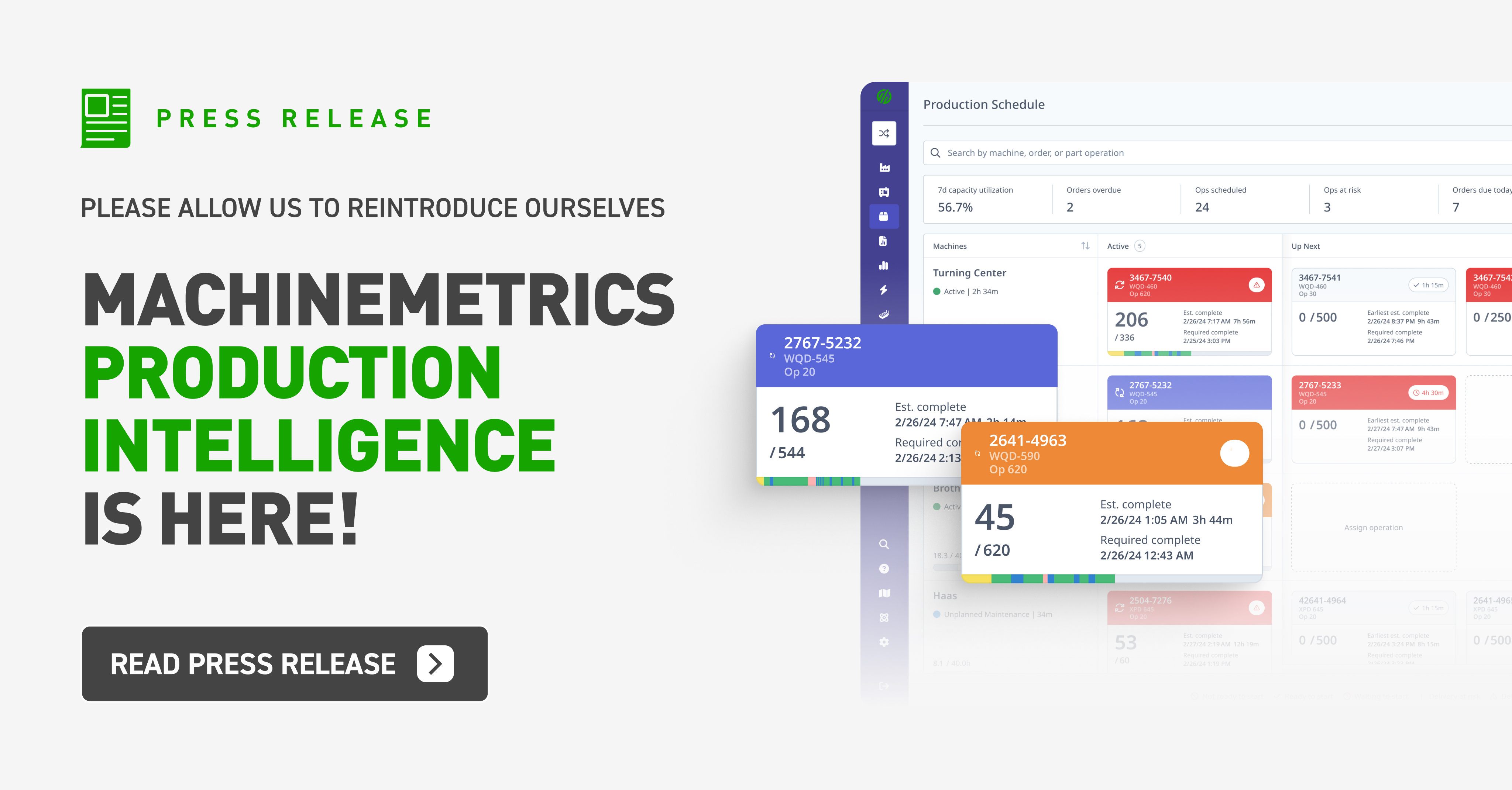

Easthampton, MA – October 16, 2025 – MachineMetrics, the Intelligent MES and industry leader in machine connectivity, today announced the launch of Manual Stations - a powerful solution that enables real-time job tracking and scheduling for manual production processes, unlocking complete visibility across every step of the production routing.

While most digital transformation efforts have focused on automated equipment, the majority of factory tasks - such as assembly, inspection, packaging, and material handling - remain largely invisible, with limited performance data and no real-time visibility into WIP. This reliance on manual tools like paper travelers and spreadsheets results in flawed schedules, inaccurate labor costs, and hidden bottlenecks.

Manual Stations turns these blind spots into actionable data streams, capturing part counts, scrap, downtime, and labor tickets, while providing an interface for operators to trigger workflows, ask for help, and automate activities using AI.

“This isn’t just a new feature. It’s the beginning of full-factory digitization,” said Rutherford Wilson, Chief Product Officer at MachineMetrics. “By capturing data from both machines and operator-driven processes, our Intelligent MES schedules and tracks every step of production in real-time, while syncing with ERP.”

Key Capabilities:

- Digital Job Tracking: Operators can select work orders, log production, scrap, and downtime through a simple, unified interface.

- Labor Insights: Accurate labor ticketing for true performance and costing analysis.

- ERP Integration: Bi-directional sync of part counts, labor data, and downtime to ERP systems—no rekeying required.

- Automated Workflows: Trigger material calls, maintenance requests, or manager notifications in real-time.

A Unified View of Production

Manual Stations delivers a single platform for tracking both automated and operator-driven processes - removing the need for disconnected timekeeping systems or complicated MES modules. With consistent UX across the entire shop floor, operators are enabled by AI-driven guidance - not burdened by manual systems.

Now available to all MachineMetrics customers, Manual Stations delivers a critical data source that powers the upcoming release of Max AI - the digital workforce built on real-time production data, ERP context, and tribal knowledge. Join us for the live launch of Manual Stations on October 16th at 1 PM ET.

About MachineMetrics

MachineMetrics (MachineMetrics.com) is the industry’s leading intelligent MES platform for discrete manufacturers. Built around real-time machine data, MachineMetrics helps companies digitize core shop floor workflows - job tracking, scheduling, OEE, and downtime - while integrating seamlessly with business systems like ERP and maintenance.

For more information, visit machinemetrics.com or contact info@machinemetrics.com.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments