MaxAI has arrived! Learn all about it

here

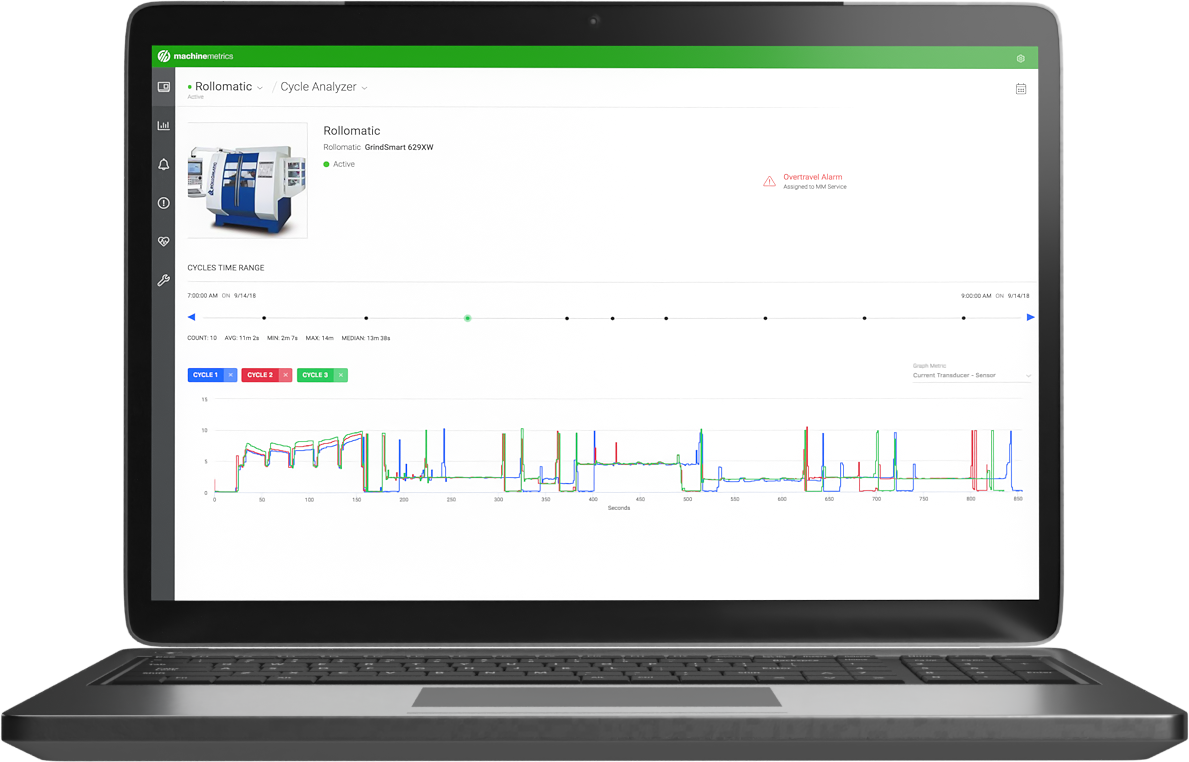

Whether you are machining short-run parts or stamping out thousands, use machine data to amplify your investment in equipment and people.

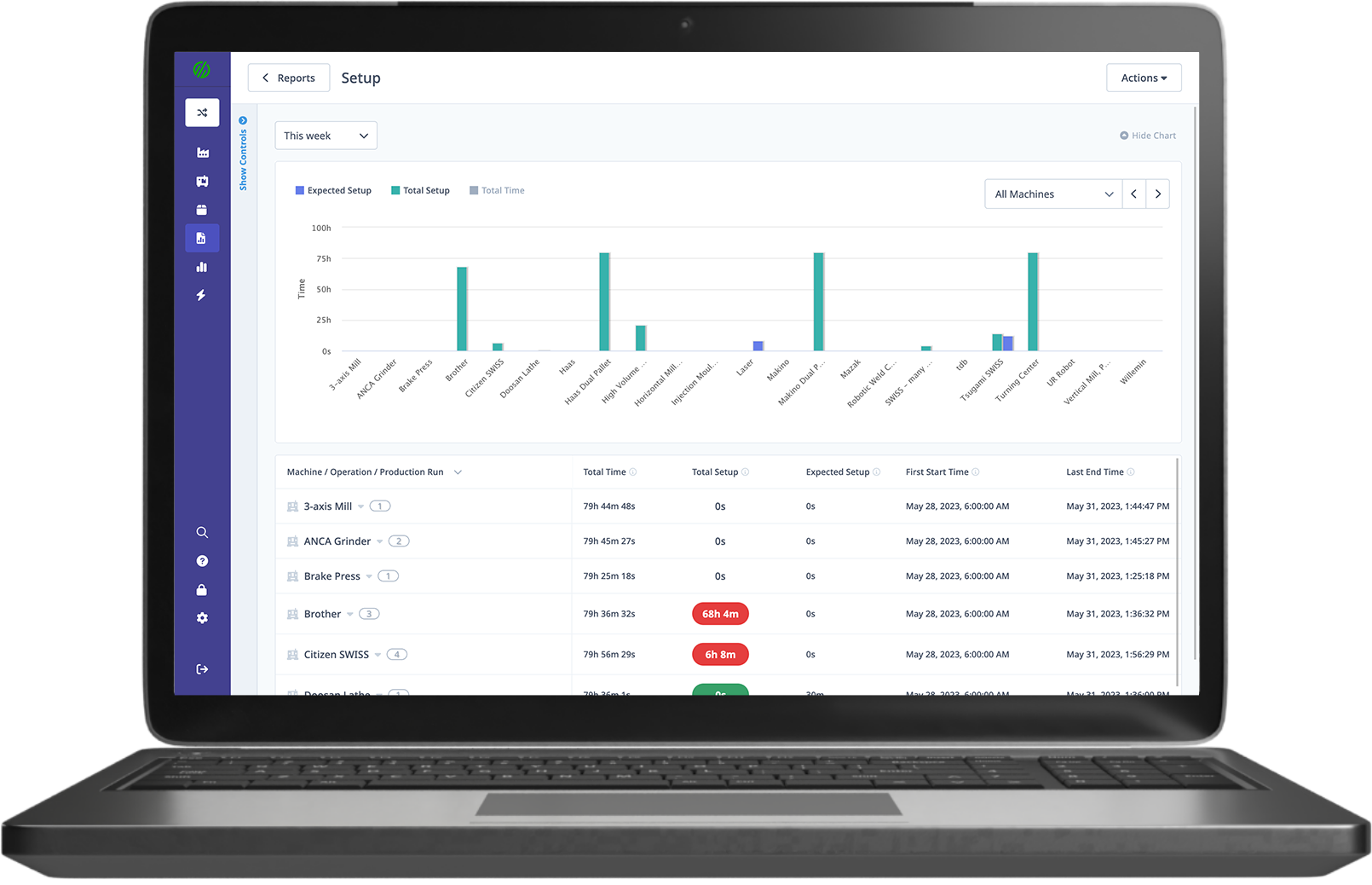

Metal fabrication and stamping operations often have several processes involved to develop a single product. This leaves lots of room for process inefficiencies.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027