Real-Time Production Management Software

MachineMetrics cloud based production management software helps manufacturing operators and managers increase machine efficiencies by providing instant production visibility and deep analytics for better, faster decision making.

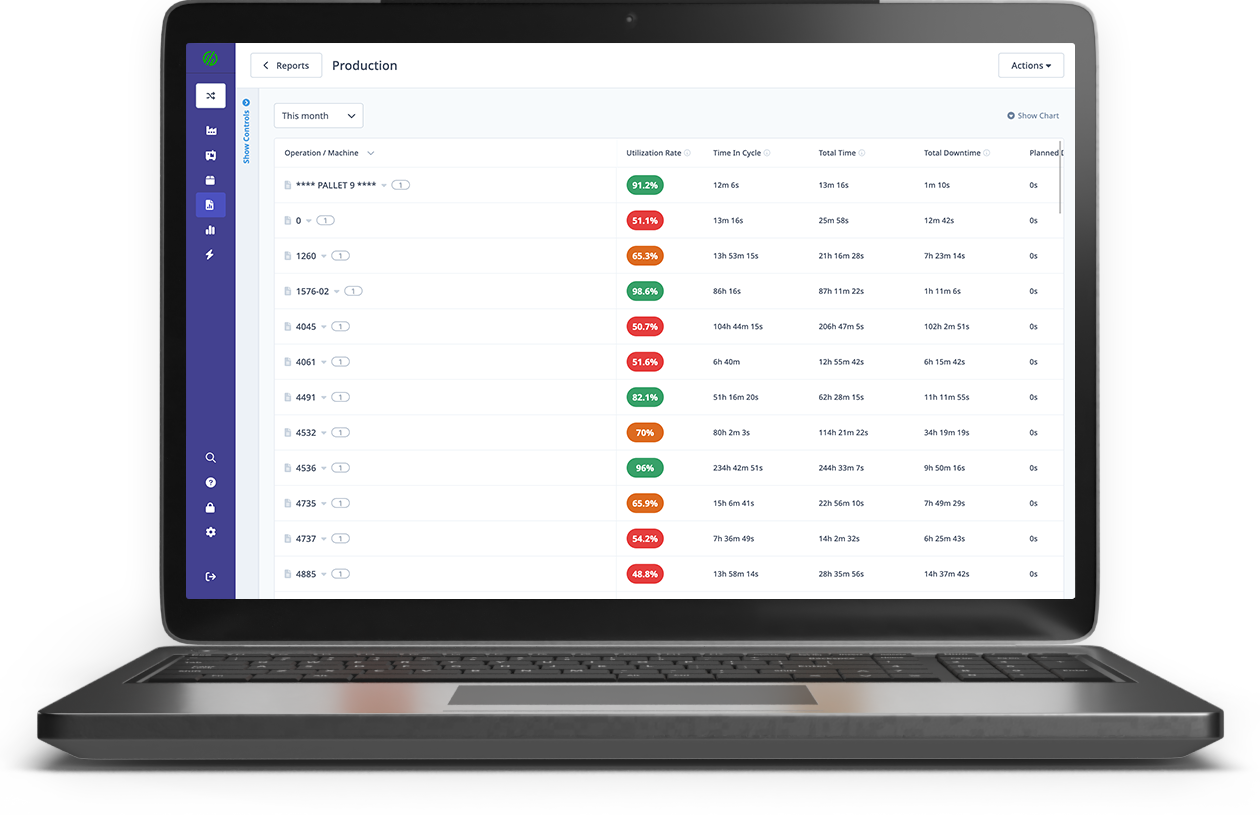

Easily track jobs, cycle times, part counts, OEE, and other key metrics for deep visibility and complete shop floor control.

Control Your Supply Chain

Whether you want to see today’s production progress and how it compares to this time four years ago, eliminate unplanned downtime, or increase your factory’s OEE, a comprehensive production management system will give you in-depth visibility to the shop floor.

With MachineMetrics, you can get to value quickly with an easy-to-implement solution and simple interfaces that show you exactly the information you need to make fast, effective decisions.

Manage Production in Real-Time

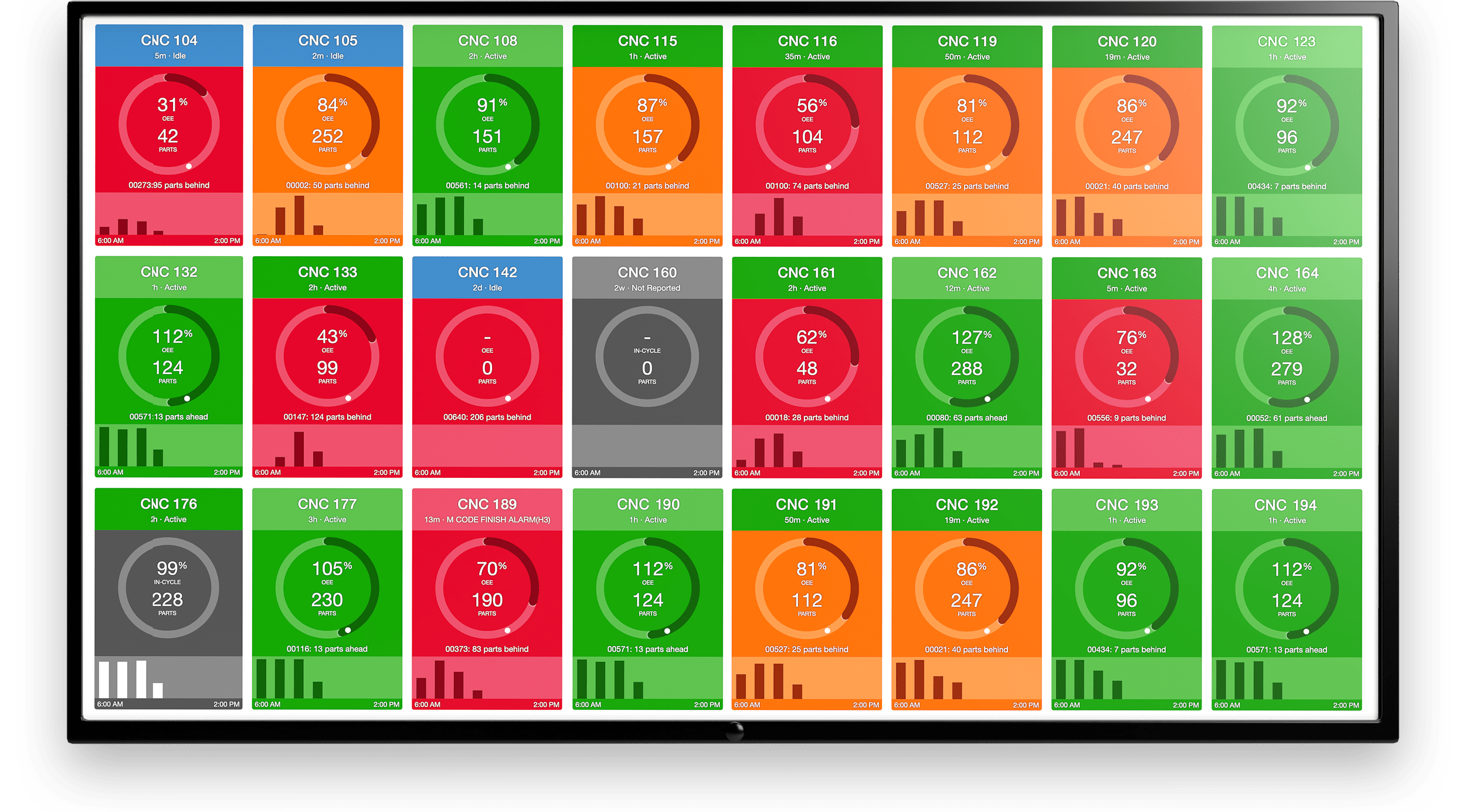

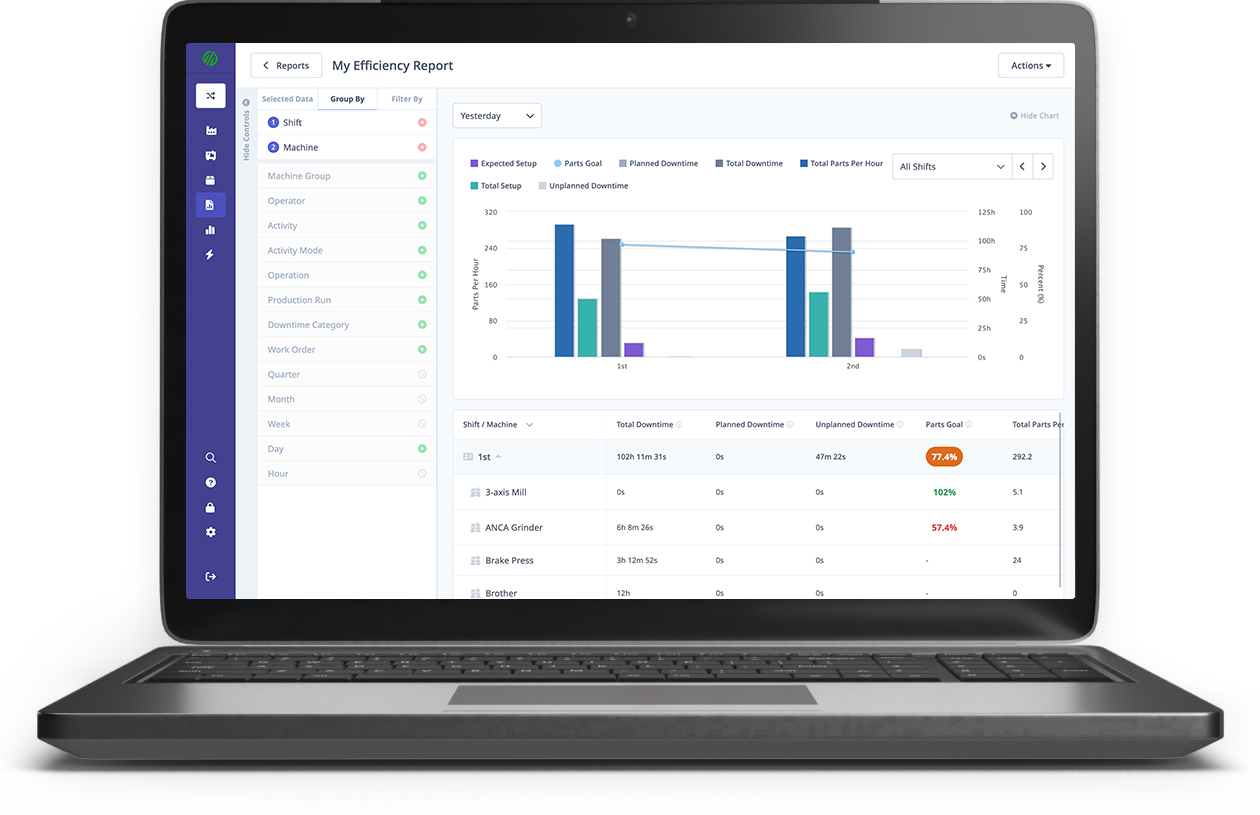

Transform your production data into easily accessible and visible data displayed across the shop floor, at machines, and available in both pre-built and customized reports for deeper analysis. Production reporting software ensures your productivity is on par with company-wide goals based on OEE, parts counts, or utilization, and get notified when production falls behind or machines go down so you can react fast.

Drive Better Production Management

MachineMetrics gives operators and managers complete visibility into the manufacturing process on the shop floor. Develop accurate cycle times, baseline machine utilization, and monitor the impact of process changes. Our manufacturing production management software increases machine efficiencies by providing both instant production visibility and deep analytics for better, faster decision making:

MachineMetrics Features

Detailed Machine Production Analytics

Track All Equipment Downtime

Knowing when and why equipment is down is key to resolving problems in the moment, and preventing them in the future. Respond to equipment failures with automated notifications, and dive deeper into your data to understand the most common reasons for downtime.

Real-Time Factory Floor Dashboards

Give Operators Accountability

With tablets placed at every machine, operators can easily see where they stand when it comes to production goals, based on part counts, OEE, or utilization. Give them the control to add human context when categorizing machine downtimes, rejecting parts, and starting/stopping jobs.

Real-Time Alerts and Notifications

Stay in the loop whenever and wherever you need to be with real-time text and email notifications that let managers know when a machine goes down or a job falls behind. Unchain managers from the floor to manage other productive tasks with custom notifications that only notify the right people at the right time, so people know when to pay attention.

Detailed Part Number and Job Analytics

Simple and Fast Machine Connectivity

No lengthy or costly setups or necessary downtime, simply plug-and-play using universal machine connectivity and data collection from PLCs. The MachineMetrics hybrid solution gives you the best of both worlds in machine data analytics by offering deep analysis using powerful cloud resources alongside, real-time, lightning-fast analysis using Edge computing. Combine the two for granular, complex insights that can be actioned in the here and now. Boost worker safety in the moment, gain a competitive advantage, boost efficiency and agility in one fell swoop—anyone can plug it in and get started.

Request A Demo

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowBook A Demo

Empower every team in your organization with real-time data and insights.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.