MaxAI has arrived! Learn all about it

here

Supercharge your maintenance programs with AI-powered predictive maintenance. Harness real-time machine condition data to anticipate issues before they occur, and take action based on accurate insights - not just a calendar.

Most manufacturers are left blind as to when their machines will go down. The result is costly unplanned downtime, unexpected maintenance events, and a reduction in throughput. While there are hidden indicators of when machines are likely to fail, it’s impossible to find these insights by manually capturing machine performance and health data.

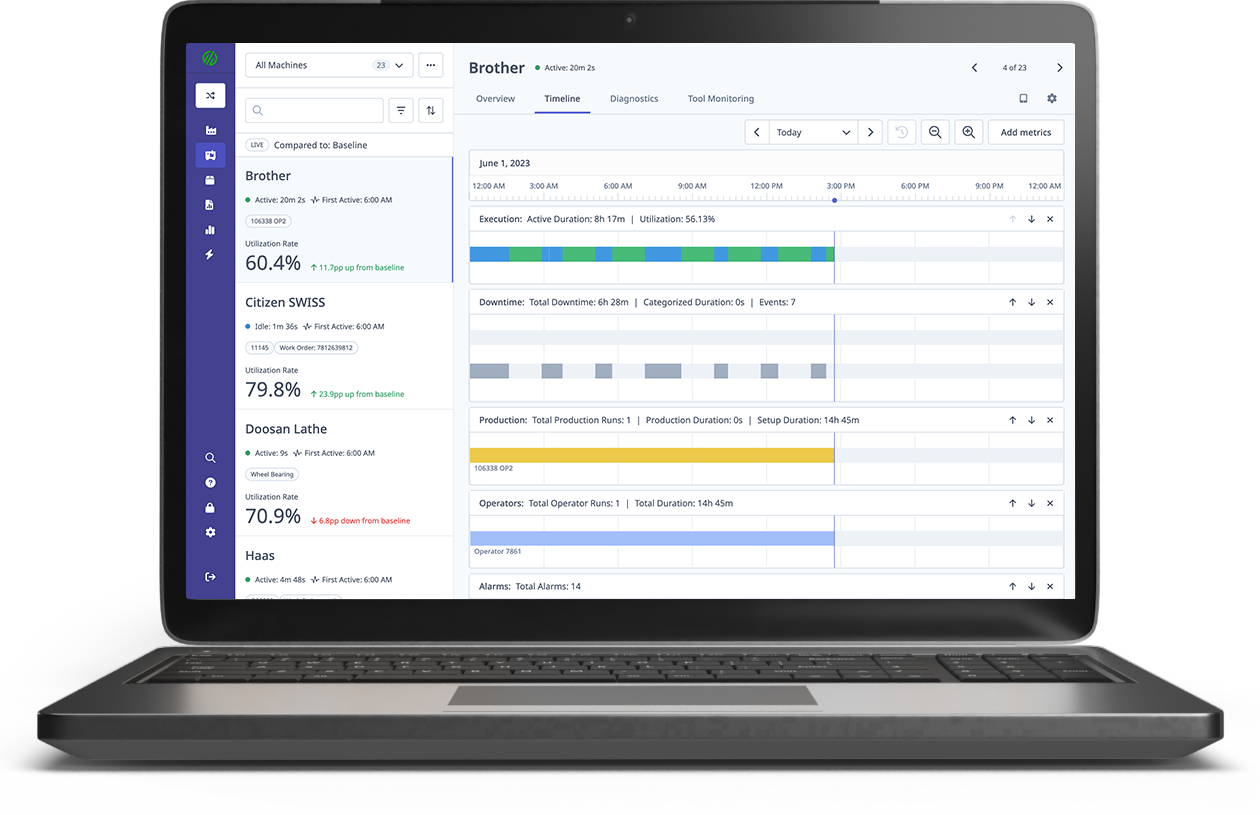

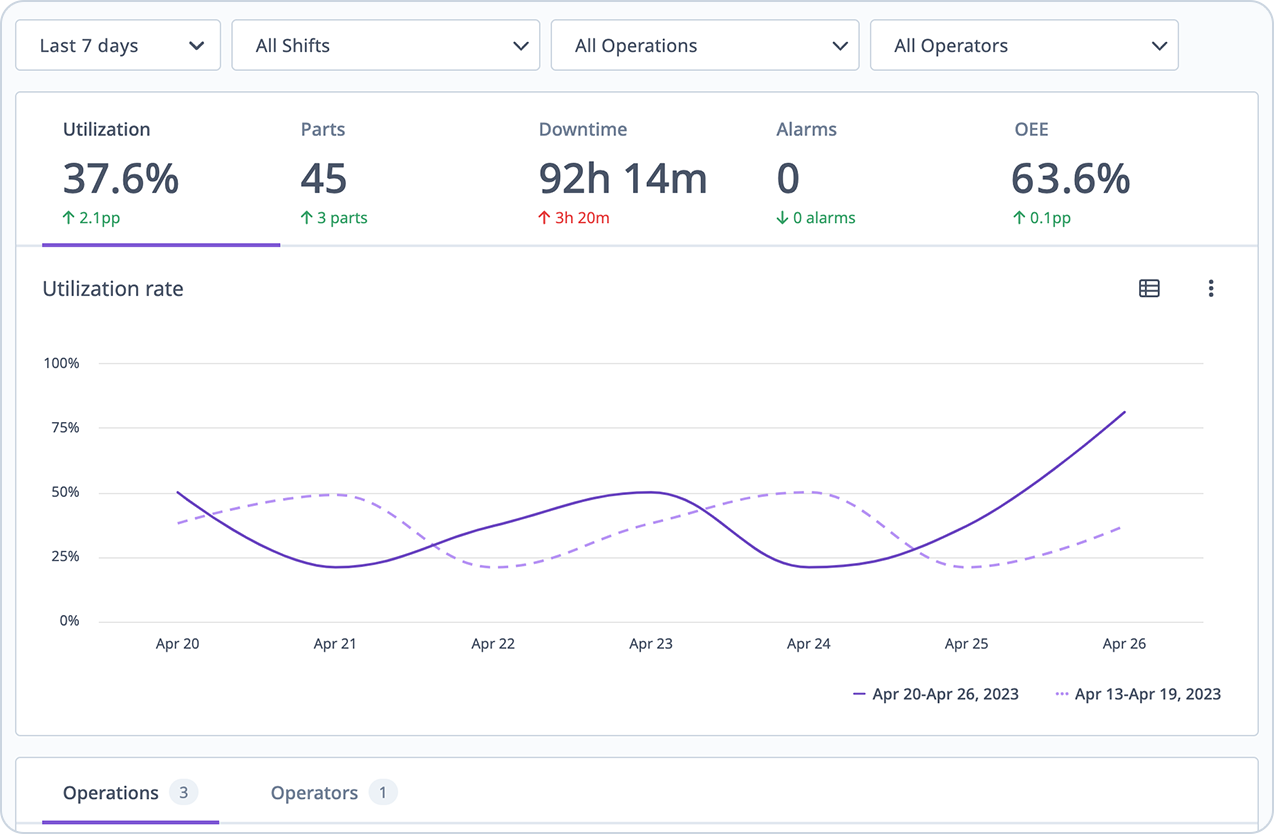

MachineMetrics captures real-time, accurate machine data to diagnose and prevent various types of failures so your team can stop them from happening in the first place.

MachineMetrics has connected to thousands of machine tools, providing our team with a large database of machine health and performance data, enabling us to understand better the indicators that lead to machine failures. Leveraging MachineMetrics, users can establish thresholds to proactively identify machine health issues, driving condition-based maintenance programs.

Know exactly how much downtime has occurred and why. Leverage machine conditions and diagnostics to ponpoint the root cause.

Push your machines to the limit without incurring unexpected downtime. Schedule maintenance based on machine health rather than basic schedules.

Feed your CMMS with critical machine information to automatically create work orders. Explore pre-built integrations with Fiix and MaintainX.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027