Manufacturing companies always focus on downtime to improve processes and increase efficiency in a facility. There are many different categories of downtime, including downtime from jams, breakdowns, operator errors, and more.

Machine setup is one area where downtime is manageable and predictable. It’s critical to efficient business processes and producing profitable parts with the least amount of time and resources. And in discrete industries like CNC machining, it can make all the difference.

Below, we’ll explore how you can use data to reduce setup times and increase uptime.

CNC Setup: A Step-by-Step Guide

Machine setup should be a meticulously planned and standardized procedure. The practices and order of tasks should be measured and documented so that all tasks are easily understood. This is essential for high-mix, low-volume producers for whom an entire job for a critical customer may consist of a single part.

While each company will have its own system, there are common steps that should be performed to ensure jobs are done correctly and are repeatable from job to job and operator to operator. Not all operators possess the same skillset, so standard work instructions are needed.

Plug-and-play Machine Connectivity

Essential steps for CNC setup include:

- Pre-Check: Different jobs impact the conditions of a machine differently. A check of oil and coolant, clearing residual cut waste, and other components of the previous job are required. Many tool carousels can house a complete array of tools, but others may be limited. Removing tools from the last job may be necessary to make room.

- Tool Loading: In most companies, excess tools are housed in a tool room. Operators must know which tools are required for the next job and retrieve the new ones as they return the old ones. This process may also include inspecting the tools to ensure they’re in a suitable condition (sharpened, ground, etc.).

- Calibration: All CNC machines have a home or start position. According to the CNC program, operators should know how to calibrate the start or home position to ensure the machine starts in the right place.

- Mounting Parts: The part, or blank, must be appropriately mounted on the vices of the machine. Ideally, work instructions will include the orientation of the blank for the job. Machine damage may occur if vices aren’t tight enough and the blank isn’t loaded in the proper orientation.

- Loading the CNC Program: Depending on the age of the OEM machinery, programs may be loaded in different ways. This may include USB, disc, or electronic methods in companies that deploy advanced machine data platforms that allow direct download to the machine.

- First Run: Once the program is loaded and XY offsets are determined, it’s a good idea to perform the first run in slow motion to test the tool path. Some equipment may do this automatically, while others will require operator instruction.

- Quality Checks: During the first run, quality checks will ensure that tool paths are correct and that each cut, drill, or mill is in the right position. These checks confirm whether the setup process was done correctly.

How Setups Affects Quality and Performance

For high-mix, low-volume manufacturers such as job shops and contract manufacturers, one of the biggest contributors to downtime is setup time. In these types of environments, most of the products produced require machine operators to perform a unique setup process to ensure that equipment is prepared for each specific job.

If any element of the setup process is done incorrectly, it can result in high scrap rates, low yield, poor product quality, and missed orders. Understandably, operators take the setup process very seriously.

But achieving the required level of precision and attention to detail also takes considerable time, even more so if the company has not established crystal clear communication between departments or struggles with workforce turnover. For companies with a large number of jobs, this time can add up in a big way.

Benefits of Setup Reduction

Modern CNC machining is a highly accurate and reliable way to produce precision parts. However, several variables must be considered to ensure the best results.

These variables include:

- Equipment made by different OEMs

- Different models of equipment

- Different ages of equipment from the same OEM

- Manual equipment

- Operators with different skillsets across departments or shifts

Taking these variables into account and implementing best practices for setup times provides several benefits:

- Greater ROI: CNC equipment is expensive. Reducing setup times means the company can produce more jobs on the same piece of equipment to realize a faster ROI.

- Increased Capacity: Lower setup time improves equipment utilization and unlocks capacity. This leads to better cash flow and significantly improved production costs.

- Improved Labor Utilization: With a precise setup process using machine data, workflows, and work instructions, operators can manage equipment efficiently.

- Higher Customer Satisfaction: Reducing CNC machine setup time increases a company’s flexibility to respond to customer demand. This can improve its reputation and drive repeat orders.

- Improved Quality: Reduced setup time comes from standardized processes, and this standardization includes instructions and procedures that ensure quality from the first part.

How to Reduce CNC Setup

Setup time begins between the end of the previous part or job and the beginning of the first good part of the next part or job.

To reduce CNC machine setup time:

- Measure and document the current state of the machine, machine settings, or job.

- Identify and time the elements that impact setup. This may include cleanup, tool selection, loading of material or blanks, etc. This is the most important part of reducing setup times. You must know how long setup actually takes to establish an accurate baseline to work from.

- Eliminate or significantly reduce all internal elements of downtime. This may include staging cleaning supplies, tools, and consumables in kits or carts to be used ahead of each task. It may also include digital work instructions that guide operators through the next step.

- When possible, organize the parts you produce into families of similar parts. This will reduce the reconfiguration needed when completing setups between different production runs.

- Calibrate the machine according to documented and standardized instructions.

- Measure the first run part for tolerance and any required adjustments.

- Document and standardize all aspects of the new procedure and make it readily available to stakeholders.

How MachineMetrics Reduces CNC Setup Time

The first and most important step in optimizing setup processes is to have an accurate measure of how long each setup is taking.

For manufacturers that don’t have technology in place to accurately track their setup times, this is much easier said than done. Supervisors are often relying on such rudimentary methods as timing their operators with a stopwatch or asking operators to self-report their setup times, adding more tasks to an already complex process. This is clearly inefficient and inaccurate.

With MachineMetrics, manufacturers can accurately track exactly how long each setup takes and use real-time reporting tools to quickly pinpoint which setups are running inefficiently and identify if those setups have any commonalities - is it always the same machine, the same operator, or the same job type? - in order to address the problems. Additionally, MachineMetrics customers use these tools to identify which setups are running most efficiently so they can establish best practices that can be applied more broadly.

Accurate Setup Times

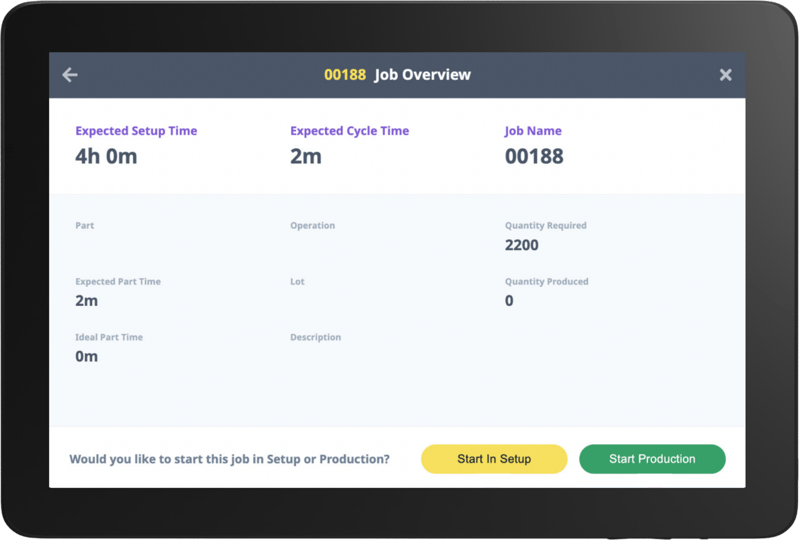

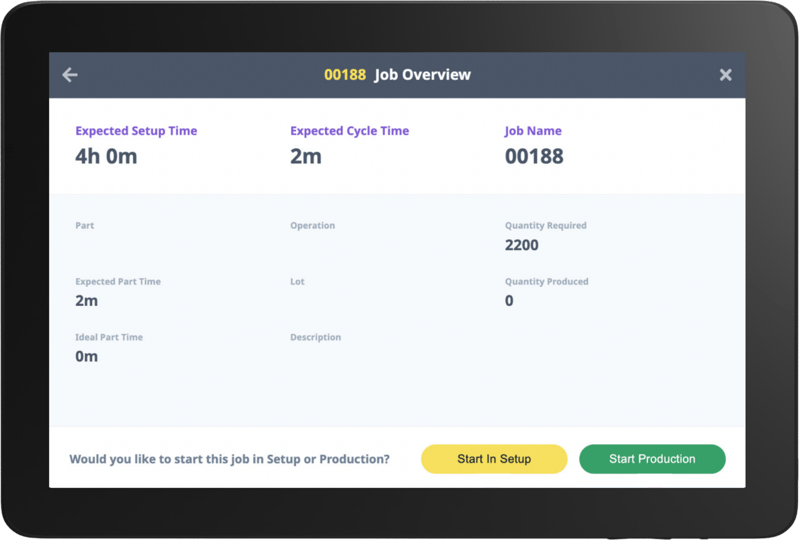

Machine operators interact with MachineMetrics through the Operator Dashboard via devices throughout the shop floor. To capture accurate setup times, the machine operator selects "Start In Setup" at the beginning of each new job. Once the setup process has been completed, the operator simply selects "Start Production."

Visual Progress

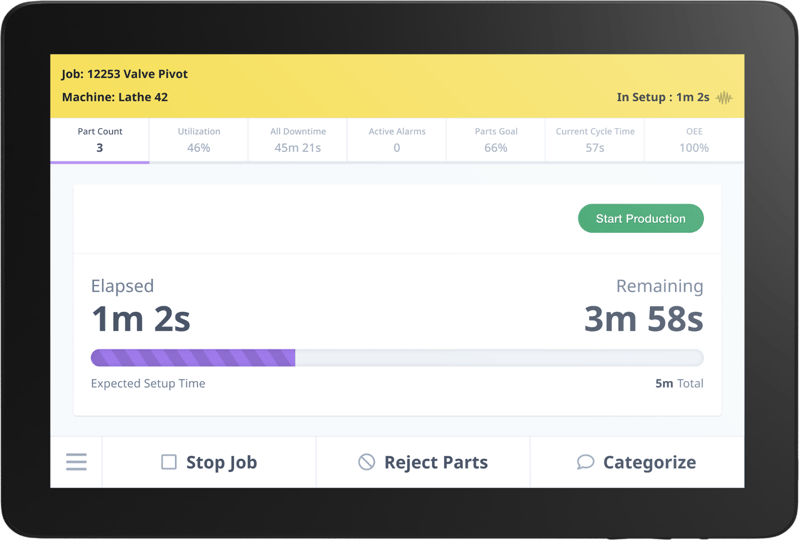

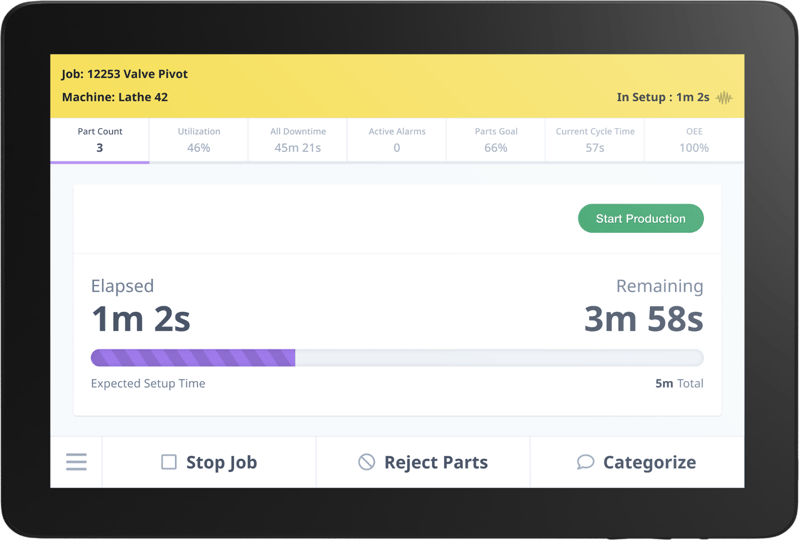

Throughout the Setup process, the Operator Dashboard provides machine operators with clear visual cues and the ability to call for assistance if required.

Setup Analysis

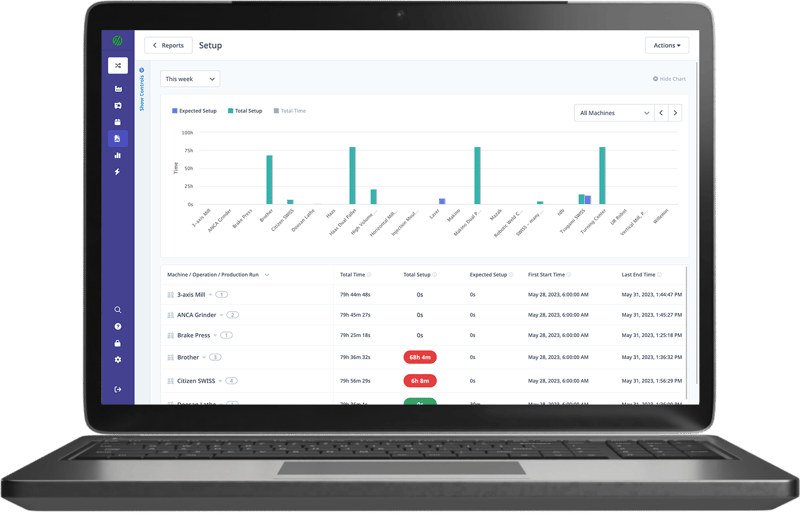

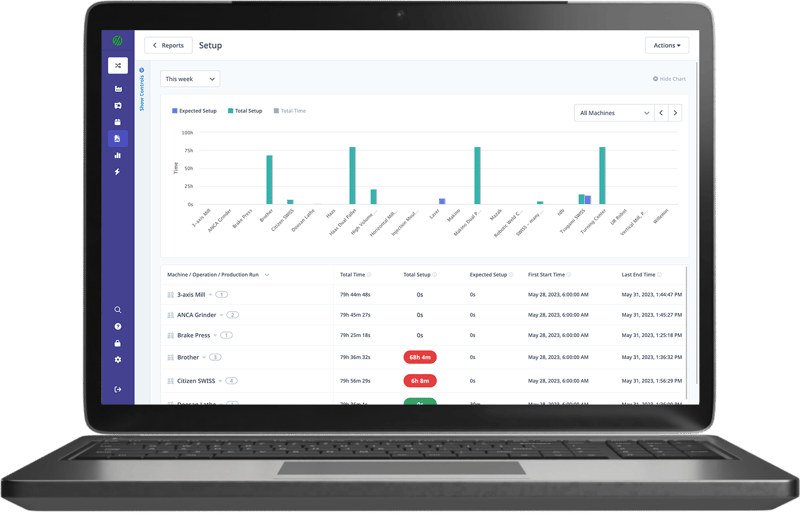

Using MachineMetrics' reporting capabilities, supervisors can easily compare Actual Setup times to the Expected Setups. Users have the ability to slice the data by a number of factors - such as machine, shift, job, or operator - to detect commonalities.

Pinpoint Setup Issues

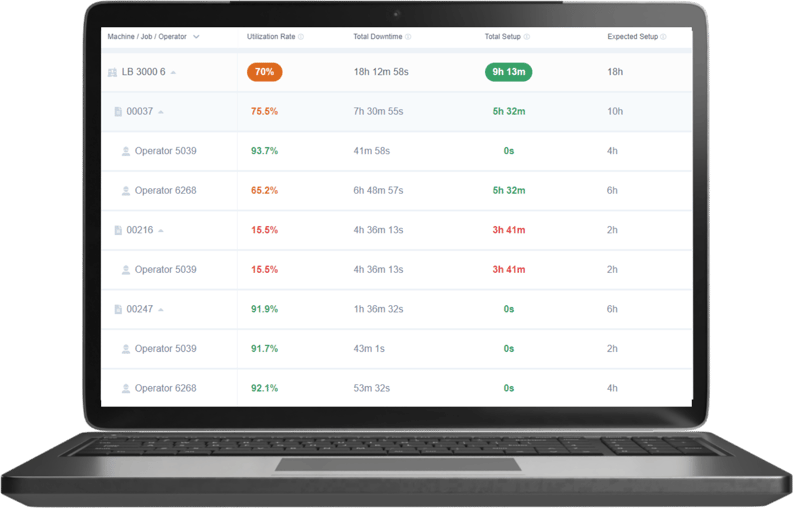

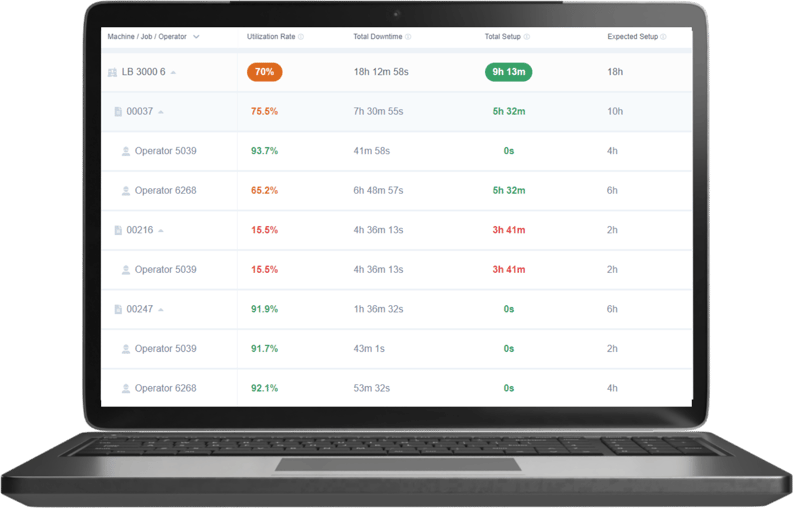

MachineMetrics provides a quick view of Setup performance that can be filtered by machine, job, or operator in order to quickly identify areas that require more attention.

Want to See the Platform in Action?

How General Grind Optimized Machine Setups

To get a better sense of what these high-mix, low-volume manufacturers are up against, let’s look at an example from a customer that was able to use MachineMetrics to dramatically improve their setup processes.

General Grind & Machine produces quality precision parts for a number of industries including agriculture, construction, and heavy equipment. With a diverse range of capabilities to meet their equally diverse customers’ needs, General Grind was conducting 126 setups on 20 different machines during just one month’s setup period.

Company leadership knew they could do better and embarked on a continuous improvement program to increase overall equipment effectiveness. They recognized that this would improve throughput, allowing them to continue their growth trajectory and boost their levels of customer service. Ultimately, the goal was to gain complete control over their machine and operational data to reduce downtime, identify production bottlenecks, and improve reaction time to factory floor issues.

Using MachineMetrics, General Grind was able to accurately measure their setups, which accounted for a total of nearly 212 hours of non-production time in just one setup period. Moreover, their actual setup times were taking an average of 35 minutes more than their standard expected time-per-setup. When you add that up, the setup overage was costing General Grind nearly 74 extra hours of valuable production time than they had planned against.

Armed with accurate data and visibility into which setups required their attention, General Grind’s production team now meets every week to review the MachineMetrics reports and uses that time to learn best practices from top performers.

Additionally, the company has also implemented a bold new setup strategy that they expect to pay dividends:

“We’ve also established what we call the pit crew. This involved putting together a team that's exceptionally good at doing different setups. They have a daily schedule that details what's going to be set up and roughly when, so they have a better idea of exactly what to expect. They can get everything prepared, complete the setup, leave, and everything starts running smoothly. We expect this to further reduce our setup times.”

— Blake Bieri, COO of General Grind & Machine

All told, since implementing MachineMetrics, General Grind & Machine has gained an additional 6,900 hours of machine capacity and increased machine utilization by 100%.

Read the full case study.

Improve Setups with Machine Data

MachineMetrics gives manufacturers the tools they need to get a clear view of what is happening on their shop floor and enables them to pinpoint the areas in need of attention.

The benefits of accurate data and insights from MachineMetrics cannot be overstated:

- Accurate data allows manufacturers to quickly identify which setups are occurring as expected and which are in need of attention.

- Comprehensive reporting capabilities enable manufacturers to identify commonalities among “trouble” setups to guide them to the root issue.

- Broadly accessible data ensures all staff are on the same page, removes ambiguity, and allows for clearer lines of communication between departments to solve problems together.

- Clear processes and best practices eliminate guesswork and empower operators to focus solely on the critical work of properly completing a setup.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments