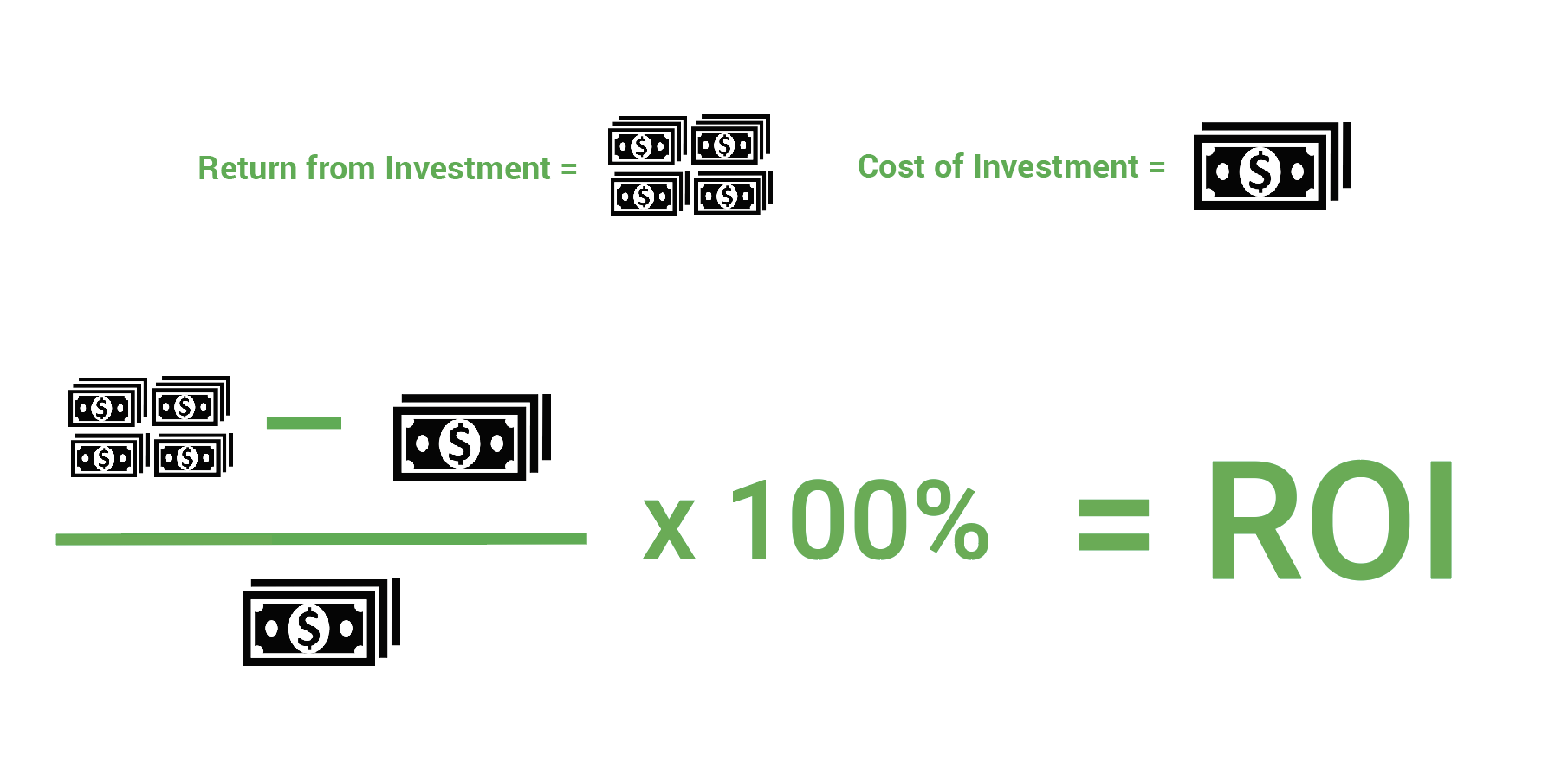

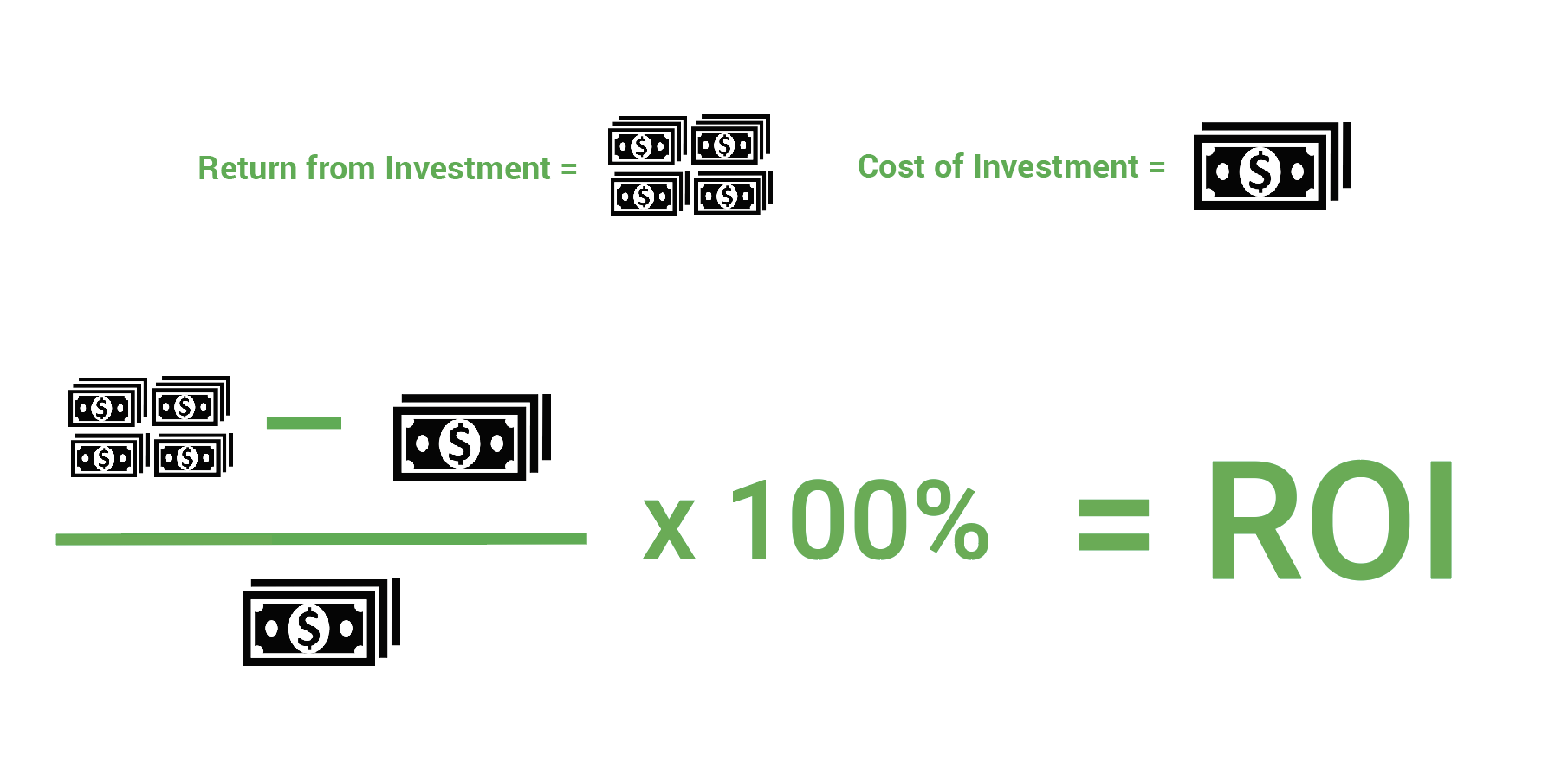

Return on Investment (ROI) means different things to different groups. For consumers it is more a matter of satisfaction and perception. But for businesses, it comes down to how fast an investment can begin to put more money to the bottom line than the initial investment removed. For larger companies, ROI can be realized over the course of years. But for small to medium sized enterprises, fast ROI is critical to success.

Return on Investment (ROI) means different things to different groups. For consumers it is more a matter of satisfaction and perception. But for businesses, it comes down to how fast an investment can begin to put more money to the bottom line than the initial investment removed. For larger companies, ROI can be realized over the course of years. But for small to medium sized enterprises, fast ROI is critical to success.

With the adoption of Industrial IoT in manufacturing reaching a fever pitch, manufacturing companies are racing to add connectivity, develop analytical strategies and deploy it across their operation to take advantage of the benefits IIoT can bring. However, cost of adoption and implementation is a major concern as companies struggle to balance the need for new capital equipment for growth or generational upgrades with the cost of IoT implementation in devices, data centers and analytics software. Among the first questions C level executives ask when discussing this technology is ROI.

Follow the Money

Any measurement of the ROI on IoT will require managers to determine how the investment will be monetized. One monetization of the investment will be through growth. This is a strength of big data in that it can manifest itself in several ways. It may spur growth through faster time to market as production realizes strong efficiency gains and lead times fall. It may also be evident through the revelation of new marketing trends to allow better production planning or in the introduction of new products based on closer-to-real-time analysis of new consumer preferences.

A second way to monetize the investment will be through cost savings. Maintenance is often mentioned as a beneficiary of newly possible predictive maintenance programs and savings of up to 25% and higher have been reported. Improved quality also falls to the bottom line as a cost savings as control and measurement of production is possible by machine, by zone within a machine and even to individual modules within those zones. This allows adjustments to be made quickly and in some cases the system can make the adjustment itself with minimal off quality and a reduced failure or fall out rate.

Active Steps for Execs

Active Steps for Execs

Ideally, any investment in IoT will result in an ROI that includes both cost savings and growth opportunity for new products and services. But there are other things for execs to consider that will enhance faster ROI:

-

Define Business Objectives – New technologies are often attractive. But executives and other key decision makers should be cautious of falling victim to Shiny Object Syndrome. Instead, they should employ the same rigor for IoT as they do for any capital expense. By defining the goals and business objectives in a systematic process, the proper scale and focus of the investment become apparent. With this focus, executives can decide if the investment is right for those goals first and then decide the best way to acquire the right IoT resources to achieve those goals.

-

Don’t do Everything at Once – With business objectives identified, execs can set about prioritizing implementation to achieve the biggest bang for their buck. One way to do this is to identify pain points and develop adoption of the IoT technology to resolve those pains. Starting with a smaller list of priorities and aligning those priorities with established business objectives will help prevent implementation teams from working at cross purposes or from chipping away at resources otherwise designated for higher priority items.

-

Understand Implementation Costs – As part of the monetization discussion above, establishing accurate implementation projections can help ein the development of a realistic timeline for ROI. These are not just the direct costs of hardware, software and training. This also includes indirect cost such as reduction in support structures such as HR, IT, staff, fringe benefits, etc.

-

Account for Velocity – Industrial IoT can lead to a major shift in the way a company operates. As a result, it is important to include velocity in any discussion of ROI. With predictive analytics, cloud-based solutions, AI and machine learning, the larger the available historical data sets the more accurate and capable a system becomes. This value increases over time and is an additional way to measure ROI once the ever-sought-after “payback” is achieved. By understanding the payback in terms of velocity, new initiatives for further deployment can be undertaken once executives have confidence in the technology.

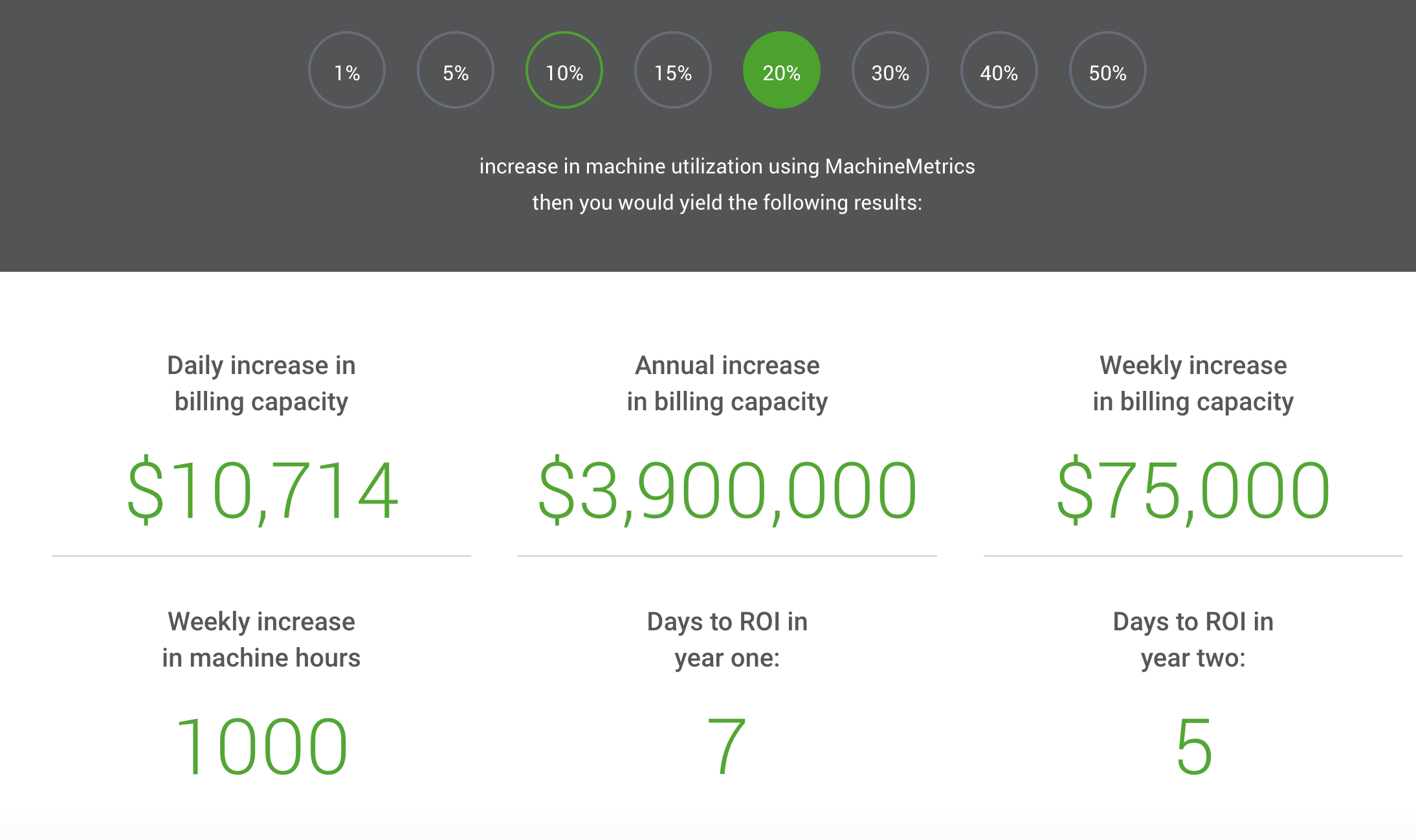

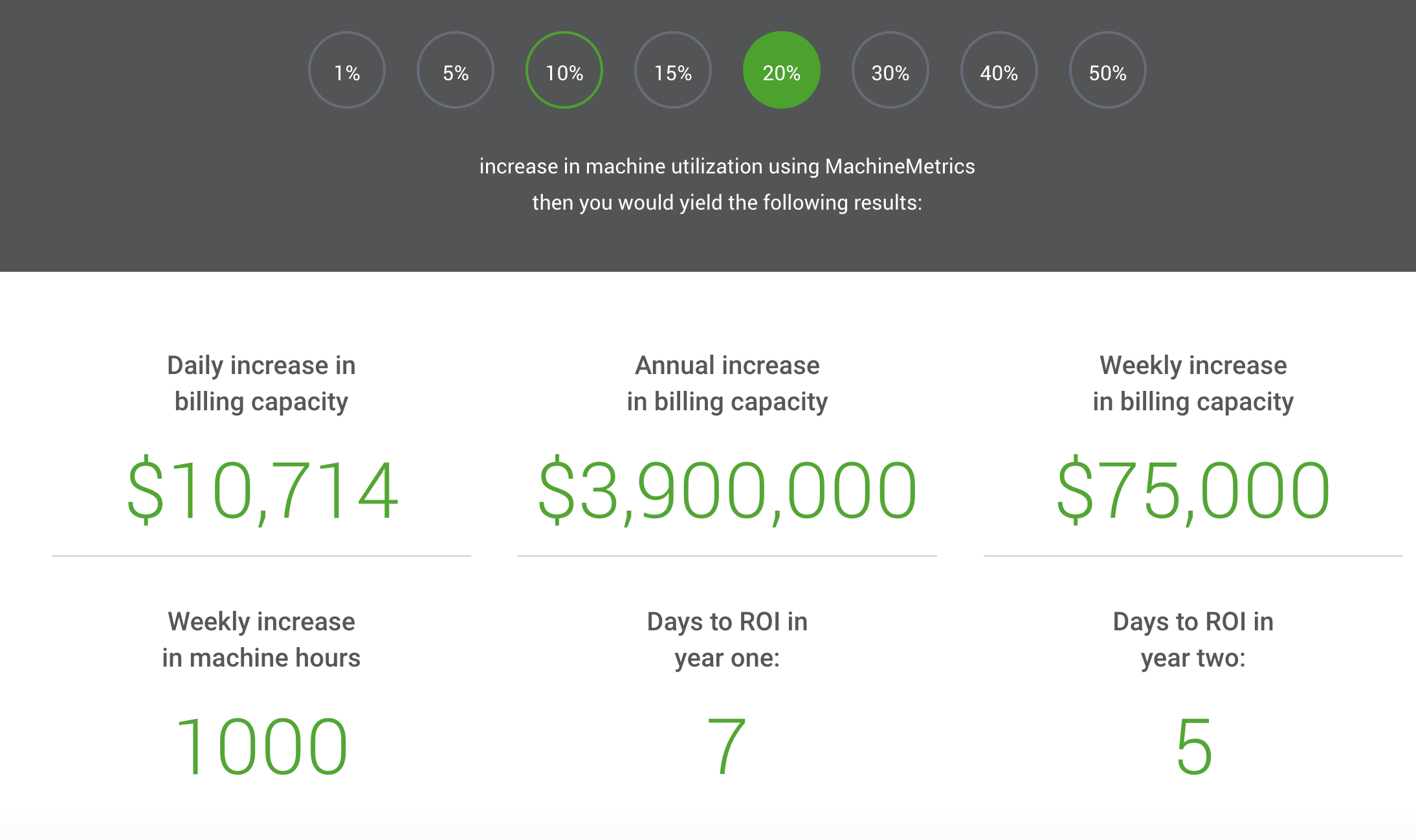

It is estimated that B2B applications for IoT will account for nearly 70% of the global value over the next ten years and account for almost $11.1 trillion USD within the global economy. With numbers that large, it is imperative that executives treat IoT as at least as important as any other investment and maybe more so. By defining objectives, setting priorities and understanding costs, execs can drive measurable ROI within their business and monetize their investment faster. Combined with the enormous potential already exhibited by Industrial IoT and alongside aggressive data analysis through savvy solutions providers, it is possible that with the right implementation plan, some companies may realize a ROI within the first year, while others (many MachineMetrics customers for that matter) achieve ROI within months, weeks, or even days!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Return on Investment (ROI) means different things to different groups. For consumers it is more a matter of satisfaction and perception. But for businesses, it comes down to how fast an investment can begin to put more money to the bottom line than the initial investment removed. For larger companies, ROI can be realized over the course of years. But for small to medium sized enterprises, fast ROI is critical to success.

Return on Investment (ROI) means different things to different groups. For consumers it is more a matter of satisfaction and perception. But for businesses, it comes down to how fast an investment can begin to put more money to the bottom line than the initial investment removed. For larger companies, ROI can be realized over the course of years. But for small to medium sized enterprises, fast ROI is critical to success. Active Steps for Execs

Active Steps for Execs.gif)

Comments