Automating Actionability With Real-Time Machine Conditions

What’s New

At MachineMetrics, we're excited to unveil our latest feature: Condition Monitoring Workflows. This addition enhances the platform’s robust condition monitoring capabilities, helping users enable actionability on real-time machine condition data.

Users can leverage MachineMetrics to transition their strategy from calendar-based to condition-based maintenance, reducing unnecessary downtime. Further, the platform can integrate with CMMS systems, like MaintainX and Fiix, to automatically generate work orders,

Why it Matters

Condition monitoring involves continuously monitoring machine conditions like temperature, load, and feed rates. This data is vital for identifying potential issues before they escalate into costly downtime or equipment failures.

MachineMetrics offers deep machine connectivity, enabling access to machine data directly from the control, as well as offering the ability to connect additional sensors. This offers users access to the one-two punch of machine performance and health data.

The data provided via condition monitoring is pivotal for maintenance teams, providing them with a pulse on equipment performance and health. This allows teams to make maintenance decisions based on data, rather than recommended schedules.

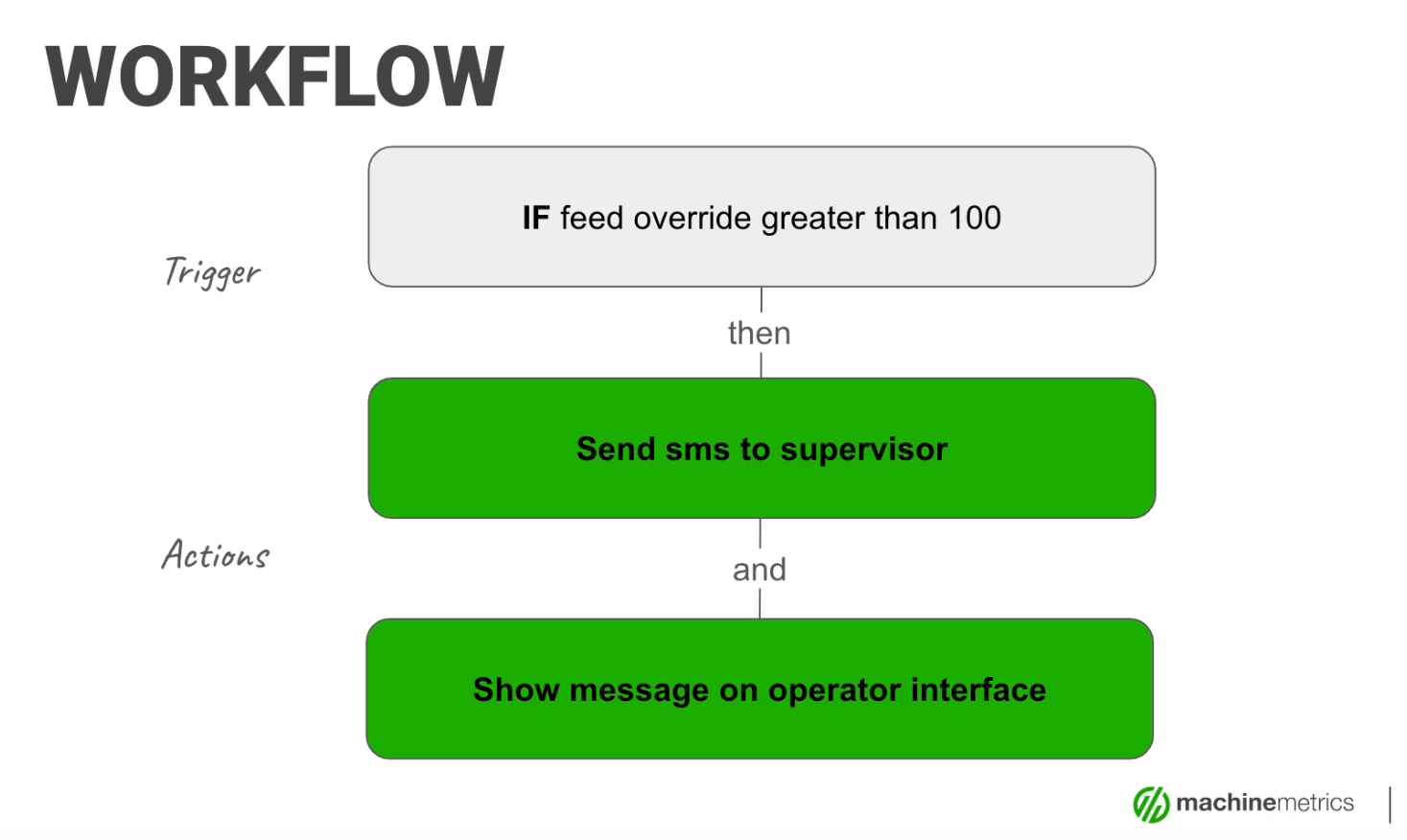

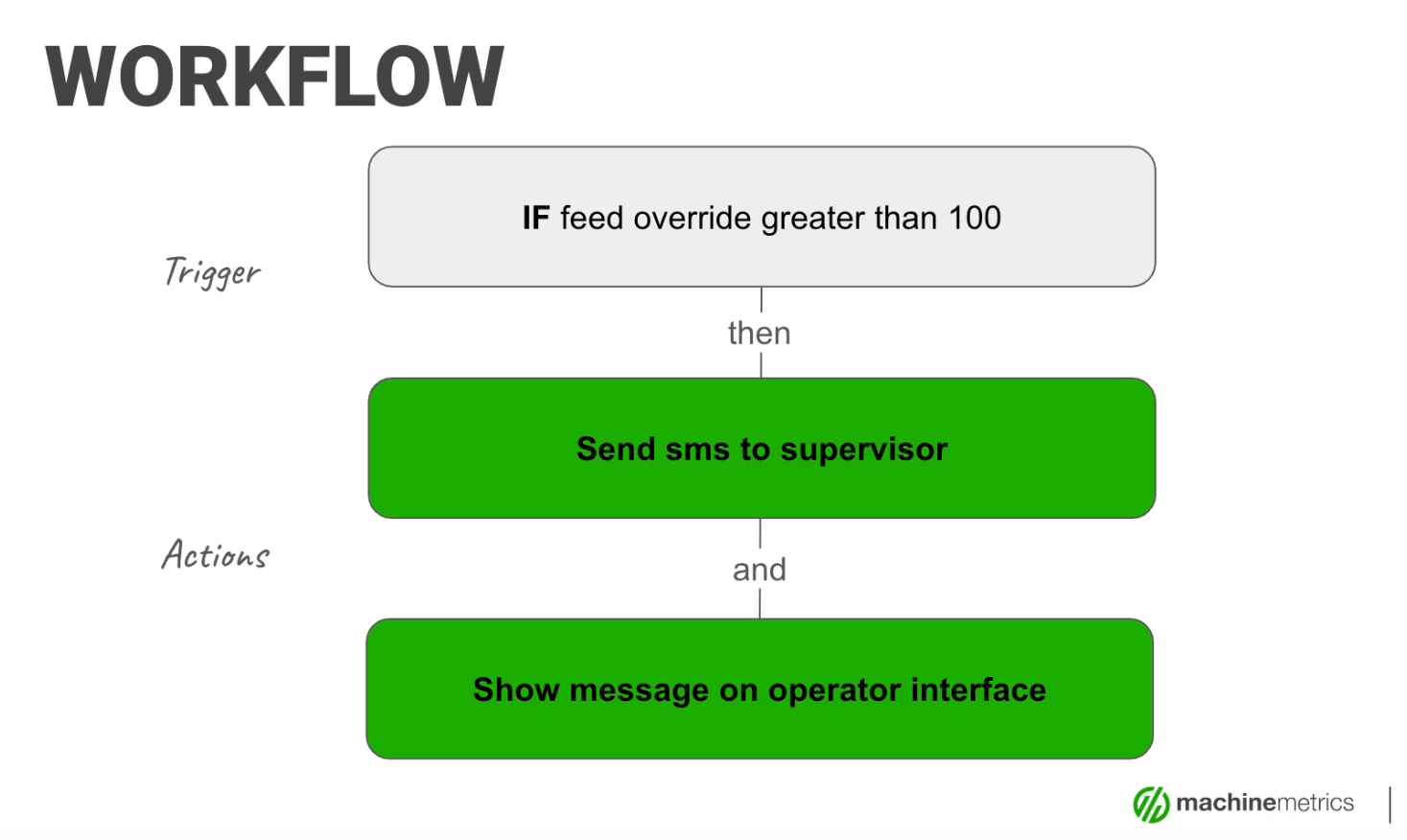

Our new feature takes this concept further. With Condition Monitoring Workflows, users can now automate actions based on specific machine conditions. For example, if a machine's feed override exceeds a predetermined level, the system can automatically alert supervisors and display instructions to operators.

What machine condition triggers are available? There are many, including the below:

- Angle

- Feed Override

- Feedrate

- Load

- Path Position

- Position

- Rotary Velocity

- Temperature

- Voltage

This combination of real-time machine condition data with automated actions streamlines maintenance and operational processes, significantly reducing response times and ensuring equipment runs at peak performance and reliability.

MachineMetrics enables users to address problems as soon as they happen, or more importantly, prevent them from ever occurring.

See it in Action

In the below video, Technical Sales Director Ben Groves, provides an overview of condition monitoring workflows. Excited to tap into your machine data? Learn more about MachineMetrics condition monitoring capabilities, or get in touch with our team.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments