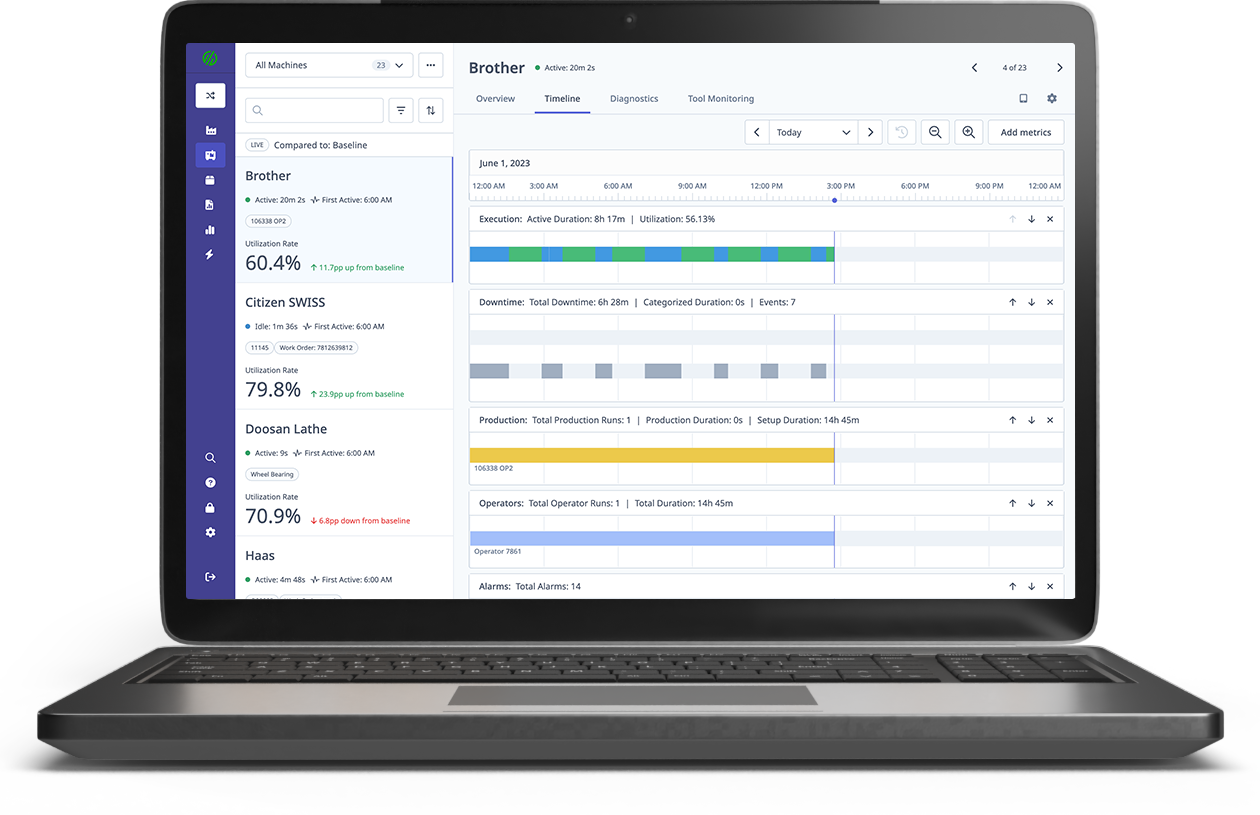

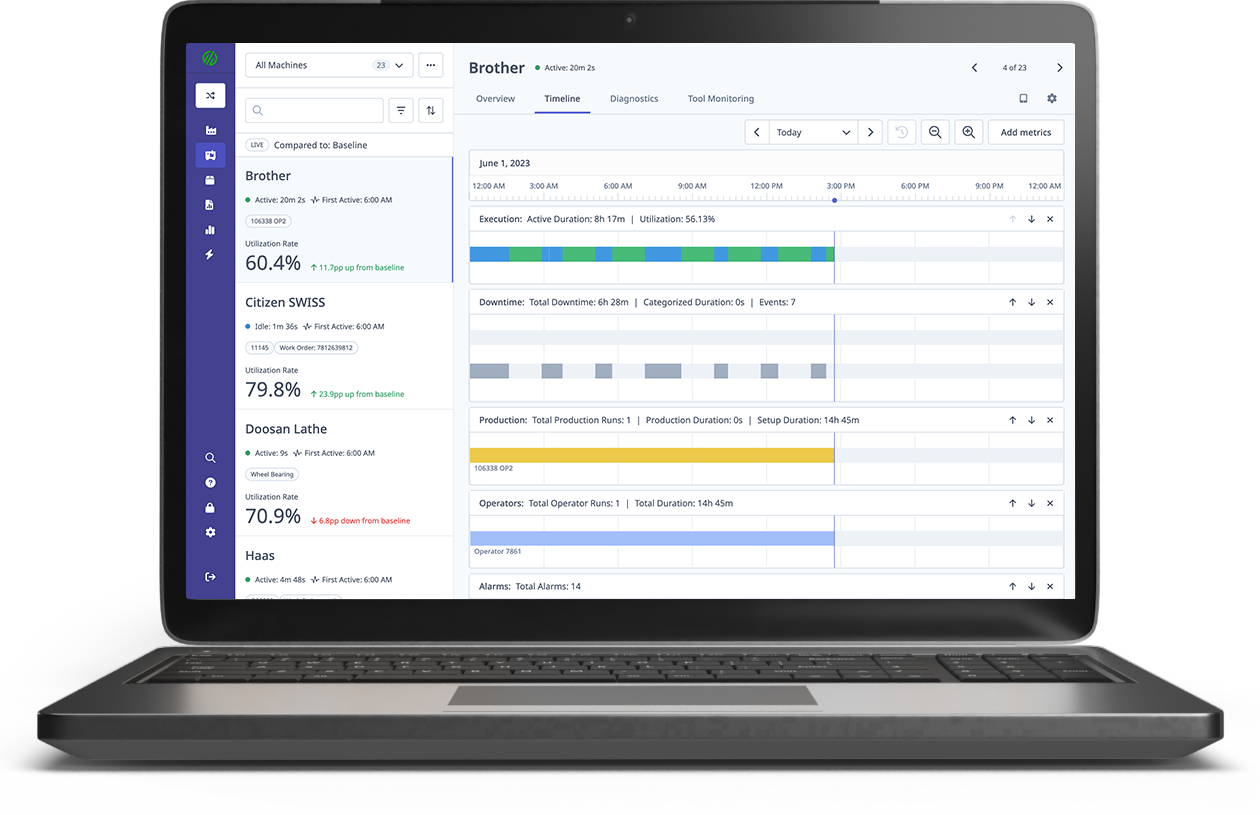

MACHINE MONITORING: REDEFINED.

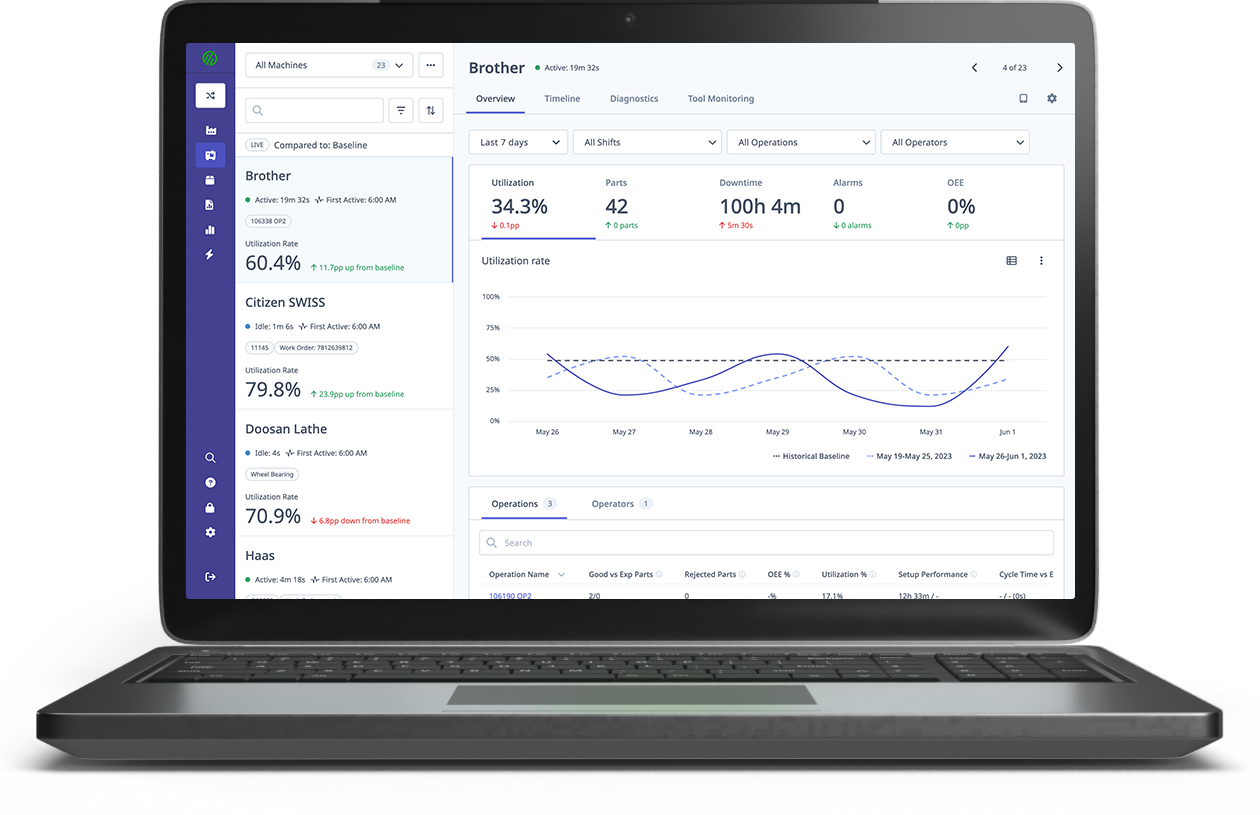

Monitor OEE, machine utilization and downtime in real time for maximum production efficiency.

CONNECT ANY MACHINE

Connect, collect & visualize data from any piece of equipment on the shop floor.

IDENTIFY PRODUCTION BOTTLENECKS

Easily identify bottlenecks and points of failure that are generating the most downtime.

OPTIMIZE YOUR PROCESSES

Configurable notifications allow the right person to take immediate action at the right time.

CONDITION MONITORING: POWERED BY INDUSTRY 4.0

Transform your approach to maintenance with real-time machine condition monitoring that deploys in minutes. Harness the power of machine data to keep your equipment running longer and healthier.

CONNECT TO ANY MACHINE

Connect, collect & visualize machine condition data from any piece of equipment on the factory floor.

MONITOR AND ANALYZE HEALTH

Diagnose issues with real-time visualizations and analytics on the health of machines via PMC and diagnostic control data.

TAKE ACTION AT THE RIGHT TIME

Keep machines running with optimized maintenance alerts driven by crucial KPIs, machine alarms, and condition thresholds.

PREDICTIVE MAINTENANCE MEET YOUR NEW BEST FRIEND.

Supercharge your predictive analytics applications with high-frequency machine data to diagnose, predict, and avoid failures on your manufacturing equipment. No sensors required.

EASILY CONNECT MACHINES

Connect, collect, & visualize high-frequency data from shop floor equipment.

PREDICT MACHINE PROBLEMS

Leverage transformed data to immediately build predictive algorithms and workflows.

DEPLOY SOLUTIONS QUICKLY

Deliver out-of the box or custom apps on the Edge to stop problems before they start.

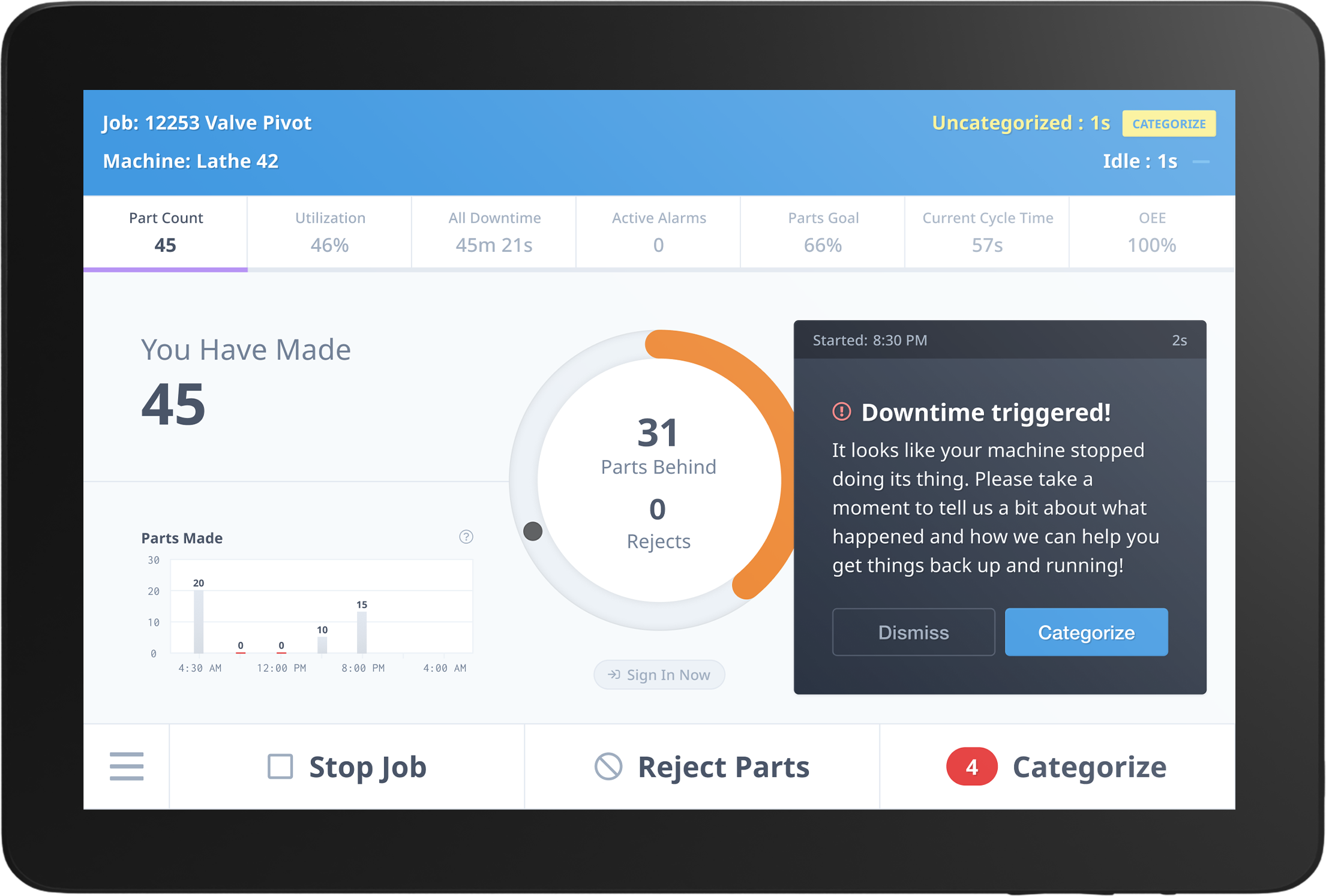

CONTINUOUS IMPROVEMENT: REDEFINED

Our powerful, intuitive, and customizable production and process optimization apps are driven by analytics to let your team know exactly what they need to do, when they need to do it, and how to do it better.

DATA COLLECTION

Connect, collect & visualize insights from any piece of equipment, system, and worker on the shop floor in real-time.

BOTTLENECK ANALYSIS

Analyze machining and process data to identify inefficiencies that are affecting productivity and profitability.

OPTIMIZE PROCESSES

Build step by step workflows that deliver optimized processes at the right time via apps and instructions to factory workers.

TRANSFORMING THE WAY YOU SELL MACHINES.

Power your sales of machines with data-driven apps that reinvent legacy manufacturing processes to create new revenue streams and business models around the sale of manufacturing equipment.

CONNECT ANY MACHINE

Easily connect, collect & visualize data from your entire fleet across customer sites anywhere in the world.

EMPOWER APPLICATIONS

Gain a competitive advantage through data-driven apps that help manufacturers get more out of your equipment.

INCREASE REVENUE

Enable new revenue models based on data by offering manufacturing subscription plans that fit financial capacities.

EMPOWER THE MACHINE DATA DIGITAL THREAD

Seamlessly connect MachineMetrics with your current shop floor systems to integrate machine data across your digital factory. Our data is completely portable through our REST and GraphQl APIs to integrate your machine data into existing BI workflows, reports, ERP systems. Extend the MachineMetrics UI to build your own operator UI and apps, bring in a 3rd-party application such as quality or work instructions, and customize operator visuals for various factory workers.

CUSTOM DASHBOARDING

Extend data from MachineMetrics into BI tools such as Microsoft Power BI, Tableau, and Klipfolio to build your own dashboards and interfaces.

RULES BASED WORKFLOWS

Build rules-based workflows for any shop floor data item including machine conditions, alarms, performance metrics, and KPIs to trigger operator actions via machine or system automation.

SYSTEM INTEGRATIONS

Connect factory floor systems like ERPs to get accurate data in and out to improve job quoting accuracy, scheduling, and inventory management.

READY TO CONNECT YOUR SHOP FLOOR?

Want to see MachineMetrics in action first? Book A Demo