Increase Production Efficiencies with machine monitoring

"We already saved over 900 hours of production time!"

- Gary Bruner, President of Carolina Precision

"Visual real-time data performance has changed our business"

Manufacturers will rush to embrace Big Data and Smart Manufacturing technologies in the coming years. Get ahead by letting MachineMetrics' OEE software help you speed up manufacturing decisions with real-time visibility into your production performance.

-

Improve on-time delivery

-

Diagnose and solve problems in real-time

-

Save 1000s of production hours

-

Decrease manufacturing downtime

-

Receive instant notifications

SPEED UP YOUR SHOP FLOOR TODAY! CALL 413-341-5747

What is Factory Floor Monitoring?

Factory floor monitoring uses automated shop floor data collection from sensors, edge devices, high-frequency data, and other methods to track machine performance, total effective equipment performance, productivity, efficiency, quality, and many other variables across the shop floor.

The data is processed in a cloud-based platform where analytics and advanced machine learning algorithms create actionable insights to drive process improvements across the factory. Shop floor monitoring leverages machine data to reduce downtime, increase efficiency, and give manufacturers a competitive edge.

Factory floor real-time monitoring also allows for optimized financial OEE to help improve productivity and operational excellence across the organization. Devices not only allow automation of equipment functions, but they also provide information that manufacturers use to manage resources and effectively improve overall equipment effectiveness.

Why is Factory Floor Monitoring Important?

Factory floor monitoring gives operators, technicians, and managers real-time shop floor data. It enables remote monitoring, provides tools for managing resources precisely, and it helps improve communication to empower data-driven decision-making.

In the machine tool industry, shop floor data collection and factory floor monitoring harness the power of machine data through precise metrics like overall equipment effectiveness (OEE). Management can use insights to increase productivity and efficiency and better understand a machine's financial OEE.

Shop floor monitoring also introduces complete visibility across the enterprise. Managers gain the same access to data as operators using HMIs on the machines. This visibility is flexible and allows users to connect to what is happening on the shop floor. It includes analysis and trends at the spindle, machine, department, shift, operator, and factory level, depending on the user's needs. Managers can optimize or revamp processes based on what is happening on the shop floor.

Benefits of Using Shop Floor Monitoring Systems

A modern shop floor is a dynamic, fast-paced, and sometimes chaotic environment. By deploying the right shop floor monitoring solution, you can realize many benefits, including:

Real-Time Visibility

A shop floor monitoring system gives users access to real-time data that has been analyzed and contains the context for specific situations. It helps drive better decision-making and accountability, identifies training and process gaps, and empowers everyone to identify and solve problems quickly.

Benchmarked Insights

Most manufacturers using manual or siloed data collection find it hard to know where they stand on the shop floor. It's even more challenging to understand where they stand with competitors or industry standards. Accurate shop floor data enables manufacturers to benchmark themselves against competitors and past in-house performance.

Reduced Cost

Manufacturers can realize significant savings by eliminating manual shop floor data collection and the labor required to enter and analyze outdated information. Automated shop floor data collection brings almost limitless opportunities for cost savings: it drives continuous improvement efforts to recapture lost equipment effectiveness, improve quality, increase efficiency, and improve productivity.

Ongoing Process Improvement

Many continuous improvement initiatives aren’t really continuous. They use the same error-laden, outdated data and must stop and evaluate results before starting up again. Shop floor monitoring immediately identifies bottlenecks, performance, maintenance, and process trends that enable process improvements. With factory floor monitoring, multiple continuous improvement initiatives are possible at once and in real time.

Improved Quality

Shop floor monitoring systems can accept quality data from IoT-enabled devices attached to or embedded in machines. These devices include advanced scanning devices, optical sensors, and temperature gauges that can automatically trigger adjustments or alerts to prevent parts from being produced out of spec. A more advanced system like the MachineMetrics Machine Data Platform has advanced tooling data capabilities and high-frequency data collection.

Improved Planning

Shop floor monitoring reveals trends that wouldn’t have been detected otherwise. It enables companies to improve their OEE and unlock hidden capacity. These capabilities allow managers to plan confidently for Capex, operations, improvements, and more.

How Do Factory Floor Monitoring Systems Work?

A factory floor monitoring system starts with data collection. Data is collected through sensors, PLCs, and machine control over existing connections. Additional sensors can be added when and where needed to increase the data flow.

Data is sent directly to a cloud-based platform for cleansing, structuring, and analysis. Edge computing may also partially structure and analyze data to reduce latency and drive simple automation at the machine, reducing the time and bandwidth needed. The cloud-based machine data platform then uses the data to generate insights and analysis at speeds far beyond human capabilities.

Advanced platforms like MachineMetrics seamlessly connect via API to other enterprise software to increase the effectiveness of those systems. The platform is also vastly customizable, so each user's data is structured and formatted to provide them with the proper insight. It uses rules-based workflows that include data for machine conditions, alarms, performance metrics, KPIs, and other information.

MachineMetrics works with common applications and allows custom-built applications. Machine data can be built into apps for crucial areas, including:

-

Machine monitoring

-

Condition monitoring

-

Predictive maintenance

-

Process optimization

-

Other business intelligence software

Why Choose MachineMetrics?

MachineMetrics offers a best-in-class machine data platform for advanced factory floor monitoring. The platform is flexible, agile, and configurable to your needs. It turns your shop floor data into actionable insights that improve production and drive continuous improvement initiatives.

The system works with embedded connectivity in newer OEM machines and legacy machines that can be connected using a MachineMetrics edge device. This feature means that your shop floor data is consistent across your factory regardless of the model or generation.

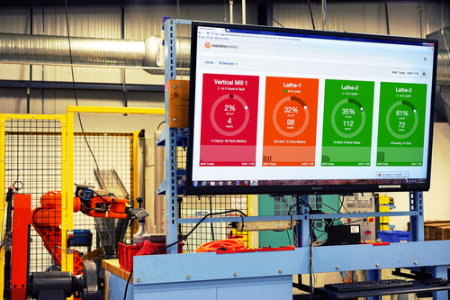

The MachineMetrics solution offers intuitive and customizable dashboards that enable users to complete their tasks quickly and efficiently. Operators see true machine conditions and can intervene before problems occur. Maintenance team members can develop advanced predictive maintenance strategies, saving downtime and parts costs. And management can see trends and plan based on the current reality on the floor.

Contact MachineMetrics to learn more.

Speed up your shop floor today! Call 413-341-5747

-

Receive instant insight with real-time factory floor dashboards

Receive instant insight with real-time factory floor dashboards -

Receive instant insight with real-time factory floor dashboards

Receive instant insight with real-time factory floor dashboards -

Receive instant insight with real-time factory floor dashboards

Receive instant insight with real-time factory floor dashboards