A large majority of manufacturers remain dependent on inefficient data collection systems. Many continue to rely on data manually captured from their operations by shop floor personnel. This information is usually input into systems and then later evaluated.

Part of the reason that this problem persists is that it is difficult to autonomously capture data from manufacturing equipment and operations. This article explains why machine connectivity is such a challenge and how MachineMetrics overcomes these challenges to ensure deep machine connectivity across all makes and models of equipment.

Why Machine Integrations Fail

There are several reasons that capturing data from manufacturing equipment is difficult, especially in the discrete manufacturing industry. The connectivity challenge is also a major reason for the high failure rate of IoT projects.

Data Variety

Many companies operate production equipment from multiple OEMs, and how those machines connect and communicate may differ from supplier to supplier.

A typical shop floor will also have machines from the same OEM that range across different models, capabilities, and generations. Connectivity and communication protocols may be completely different for a new machine compared to the same machine that is decades old.

And that's just for equipment that performs the same operation. Complimentary equipment or upstream sub-processing equipment will all have the same problem with their functionality and connectivity needs.

Data Volume

Many manufacturers contemplating a production monitoring platform understand that their equipment has landlocked data. It's also important to consider the data's volume and complexity. The more complex each piece of machinery is, the larger the data points available for analysis.

Teams looking beyond their pilot often try to "drink from a fire hose," even if they’ve resolved the connectivity issues to account for data variety. Once the connected assets begin sending data, the floodgates are vast.

Data Speed

Companies are also challenged with data speed. What good is a real-time data platform if the system bandwidth can't handle the flood of data or the responses have latency so high the machine can’t respond in time?

As more assets are added and the system scales, each machine or machine type will repeatedly encounter the same problem. For many, the only solution is expensive and tedious custom development and equally tedious manual coding of data points, making the solution as cumbersome as the original problem.

Overcoming Connectivity Challenges

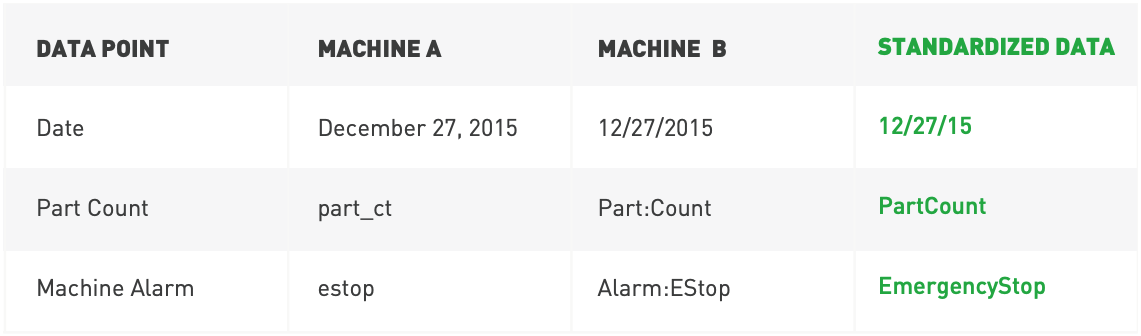

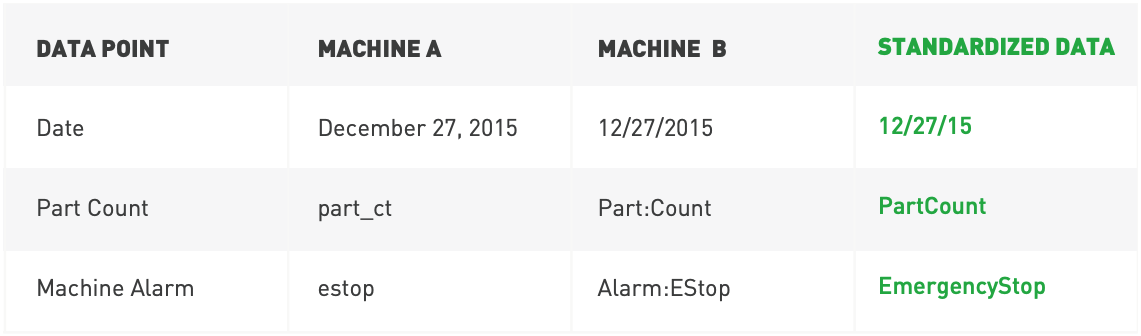

While daunting, these challenges can be overcome. For machine data variety, a solution must allow fast connection across any machine type, from digital to analog assets. This solution must also quickly and accurately transform the data into a common model.

Once the data has been standardized, a solution will require the capability for analysis of data across multiple areas of the system. This eliminates redundant data and reduces unneeded storage. It must also be versatile and process data at the edge or in the cloud, depending on the required outcome or complexity of the analysis.

The final obstacle of conquering data speed challenges requires lightning-fast edge processing. This differentiation requires a powerful platform and analytics capability working in sync between cloud and edge to produce real-time results and actions with little to no latency.

Finding the Right Solution

The MachineMetrics Production Monitoring Platform was designed with all these challenges in mind, enabling teams to immediately connect any OEM, generation, or asset model.

Further, MachineMetrics enables users to easily take action on their production data with pre-built reports and dashboards, notifications, and workflows.

With our Free Trial, users can prove the platform before scaling. See our platform in action, or set up some time with our team today.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments