Manufacturers understand that maintenance is a make-or-break activity, especially in high-dollar, fast-moving, and high-competition verticals. Maintenance strategies of times past simply can’t cut it in today’s fast-moving world, and manufacturers still using these practices are quickly falling off the map. Modern maintenance utilizes technology including IoT devices for data collection and machine learning for data processing to reach better predictions and actionable insights. Combined, unplanned downtime can be reduced to a degree that it is practically eliminated, not to mention other benefits such as the boost in employee morale, reduction in opportunity costs, augmented client impressions, and reduced waste.

While that all sounds good, the question bears asking: How do you take your manufacturing company from a state of reactive maintenance to predictive and prescriptive maintenance? How do you reap the benefits of a modern maintenance strategy while avoiding pitfalls along the way?

To understand the answer to those questions, one must first understand the maintenance methods currently at play and what changes from one stage to the next. In this article, we will cover a variety of industrial maintenance techniques.

What is Factory Maintenance

Factory maintenance is a formal strategy used by manufacturers to ensure machines and equipment operate in good condition. The process includes several types of breakdown and scheduled maintenance plans.

When deciding which maintenance strategy to deploy, there are various costs to consider. Part costs, technical labor, and other maintenance-related materials can make maintenance quite expensive. In every strategy, there are trade-offs between the level of factory maintenance and the costs involved.

Breakdown Maintenance

When a machine suffers an unplanned stop due to a breakdown, the maintenance team swings into action. Repairs may include temporary solutions to get the equipment going until the next changeover or until a part arrives. Maintenance technicians may also use corrective maintenance to ensure the problem doesn’t happen again.

Maintenance managers must weigh the cost of production losses for extended repairs against that of safety or machine long-term health.

Planned Maintenance

Many maintenance strategies involve planned maintenance, such as preventive maintenance, conditions-based maintenance, and predictive maintenance. Each company must determine the most appropriate maintenance strategy for its operations.

Planned maintenance includes service, wear and tear, consumables, and other machine health-related tasks. It utilizes a maintenance plan that covers as many planned tasks as possible at the lowest cost.

Planned maintenance tasks include:

- Oil changes

- Lubrication

- Belt tightening and replacement

- Change of consumables

- Setting adjustments

- Deep cleaning

- Electronics checks

- Diagnostics

Maintenance professionals often turn to computerized maintenance management systems (CMMS) to help manage this strategy. These systems may have predictive capabilities, using data to plan an optimal maintenance schedule.

For example, a CMMS may receive data from an oil use sensor on a machine running heavy-duty products, indicating that the oil requires early changing. Similarly, machines may run light-duty applications that can extend the oil life, saving money.

CMMS systems can also identify trends to point maintenance managers in the right direction on specific assets or equipment types. These insights can help managers develop hybrid maintenance strategies based on the type of product run, age of equipment, or past machine health data.

Why is Factory Maintenance Important

Factory maintenance is critical for protecting extensive Capex investments. Its most essential function is facilitating efficient production with the least number of maintenance bottlenecks.

Inadequate maintenance impacts more than just the cost of replacement parts. It also results in:

- Lower efficiency

- Lower equipment utilization

- Poor quality

- Higher scrap rate

- Increase of waste as a percentage of materials

- Higher labor costs – overtime and rework

- Less ROI for Capex equipment

Plant maintenance is also important because it impacts many areas vital to efficient production, including service levels, customer satisfaction, and employee morale. Optimally maintained equipment reduces operating costs and increases the lifespan of the equipment.

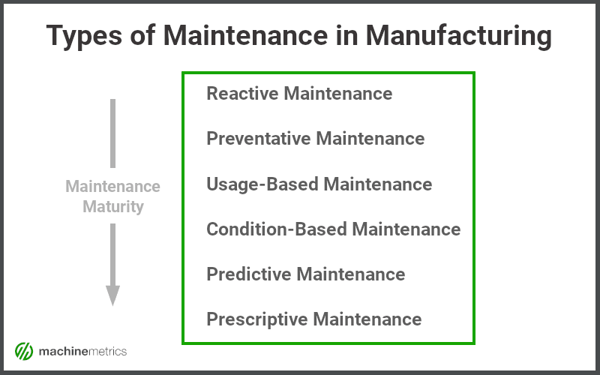

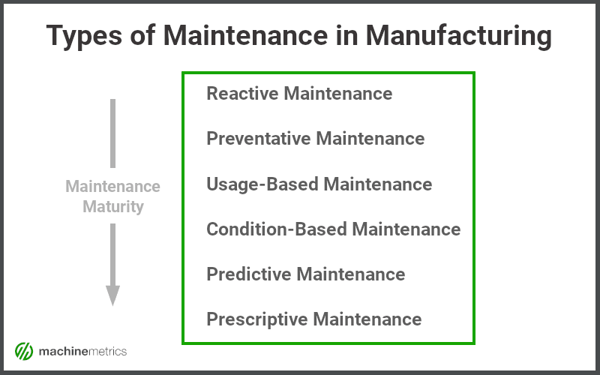

Types of Maintenance in Manufacturing

We cover each of the below maintenance strategies in the context of manufacturing. Select any to jump to the corresponding section:

- Reactive Maintenance: When it breaks, you fix it.

- Preventive Maintenance: You schedule replacements ahead of time before parts break, usually at a regular interval.

- Usage-Based Maintenance: You replace parts when the machine has been used a certain amount before they break.

- Condition-Based Maintenance: You replace the parts when they seem like they are getting too worn out to continue to function appropriately.

- Predictive Maintenance: You utilize historical data to make predictions about when a part will break and replace the parts based on these predictions, prior to them breaking. This usually, but not always, utilizes artificial intelligence and machine learning.

- Prescriptive Maintenance: Advanced data analysis methods are used to do more than predict failure points, but instead provides hypothetical outcomes in order to choose the best action that can be taken prior to failure, safety hazards, and quality issues arise as well as the timing of implementation.

Reactive Maintenance

Reactive maintenance is the starting point for most manufacturers. It’s the traditional method of maintenance that has been with manufacturing as long as manufacturing has existed.

What Is Reactive Maintenance?

Just as the name says, this type of maintenance means you react to whatever happens. You may or may not be prepared or expecting it. A part breaks and clogs up the whole production line, often literally and metaphorically. Unscheduled downtime ensues. Workers lose pay. The company loses revenue. And everyone just has to wait until Ralph The Maintenance Guy waltzes in to replace the offending part (which you may or may not have on hand.)

This could mean days of downtime, missed deadlines, and massive hits to your budget, especially if the tool, machine, or part that broke is expensive or hard to find. Employees get paid to reach out to clients with the dreaded “There’s been a delay…” message. And the costs and risks trickle down the entire supply chain. It’s a vicious, expensive cycle.

Calendar-Based Maintenance (Preventive Maintenance)

Once manufacturers see that reactive maintenance isn’t working, the next logical step is calendar-based maintenance, also known as time-based maintenance (TBM) or preventive maintenance.

What Is Calendar-Based Maintenance?

This is a form of planned maintenance that is scheduled ahead of time in order to replace parts before they break down. This is done at a set interval such as every 30, 60, or 90 days. In this way, manufacturers can expect a certain amount of downtime or schedule maintenance during off hours. This helps ensure that equipment will be up and running during all planned production periods barring emergencies or unforeseeable circumstances. Calendar-based maintenance uses the concept of “Mean Time Between Failure” (MTBF) to determine the best interval at which to replace parts based on when they have failed in the past. It works best for parts that encounter regular use and predictable wear-and-tear.

Preventive maintenance can work well for machinery that is used on a regular schedule, that has affordable parts that can be easily replaced, has a predictable wear-and-tear rate. It’s simple, predictable, and effective in these cases. Preventive maintenance can be beneficial when paired with other maintenance strategies such as predictive or prescriptive maintenance.

Usage-Based Maintenance

What about all of those instances that aren’t readily covered by preventive maintenance or for which that method would be far too excessive and expensive? Manufacturers then move toward usage-based maintenance to account for variable machine usage, create more sensible timelines, and reduce costs in the long run.

What Is Usage-Based Maintenance?

Just as calendar-based maintenance uses a set time interval to replace parts, usage-based maintenance utilizes a usage interval, eg:

- Replace your loofah every 30 days (calendar-based maintenance)

- Change your car’s oil every 5,000 miles. (usage-based maintenance)

In the latter scenario, it doesn’t matter if it takes you one month or one year to hit five thousand miles, the oil only needs to be replaced once it has been used to its potential and further use could cause degradation of other parts of the automobile.

To continue the metaphor, for a person who takes a year to drive 5,000 miles, a monthly oil change would be ridiculous. They would be getting an oil change approximately every 416 miles if they drive around the same amount each month. That means their oil change cost is 1200% higher than it needs to be, plus the time and risk involved at the eleven unneeded changes. On a usage-based maintenance system, they have the same if not lower risk of downtime and save a lot of money over a twelve-month period. The same applies to manufacturing machinery. For machinery that isn’t used consistently, usage-based maintenance can prevent over-maintenance of equipment and save a lot of time and money.

Usage-based maintenance is a step in the right direction in that it accounts for actual usage over time intervals which could be arbitrary in some cases. It reduces the likelihood of over-maintenance and reduces waste. However, it can be taken further to greater effect with predictive and prescriptive maintenance.

Condition-Based Maintenance

Condition-Based Maintenance takes some of the guesswork out of predicting maintenance schedules using the calendar- and condition-based maintenance methods mentioned previously.

What Is Condition-Based Maintenance?

This form of maintenance is similar to usage-based maintenance, but with much more frequent monitoring and a greater volume and depth of data. Is the tool showing signs of wear? Is performance decreasing or is it showing other signs of impending failure? Maintenance only occurs when the quality of an item dips below a certain predetermined threshold. Measurements may occur continuously using sensors connected to the tool or machine, or it may come from less frequent analog methods of data collection such as visual inspection.

Pros & Cons of Condition-Based Maintenance

Condition-based maintenance is a step up from usage-based, calendar-based, and reactive maintenance when it comes to the cost of parts. Because condition-based maintenance only replaces parts when they are expected to fail soon manufacturers get more usage for their money without the damage and downtime that comes from pushing parts to the point of failure as occurs with a reactive maintenance strategy.

There are additional costs associated with frequent monitoring, whether that is done through a sensor or a human inspector. However, these costs are generally offset with savings from reduced downtime as well as part and machine longevity.

If sensors are used, costs associated with the installation can add up, especially in hostile operating environments where sensors may get destroyed regularly. Some sensors may require that manufacturers modify their machinery in order to implement them, oftentimes voiding their warranty. Additionally, training employees to inspect, install, and calibrate sensors can become costly.

The time between maintenance actions can be unpredictable using this method, because parts are only replaced as needed. This makes it more difficult to plan for scheduled downtime well in advance.

Condition-based maintenance improves the usage of parts while largely protecting machines from critical failures and unscheduled downtime, but training workers and using aftermarket sensors can become expensive and time-consuming, especially if sensors must be replaced frequently. Schedule unpredictability can also lead to increased opportunity costs. This system is best implemented on machines that require frequent part replacements that are easily monitored and straightforward to fix. For broader benefits to manufacturers, predictive and prescriptive maintenance are often notably more effective.

Predictive Maintenance

Predictive maintenance outperforms our prior-discussed options by blending many of the benefits of each category. This system helps manufacturers predict when maintenance is most likely to be needed, and it does so with increasing accuracy.

What Is Predictive Maintenance?

Predictive maintenance utilizes technology such as artificial intelligence, machine learning, and IoT devices in order to predict when failures will occur so manufacturers can plan for them in advance and replace parts before consequences arise. The goal of predictive maintenance is to hit the Goldilocks zone of maintenance frequency—not too often and not too rarely. This avoids pitfalls in over-maintenance such as excessive parts and labor costs, waste, and increased risk of human error. It also prevents issues associated with under-maintenance such as critical failure, unplanned downtime, and damage to machinery or employees.

In order to do this, data is collected from factory machines equipped with IoT sensors which is then analyzed based on both current and historical data, often utilizing machine learning, to find trends and predict failure.

Plug-and-play Machine Connectivity

Pros and Cons of Predictive Maintenance

Manufacturers need to keep fewer spare parts on hand when they know the most likely periods of failure for a given piece of equipment. Users of predictive maintenance techniques get the best of both worlds by reducing downtime while optimizing resource usage.

Similarly to condition-based maintenance, some IoT sensors used for these purposes cannot withstand hostile manufacturing environments such as those with metal shards, lubricants, corrosive materials, and similar. Sensor replacement and recalibration can become costly, especially if those sensors void the warranty of factory machinery. Additionally, employing data professionals to monitor and analyze sensor data in order to create actionable insights can come with a hefty price tag.

MachineMetrics resolves all of these problems and more. Our data-monitoring devices keep your machine warranty intact and, because they don’t require sensitive calibrations, they can withstand even the most intense manufacturing environment demands. Our devices pull data from the computers of your machinery and send it, encrypted of course, to the cloud. Don’t have an in-house data scientist? No problem, we can handle that for you. Our industrial IoT platform is flexible and intuitive, so you can see results from your digital transformation efforts almost immediately—only five days to ROI.

Prescriptive Maintenance (RxM)

Prescriptive maintenance (RxM) takes predictive maintenance one step further to provide the most valuable solution to impending maintenance issues. Prescriptive maintenance empowers manufacturers to resolve their own maintenance needs without the need for a vast array of experts.

What Is Prescriptive Maintenance?

Prescriptive maintenance utilizes the same technology as predictive maintenance—industrial IoT and machine learning—but also offers scenario simulation to guide action. If predictive maintenance tells you that your tool will fail within 30 minutes because of its current vibration patterns and past data that says those patterns precede failure, then prescriptive maintenance will tell you that if you reduce the load on that tool by 30% now, you could extend the tool’s life by three hours. Prescriptive maintenance tells you what to do next to get the most value from what you have—time and tools alike.

State of Maturity: Prescriptive Maintenance

A mature maintenance strategy utilizes multivariate approaches and may combine both predictive and prescriptive maintenance capabilities. This allows manufacturers to predict, with the absolute most accuracy feasible today, when to expect part failures on short, medium, and long-term scales. It also helps in optimizing processes to get the most life out of tools and parts while avoiding unplanned downtime with great precision. Prescriptive maintenance solutions are able to help guide technicians towards expedient repairs by augmenting their situational intelligence and knowledge-base with the use of artificial intelligence.

While some implementations of prescriptive and predictive maintenance can be fragile and expensive, MachineMetrics offers an industrial IoT platform that can withstand a broad array of manufacturing environments, collect data at 10,000 points per second, and send this information to data professionals on hand, ready and waiting to optimize your factory floor. Experts in advanced digital transformation, we have used our experience to simplify our process to such a degree that you can install our IoT devices on your machines—without voiding your warranty—without us ever stepping foot in your factory with our Do-It-Yourself plan. (But we’re happy to come help if you want, too.)

Then, you’re on your way to a fully-mature, easy-to-understand, morale-boosting, revenue-skyrocketing super system for all your maintenance and manufacturing needs. Reach out to see what we can do for you today.

Ready to connect your shop floor?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments