MaxAI has arrived! Learn all about it

here

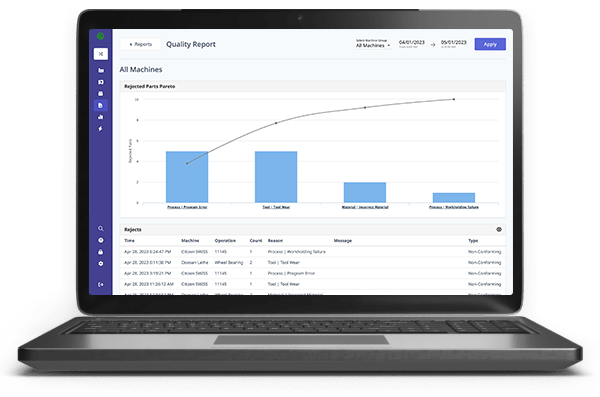

Tools, dies, and molds are key components in mass production. It’s essential that manufacturers of tooling have highly precise production requirements, but few have insight into the wasted costs of manufacturing high-quality products.

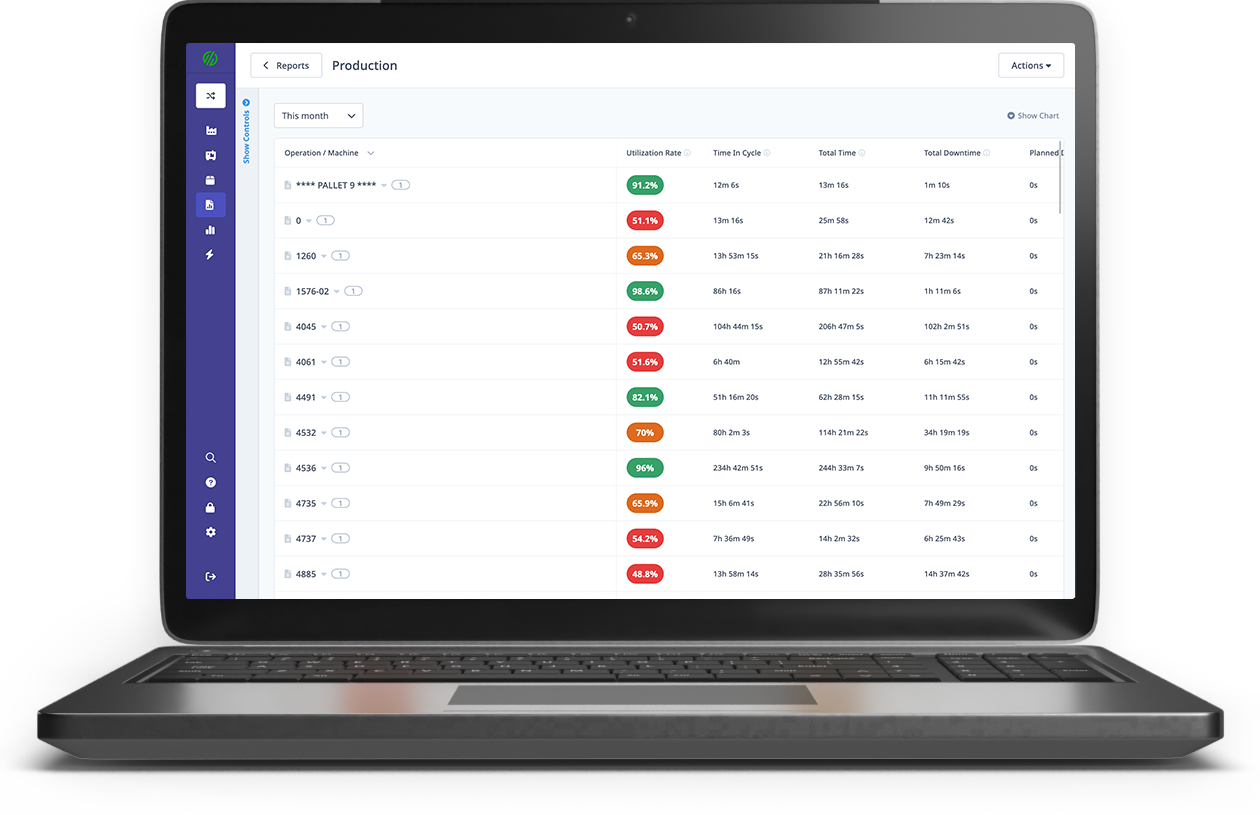

As manufacturing costs rise, the price of molds, dies, and tools have remained stagnant. To compete, manufacturers need machine data to drive production efficiency.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027