Unleashing Digitization in Manufacturing

Recently, we had the opportunity to host an event with MachineMetrics users and prospects to learn how manufacturing leaders are leveraging digital technologies to increase operational efficiency. Our “Let’s Get Digital” event was a fantastic success, enabling local manufacturers to get an in-person tour of the AccuRounds facility, as well as network with colleagues at Trillium, a local brewery. (Stay tuned: We’ll be hosting more of these in-person events in the future!)

We also held a panel with several manufacturing leaders to better understand the driving factors behind digitizing their operations and leveraging data to make better decisions. This was complemented by a presentation by our very own Rob Urbani, a Senior Value Engineer, who outlined a framework for measuring the ROI of digital solutions.

Below we share a couple of the questions and answers from our panel. Thanks again to our three guest panelists for their insights:

|

|

|

| Morgan Waldau, Production Engineer at Waters Corporation |

Mike Tamasi, Owner & CEO at AccuRounds |

Bruce Watkins, President & GM at Karl Storz |

Question 1: What was the driving factor behind the decision to digitize your business, and what led you to that moment?

Morgan Waldau, Production Engineer at Waters Corporation:

MachineMetrics was already part of the shop operation when I joined Waters. The concept behind it was that we weren’t optimizing machine capacity, and we didn't know why. We knew there had to be a better way than sending an engineer to the shop floor to check each machine's run status manually. It was an issue of visibility and opening up that line of communication between operators and management to learn where we need to improve. We wanted a tool to help realize increased utilization to recapture those hours.

As far as why we chose MachineMetrics, we like supporting businesses close to us. We also thought the customer service would be better. And that's been proven every time we ask for something or suggest an idea. This has always been the case when dealing with MachineMetrics, and that's not something you can always do in a bigger business. The benefit of working with a smaller, agile company was great.

Mike Tamasi, Owner & CEO at AccuRounds:

When I was in college, computers were my MachineMetrics. As an owner, you're always looking for the latest, greatest opportunity and what will make your company better, and how to progress. We're in a high-cost labor market and are always looking at technology.

We reviewed MachineMetrics a few years ago, and we weren't ready. Fast forward three or four years, and MachineMetrics had come a long way. They were established, and we were more prepared. After reviewing several MachineMetrics competitors, we realized they were now the leader and the most mature solution. I think we're in year four, and we're still just scratching the surface of what the platform can do for us.

Bruce Watkins, President & GM at Karl Storz:

I've been with Karl Storz for 15 years and in high-tech, precision manufacturing for 38. When I came to Karl Storz, I realized that doing business in New England isn't the cheapest endeavor. If all we're going to do is copy what other people are doing, I thought “we're dead and may as well go offshore.”

We began with GBMP, the Greater Boston Manufacturing Partnership, and got a workforce training grant to help train our people in lean philosophy. We vertically integrated manufacturing for our small sports medicine business even though others advised us to keep our core competency and outsource everything else.

We made a conscious decision to stay in New England and convert and integrate a lot of our screw machine parts businesses. We started with data analytics using Excel. But we quickly outgrew that, which led us to MachineMetrics. I love MachineMetrics because they came and set up at no cost so we could experience it. The cost model was very affordable and was like a pay-as-you-go model.

Question 2: How are you using data as a foundation for investment decision-making, and how do you leverage data to drive those decisions?

Mike Tamasi, Owner & CEO at AccuRounds:

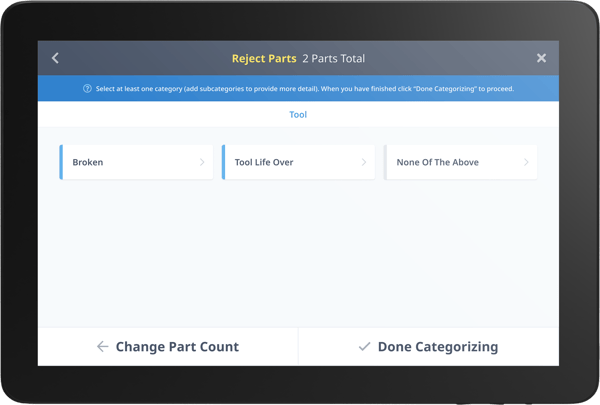

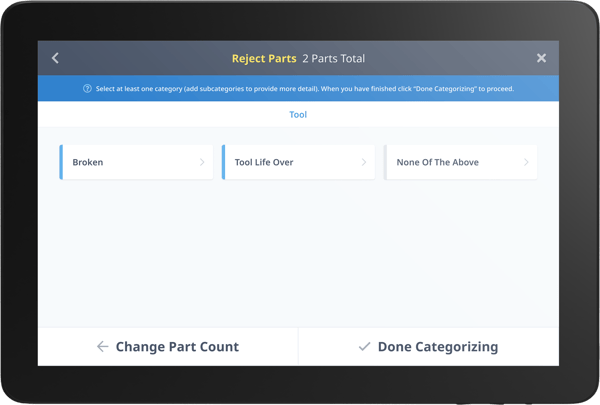

When you talk about data, we were trying to do what MachineMetrics does with their platform on paper. Everything was manual and handwritten. We were looking at two-day to three-day-old data, and it was too late to make decisions.

Having MachineMetrics in place allowed us to communicate more effectively with our team members on the floor because having the hard data in real-time at our fingertips allowed us to make better decisions. Decisions need to be made minute by minute, hour by hour, not even day by day. And it was highly challenging.

With MachineMetrics, we could have a conversation at the machine because we're looking at a process and not looking at a person's performance. We started small with ten machines, and we now have 27, and we’ll go to 35 or so soon.

What's important at the front end is including people in the decision-making process. Try to involve as many as possible. And from a systems integration standpoint, the future of our success will be to integrate different systems, hardware, and software and accelerate process flow. And because our ERP system talks to MachineMetrics, it opens doors to communication and allows workflows. Those are important considerations as you look to implement any data analytics solution.

Morgan Waldau, Production Engineer at Waters Corporation:

At first, this was met with resistance, and operators were really against it. They felt like they were being monitored like Big Brother. But once MachineMetrics was deployed and operational, the operators realized it was protecting them because scrap was much lower. In fact, they were applauded for it because we need that information.

It’s a reflection on the production and the processes. If an operator takes longer to set up, that isn’t necessarily on them; that may also be the process. I think it was a good segue though to the future of our machine shop because we want to implement more technology.

It's helping inform our decisions because we’re thinking of bringing in robots. MachineMetrics was an excellent way to introduce new technology into the shop. I don't believe that we've had anything this significant come in that would be a culture shock to them over the past few decades, so this was a good start to where the shop is heading.

Bruce Watkins, President & GM at Karl Storz:

Again, the machine shop is vertically integrated into our business, captive to the main light assembly facility. Each machine in our facility has a contribution margin annually of about $800,000. Every machine we bought has paid for itself in less than a year. We have about 20 machines. And we have about 300 parts that we do on those 20 machines. So, set up reduction management is absolutely critical.

MachineMetrics has allowed us to stay in the space of facts and objective evidence and not emotions. It allows us to use those facts to manage and improve performance on those setups. That's where it's helped us focus on the data and not just the hallway, emotions, and conversations about a good and a bad setup.

The advantage is in starting small. That's what's great about the upfront investment with MachineMetrics.

Plug-and-play Machine Connectivity

More from Our Panelists [Video]

Luckily, we were able to capture footage from the event. Check out the videos below to hear directly from Morgan, Mike, and Bruce on the impact of MachineMetrics on both the shop floor and their bottom line.

Morgan Waldau, Waters Corporation

Mike Tamasi, AccuRounds

Bruce Watkins, Karl Storz

Thanks for watching!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments