The Industrial Internet of Things (IIoT) is transforming how manufacturing companies measure and improve processes. By using a machine data platform, companies can rapidly realize fast ROI and unprecedented improvements in efficiency and productivity.

But industrial IoT and machine data platforms alone aren’t magic wands that can be waved to create new value. While they do empower accelerated process improvement across an enterprise, they still need established measurement metrics and manufacturing KPIs to provide context to the insights a machine data platform generates.

Measurements like takt time can give meaning to what the data shows, driving analytics and insights. Managers can view performance and implement changes where needed.

What is Takt Time?

Takt time is the rate at which production must operate to meet customer demand.

When customers order products, they’re given lead times regarding when they can expect their goods. Takt time is used to measure a manufacturer's output against demand.

But it’s more than just increasing machine speed. A complex manufacturing operation requires multiple orders and order quantities from many customers. Companies within the same industry will have different takt times based on equipment age, minimum production lot sizes, and other factors. Looking at takt time individually and holistically provides valuable information to management.

If takt time is shortened, the operation is more efficient and has the capacity for new orders. If it exceeds what is needed to meet the lead time, processes are less efficient and customer dissatisfaction is high. Because of this, takt time helps measure the efficiency of a manufacturing operation.

Why is Takt Time Important in Manufacturing?

Takt time helps manufacturers ensure that production flows efficiently from one workstation to the next. Along with other manufacturing KPIs like cycle time and lead time, takt time allows managers to understand this flow at both micro and macro levels and adjust production lines when needed.

Takt time is also vital to a company's ability to meet customer demand. Modern manufacturing runs multiple orders across many product ranges simultaneously; takt time helps plan, execute, and meet demand through an efficient workflow.

Why Should You Calculate Takt Time in Manufacturing?

Many manufacturers make the mistake of focusing their KPIs on the internal production process without considering its destination, but this leaves out the most important part of manufacturing – the customer.

Takt time gives manufacturers valuable insights into the time required to produce each item in the schedule. This allows them to better meet customer demand, tying internal KPIs and performance to the end user.

Because takt time takes demand into account, process improvements will directly benefit the customer. This process is a much better measure of efficiency and productivity than managing only internal KPIs.

Takt time also changes depending on the product mix, which means that month-to-month and week-to-week takt time may differ, presenting managers with greater or less challenge in meeting daily customer demand. This means that any decisions will impact production lines, supply chain management, maintenance strategies, inventory management, and quality.

How Do You Calculate Takt Time?

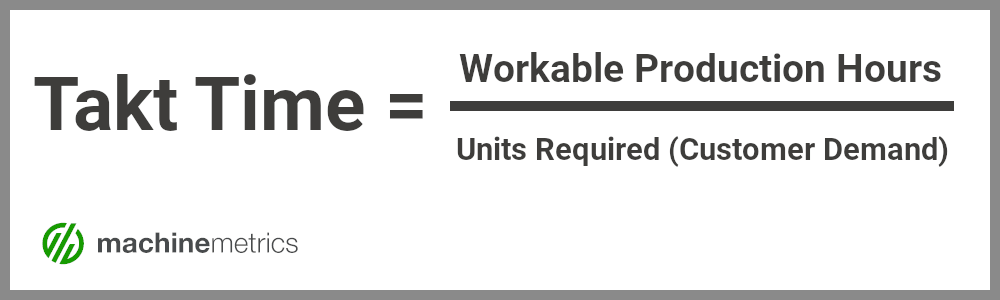

The calculation of takt time is straightforward: the number of workable production hours divided by the number of units in manufacturing orders. Workable hours within the calculation shouldn’t include breaks, lunches, and other stops.

Takt Time (TT) = Workable Production Hours (PW) / Units Required by Customer (UR)

or

TT=PW/UR

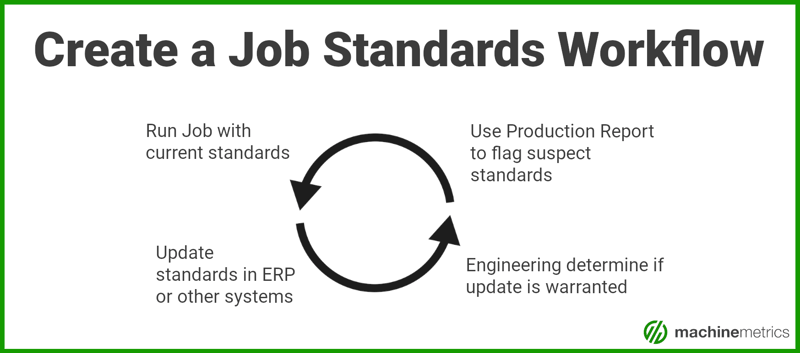

The traditional measurement of takt time relied upon manual data tracking, calculation, and analysis. Today, machine data platforms that record data in real-time can automatically calculate takt time.

This real-time access to takt time means managers can identify and respond to bottlenecks quickly. As production needs, inventory levels, and supply chain issues come into play, a machine data platform will deliver insights based on a data-driven, accurate takt time. Managers can understand what is happening on the production or shop floor and what needs to be done.

Main Benefits of Reducing Takt Time

For manufacturers planning capacity, production schedules, labor utilization, and more, it’s easy to miss something or overtax a particular resource. When these mistakes are made, production lines run less efficiently.

In some cases, workers may have too much to do to meet their production targets. In others, the product mix may leave the facility with too much labor on a given shift or day. Takt time helps manage these types of balances across multiple production lines.

Takt time helps managers deal with these problems based on how they impact the ability to complete all jobs on time. Some core benefits of measuring takt time include:

Accurate Service Delivery Times

Because takt time takes demand into account, companies can quote realistic delivery times. They can also use takt time to reduce lead times and improve service levels.

Reduced Bottlenecks

Bottlenecks may occur at a workstation or other place within a production process. They may also occur on a product-specific basis. Since takt time measures the performance of multiple products across production lines, bottlenecks can be eliminated regardless of whether they’re permanent or product-specific.

Standard Work

As managers use takt time to implement process improvements, they can implement standard work across each workstation. This reduces errors from operator to operator and improves efficiency as goods are produced more consistently.

Reduced Waste

With optimized production processes, standard work, and the elimination of non-value-added tasks, companies can lessen labor and material waste at each workstation.

Faster Process Improvement

Takt time allows teams to identify underperforming production lines more easily. As they zero in on a problem area, takt time changes for that entire production line regardless of whether the product is running. As process improvement initiatives are streamlined, teams can move on to the next bottleneck or process challenge.

Evenly Distributed Workloads

Takt time helps managers distribute workloads evenly across multiple machines. This smoothens the flow of production, helps balance the shop floor, and reduces the strain on staff and equipment. It also allows for better planning of maintenance, material flow, and other production-related tasks.

Takt time can be determined manually with a takt time calculator or automatically with a machine data platform. It can then be used as a tool alongside cycle time and lead time to develop a comprehensive plan for improvement and to meet customer demand.

How Do You Reduce Takt Time?

Because takt time is the speed production must run to meet demand, it’s only reduced by optimizing processes. Continuous improvement initiatives can help align takt time with demand; as processes improve, the cycle time of each product becomes more aligned with the required speed.

There are several ways to optimize processes and reduce takt time:

Measure Individual Cycle Times and Other Metrics

Cycle time is the time spent producing a good from raw material to the final product. Most manufacturing companies have many different products in their portfolio. The blend of other products ordered by customers is the "product mix" in production at any given time.

Plug-and-play Machine Connectivity

By measuring the cycle times and understanding their complexity, companies can plan resources for periods where takt time may be greater or lesser than desired. This measurement helps them make decisions in scheduling and planning to balance out takt time.

MachineMetrics automatically captures cycle times to ensure data accuracy and effective benchmarks. This allows managers to better understand and manage their take time.

MachineMetrics automatically captures cycle times to ensure data accuracy and effective benchmarks. This allows managers to better understand and manage their take time.

Other process metrics to consider include:

- Efficiency: Production time divided by total process time

- Turnaround Time: Time from order placement to delivery

- Throughput: The number of produced units divided by the amount of production time for each unit

- Quality Rate: The percentage of first-quality parts divided by the total units produced

Remove Non-Value-Added Time

A core principle of Lean and Six Sigma Methodologies is removing non-value-added time or waste. As improvement teams study and measure a product's cycle times and other performance attributes, they can divide activities and tasks into value-added and non-value-added time.

By eliminating the non-value-added time from process steps and formalizing it in the part's workflow, cycle time per product is lower. This leads to reduced takt time for the day, week, or other period being observed.

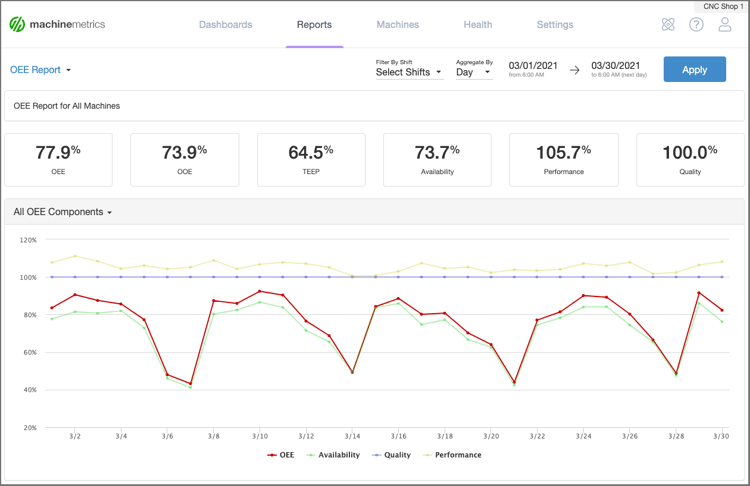

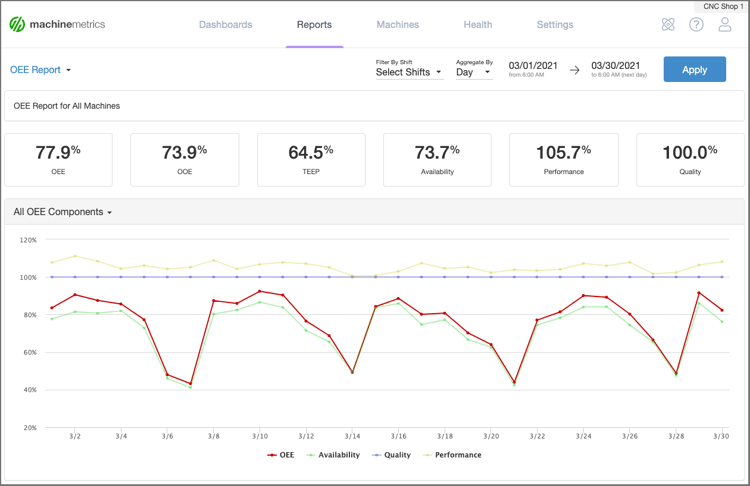

Consider Your Overall Equipment Effectiveness (OEE)

OEE is another way to review and improve processes. OEE considers availability, performance, and quality, and many companies assume their OEE is much higher than it is. By looking at the causes of downtime, companies can increase their OEE, and in turn, decrease their takt time.

Tracking historical OEE performance with MachineMetrics allows users to drill in at the machine, operator, or shop floor level.

Tracking historical OEE performance with MachineMetrics allows users to drill in at the machine, operator, or shop floor level.

Improving Takt Time with MachineMetrics

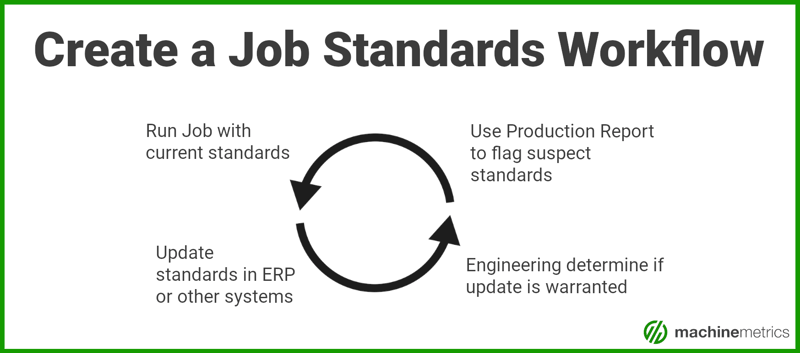

Once a team has assessed production, taken performance benchmarks, and identified the root causes of problems, they can implement strategies to improve processes. The best way to do this is by using real-time machine data.

Improvement methodologies like Lean and Six Sigma began before the age of industrial IoT. But with advanced machine data platforms like MachineMetrics, processes can be taken to the next level with greater data accuracy and more actionable data.

Here are a few ways MachineMetrics can help you to reduce takt time:

-

More Efficient Processes: Real-time data is captured for all machines throughout the factory floor, so managers can view up-to-date production conditions. This visibility encompasses the velocity and current status of the entire product mix on the shop floor. Decision-makers can craft new strategies built on this data to manage schedules, improve forecasting, and execute production plans better.

-

Optimized Inventory Strategies: Demand shifts over time. With real-time data and the insights produced by advanced analytics, inventory purchase, delivery, and allocation strategies are aligned with demand. They can also be linked seamlessly with ERP or planning software.

-

Accurate Holistic View of Production: A nightmare schedule of a complex mix of products may seem like an impossible burden on takt time. With a machine data platform, managers and planners can pace the scheduling of orders across multiple time sets to smoothen and reduce takt time as process improvement and inventory optimization takes hold.

Real-time data and advanced analytical insights drive process improvement, inventory optimization, waste reduction, OEE, and quality management strategies. These improvements mean that takt time can be reduced so that companies realize a competitive advantage.

MachineMetrics creates significant value that enables sales and marketing teams to reduce lead time for delivery. This reduction increases customer satisfaction and improves brand recognition.

Takt time is a valuable core metric for manufacturing production. Ensuring you have the accurate data necessary to track and reduce takt time is increasingly important given growing market competition.

Can we show you how we do it? Schedule some time with our team today:

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments