Interested in discovering how a lean manufacturing system and lean techniques can have a beneficial impact on your manufacturing processes?

With a number of great lean strategies out there, how do you find the one that will have the most impact in your business?

A good approach is to review the lean techniques that are currently proving themselves where it matters most - on the shop room floor.

Below we share a brief description of 5 effective lean strategies along with an explanation of how each tool can improve your manufacturing processes.

Keep in mind, although lean manufacturing and specific lean tools and techniques can have a dramatic impact on your business by itself, you can often multiply the benefits by combining them.

What is a Lean Manufacturing System?

A lean production system is a framework that helps maximize value and minimize waste by optimizing key aspects of the production process. Lean manufacturing traces back to the Toyota Production System that was developed in Japan in the decades after 1948 and formally published as the Toyota Way. There are many different ways to implement lean manufacturing, but they all follow these five core lean manufacturing principles.

- Defining Value: Identifying what customers truly value to ensure that processes align with that goal. Lean manufacturing examples can include determining whether your customers value shorter lead times vs. increased customization.

- Value Stream Mapping: Analyzing the entire production process to determine which activities add customer value and which don’t. You might use real-time data from machine monitoring to identify parts of your workflows that aren’t contributing.

- Creating Flow: Ensuring that production steps interact seamlessly. Implementing dynamic scheduling to identify and eliminate bottlenecks is a prime example.

- Establishing a Pull System: Producing only what’s needed when it’s needed to minimize overproduction, inventory management, and waste. The popular Just-in-Time production manufacturing system is widely used to establish pull.

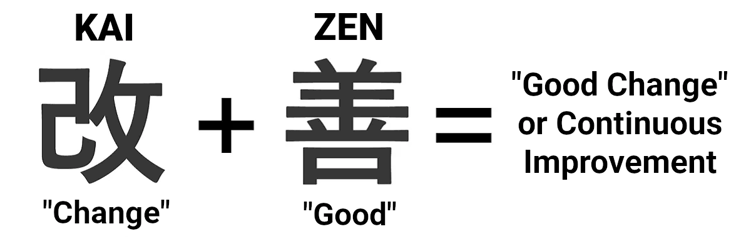

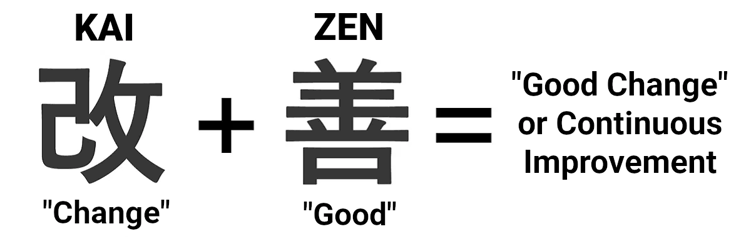

- Pursuing Perfection: Committing to continuous improvement. Your team might implement concepts such as Kaizen, supported by OEE analytics, to track progress.

Together, these principles provide a strong foundation that makes lean manufacturing systems valuable assets for organizations that implement them effectively.

Why Lean Manufacturing Matters

An Industry Week study shows that 70 percent of US manufacturing facilities already use lean principles to some degree. Lean manufacturing transforms inefficient work processes into streamlined systems that let your facilities deliver greater value while reducing waste. The focus on efficiency and continuous improvement empowers your organization to compete in a rapidly evolving industry.

While there are many requirements to ensure that your team implements lean manufacturing effectively, those who do can expect major improvements in productivity. Research by Industry Reimagined 2030 found that 95 percent of companies implementing lean manufacturing increased productivity by at least 20 percent. You can unlock lean manufacturing benefits by implementing these methods.

1. Kaizen (Continuous Improvement)

Kaizen is a strategy where employees work together proactively to achieve regular, incremental improvements in the manufacturing process.

This strategy is effective because it focuses the collective talents and resources of your company on creating a culture continually on the lookout for ways to eliminate waste from manufacturing processes and potential waste reduction techniques.

Learn more in our complete guide on Kaizen in manufacturing.

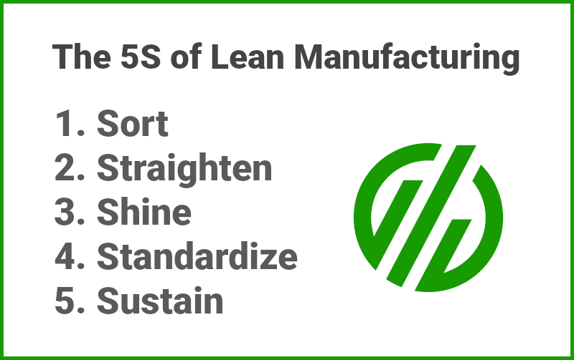

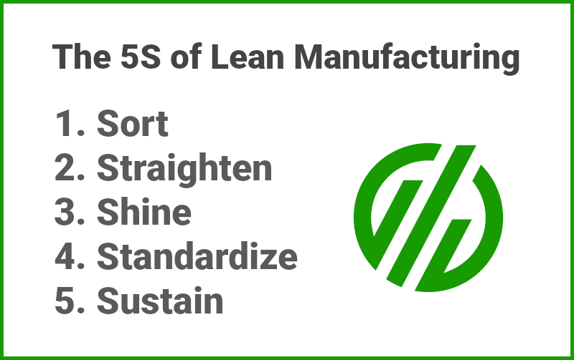

2. 5S (The 5S System)

The 5S approach emphasizes the organization of your work area. This strategy involves SORTING - eliminating that which is not needed. Once that’s done, the remaining items are SET IN ORDER. Then, you create a work area that SHINES. After that, you STANDARDIZE - writing standards for each of the above elements of the process. Finally, you SUSTAIN the strategy by regularly applying the standards.

The 5S approach eliminates waste resulting from a poorly organized work area, fulfilling a key requirement for any lean manufacturing system.

3. Six Big Losses

Productivity inefficiency in virtually any manufacturing category can usually be traced back to 6 universally occurring loss categories.

The Six Big Losses include:

- Breakdowns

- Setup and Adjustments

- Small Stops

- Reduced Speed

- Startup Rejects

- Production Rejects.

The Six Big Losses approach gives you a guideline for attacking the most common causes of waste in manufacturing processes.

|

Learn how Morgan Olson, a leading walk-in van body manufacturer used MachineMetrics to identify bottlenecks and reduce waste by 50%. Read the full story.

|

4. Overall Equipment Effectiveness (OEE)

OEE provides a framework for measuring productivity loss for a given manufacturing process, making it a key metric to track in any lean manufacturing system. Three categories of loss are tracked: down time, slow cycles and rejects.

This lean technique establishes a baseline and gives you a means to track progress in eliminating waste from a manufacturing process. Achieving 85% OEE is a reasonable target to shoot for in the beginning. Once that’s achieved, you can focus on additional ways to elevate your results.

Learn more in our complete guide on OEE.

5.Machine Monitoring

Machine monitoring dovetails nicely with OEE. Machine monitoring software automatically collects data from machines and uses this data to provide real-time visualizations and notifications, as well as historical analytics to help operators and management make faster and more informed decisions.

In addition to providing you with at-a-glance performance on a machine-by-machine basis, machine monitoring gives you a window onto your entire manufacturing process.

If you are utilizing secure, cloud-based manufacturing process software, it also puts information at your fingertips anywhere there’s an internet connection.

Machine downtime, quality issues, and poor performance can be categorized automatically or by the operator. Maintenance systems such as Total productive Maintenance (TPM) can also help in this area.

Getting Started on Your Lean Manufacturing System

The key to creating a truly lean manufacturing process is being open-minded. You may find through experimentation that a combination of lean implementation strategies deliver the optimal result.

MachineMetrics can serve as the backbone to any lean manufacturing program by providing real-time manufacturing analytics and allowing you to track the positive impact your lean implementations have on your productivity and efficiency over time.

Learn more about our machine monitoring solution, or book a demo today.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments