Key Takeaways:

- Cloud technology enhances collaboration and data accessibility for manufacturers, driving innovation and agility.

- The cloud enables manufacturers to scale operations quickly and integrate new technologies seamlessly.

- Adopting cloud-based solutions supports real-time decision-making, reducing downtime and boosting efficiency.

Cloud computing and software as a service (SaaS) are increasingly popular in the manufacturing industry, with many companies taking advantage of their benefits to optimize processes and improve efficiency.

Despite the advantages that cloud computing and SaaS bring to the table, many executives and IT decision-makers are hesitant to embrace them due to a variety of concerns including security and cost. There is also a fear that the cloud represents a new way of managing data and business, one that is unfamiliar to those that have been in the industry for many years.

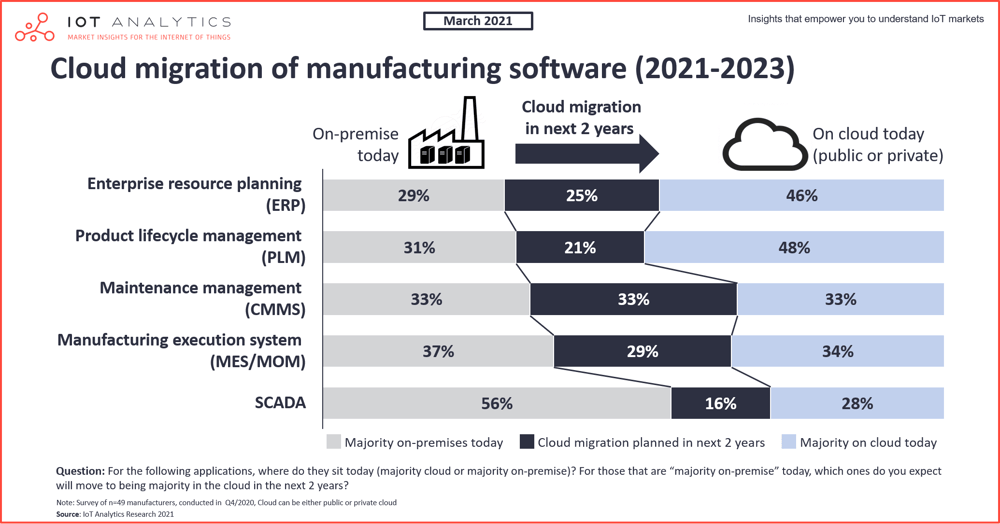

[Source: IoT Analytics]

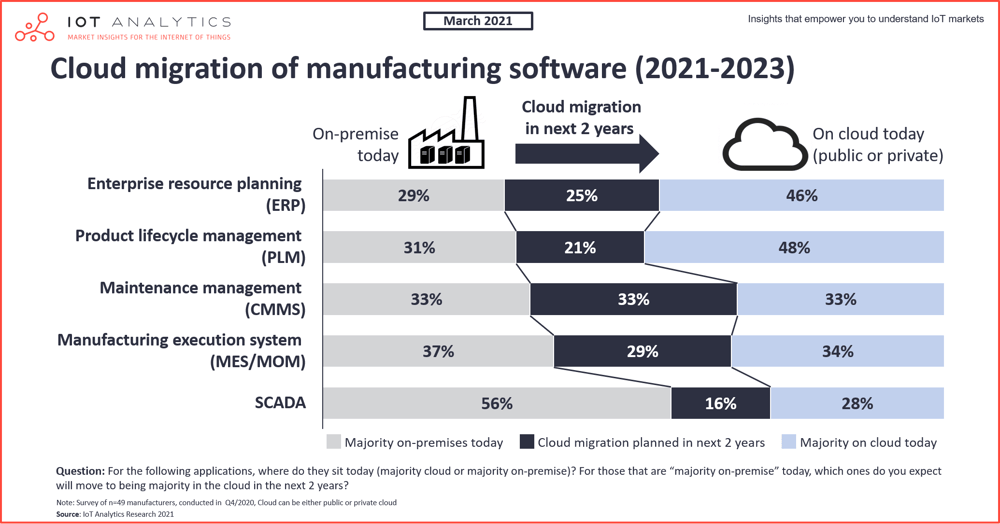

[Source: IoT Analytics]

But without adopting the advanced technologies needed to transform operations and address oncoming market challenges, there comes a point when the fear of the unknown becomes the fear of being left behind.

Security

Mention the cloud or any SaaS application, and you’ll quickly hear security concerns from managers, IT professionals, or both. Each week brings news stories of data breaches, ransomware, and hacks that cause embarrassment or result in the loss of millions from the compromised ability to do business.

But there are two counters to these security concerns:

- Security for cloud-based platforms has significantly improved in recent years. Vastly improved industry standards are powering changes like segmented IT networks, automated closure of ports and other access points, and nuts-and-bolts basics like heightened password and access protection across all entry methods (HMI, PC, tablet, etc.).

- The security argument is less of a cloud problem and more of a problem with business processes. Security breaches commonly occur with insecure interfaces or network services, weak encryption, basic password protocols, and access via insecure mobile interfaces. These weaknesses have always been part of their fragmented legacy software systems because strict security management protocols weren’t implemented to prevent them in the first place, as compromised siloed systems were easier to contain and fix.

Technological advances have made the fear of cloud security much less relevant today. The fear of breaches into a cloud system means a company is arguing that it will require them to do what they should have done all along – enacting protocols to address access issues quickly.

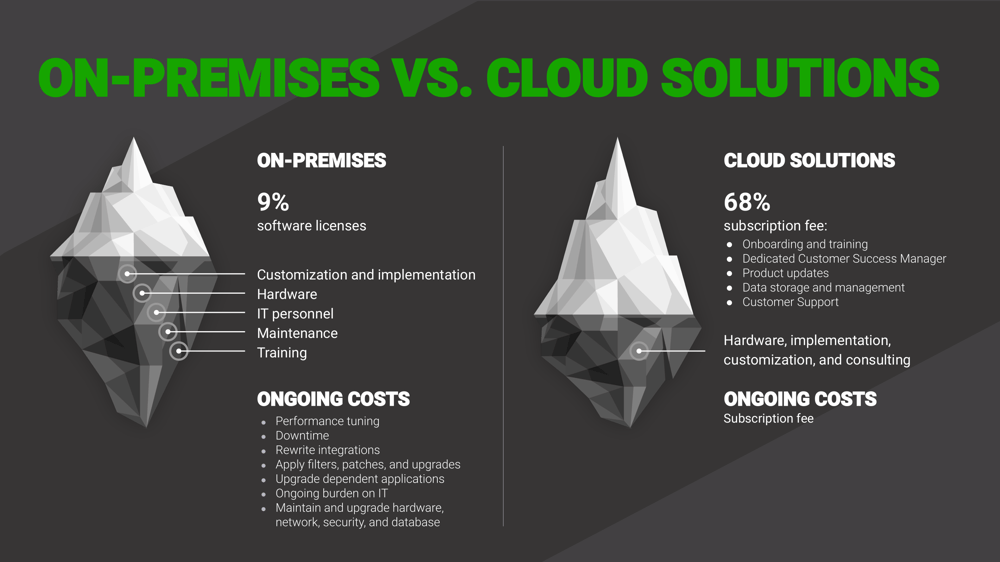

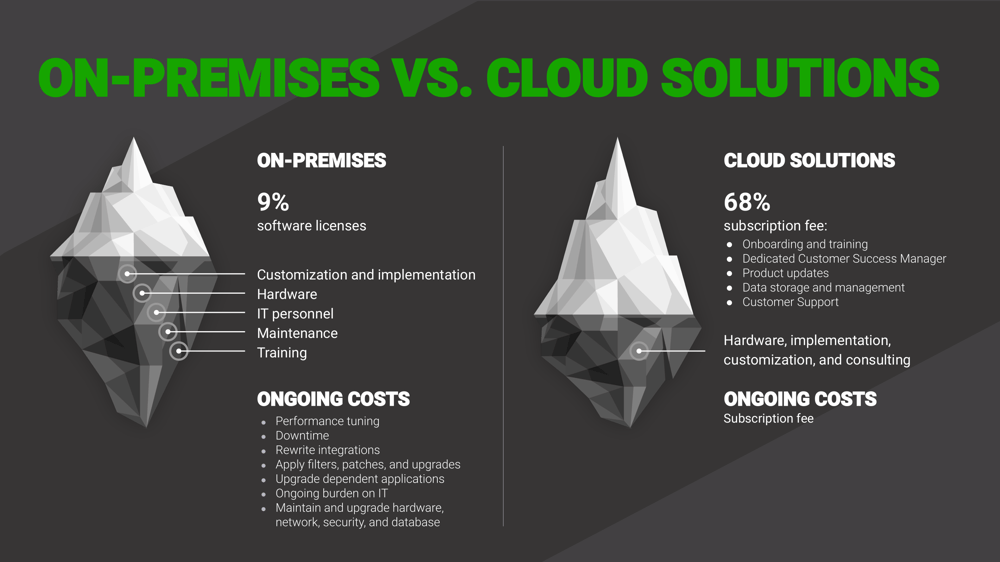

Cost

The fear of system implementation and maintenance costs are built on experience. Buying standalone systems with little to no interoperability increased overall software costs and required expensive cabling to install and implement. Even once these systems were online, they required costly maintenance, upgrades, repair, and labor to keep them going.

Cloud-based SaaS systems offer much lower entry and implementation costs. They also reduce the need for highly skilled IT teams. Many platforms are now fully connective across APIs and other connectivity modes, and many even offer modular ‘a la carte’ options to select only what is needed.

SaaS is much less expensive on the front end and requires less maintenance. Scalability is also proportional in cost to business growth, meaning you don’t need to buy too much and “grow into it.”

The overall impact of these features results in a much lower cost. SaaS cloud-based ROI is almost always significantly higher than multiple standalone on-premises systems.

[Full-size image]

[Full-size image]

The Fear of Something New

The fear of something new is more than one thing. For managers and executives, it’s remembering their Frankenstein legacy software, where multiple fragmented systems worked in a patchwork ad hoc manner to produce poor results, but it "felt" like there was a greater sense of control with solutions being on-premises.

For IT staff, cloud and SaaS solutions mean a serious consideration that their skills won’t be as necessary. It may also mean that the remaining team needs retraining, upskilling, or new careers altogether.

A Tipping Point

Change can be scary, but it’s occurring in manufacturing and other industries at lightning speed. And the result is that whole economies and business processes are changing. Those that remain paralyzed risk seeing the fear of something new become the fear of being left behind.

Advanced technologies like IIoT and machine data platforms provide a means to do things better, at a lower cost, and with greater security. They enable manufacturers to improve processes, unlock capacity, and capture cost savings in overhead, CapEx, productivity, and more.

MachineMetrics captures and standardizes machine data, making it accessible both at the edge and in the cloud. Legacy systems like ERP, MRP, CMMS, and QMS can be connected to provide complete visibility using a company’s machine data to respond to and improve processes in real-time.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

[Source:

[Source:  [

[

.gif)

Comments