MaxAI has arrived! Learn all about it

here

AI-powered process optimization for discrete manufacturing, fueled by real-time machine data, ERP context, and tribal knowledge so teams know exactly what to do, when to do it, and how to do it better.

Operating without data leads to process inefficiencies and poor decision-making which affects every component of a company’s operation ranging from significant downtime to production losses.

Harness the power of data to add human context to machine data. Analyze and identify process bottlenecks to deliver new, optimized processes to factory workers at the right time.

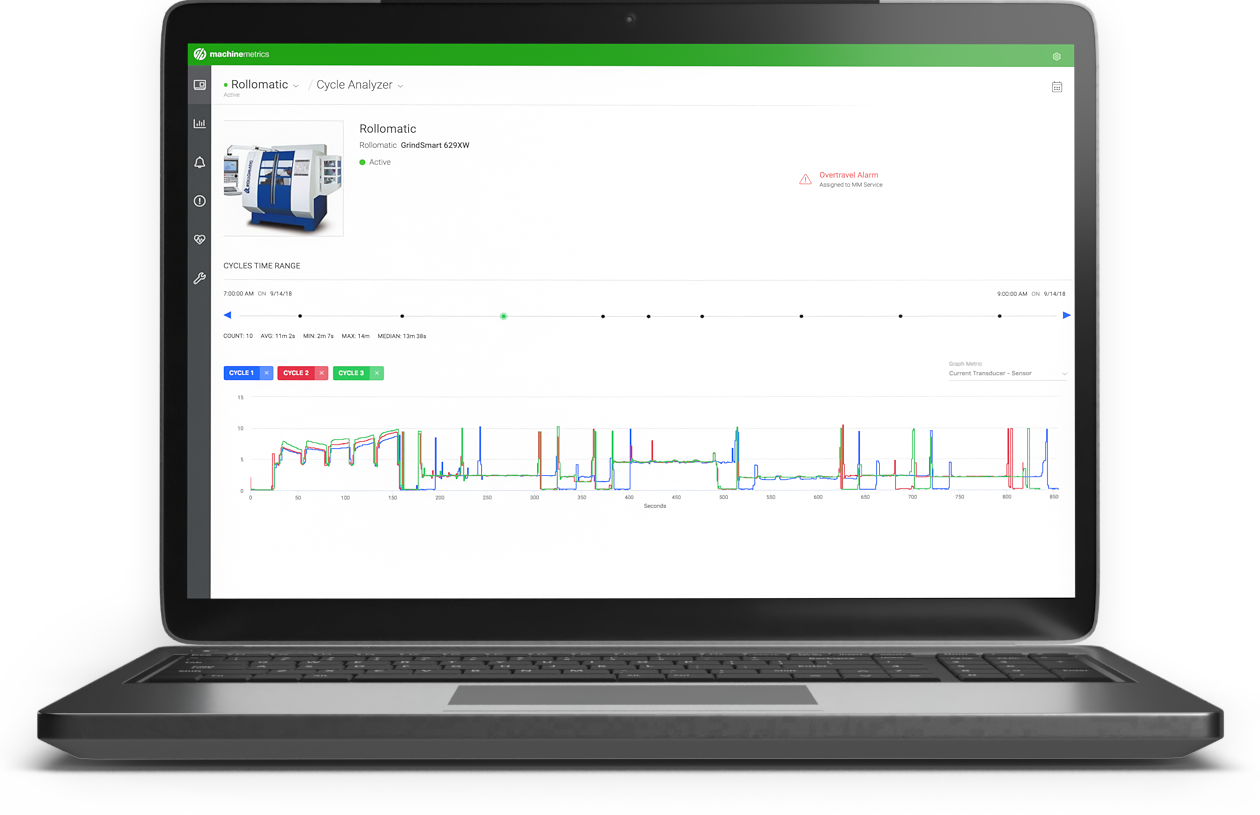

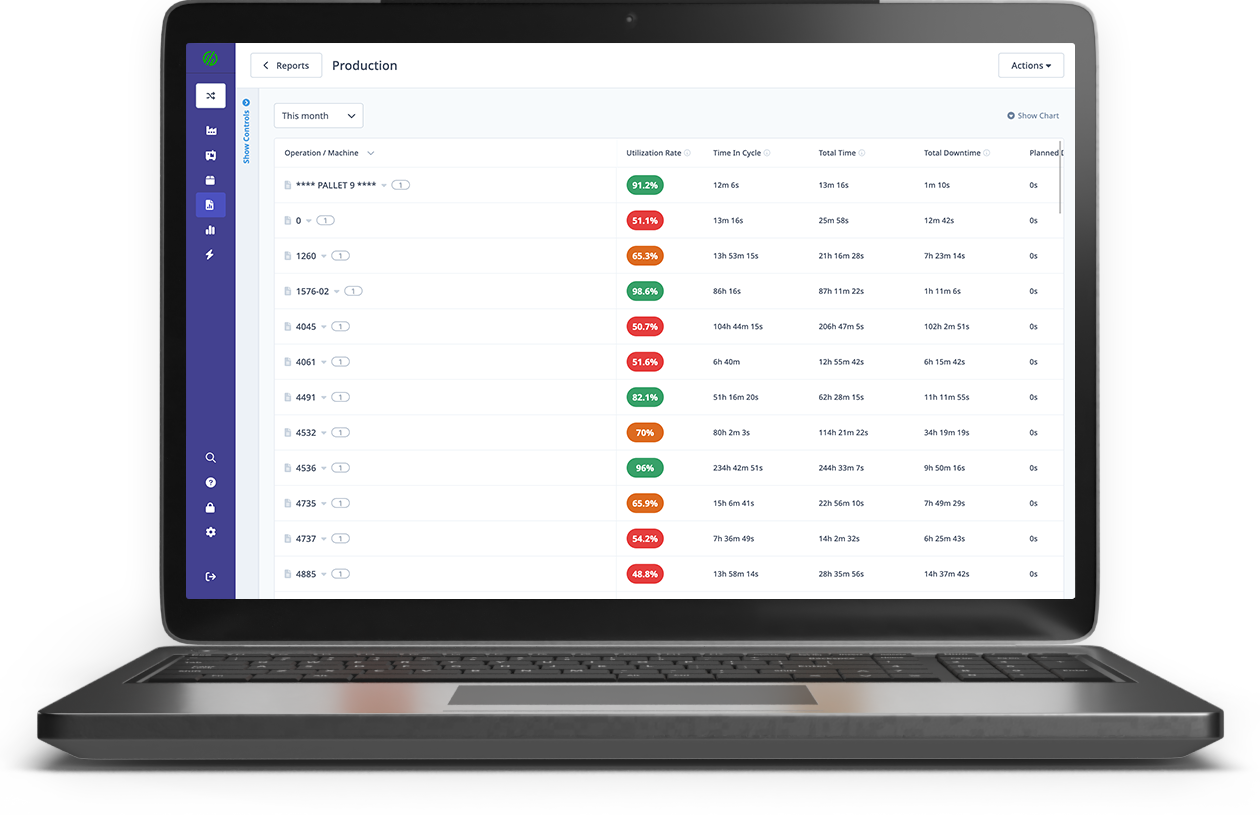

Monitor and improve factory floor production efficiency by collecting and measuring all processes related to production, from machine performance and availability to operator productivity and quality.

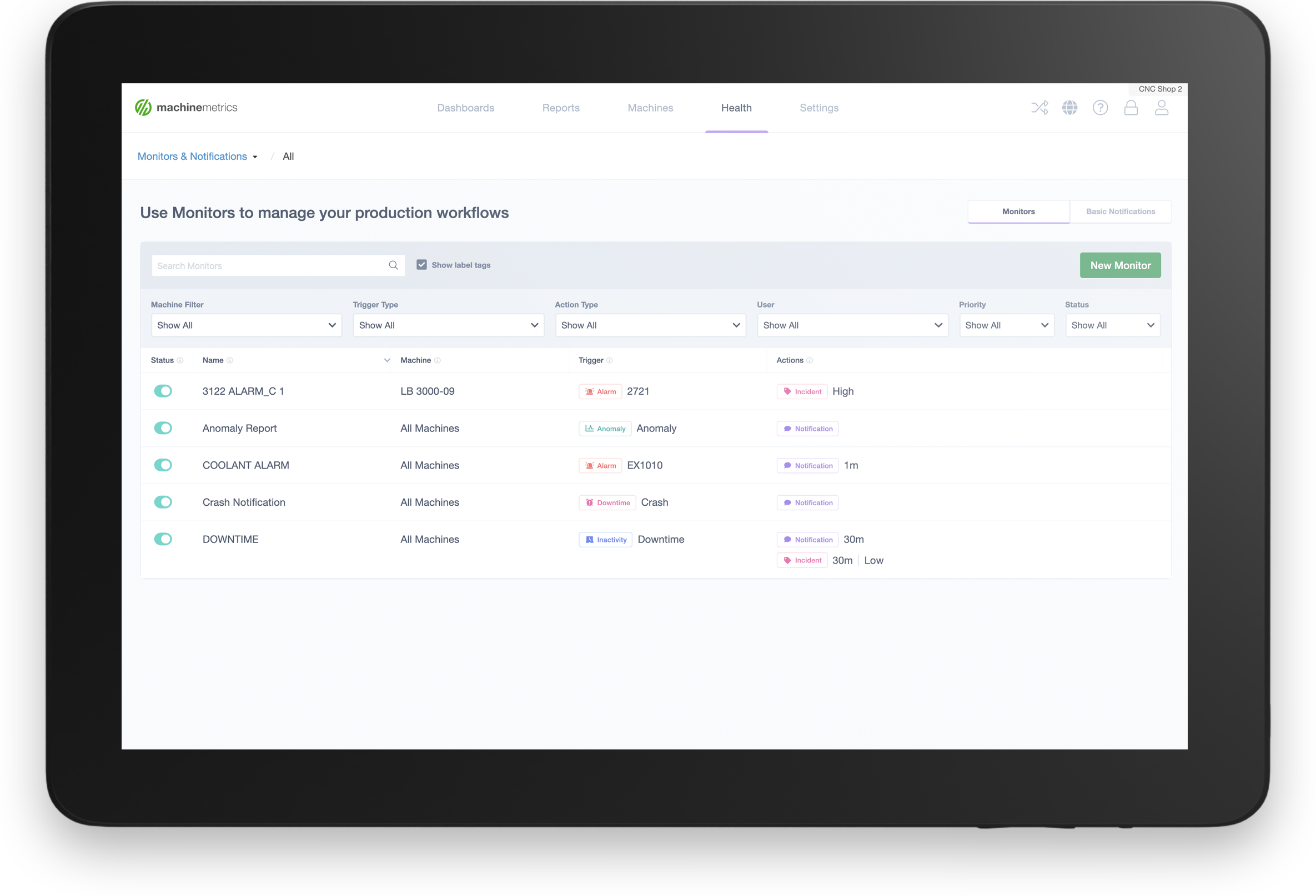

Diagnose problems with deep alarm analytics and AI-driven predictive notifications.

View machine utilization by hour, shift, day, week, and month to view trends to uncover opportunities for improvements.

Improve equipment uptime and service productivity by preventing unplanned downtime.

Improve processes with automated cloud machine monitoring & OEE software to provide visualizations of real-time manufacturing production data.

Monitor spindle load or any other analog metric over the course of a part cycle. Overlay multiple cycles from any point in time to analyze discrepancies or changes over time.

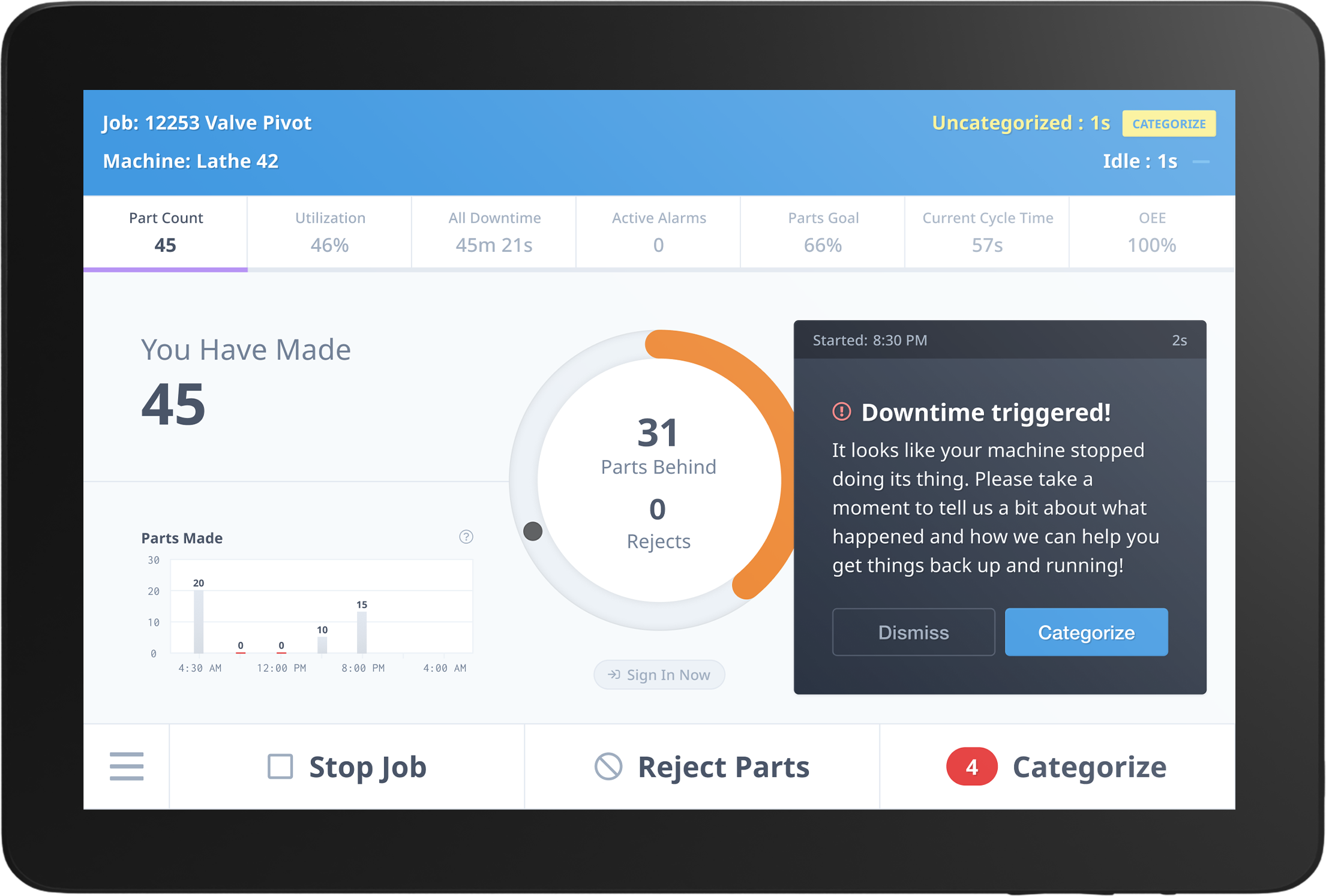

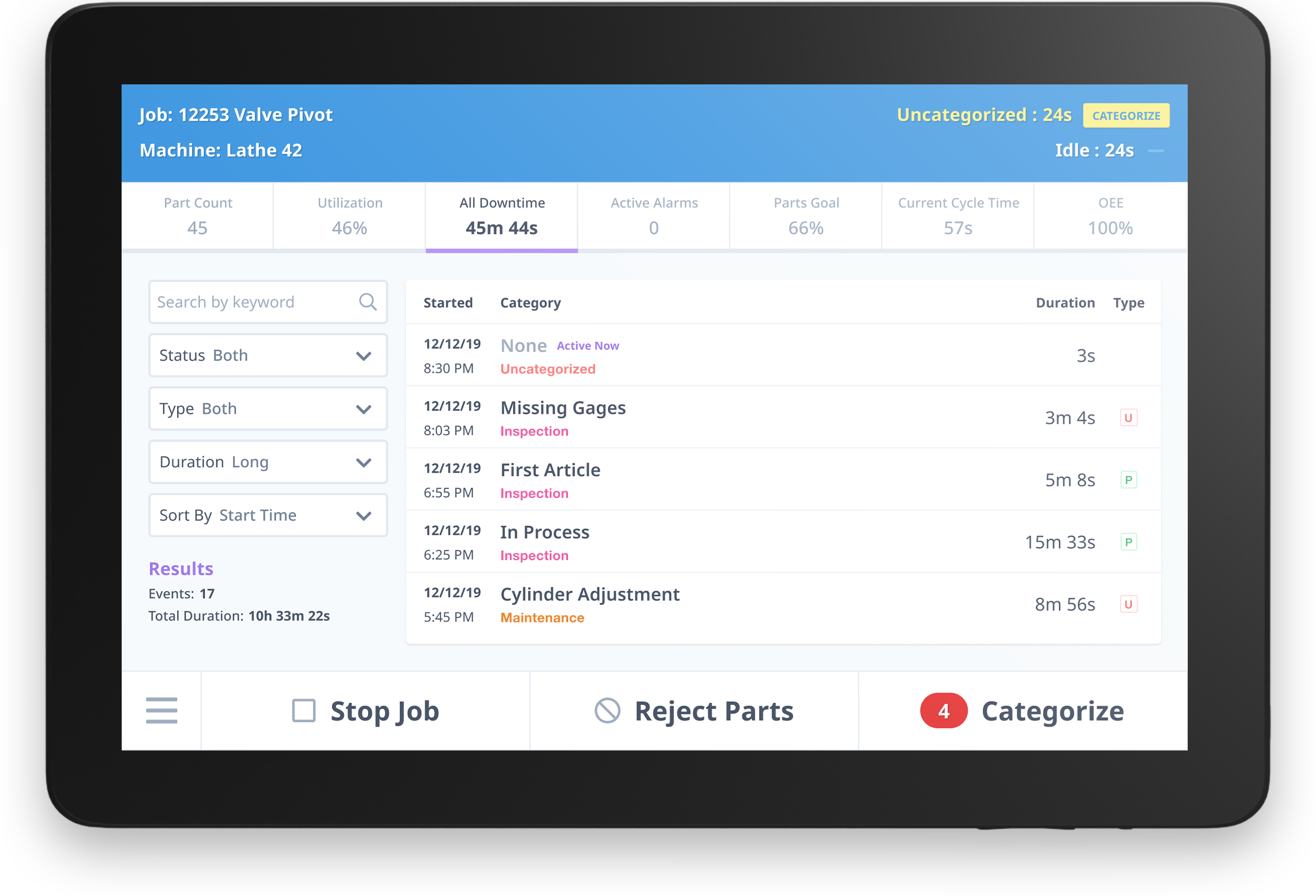

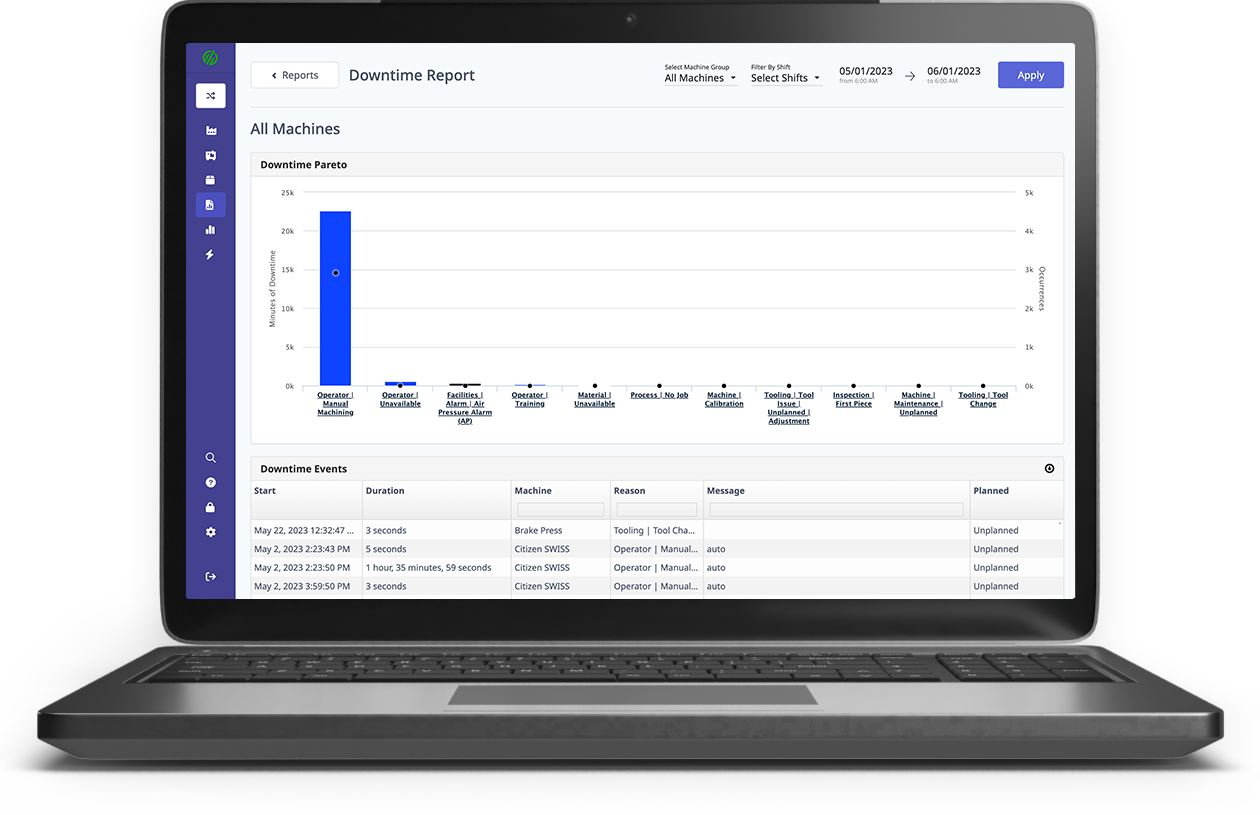

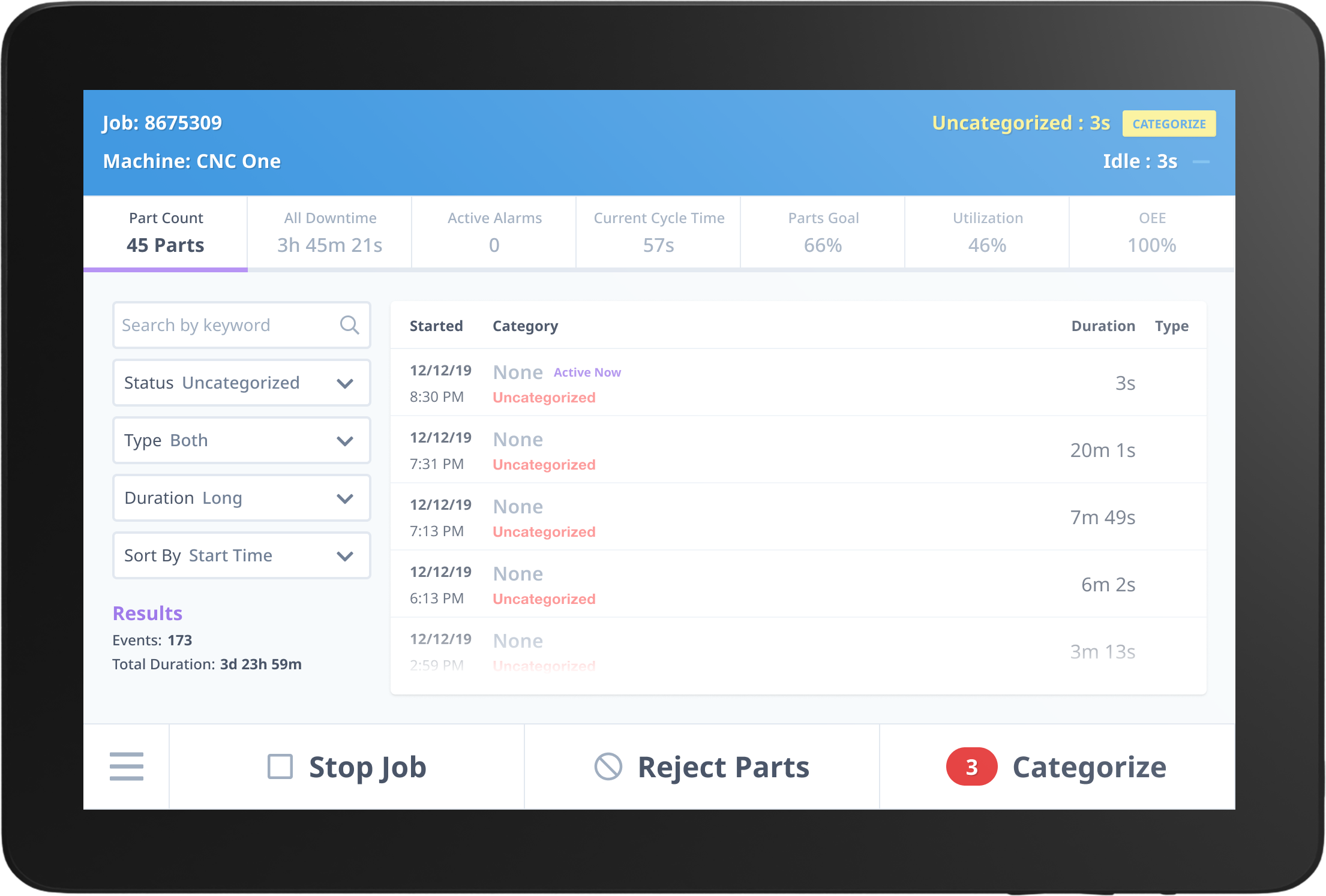

Track your processes with operator feedback to highlight bottlenecks that are generating the most downtime so you can rework and deliver better, more efficient processes.

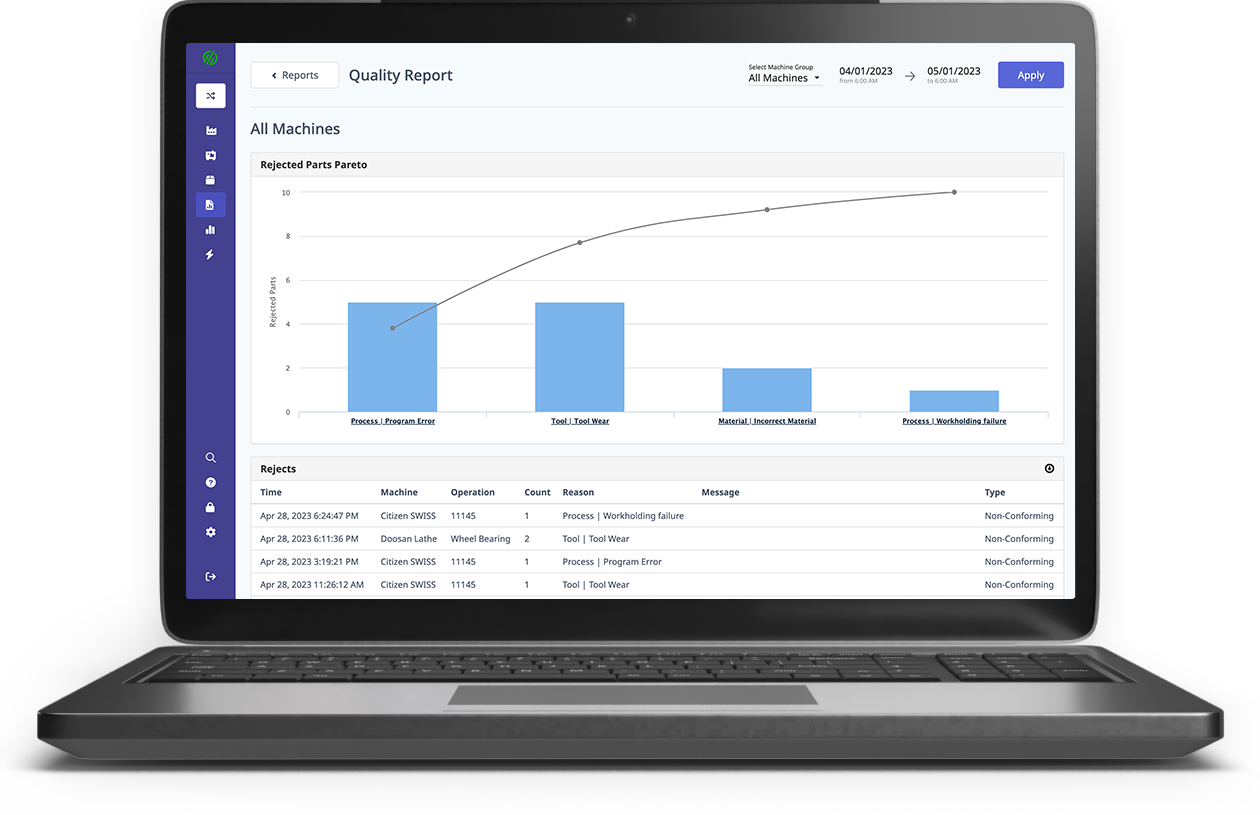

Identify production process inadequacies with operator insight. Analyze quality data and human feedback from operators to build and deploy alert systems to employees when they occur.

MachineMetrics helps you deliver step-by-step instructions that enpower factory workers to be more efficient. Customize notifications and workflow systems to deliver the right information to the right person at the right time.

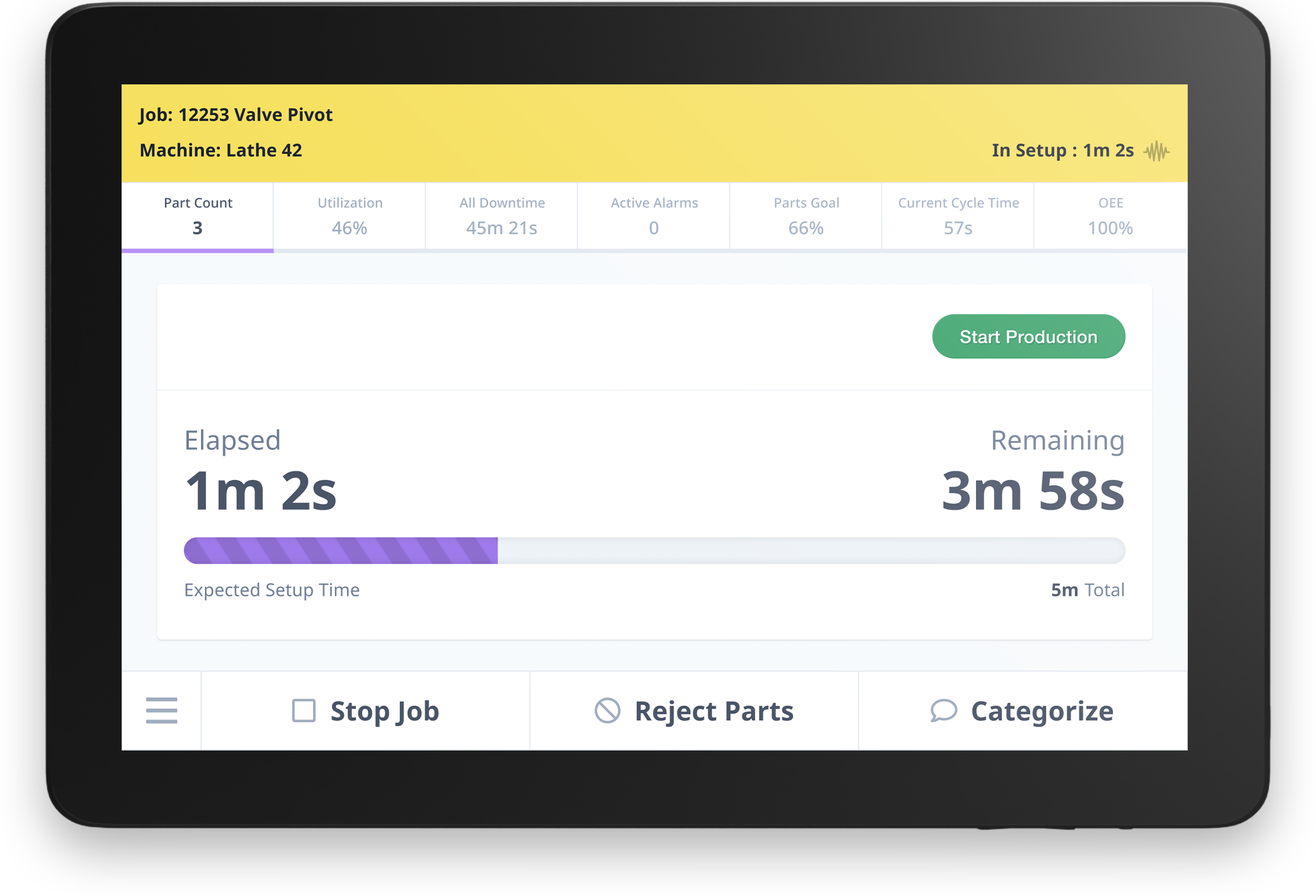

Start, stop and track setup time to identify areas for improvement. Display setup stages and instructions to encourage operators to complete on time.

Track the performance of each changeover and operator analytics. Measure average changeover times by shift to build more efficient systems that reduce downtime.

Create workflows that integrate with your ERP that leverage real-time production data to reschedule and reorganize jobs when parameters are triggered.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027