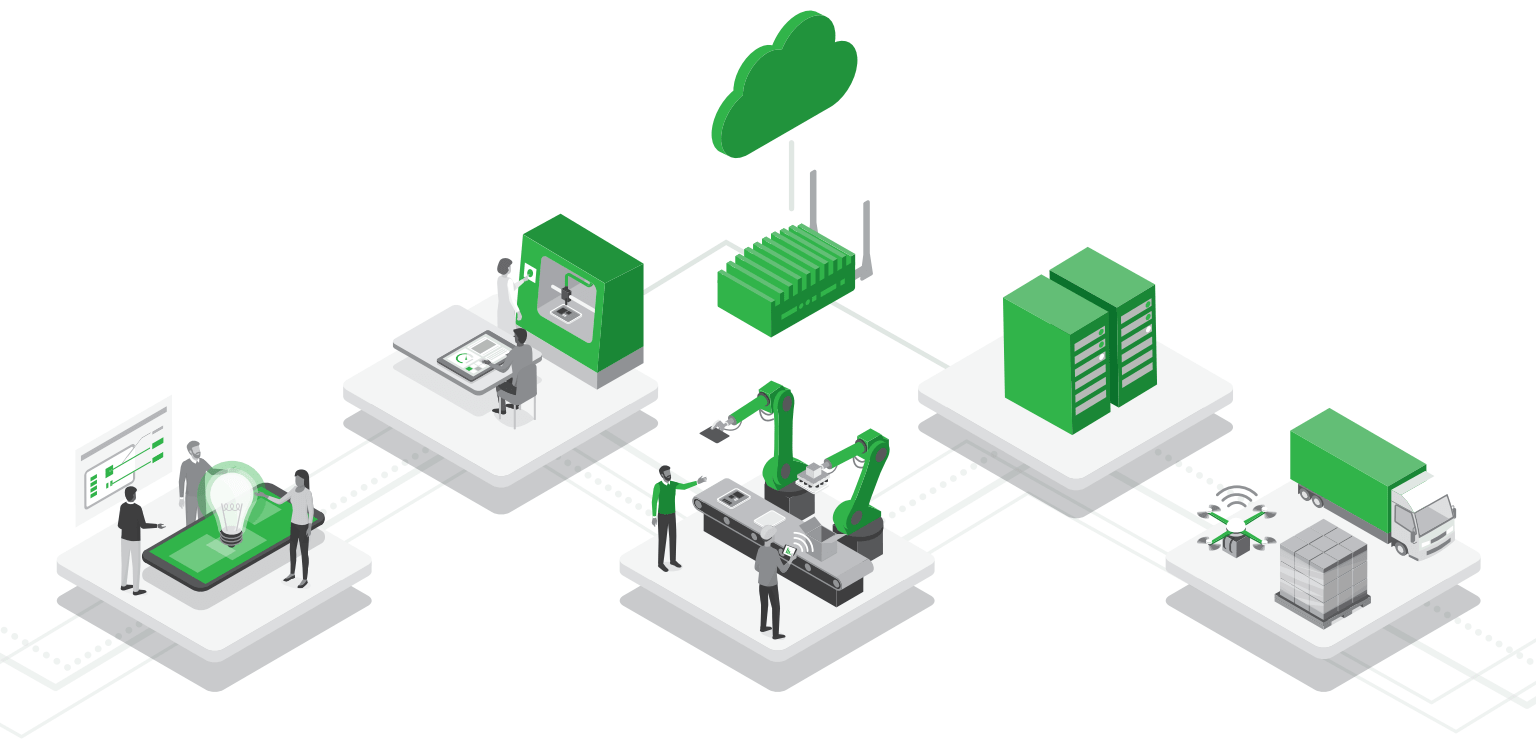

One of the best places to start is by enhancing your data collection methods. Automating machine data collection provides real-time, accurate production data that can be used to make better decisions as well as automate tasks.

As a manufacturer, we invite you to continue to research digital transformation and develop a better understanding of tangible strategies for driving the next generation of efficiency and growth.

To learn more about taking actionable steps to advance forward into Industry 4.0, read our comprehensive guide on the subject: "Digital Manufacturing Transformation Roadmap."

Comments