Pindel Global Precision is a contract machining company headquartered in Wisconsin and serving a diverse range of industries, including agriculture, hydraulics, electrical, and general industrial manufacturing. With over 75 years of experience, the company is recognized for delivering precision machining solutions that meet demanding tolerances and performance standards.

Despite its legacy of precision and cross-sector service, Pindel wasn’t immune to the systemic inefficiencies that plague modern manufacturing. Facing familiar manufacturing hurdles - such as coordinating precision work and aligning with evolving customer demands - Pindel set out to modernize its operations. Guided by Thomas Deslongchamps, Director of Training and Continuous Improvement, the team developed a connected factory architecture aimed at closing the “whitespace” between systems: the unseen disconnects where critical information and ownership can be lost.

By integrating its MES, ERP, and key QA, quoting, and collaboration tools, Pindel unified its production ecosystem. As a result, the company increased machine utilization by 35%, cut first-article inspection response time by roughly half, reduced lead times to 10–20 days, and automated ERP reporting that now saves 1.5 hours every morning. What was once a collection of disconnected activities is now a live operational picture that shows exactly where the next opportunity lies.

The Challenge

Before this project, Pindel had strong expertise and high output but lacked consistent visibility across departments. Critical data often got lost in the whitespace between systems, creating blind spots where inefficiencies multiplied quietly over time.

- Disconnected systems: Data lived in spreadsheets, emails, and on whiteboards. Job status updates and cycle times weren’t tied together. “If there’s disaggregation across that tech stack,” Deslongchamps explained, “issues might pop up on the quality side, but they’re not necessarily going to raise a flag when we quote on the job the next time if those systems aren’t connected ... If we don't have that data flowing back into our ERP system, it's just not nearly as easy to flag those issues and create this flywheel of continuous improvement … We're trying to get to the point where it's a virtuous cycle of improvement.”

- Manual processes: Critical tasks like quality notifications and daily reporting relied on people remembering to send emails or update logs. Teams were fixing problems after they happened instead of seeing them in real time.

- Tribal knowledge risk: Operations depended on the experience of a few long-time employees. Processes worked, but they weren’t repeatable or visible. When those key people weren’t there, production often slowed down while others waited for context. “We wanted to create highly cohesive, highly trained teams, and enable them with advanced technology,” said Deslongchamps.

- Operational inefficiency: Machines sat idle waiting for inspections, approvals, or new job assignments. The team knew the potential was there, but without connected data, no one could see where capacity was hiding.

The Solution

Pindel connected its entire manufacturing environment into one synchronized view. The goal wasn’t to replace systems. It was to connect them so that every team could work from the same set of facts and act faster.

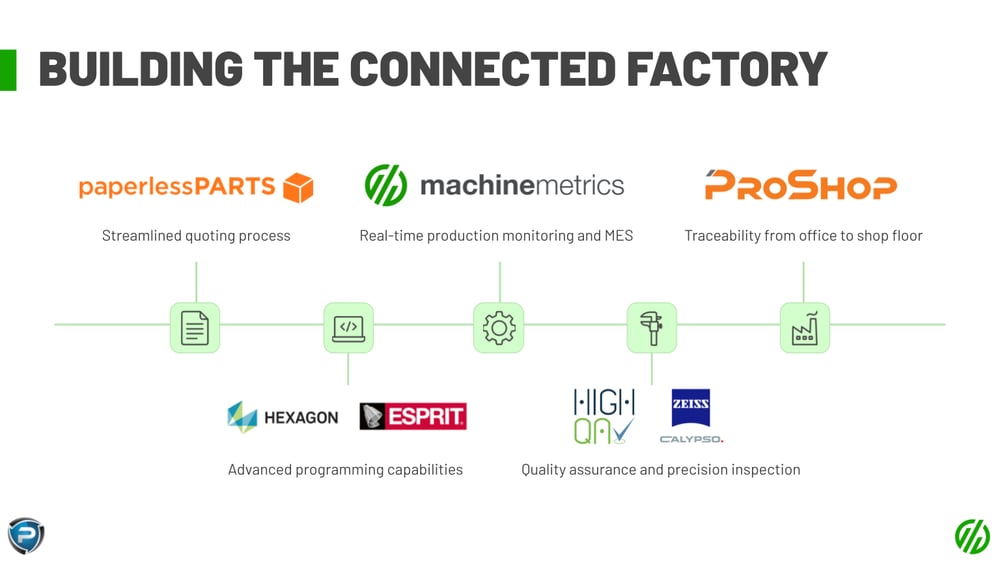

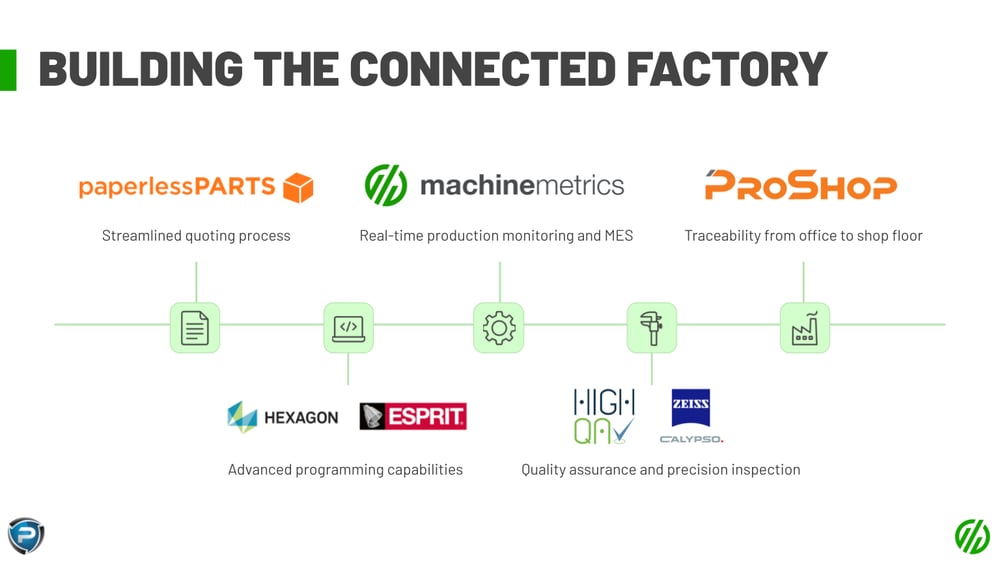

Core solution components:

- MachineMetrics for automated machine data collection, real-time dashboards, and analytics.

- ProShop ERP as the operational backbone linking scheduling, quoting, and traceability.

- Paperless Parts, Hexagon, and High QA to digitize quoting, programming, and quality data.

- Transparent scheduling for all departments with role-based checklists for Engineering, Quality, and Production.

- Automated ERP reports sent nightly before each shift, giving every supervisor a shared data snapshot.

- Quality teams are automatically alerted when a setup finishes, reducing idle time and eliminating manual follow-ups.

The Technical Approach

Pindel built its connected factory around reliability, scalability, and data integrity; connecting machines, people, and processes without adding complexity. By collecting data at the edge in real time and synchronizing with ERP systems, Pindel now has an always-current picture of performance.

Key technical elements:

- Connectivity: MachineMetrics captures machine states, part counts, and activity transitions across a mixed CNC fleet.

- Data exchange: Integration between MES and ERP systems aligns planned and actual data, the foundation for scheduling intelligence and real-time job tracking.

- Standardization: Activity codes like Setup, First Piece Inspection, and Production were unified across departments to eliminate inconsistency and manual translation.

- Real-time dashboards: Shared floor displays and supervisor dashboards provide clear insight into what’s running, what’s waiting, and what’s next.

- Automations: Automated ERP reports and quality alerts remove repetitive administrative work and reduce release-to-run time.

- Scalability: Open APIs and a repeatable deployment model allow the same structure to scale to new lines and facilities with minimal engineering effort.

Results and Business Impact

Pindel’s connected factory initiative reshaped how Production, Quality, and Engineering teams work together, turning fragmented data into a single, actionable view of performance. The results show what happens when visibility and accountability meet automation: measurable efficiency gains, faster throughput, and stronger team coordination.

- +35% increase in machine utilization within three months by exposing avoidable downtime, improving setup handoffs, and extending lights-out runs.

- ~50% faster first-article inspection release after adding a new “First Piece Inspection” activity that automatically notifies Quality.

- 10–20 day lead times achieved across new and repeat jobs thanks to improved scheduling, cross-department checklists, and faster quality turnaround.

- 1.5 hours saved daily in reporting time through automated ERP extracts that arrive before shift start.

- Cultural alignment between Quality, Engineering, and Production as all teams began working from the same live operational picture.

Broader Value and Lessons Learned

Beyond the measurable gains, Pindel’s journey shows how operational visibility can drive cultural change. Once every team worked from the same live data, communication improved, handoffs became smoother, and small process improvements multiplied into a more predictable workflow. With the whitespace now connected, departments that once operated separately began functioning as one system, unified by data and shared accountability.

- Expansion and scalability: The same framework now extends across additional lines and departments with consistent tagging and alerts.

- Cultural alignment: Shared dashboards and checklists created transparency, helping teams solve issues together instead of in isolation.

- AI readiness: With structured, connected data in place, Pindel is testing AI-driven use cases like predictive scheduling and continuous improvement assistants.

- Practical roadmap: Close the whitespace first. Start small, automate where friction lives, and scale once visibility is consistent.

"At the end of the day, what we are trying to do is make more parts better, faster, for our customers. That's the goal. And so, part of that is asking how do we minimize or eliminate, if possible, manual data entry? How do we get our data to work for us instead of the other way around?”

Future-Proofing the Operation

By deploying next-gen digital tools, Pindel transformed fragmented operations into a connected, data-driven ecosystem. Real-time visibility improved reliability, automation freed up expert capacity, and integrated platforms closed the loop between ERP and the shop floor. With shared data driving alignment and clean infrastructure in place, Pindel is now positioned to scale into intelligent, self-optimizing, AI-ready manufacturing.

The solution has also allowed Pindel to focus on its core competency, as Deslongchamps says: “We're not in the business of data analytics… we're in the business of making parts for our customers, and we want to focus as much as possible on that.”

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments