Increase Response Times, Improve Machine Health.

Drive Maintenance with Real-Time Data & Automation.

When machines need maintenance, your operators shouldn't have to search for help or submit a tedious, manual work request. When machines go down, your maintenance personnel shouldn't be forced to react to something they could have prevented in the first place.

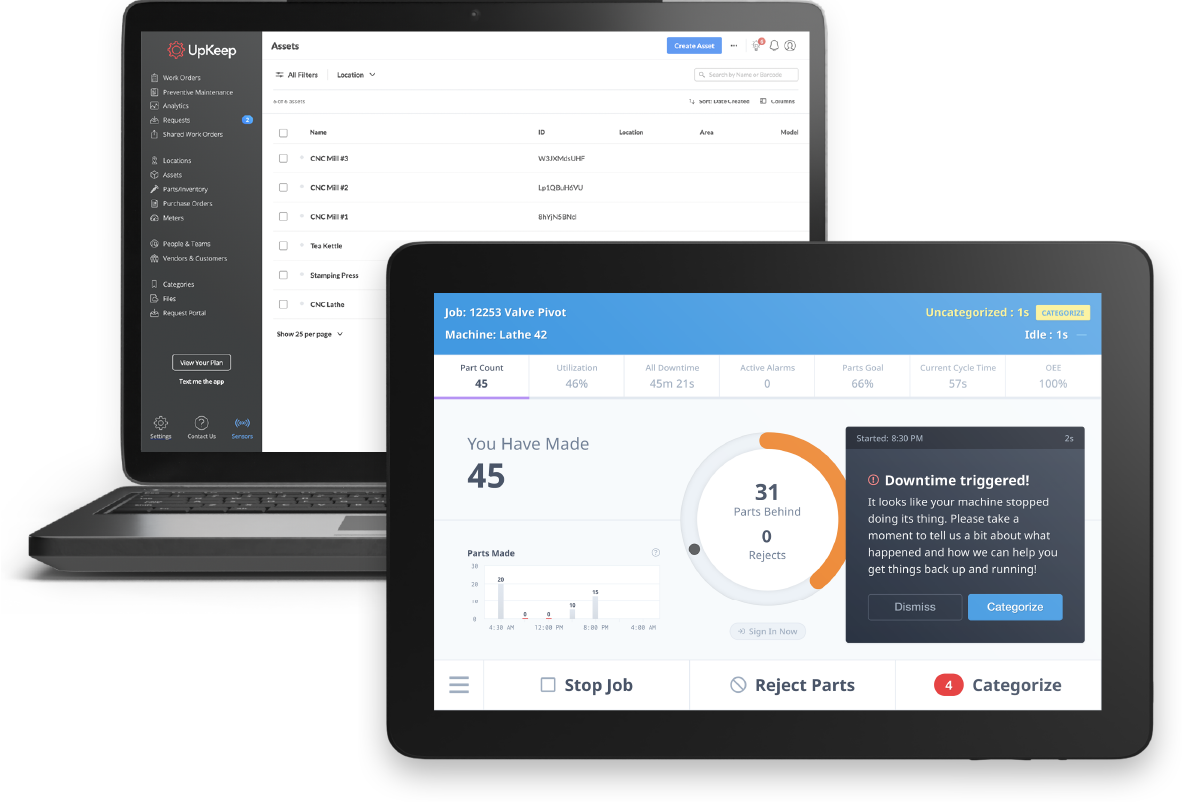

Connect MachineMetrics' machine data platform with the UpKeep CMMS solution to gain visibility into machine health, streamline communications, and transform data into decisive action.

HARNESS THE POWER OF MACHINE DATA.

Keep valuable equipment running longer and healthier, reduce unplanned downtime, & increase shop floor efficiency and communication.

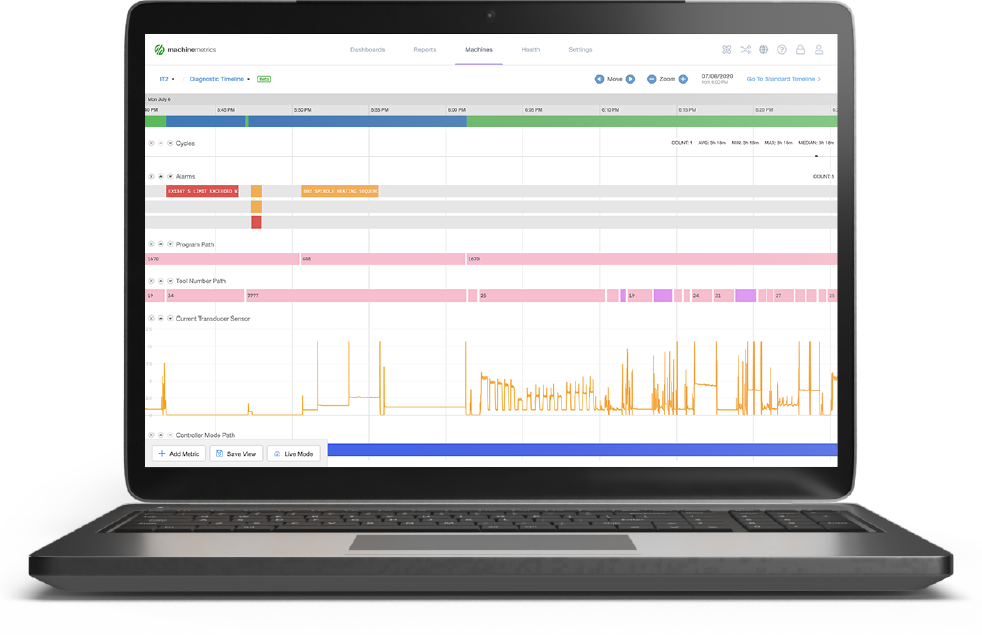

Connect, collect & visualize data fromany machine with plug-and-play technology.

Prevent unexpected, costly downtime and breakages with real-time condition monitoring.

Quickly diagnose issues with machine health data visualizations and analytics.

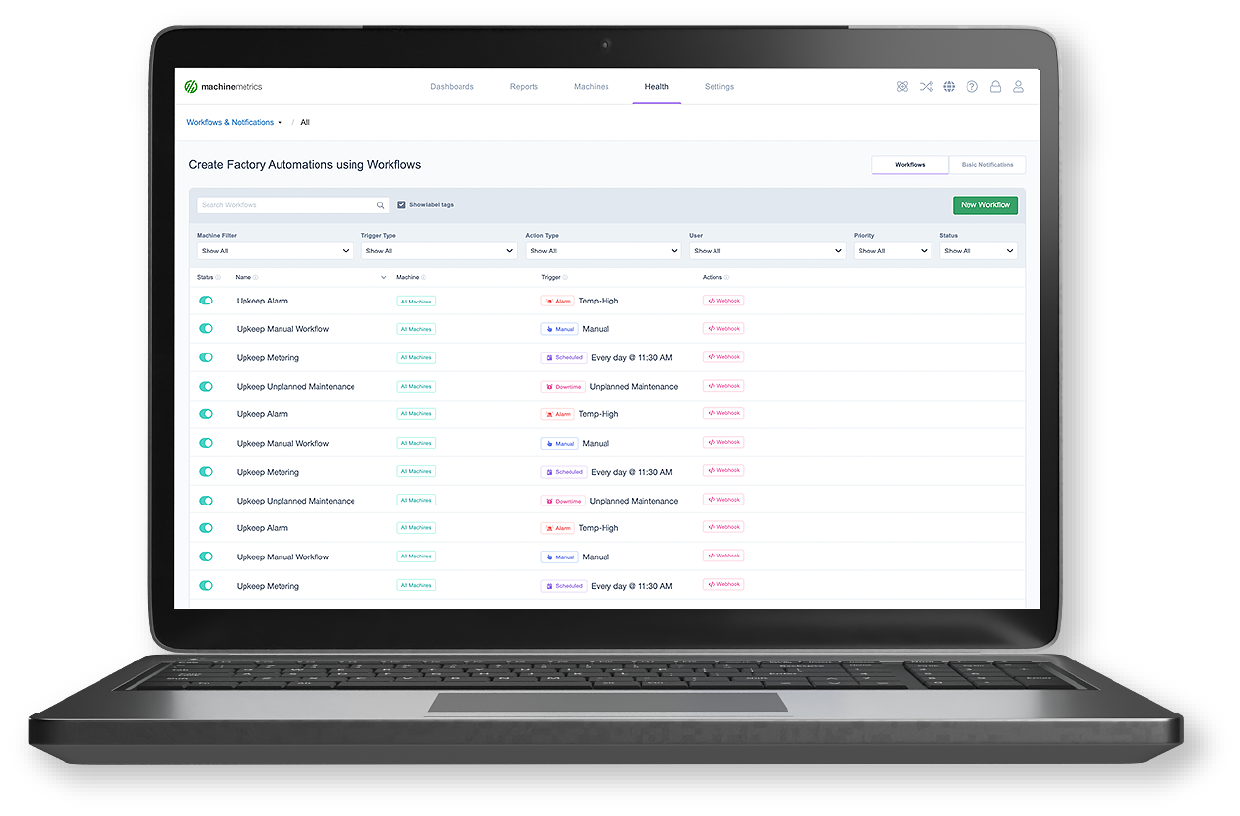

Automatically trigger the creation of work requests or work orders in UpKeep based on machine conditions.

The Benefits of Integrating MachineMetrics and UpKeep.

Maximize uptime and prevent equipment failure by identifying and resolving issues before they become a serious problem.

Optimize maintenance response times with real-time work order triggers based on equipment condition.

Maximize machine health and avoid over- or under-maintenance by relying on accurate data instead of estimates.

What Does a MachineMetrics & Upkeep Integration Look Like?

CHECK OUT THIS DEMO NOW

You won't be disappointed.