For most manufacturing companies, collecting, analyzing and making decisions from equipment data is extremely time-consuming.

Until now, remote machine monitoring and machine diagnostics (RM&D) process has been a painful, frustrating and labor-intensive experience for manufacturing companies.

Many have a difficult time coping with maintaining day-to-day operations while trying to implement a system on-the-fly.

Improved Software Paving The Way For Implementation

But today, software advances have made adopting a remote monitoring & diagnostics strategy much more practical and far less time consuming.

One fact is indisputable: RM&D is a proven tool for improving machine performance.

The benefits offered by implementing a remote machine monitoring and machine diagnostics process are extensive.

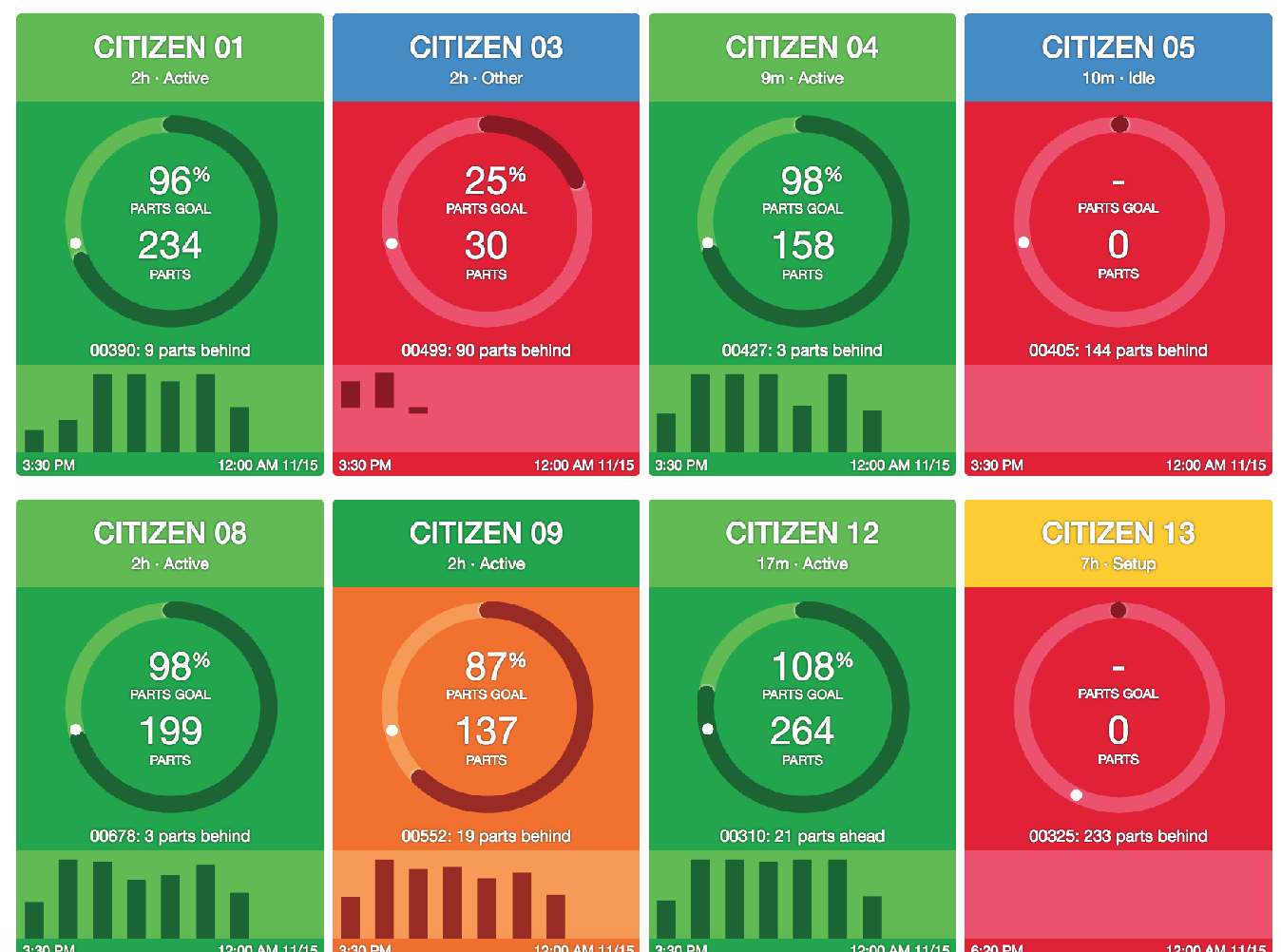

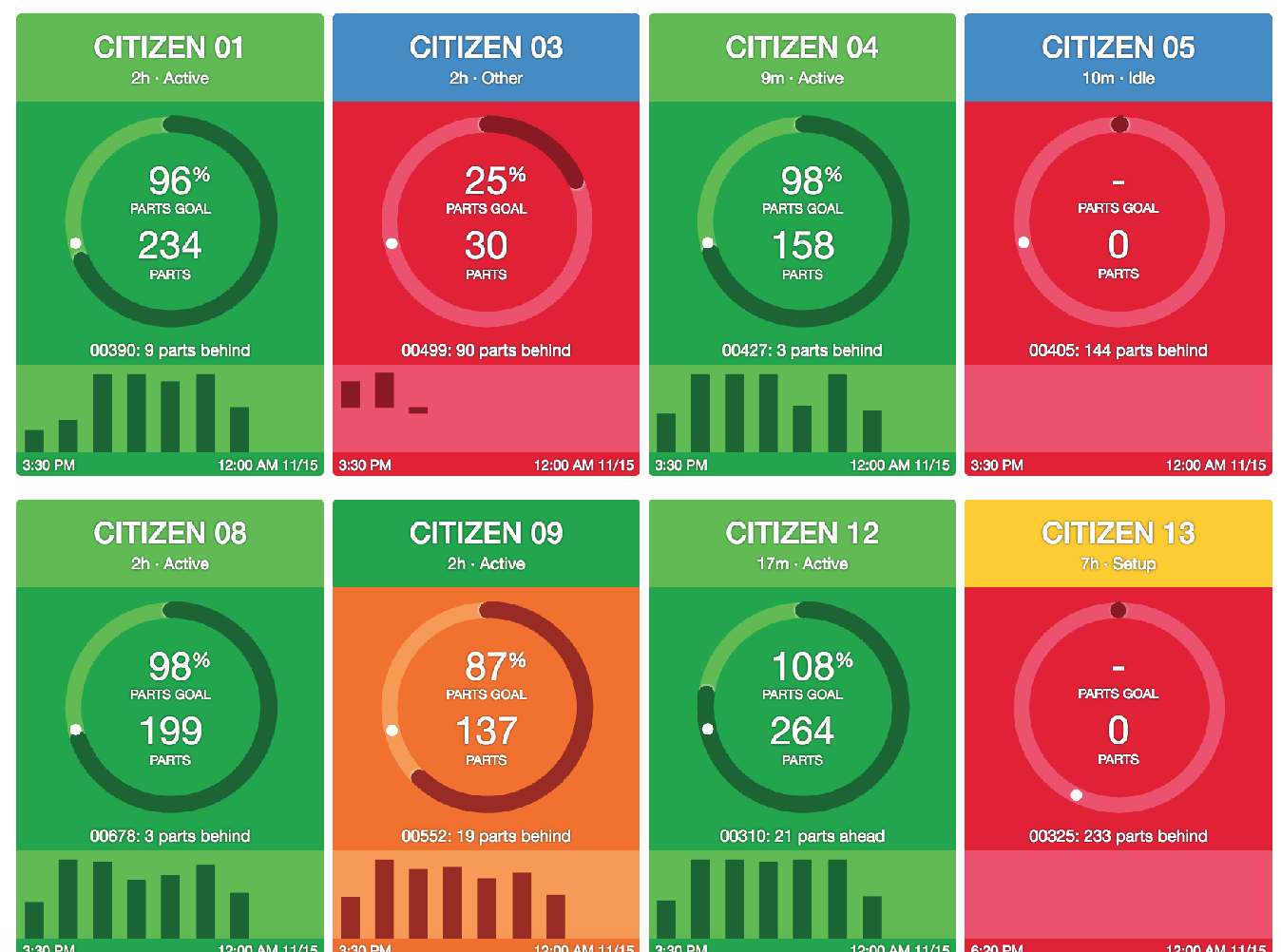

The first step to improving performance is figuring out how your production process is currently performing.

That’s where a machine monitoring solution shines.

A remote machine monitoring and diagnostics process gives you an “inside look” at your shop floor equipment which allows you to not only assess the overall efficiency of your operations but also shine a spotlight on potential areas for improvement.

This information gives you the insight you need to start down the road to optimizing your equipment and developing more effective maintenance strategies.

Additional Benefits Can Have A Dramatic Impact

In addition to improving your production process, remote machine monitoring and machine diagnostics (RM&D) delivers additional, less obvious, benefits.

Next generation products can be produced more efficiently. You can enhance your customer experience. Employees will likely be energized and motivated by the fact that the result of their efforts become more visible.

If you decide to implement a machine monitoring system, the question becomes, should you go with a pre-built, “appliance” system, or build your own?

If You Decide To Do-It-Yourself

Here are a few issues to consider if you’re contemplating the homegrown route:

Creating a centralized remote machine monitoring and machine diagnostics system that connects devices and sensors can more difficult than anticipated.

Then, there’s the issue of developing an elegant user interface that’s customizable for end-user accounts and optimized for both browser and mobile environments.

Putting an RM&D system in place that collects and houses large amounts of data so that it can be used for reporting in a practical way requires time and expertise.

Many companies looking to do it themselves underestimate the time and cost of doing this - while under the increasing pressure to meet customer expectations that seem to rise with every passing month.

On the other hand, opting for a pre-engineered (or “Appliance”) solution is gaining tremendous support as a way to dramatically reduce the engineering costs and risk.

Not to mention keeping stress, time and money under control.

Pre-Built Offers Fast Start Up and Flexibility

Many of today’s pre-engineered machine monitoring solutions are controller neutral and can be installed on a diverse range of equipment.

Often, remote machine monitoring experts can make your system operational in just a few days.

Because most of these out-of-the-box solutions are scalable and customizable, you can can quickly and easily expand monitoring to other equipment and additional plants.

Cybersecurity? Going with the appliance option means security is in the hands of experts who make it their business to keep up with the latest online security threats.

In the end, only you can decide on the best solution for your needs.

For many manufacturing companies, the benefits of a pre-built, pre-configured “appliance” solution - scalability, less cost, less manpower and reduced risk - make it an attractive choice.

And, by choosing an appliance RM&D solution, your organization can stay focused on building and servicing equipment to meet customer needs - instead of trying to deal with self-inflicted complications.

Interested in an RM&D solution?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments