MaxAI has arrived! Learn all about it

here

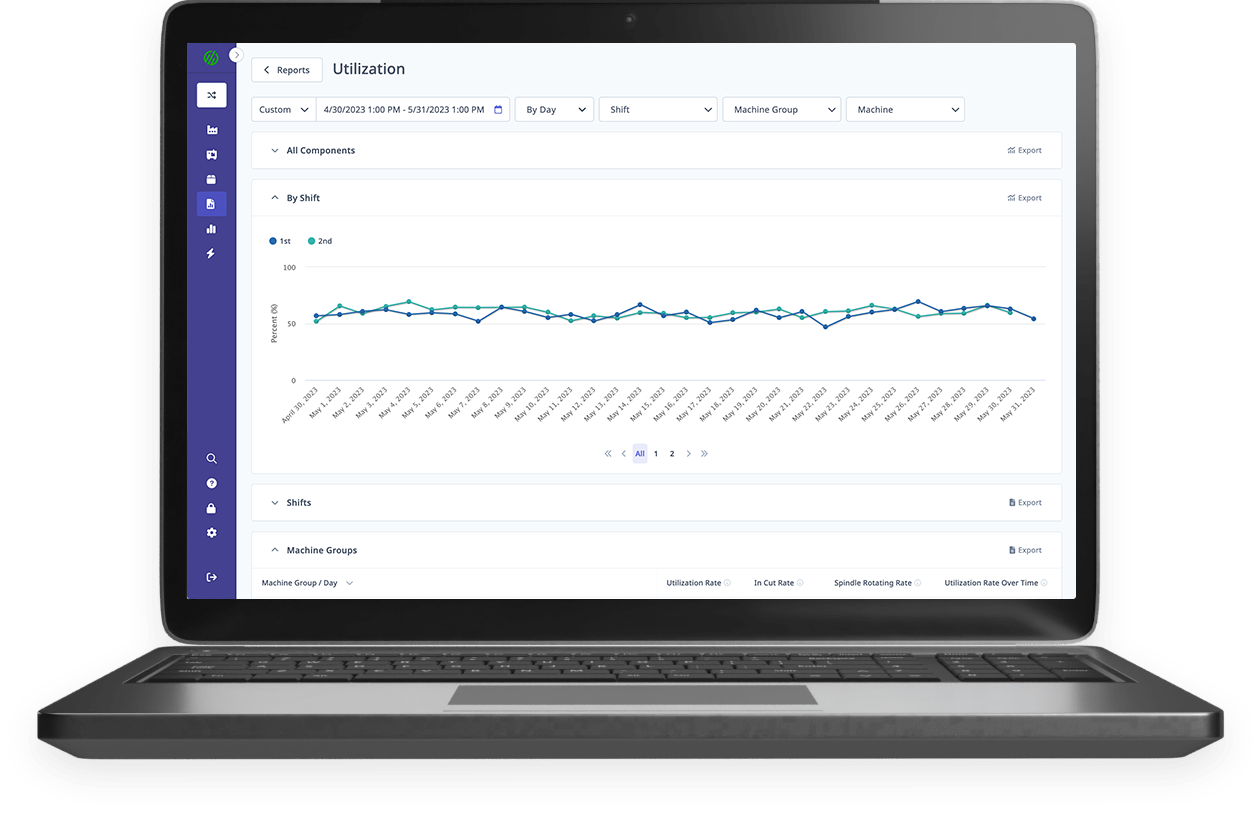

Whether your production environment is high-mix low-volume or low-mix high-volume, use machine data to amplify your investment in equipment and people.

Leverage real-time machine conditions to manage equipment health, reduce downtime events, and empower your maintenance team to advance from preventive to predictive.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027