Machine condition monitoring is a practice whereby the machine's health over a specific period can be assessed. By capturing data from the machine, efficiency, overall equipment effectiveness, and other variables can be used to determine future performance to optimize parts replacement, wear and tear, and downtime for service.

But what about monitoring the tool conditions? While machine condition monitoring leverages electronically captured data, the tools themselves are precise, hardened tools that perform the cutting, boring, or milling of a piece. By extending the concept of machine condition monitoring to include tooling, companies can predict tool failure and reduce cost.

What is a Tool Monitoring System?

A tool monitoring system analyzes machine data from many devices to determine the health, lifespan, and remaining utility of a tool. Monitoring the health and lifespan of a tool is more difficult to perform than machine condition monitoring. It attempts to leverage the data from the CNC machine to understand and predict the condition and lifecycle of the tool. The more precise the prediction of tool failure, the lower the overall tool cost incurred.

By monitoring various factors, monitoring software that measures the health of a tool can inform operators of tool wear and how long a tool will last. This offers greater visibility into the process and empowers operators to get as much life as possible from each tool. They can also manage their time better to perform changes with less downtime. Predicting the tool failure allows operators to replace the tool at an optimal point, while avoiding damage to the machine and part being produced, lowering scrap and tool costs.

Maximize tool life and eliminate scrap

How Do Tool Monitoring Systems Work?

Tool monitoring systems operate on one of three levels, each increasing inaccuracy. Level one monitors averages created by failure points while level two uses power to measure predictable waveforms and level three uses advanced algorithms for collected data. For companies implementing systems that monitor tooling, there are essentially three levels of approach. Each offers a varying degree of certainty as to indicating when a tool failure will occur, and as a result, each step offers varying degrees of effectiveness.

Level 1

The first type is the most basic, and it is widely used across the machining industry. It is simply a variation on an old reactive maintenance practice where the tool is allowed to run to failure. This method uses the failure points to create an average used as a replacement guide. Approximately 95% of the industry is doing this.

While this method is easy to implement (resulting in its industry-wide use), it does have significant drawbacks.

The setpoint for the average can become arbitrary or subjective, especially when different materials are used in the machine. The lowered averages then drive up tool costs.

Furthermore, there can be all sorts of other variables that are not accounted for that interrupt the work of the tool, causing it to stray from the average. This results in one of two things:

- Large amounts of scrap parts by allowing tools to run to failure or

- Wasted tooling and unnecessarily high tooling costs

An image of a "good" part (top) and a "bad part" (second from top). Below these are two endmills: the first is new, while the bottom is broken. For this manufacturer, when the endmill breaks (like the bottom one), the slot does not get cut, and the part becomes scrap.

An image of a "good" part (top) and a "bad part" (second from top). Below these are two endmills: the first is new, while the bottom is broken. For this manufacturer, when the endmill breaks (like the bottom one), the slot does not get cut, and the part becomes scrap.

Level 2

The second level is more advanced. This system analyzes the power being used by the spindle and tracks the waveform, like the sound waves on a recording, to predict failure points. By reading the amplitude of the power over time, increases and decreases in the load can indicate the failure point.

This system, too, has drawbacks. While addressing the issue raised by subjective averages in Level 1, Level 2 still can only capture tool conditions at or very near the failure point. This means that the system is still open to potentially higher scrap rates. It also means added downtime and potential damage to the machine depending on the type of failure.

Level 3

The most advanced solution available, this approach utilizes algorithms that can detect an approach to failure in time to replace the part within an acceptable maintenance stop and with significantly reduced scrap.

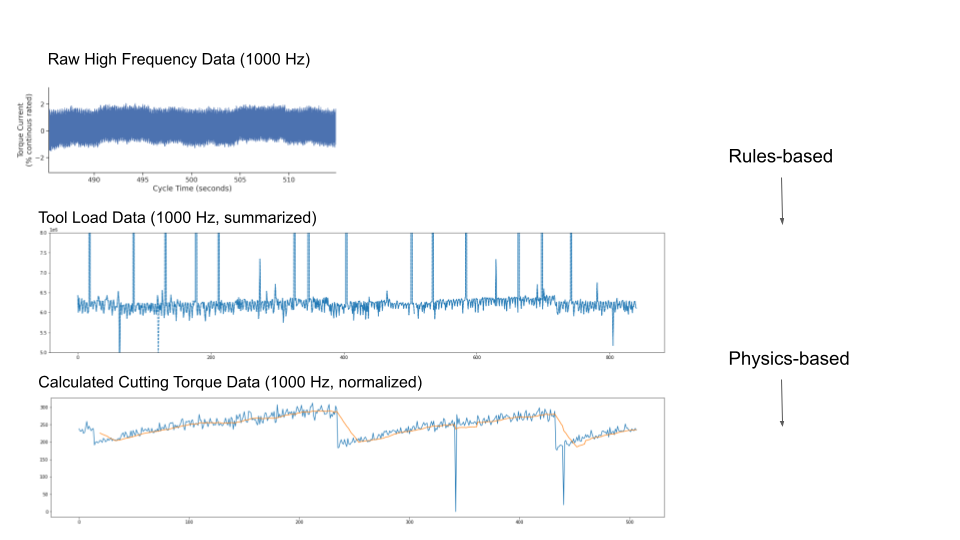

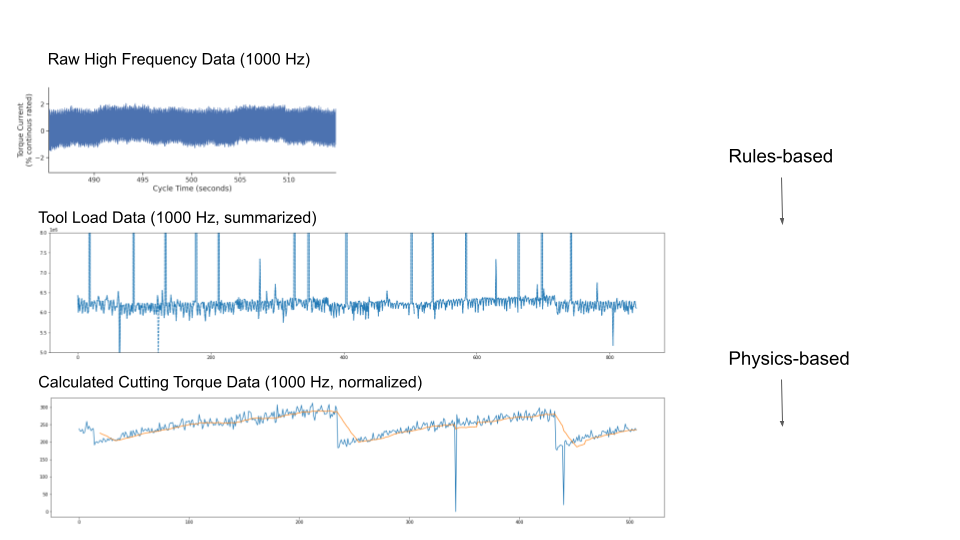

Level 3 monitoring systems, such as those pioneered by MachineMetrics, use high-frequency data and advanced algorithms to diagnose, predict, and avoid failures.

These systems also require no sensors to monitor the tool. By measuring high-frequency data from torque usage, data can be parsed, cleaned, and analyzed. This data is pulled directly from the machine control, thus optimizing monitoring to cover the last mile and becoming an integral part of a more advanced tool condition monitoring system that improves machine control.

Key Benefits

There are many benefits to an automated machine tool monitoring system, including:

Condition Monitoring

Operators are notified of broken or worn tools preventing damage to parts or machines.

Accurate Tool Lifespan

Tools can be optimized for specific situations such as machine type, environment, or material.

Extended Tool Lifecycle

Also known as tool optimization, optimizing the replacement of tools means the lifecycle is maximized, and the tool is never replaced too early or too late.

Improved Quality

Broken tools are only part of the problem. Tool wear can also generate scrap by producing pieces that are slightly out of spec. CNC machine tool monitoring software can identify this wear to prevent them from further use.

Predictive Maintenance

Predictive maintenance is the most impactful method available for improving quality and reducing costs. It has the ability to accurately predict tool failure and alert teams to fix the problem, avoiding scrap altogether.

Power Monitoring

Power monitoring is where tools are monitored continuously throughout the production cycle to help manage power used by the machine. Understanding the power used for each job and exerted by the tools can help detect tool wear earlier. If the power spikes unexpectedly, it can cause a shutdown. Spikes can also indicate excessive force when it isn’t expected and lead operators to the tool that needs replacing. Power monitoring may also work in conjunction with other program aspects, such as force monitoring, to provide an even more complete picture.

High-speed Data Processing

Data is one of a company’s most valuable assets. When processed in real-time and at the point of occurrence, it can be used in the framework of the same advanced analytics platform powering production monitoring to provide actionable insights. These insights not only help operators and managers develop solutions to problems. As part of the data ecosystem, they provide valuable information by job, machine, operator, shift, and more.

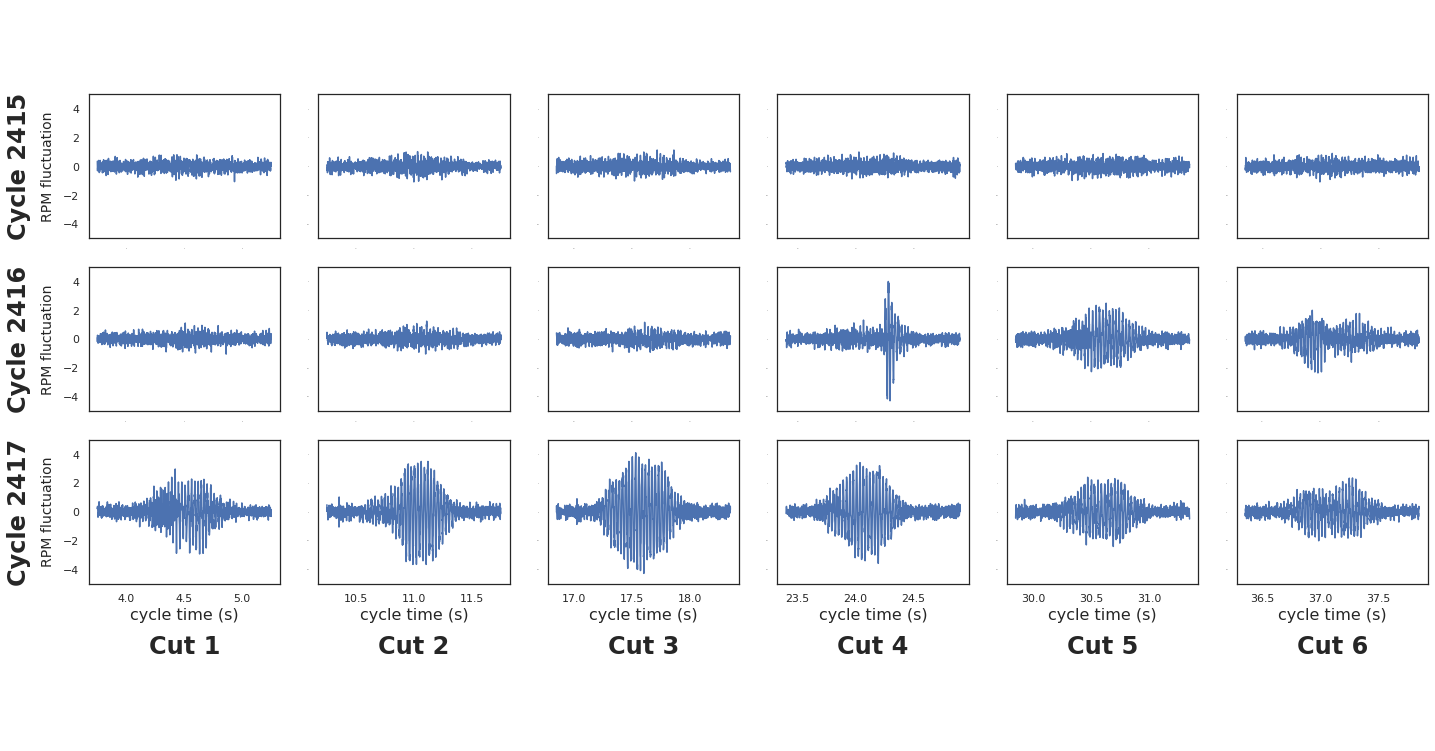

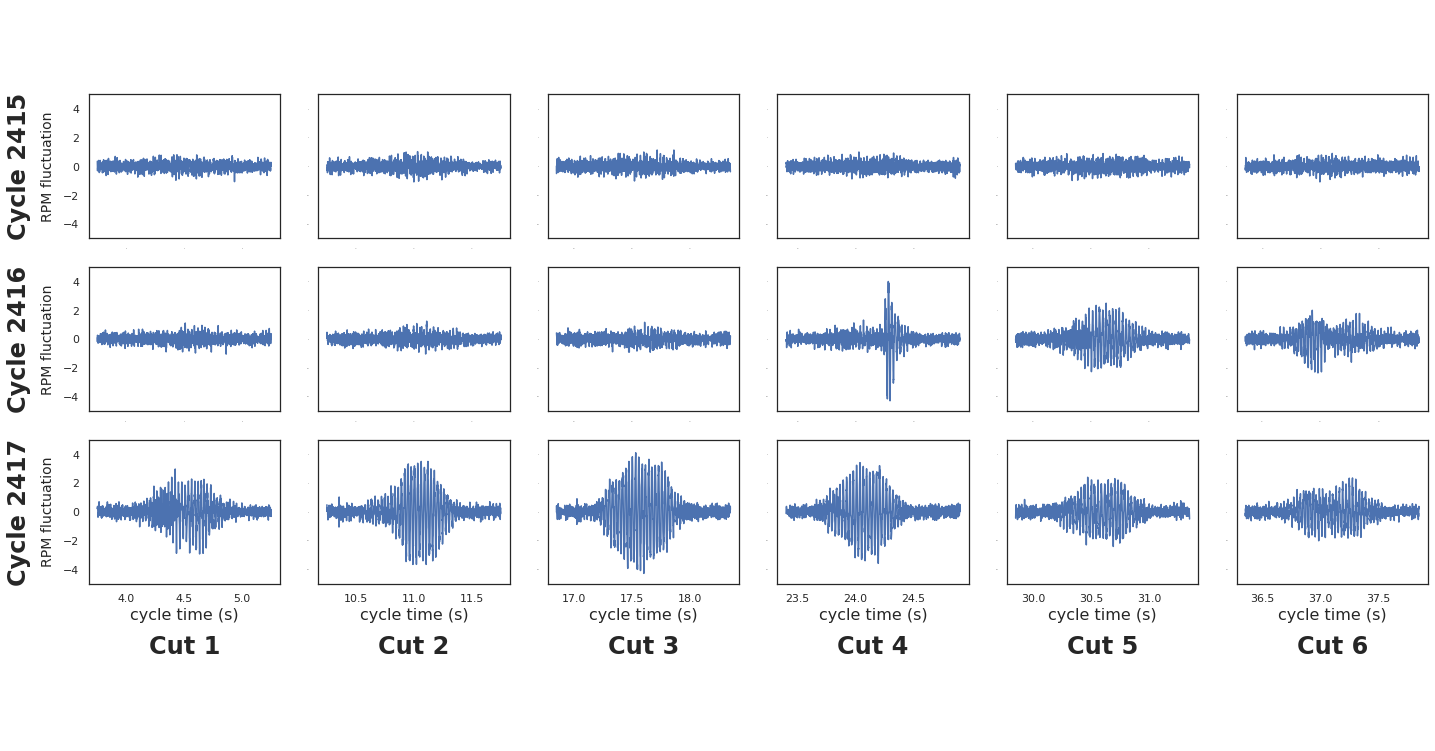

Real-time Tool Wear Detection

Advanced data capture systems such as that offered by MachineMetrics can tap into high-frequency data that can be leveraged to detect tool wear in real-time. The results are analyzed, and using machine learning, the system can begin to assign traceable and plottable attributes to each signal that accompanies tool wear. This capability works alongside other devices so that tool wear can be monitored and plotted.

With tool monitoring, you can replicate the ear of an advanced machinist with years of experience listening to tools and machines for any signs of impending failure.

With tool monitoring, you can replicate the ear of an advanced machinist with years of experience listening to tools and machines for any signs of impending failure.

Maximize tool life and eliminate scrap

Are Software for Monitoring Tools for You?

If equipment is not performing to measured production rates or proper take time, tool monitoring may be a good solution. If cost and quality are all over the board, then proper tool health can be an important part of the solution. Because it is more difficult to do than machine production monitoring, many companies may shy away from it. But why a company needs such a monitoring system goes hand in hand with why they need production monitoring.

The same is true of understanding OEE. Many companies just beginning their digitization and monitoring journey have a highly inflated opinion of what their overall equipment effectiveness is. And when the production monitoring begins, that opinion is shattered. It represents the next level drill-down for continuous process improvement to get a handle on a host of issues.

A company can also use such monitoring software to address more strategic needs. Perhaps the data leads to training issues that mean even an experienced operator needs refreshing. It can also be used to determine whether the company’s equipment base is up to producing the level of quality based on complexity. Product specifications and trends shift over time, and legacy equipment may not always keep apace.

Another strategic reason would be for the company to take on new business. Aerospace, medical, and military-grade parts require extremely tight tolerances. If a company is considering taking on new business where current efficiency and process controls are out of tune, the monitoring system can help identify the problem areas and direct them to a process solution enabling them to take on higher quality work.

When Does Tool Monitoring Make Sense?

Tool monitoring makes sense when a company has little or even no idea what its true OEE is. It also makes sense when processes need optimizing. Many businesses can realize double-digit improvements of as high as 20% when using it in combination with production monitoring. This condition can continue for years and frustrate operators and managers who don’t understand why a machine isn’t able to produce parts at the established rate.

Tool monitoring also makes sense when companies are suffering efficiency losses due to missed or incorrect cycle times where tool failure means the job never operates at the production rate according to specifications. And it is an excellent choice for companies that have a high loss from quality fallout and can’t pinpoint exact reasons why and where these fallouts occur.

BC Machining Turns to MachineMetrics for Predictive Tool Monitoring

When BC Machining sought help to address continuing tool breakage and high scrap rates, they engaged MachineMetrics for a solution. BC Machining serves the medical, defense, transportation, and power tool industries where precision is critical.

BC Machining had been experiencing excessive tool breakage in their Swiss CNC machines, creating scrap both at the point of breakage and near-end-of-tool-life when parts can vary out of spec.

Using the MachineMetrics solution of capturing high-frequency data and analyzing it through advanced algorithms, BC was able to identify tool breakages to prevent scrap parts.

The drop in lost parts, sorting, and uncertainty translated into near 100% failure detection and a $72,000 annual savings per machine.

Read the complete case study with BC Machining.

MachineMetrics offers a monitoring system for tool assessment that collects data directly from the source – the CNC machine itself. Through custom algorithms designed to monitor torque usage, inputs can be entered into the system as time-series events or machine learning models to predict tool failure accurately.

MachineMetrics' high-frequency data adapter can detect the problems and analyze the data at the edge to automate solutions and alert staff to issues before the failure occurs, preventing costly scrap and downtime. With advanced machine diagnostics, tooling is optimized and incorporated into an aggressive and fully automated predictive maintenance system. To see how MachineMetrics can be deployed to help you get a handle on your tool's health needs, book a demo with our team today.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments