Real-Time Lean Manufacturing Software

MachineMetrics' real-time lean production software helps shop floors increase lean efficiencies by providing instant production visibility and deep analytics for faster decision making.

What is Lean Manufacturing Software?

| Lean manufacturing software uses real-time production data to generate analytics and insights to drive process optimization and automation. With real-time machine data collection, a cloud-based lean manufacturing system supports lean management principles across continuous improvement, maintenance, quality, production, and planning. |

|

Why Use Lean Software?

MachineMetrics real-time lean production software helps shop floors identify lean efficiencies by providing instant production visibility and deep analytics for better, faster decision making.

Lean Tools For Continuous Improvement

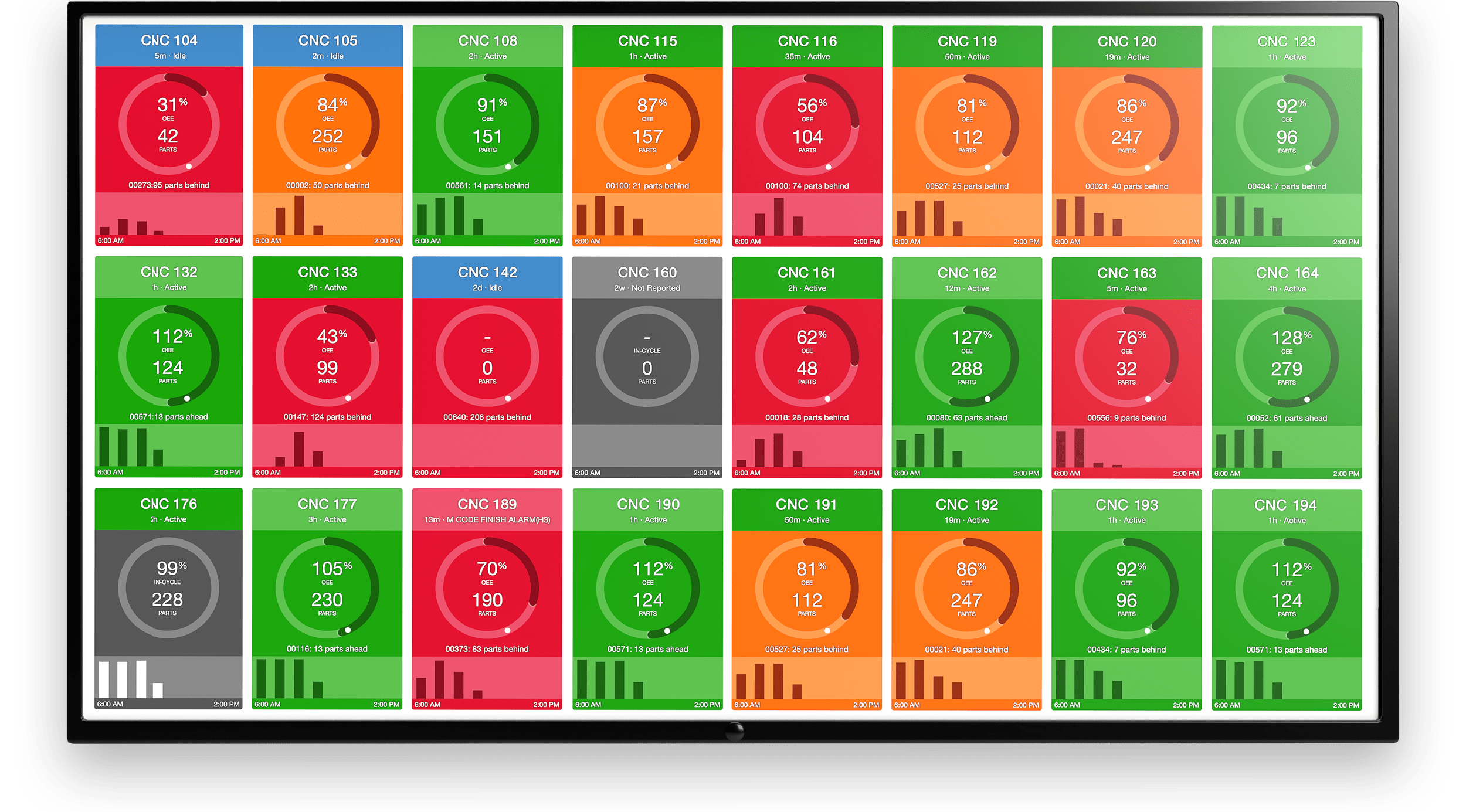

Shop Floor Dashboards

MachineMetrics real-time production dashboards can be placed across the shop floor, with easy-to-read, color-coded cells to indicate equipment performance.

Enable operators and managers to course-correct in real-time to ensure production goals are consistently met.

Real-Time Notifications and Alerts

Immediately trigger notifications when jobs fall behind schedule or machines go down to alert the right person of the problem. Take it further with predictive maintenance and get equipment fixed before it fails.

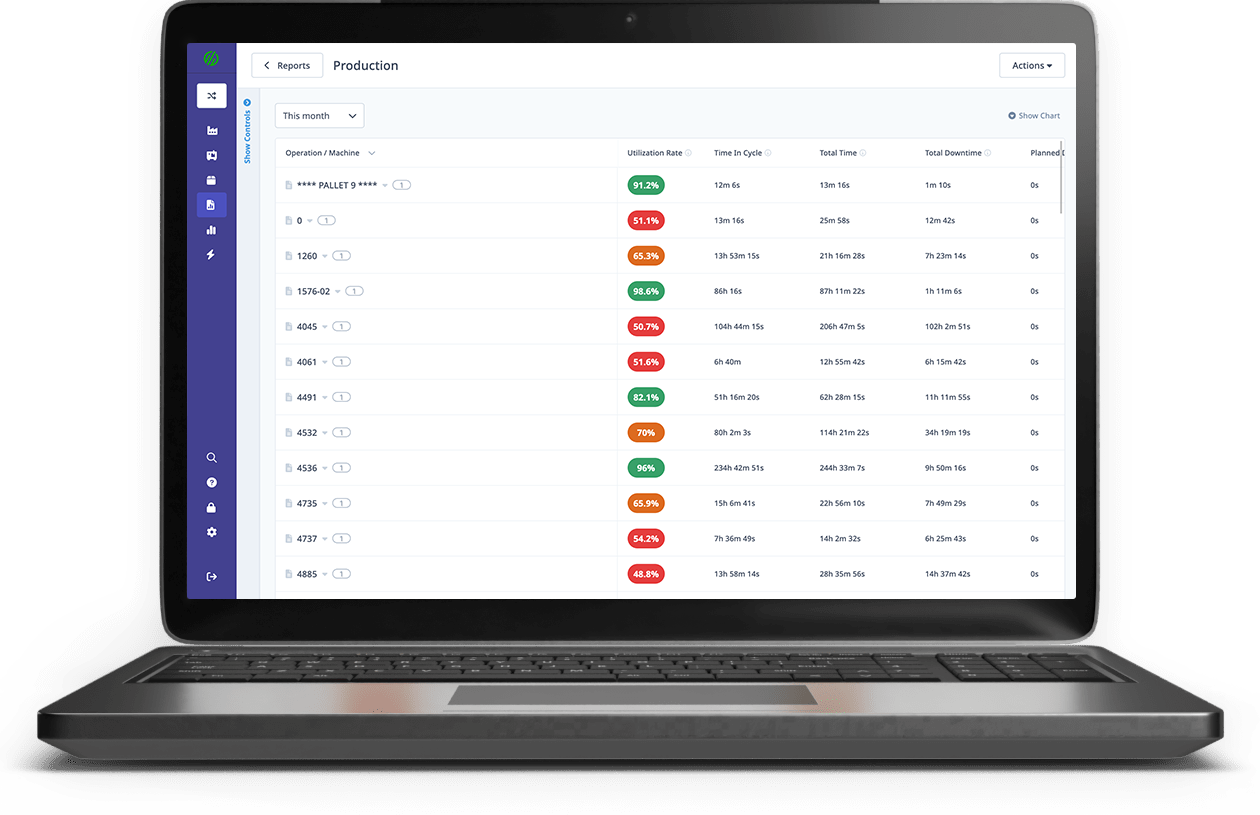

Deep Production Analytics and Reports

Populate data in default and custom reports and dashboards for deep analysis. Benchmark and measure against your current performance to improve machine performance, operator productivity, and plant capacity.

Enable your continuous improvement leaders to make better decisions with accurate production data that can pinpoint and prioritize process inefficiencies.

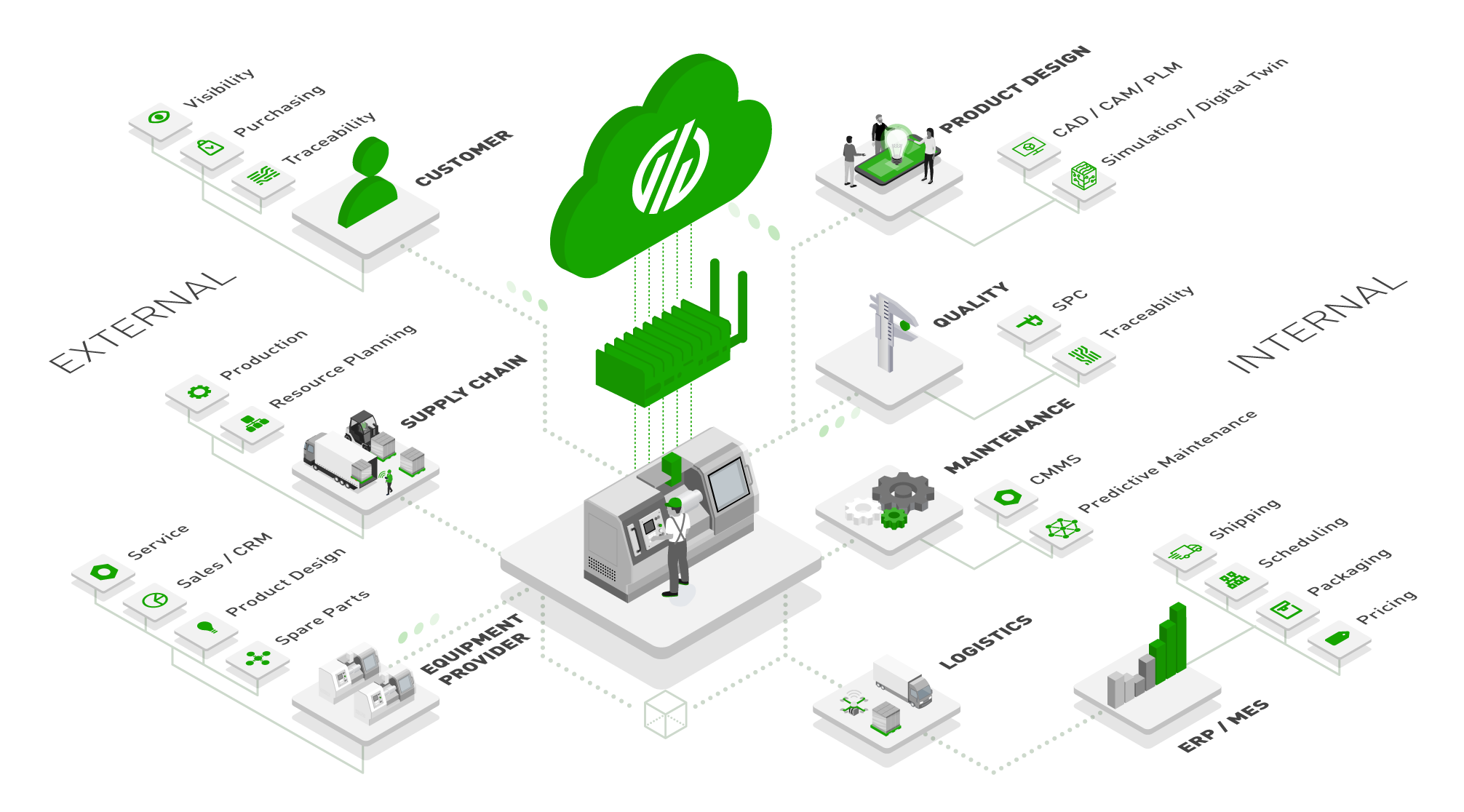

Drive Your Entire Tech Stack with Machine Data

Use the accurate, real-time production data from MachineMetrics to fuel and drive other systems, including your ERP, MES, Quality Management, CMMS, BI, and more.

Machine data doesn't lie, use it to inform your most important shop floor functions to take your maintenance, quality, production, and planning to the next level.