CNC Machine Monitoring Software

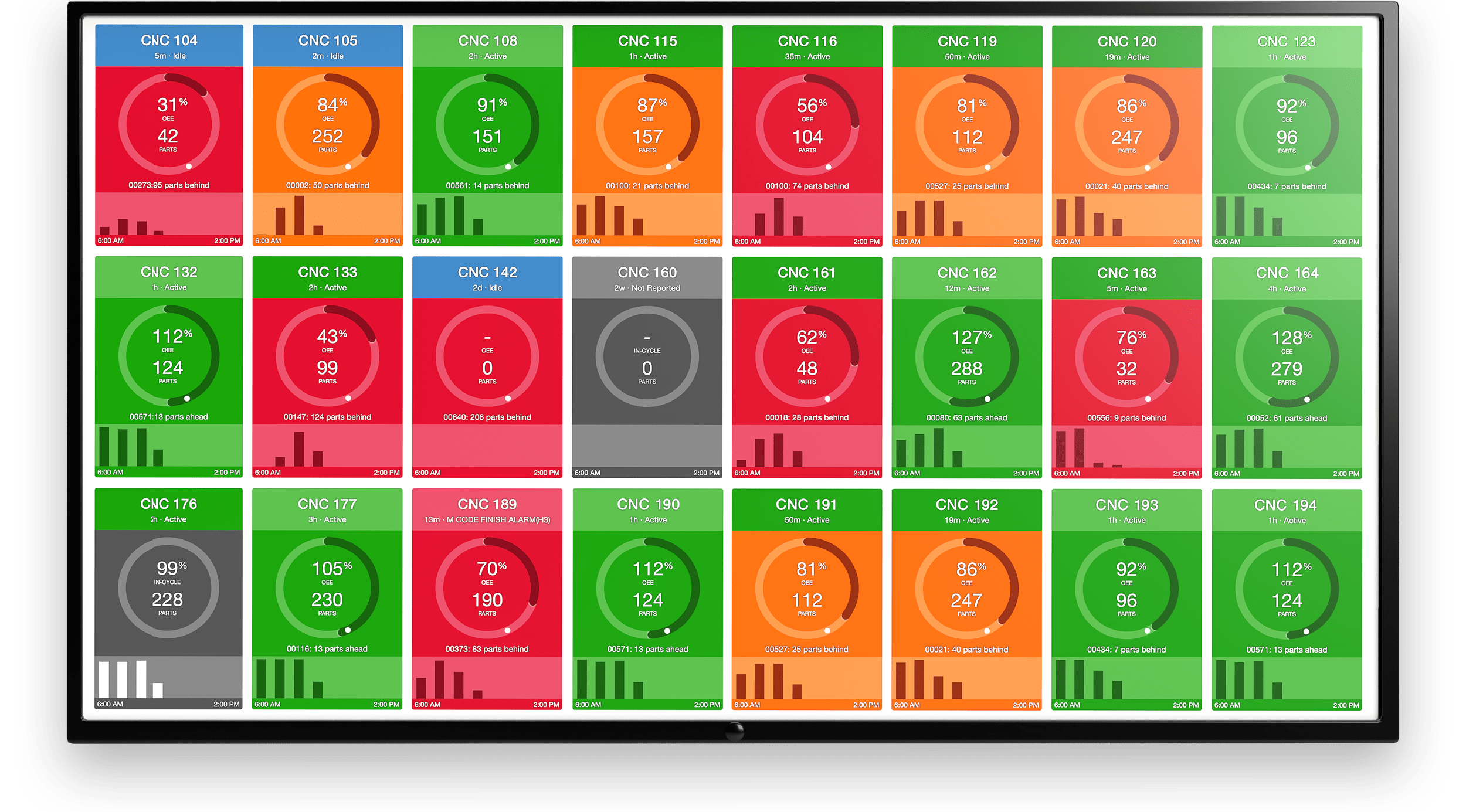

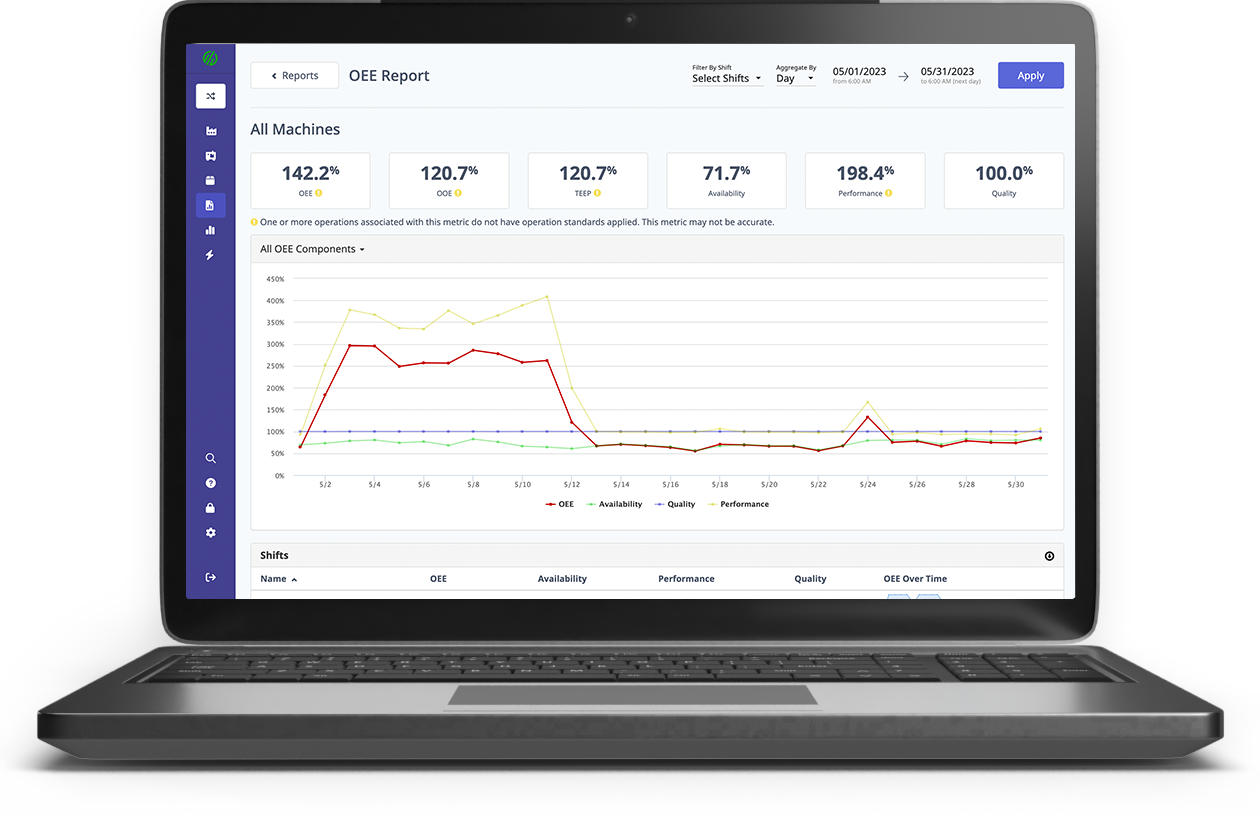

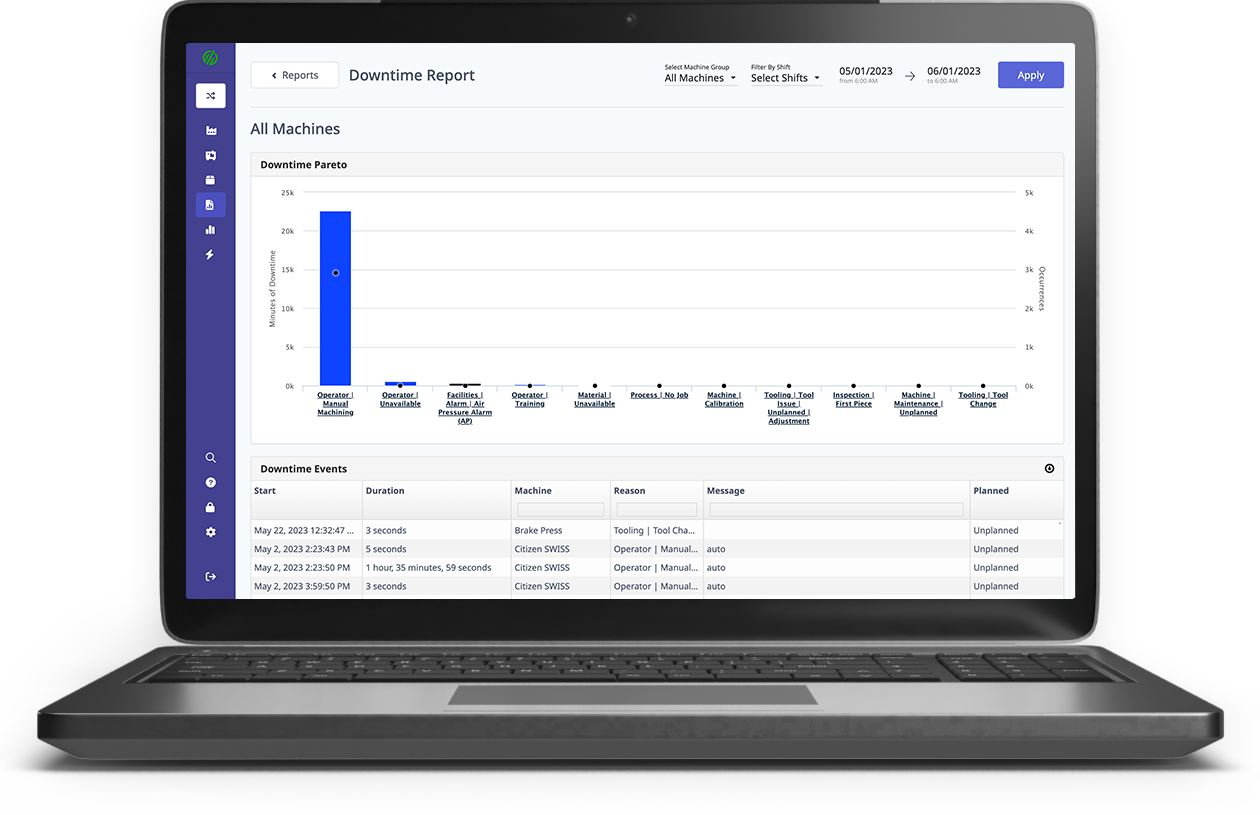

MachineMetrics has simplified IoT machine monitoring for the shop floor: our fully automated CNC machine monitoring systems & OEE software provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster, smarter, more confident decisions based on real-time data.

EASY TO USE, AMAZING RESULTS

Featuring simple “self-install” IIoT connectivity, MachineMetrics cloud-based machine and OEE monitoring software gives your team the ability to track real-time OEE, quickly identify production bottlenecks, and measure the effects of process improvements. For those needing advanced CNC machine monitoring software, results speak for themselves: we’re driving manufacturing efficiency by more than 20% on average for customers.

TAKE ACTION ON PRODUCTION DATA

For manufacturers, installing web-enabled shop-wide machine monitoring systems is that first and most important step to harness, structure, and take action on production data. CNC monitoring solutions require precise, real-time data, and those using MachineMetrics can finally bring smart manufacturing to the factory floor with software that’s simple to integrate, easy to use, and produces powerful results. MachineMetrics machine utilization software is a user-friendly platform easily integrates with any machine type including Precision CNC, Stamping, Grinding, Die or Mold, and more.

KEY BENEFITS OF A CNC MACHINE MONITORING SYSTEM

HOW MACHINE MONITORING SYSTEM WORKS

MACHINEMETRICS FEATURES

SIMPLE MACHINE INTEGRATION

Plug-and-Play universal machine connectivity and data collection from PLC's supporting protocols including: MTConnect, Fanuc, OPC-UA, UMATI, Mitsubishi, Citizen, Haas, Heidenhain, Siemens Sinumerik, Modbus, and Ethernet IP. MachineMetrics Edge supports digital and analog I/O for machines without a standard connectivity option to integrate even the most challenging equipment.

MACHINE DOWNTIME TRACKING

REAL-TIME FACTORY FLOOR DASHBOARDS

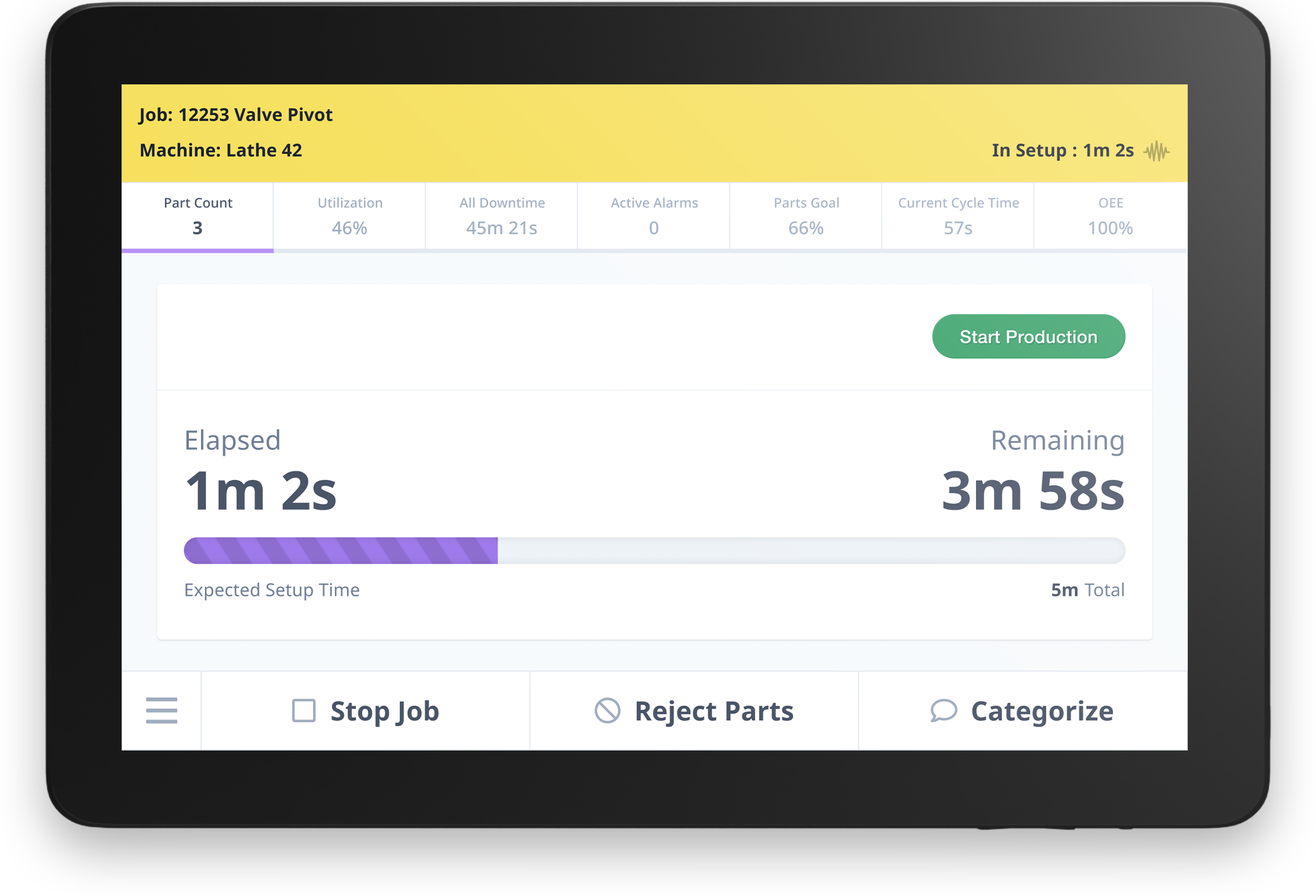

OPERATOR VIEW TABLETS

ALERTS AND NOTIFICATIONS

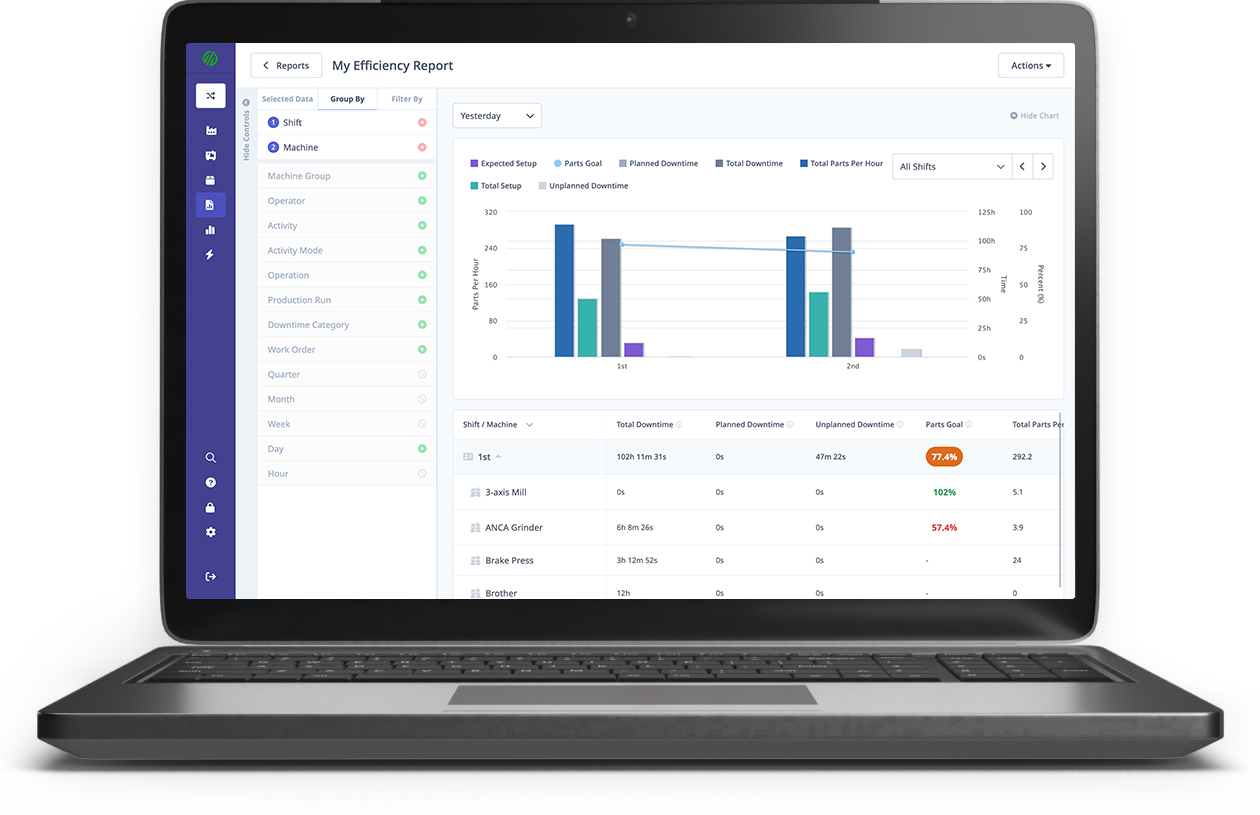

OEE PERFORMANCE REPORTING

QUALITY TRACKING AND REPORTING

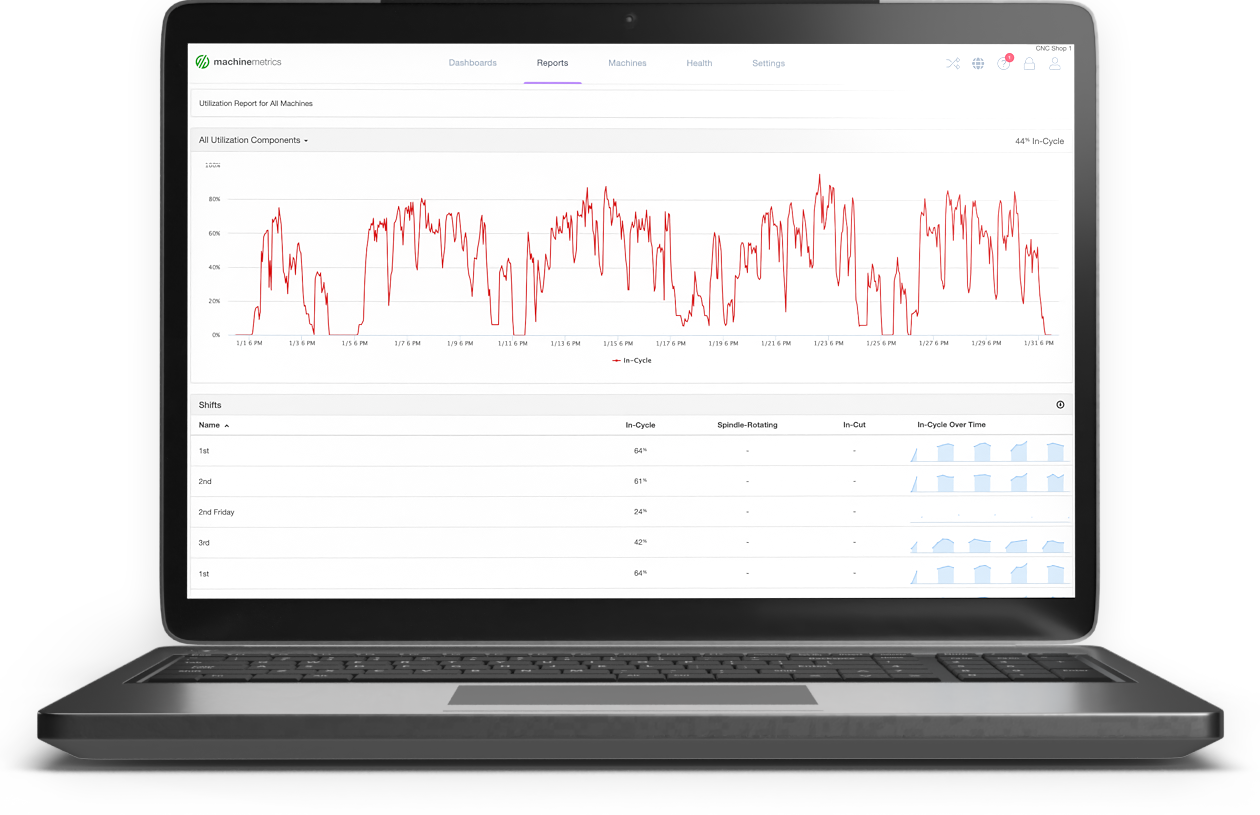

MACHINE UTILIZATION REPORTING

JOB SETUP/CHANGEOVER TRACKING

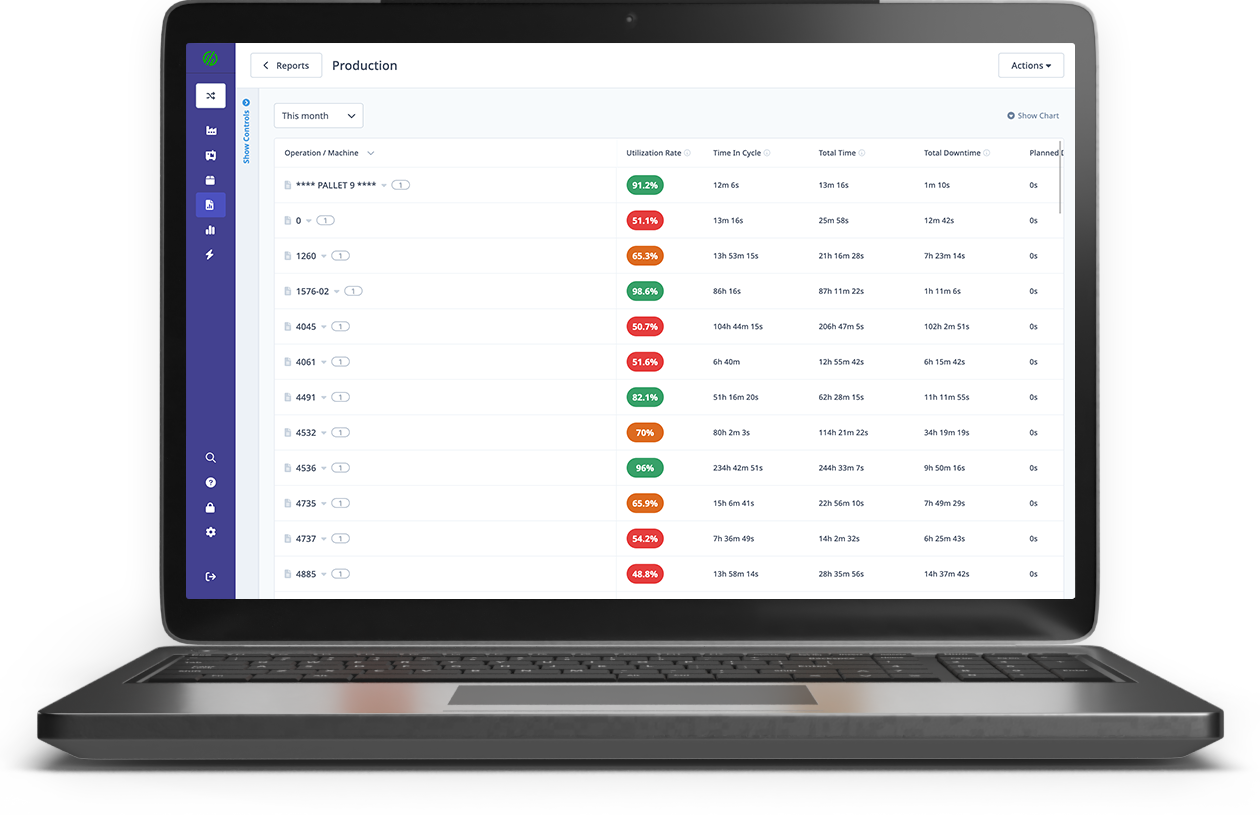

DETAILED MACHINE PRODUCTION ANALYTICS

DETAILED PART NUMBER AND JOB ANALYTICS

FAQ

Book A Demo

Empower every team in your organization with real-time data and insights.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Request A Demo

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo Now