The Intelligent MES for discrete manufacturers - connecting machines, ERP, and operations

while automating everything in between.

By capturing data from machines, people, and ERP, MachineMetrics delivers accurate, real-time insights. No delays. No guesswork. Just full visibility and total control to optimize every move on your shop floor.

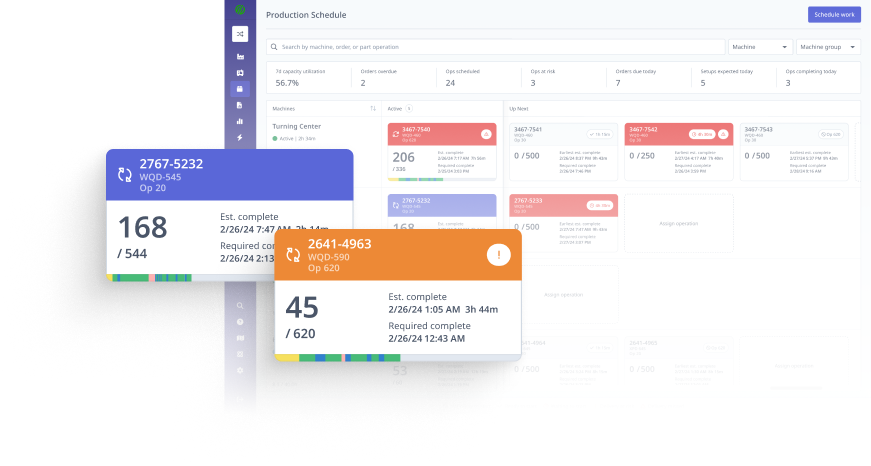

Leave behind outdated scheduling methods and embrace a future driven by real-time machine data, ensuring unparalleled scheduling accuracy, work-in-process optimization, and on-time delivery.

Disconnected systems create chaos. MachineMetrics unifies machine data, ERP, and workflows - automating execution so production stays on track without constant oversight.

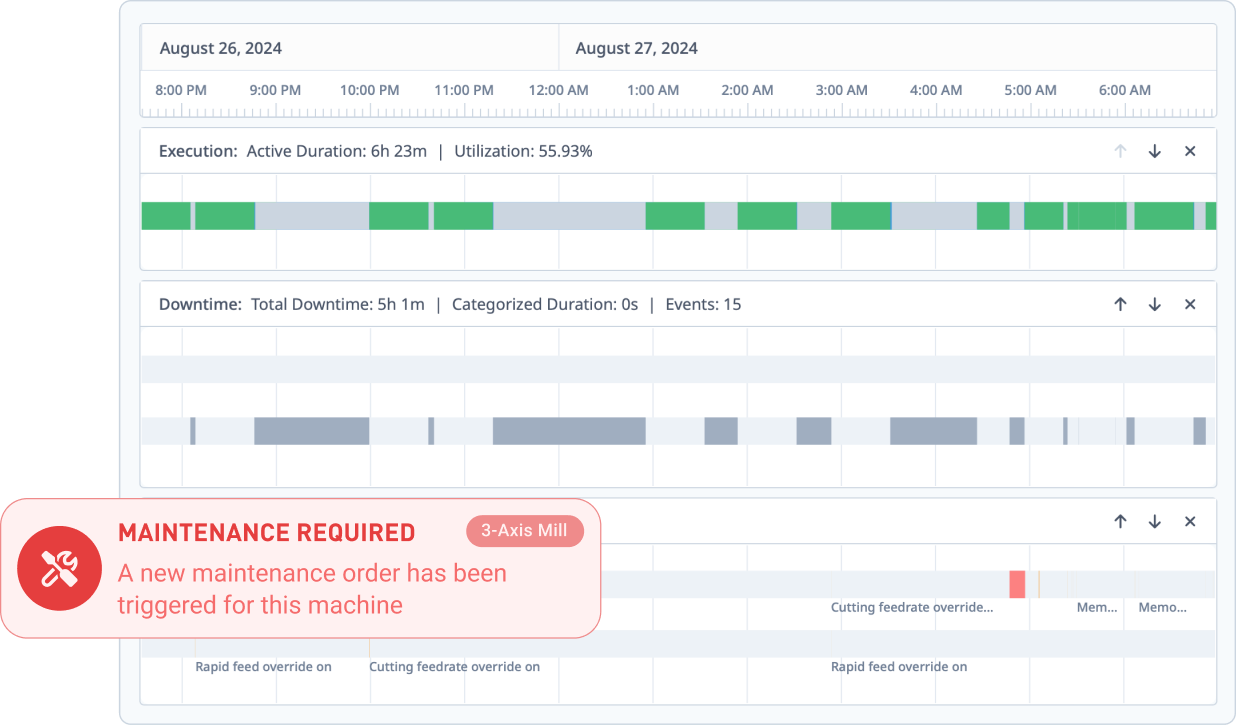

Every second of downtime costs you. MachineMetrics gives instant visibility into every machine, every shift, every job - so you can make decisions that keep production moving forward.

MachineMetrics uses AI-driven insights to eliminate inefficiencies before they become bottlenecks - boosting output, reducing waste, and keeping production profitable.

Easthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027