Manage the shop floor With Confidence

Instant visibility into the status of your factory, including part counts, machine utilization, and OEE. Take control of the shop floor by enabling real-time production data, instant notifications, and automation.

Key Benefits of Shop Floor Software

Visualize and control your production with real-time operational data to make better decisions and drive productivity across the operation. MachineMetrics real-time shop floor management software gives you the tools to get deep insight into operational performance so your team can take action quickly.

Don't let delayed, inaccurate, manual data collection slow you down. MachineMetrics offers a real-time shop floor control system to automatically extract equipment data and populate it in pre-built reports. Take it further with advanced custom reporting and automations as your continuous improvement journey advances.

Shop Floor System Features

Connect in Minutes with our Edge Device

Plug-and-Play universal machine connectivity and data collection from PLC's supporting protocols including: MTConnect, Fanuc, OPC-UA, UMATI, Mitsubishi, Citizen, Haas, Heidenhain, Siemens Sinumerik, Modbus, and Ethernet IP. MachineMetrics Edge supports digital and analog I/O for machines without a standard connectivity option to integrate even the most challenging equipment.

Downtime Tracking and Analysis

Categorize downtime reasons at each machine, identify the most common reasons for downtime, and track exactly how much downtime your factory is experiencing. Leverage the real-time data to respond to and resolve downtimes faster.

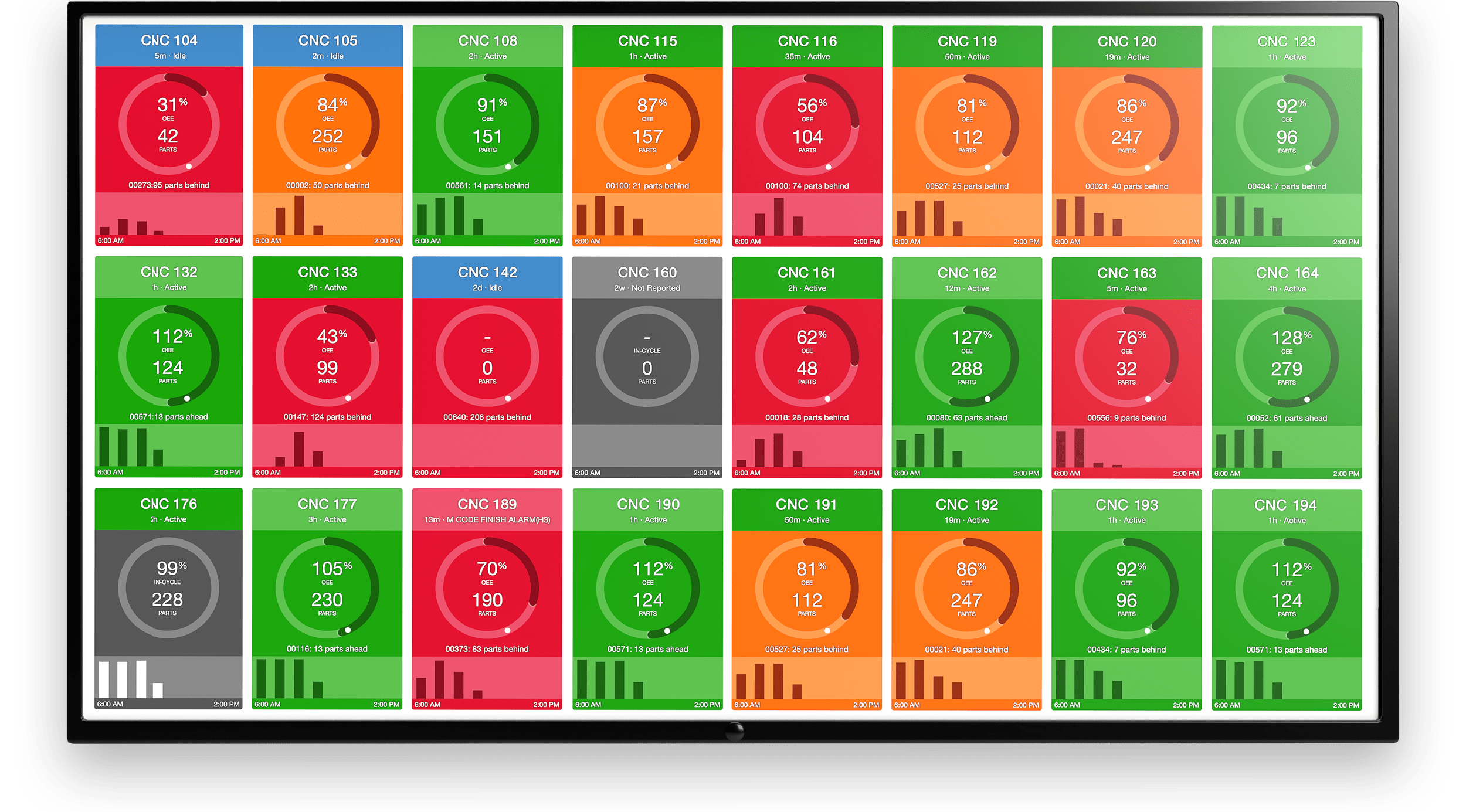

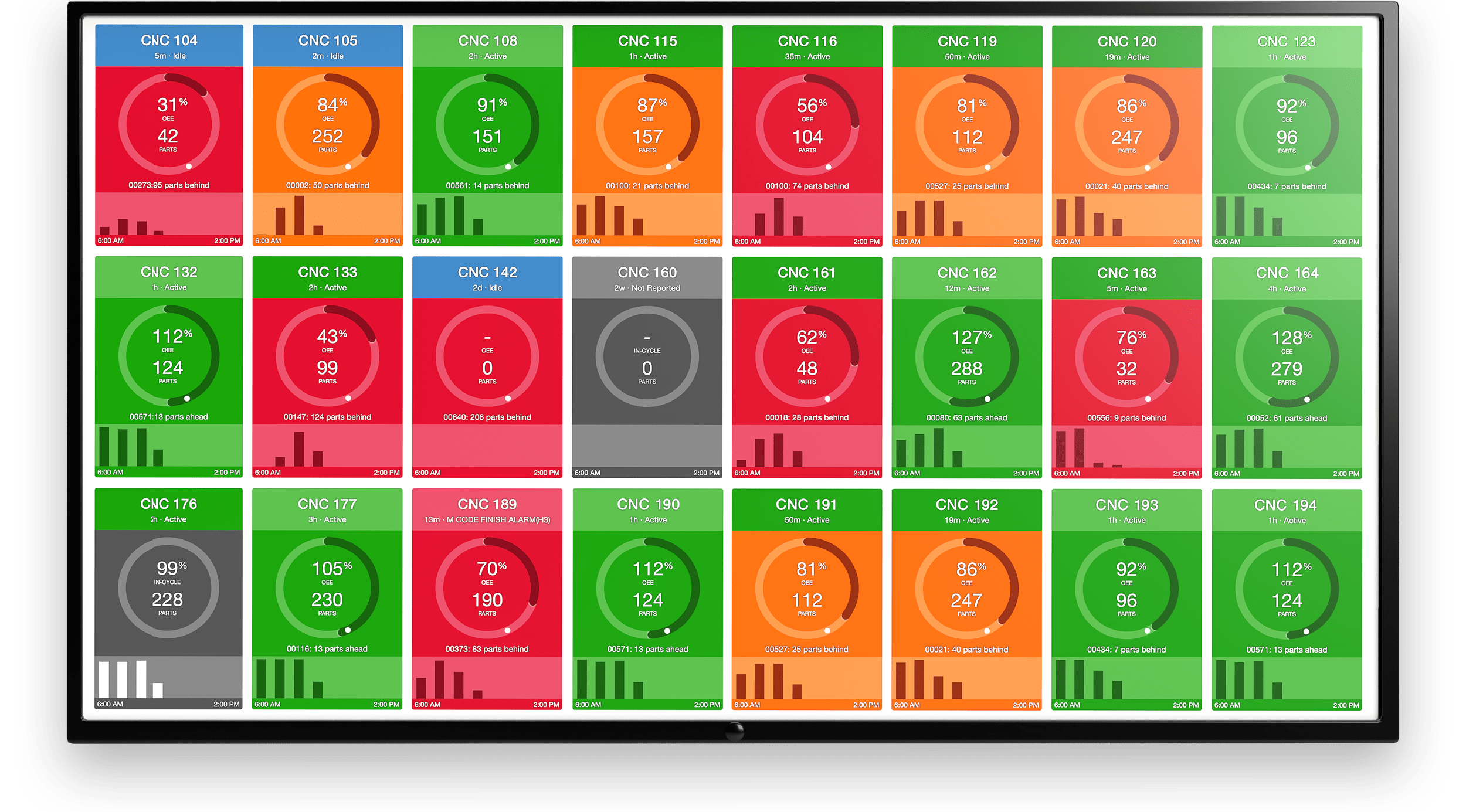

Shop Floor Visibility and Control

Get shop floor level control with real-time dashboards displayed on monitors across the factory. Operators and managers get immediate visibility into production status, whether it be tracked by part counts or OEE. Color-coding indicates if jobs are performing at or below expectations, allowing you to act quickly.

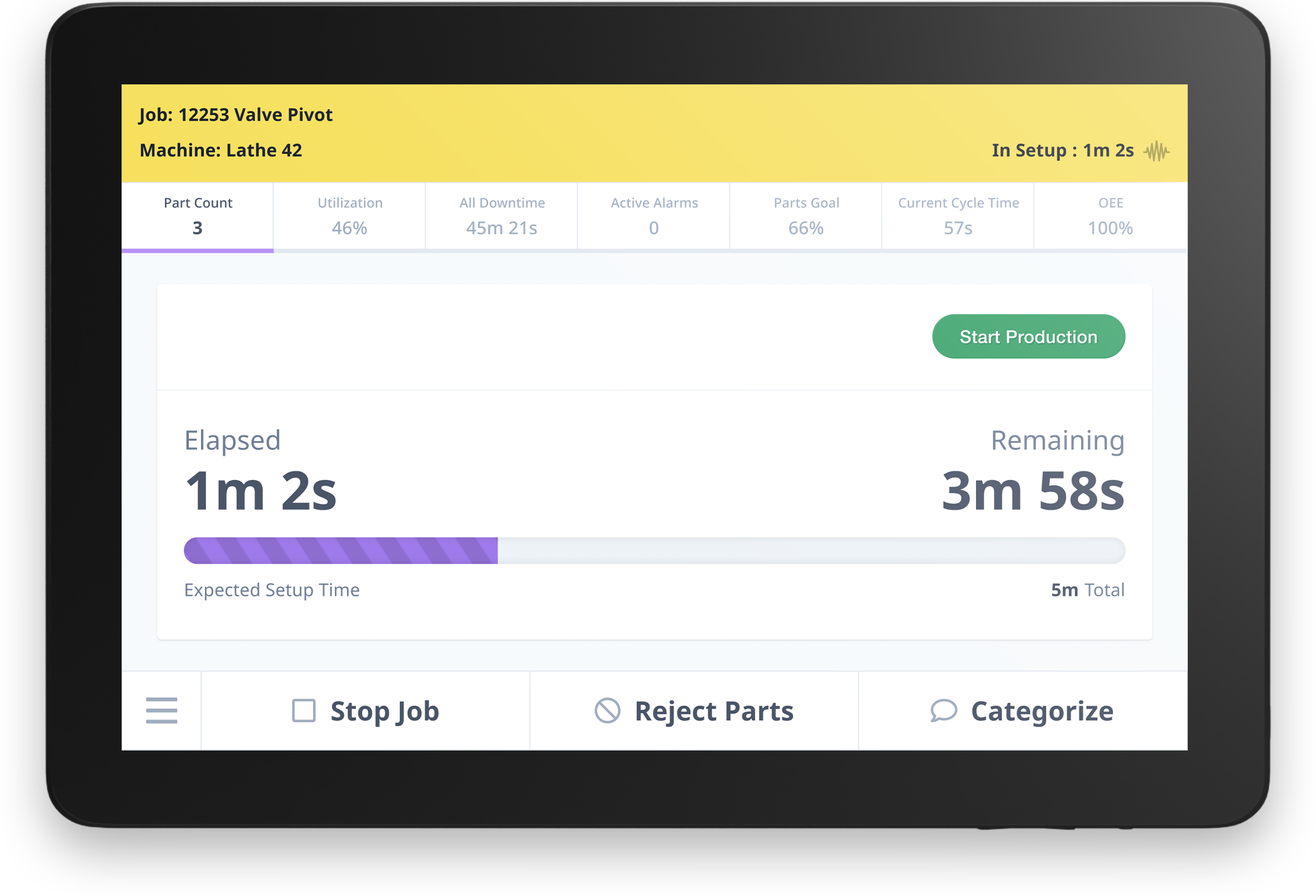

Operator View Tablets

With operator interfaces placed at every machine, operators can add human-context to machine data, providing more granular information on why machines have failed or parts are scrapped. Operators have instant visibility into their performance against production goals for a helpful sense of accountability.

Alert the right person at the right time

Jobs behind schedule or machines down? Immediately trigger notifications to the right person so they can fix the problem as fast as possible and resume normal operational efficiency.

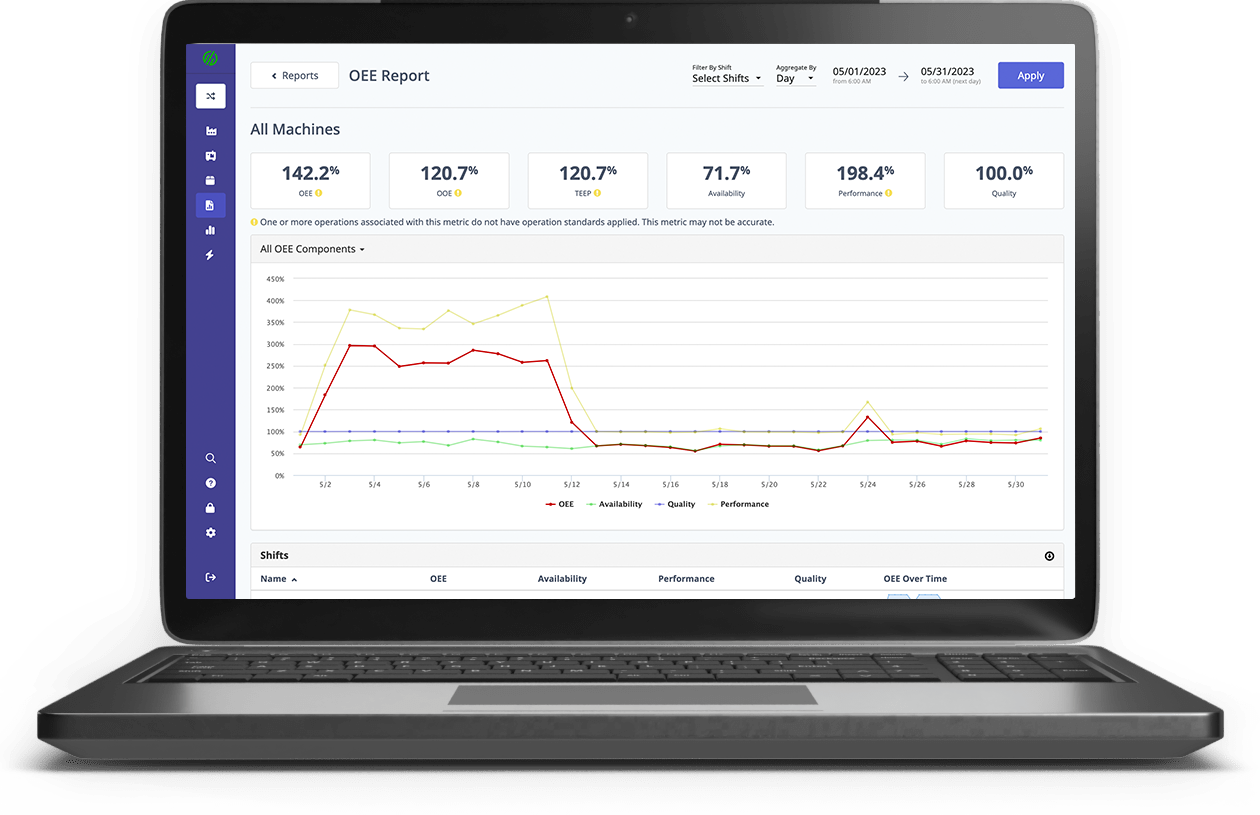

OEE Performance Reporting

Automate OEE reporting with machine scheduled availability, performance of meeting ideal cycle times, and quality. Dive deeper by segmenting the data by shifts, individual jobs, and more to identify and fix issues fast.

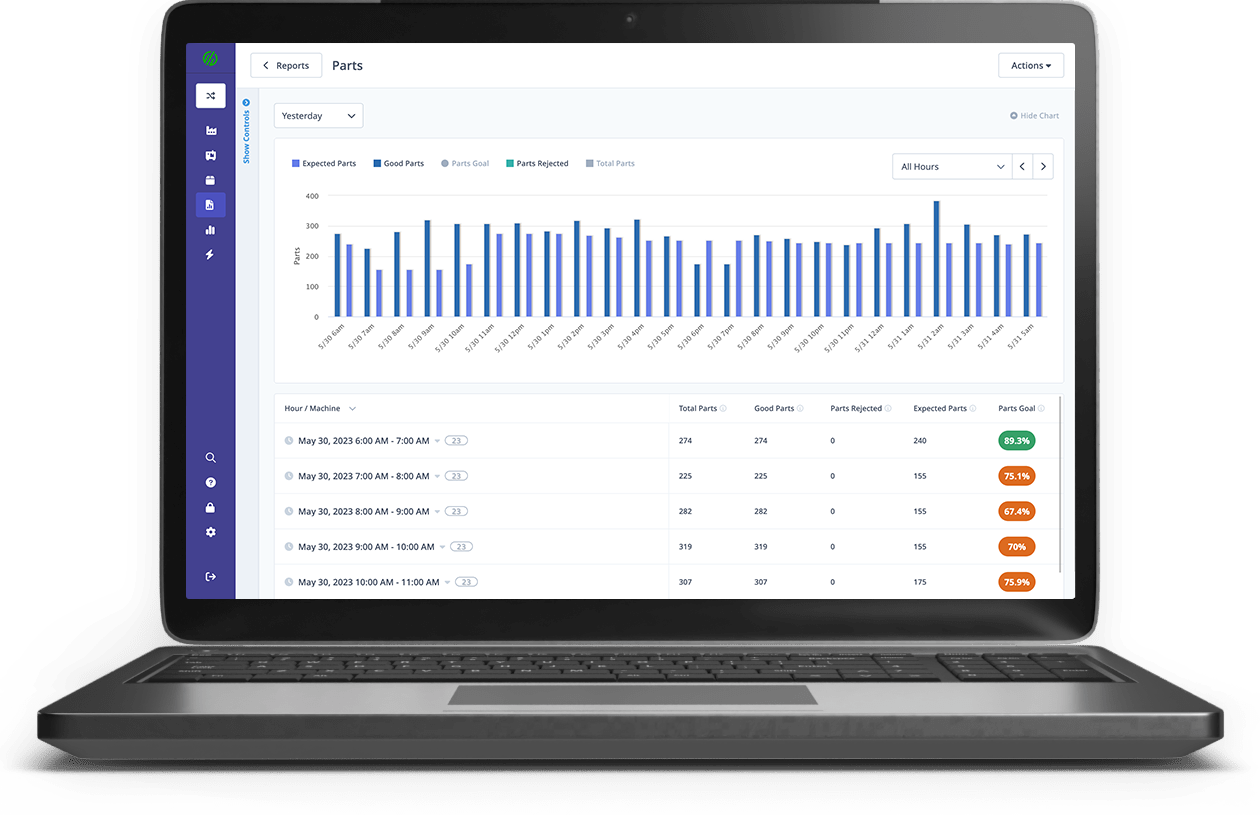

Real-Time Quality Tracking and Reporting

Track all your quality data in MachineMetrics and analyze pareto reports to reveal the largest reasons for scrap parts. No need for paper or spreadsheets.

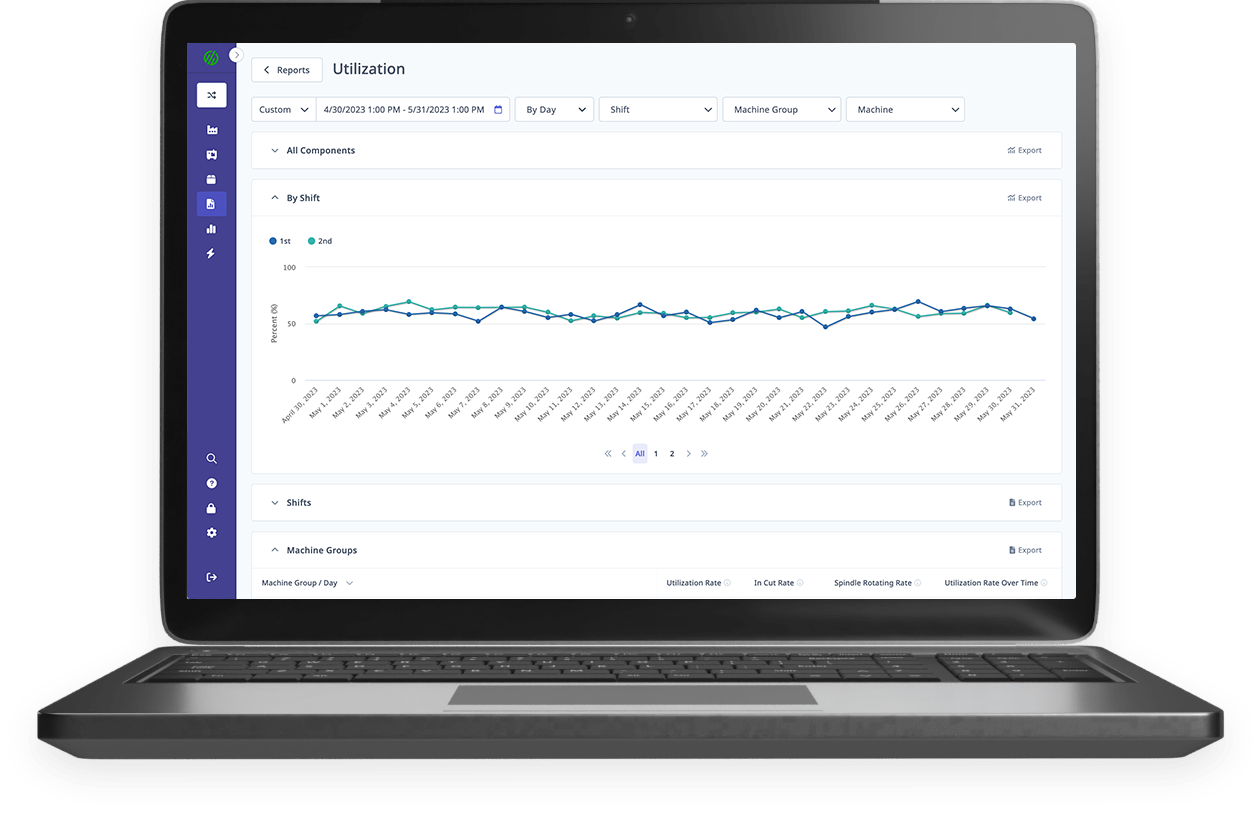

Machine Utilization Reporting

Drive maximum capacity from equipment with machine utilization reports. Evaluate trends over time, baseline production, and see where you stand against the industry.

Job Setup and Changeover Tracking

Track setup times to develop accurate benchmarks and develop processes improvements. MachineMetrics tracks setup time by incorporating it into the workflow when dispatching jobs. After a job enters setup, the Operator View counts up to the expected setup time. All time beyond the expected setup time will be considered unplanned setup, and be visible in downtime reports.

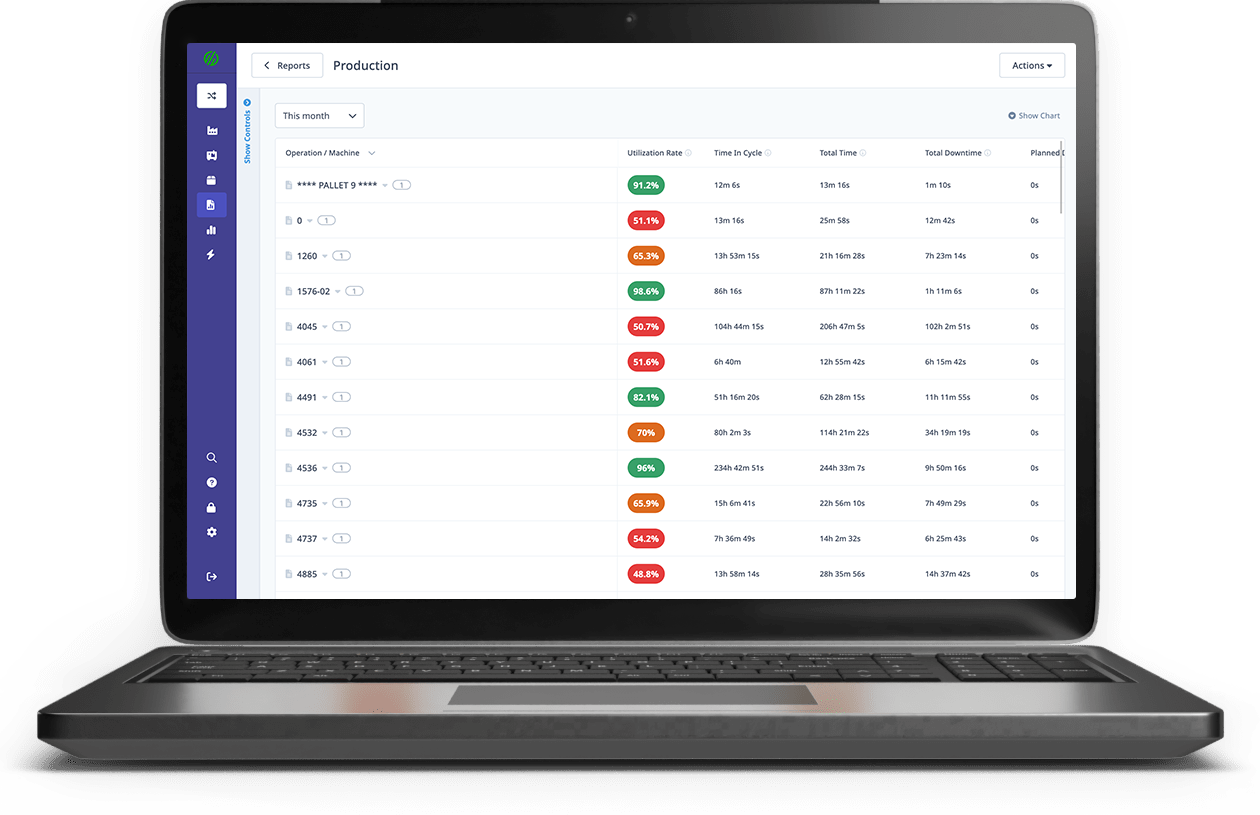

Deep Production Analytics

Populate production data in pre-built reports or build customized reports and dashboards for deeper analysis. Benchmark against historical performance to track performance improvements across individual machines, cells, or the entire operation.

Request A Demo

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowBook A Demo

Empower every team in your organization with real-time data and insights.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.