This past week was full of news around the Covid-19 pandemic, and we started seeing closures of factories in North America. I do hope everyone reading this and their families and co-workers remain healthy. My sincerest gratitude to the hospital workers, doctors, and nurses who are caring for the sick, and risking their health on the front lines. As I sit home for the second week, fear and uncertainty continue to grip our nation and our world. Lives have changed globally. I can only contribute our data to help others understand how this is and will be impacting our lives in manufacturing.

MachineMetrics customers represent a statistically significant number of machines across hundreds of small, medium, and large manufacturers in the United States. Machines are primarily used for metalworking such as CNC Mills, Lathes, Grinders, but also fabrication such as Lasers, Presses, and Welders.

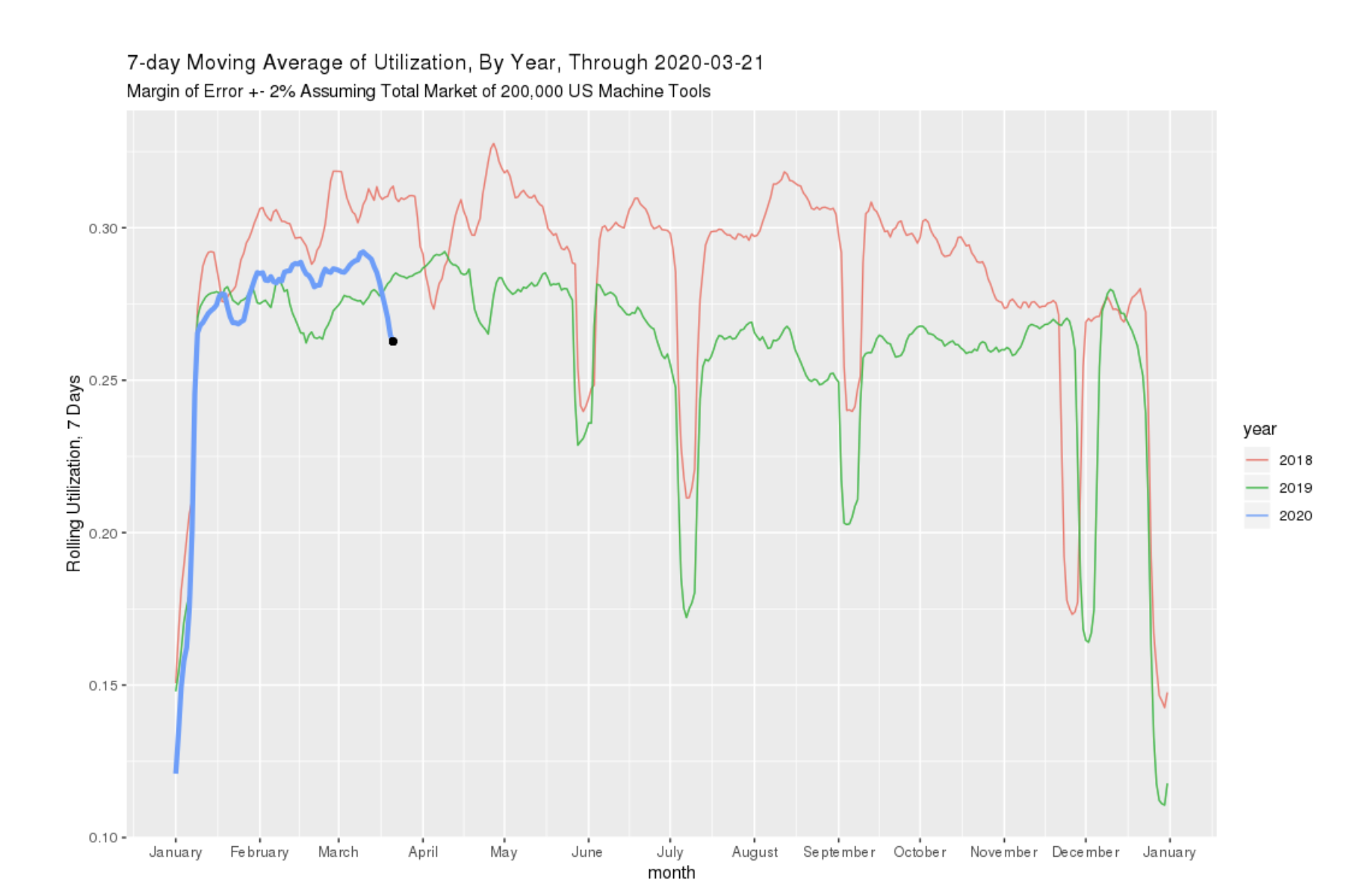

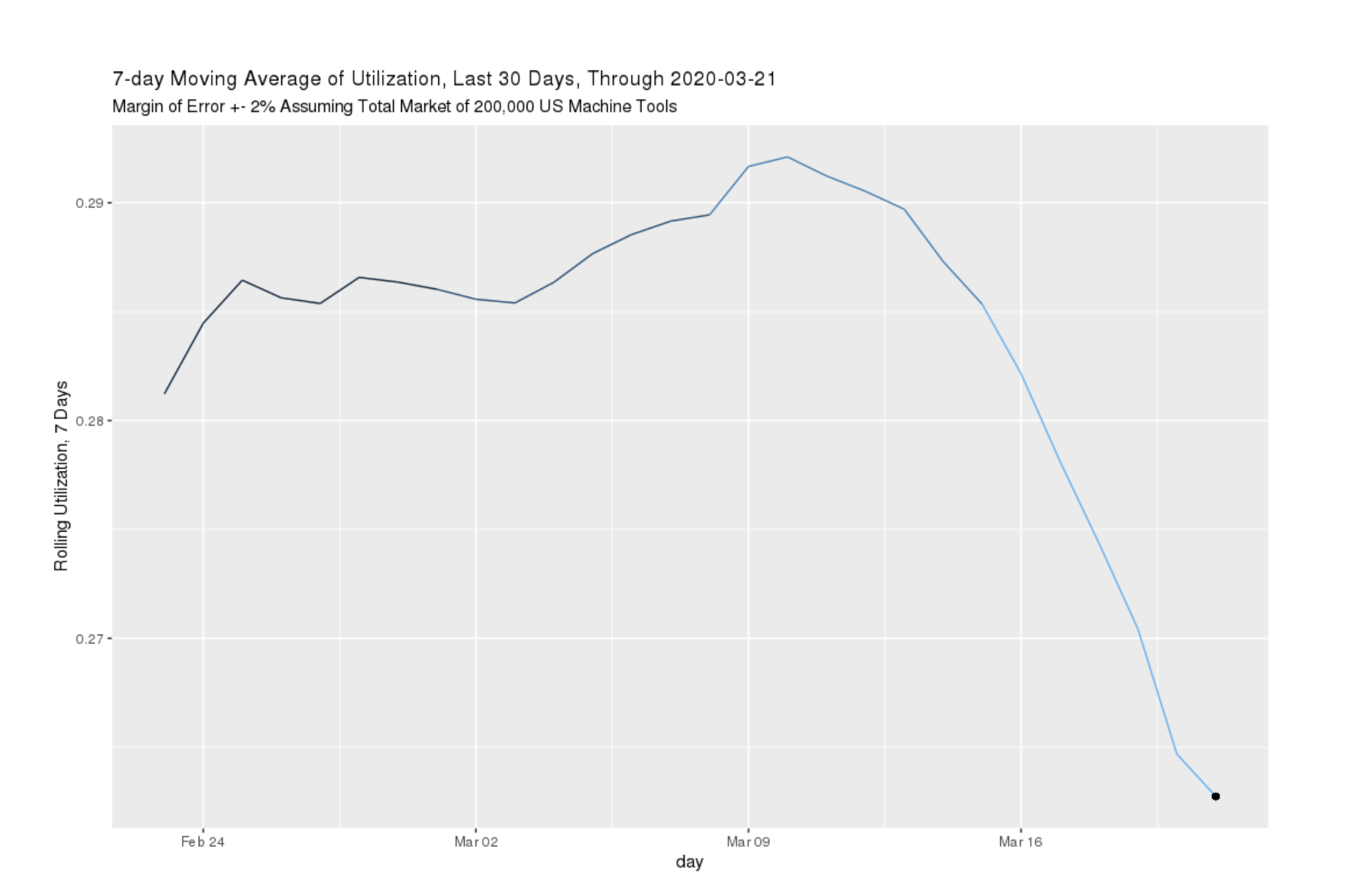

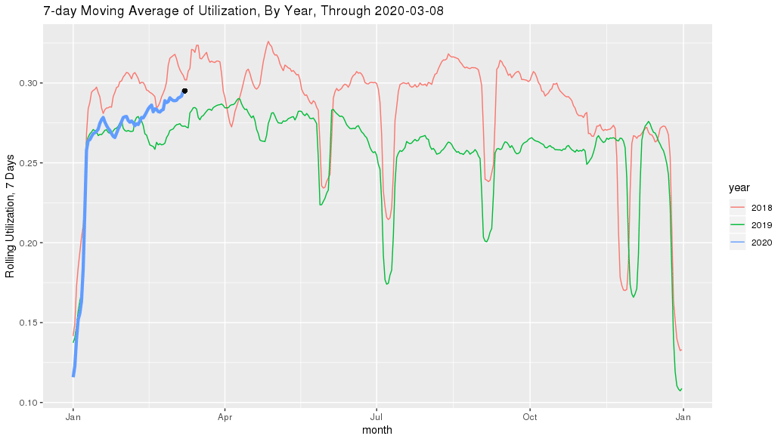

Last week continued a drop in our customer’s machine utilization as we fall below 2019 levels. I don’t anticipate that this week will be much better. We saw automotive take a particular hit as the major OEMs closed their factories last week. As of Yesterday, 3-21-2020, average machine utilization dropped to 26.3% - a drop of 2.2 points from 28.5% one week ago. This is significant but still just above productivity levels last fall. Most factories are still producing.

A view of the last 3 days shows this drop in more detail. March 10 had a peak production of 29.2% but every day since has dropped.

When segmenting data by industry, Automotive - typically the best performer, has dropped to #4 leaving aerospace as the top performer in machine utilization. This correlates to the plant closures that have been publicized. Some industries such as Medical Device and Aerospace & Defense has seen a slight uptick in utilization these last few days. Many of our customers tell me that they continue to have no shortage of work and remain in operation. Given our dataset, we can conclude the automotive is currently the main driver of decreased productivity so far, but if other industries follow suit, we have a long way to drop.

.png?width=990&name=image%20(47).png)

In light of the publicity our analysis has received, we decided to take a closer look at our methodology. Today, we have updated a couple of assumptions and identified an issue that caused our previously reported data to be artificially high for the 7-day rolling day average that accounted for daylight savings. The conclusions and general trends remain unchanged. As stewards of data, we feel it is our responsibility to inform the community of changes in both our calculations and assumptions. The difference between the previous calculation and the corrected calculation can be seen in the chart below. Notice the difference for the 7 day period around daylight savings in the spring and the fall.

General trends, especially for the beginning of 2020, stay unchanged. American manufacturing remained strong and was on an upward trajectory, peaking at just below 30% utilization on March 12th, well after multiple states had declared states of emergency.

.png?width=1644&name=image%20(46).png)

Below we have included the recording of the live panel discussion on this topic with our Co-Founder and CEO, Bill Bither, along with industry leaders from Pindel Global Precision, Rassini, and Gardner Business Media.

Last week I published my first post on the Impact of COVID-19 on U.S. manufacturing as seen from our customer's anonymized and aggregated data. I was hoping that this outbreak wouldn't become a pandemic - but here we are just 7 days later, I'm working from home along with the rest of the company. My three high schoolers are home from school for at least 3 weeks, and the market is down again almost 10% causing trading to stop. In just one-weeks time our lives have significantly changed.

Manufacturing is still on a significant upwards trend - seemingly bucking the overall economy. Is this due to domestication of the supply stream, or manufacturers temporarily increasing inventory in a "war time" panic. It's hard to say - however I have had some evidence from our customers that work normally sent to China is coming their way. Forbes published an article last week based on our data that Covid-19 may be delivering a local manufacturing renaissance.

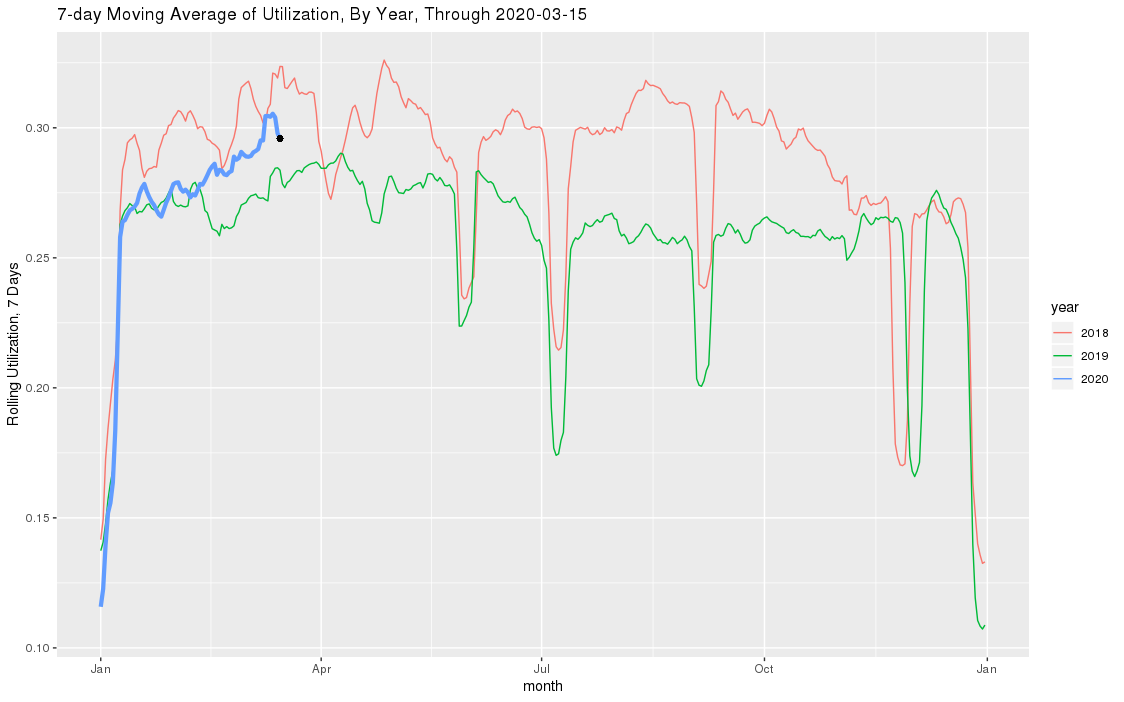

The rolling 7-day average of machine utilization last week was 29.5%, which is the highest since October 2019. Throughout last week machine utilization continued to spike through Thursday when the rate peaked at 30.5% for 2 days, a 1% increase from the beginning of the week. This past weekend we experienced a relatively significant 1% drop in productivity compared with the previous weekend back to 29.5%. Still a high number, but a possible leading indicator of a downtrend trend. Note that with our data at a 30% utilization rate, our margin of error is 0.7%. Anything moving more than 0.7% would be considered measurable and significant which is the case here.

I do believe that we will see a downward trend here as manufacturers send their employees home - offset to some extent with domestication of the supply chain. Executives, and office workers are beginning to work from home now while essential factory workers are continuing to come to work. Having remote access to factory data will be essential during this pandemic.

I do hope that U.S. Manufacturing is able to weather this downturn well, that we all stay healthy, and get back to the office soon.

The entire world is on edge with the Coronavirus epidemic - we hope it’s not going to turn into a pandemic. The media is stating that U.S. manufacturers are experiencing supply chain issues from China. MachineMetrics is in a unique position to comment on this crisis given it has aggregated anonymous machine utilization data from manufacturers. We’re able to see economic trends in manufacturing from thousands of machines in real-time. Recently, we posted our first 2019 state of the industry report. Reading this report will give you a better idea of how we collect and aggregate data.

Given the significant changes to our economy over the last few weeks, our data science team has been paying particular attention to this data to help understand how manufacturing is being impacted by these events. We plan on posting the results at a greater frequency given the potential global economic impacts this is having.

This plot shows 2018, 2019, and 2020 rolling 7-day machine utilization rate:

The green plot represents 2019 and as we can see is significantly lower than the red 2018 plot. The Institute of Supply Management correlates with the MachineMetrics machine utilization data.

2020 has shown a faster ramp-up of machine utilization, which an average utilization rate of nearly 30% for the first week in March, the first time we have seen this since October 2018. This is a great sign of the industry’s performance to date. Supply chain issues and travel restrictions seemingly have not impacted U.S. manufacturing yet. Could the supply chain issues temporarily be boosting U.S. manufacturing output as manufacturers choose domestic sources? Is inventory high enough that the supply chain impact is delayed? The market is certainly afraid of what might happen if supply chain issues do cause a slowdown in production with stocks tumbling over the last 2 weeks, and futures for March 9 looking poor as I write this. When will this impact manufacturing? We will have to just wait and see. Stay tuned for next week’s summary when we post an update. Will the strong U.S. manufacturing performance continue, or will we start to see a slowdown?

MachineMetrics is committed to supporting the front-line worker on the manufacturing floor and in the medical field. At this critical time, we’re happy to offer support to all manufacturers and manufacturing efforts contributing to the fight against COVID-19.

If this is you, email info@machinemetrics.com and we’ll be in touch.

Easthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027