Key Takeaways:

- IoT technology is revolutionizing advanced manufacturing by enabling real-time data collection and analysis.

- Manufacturers can use IoT to improve efficiency, reduce downtime, and optimize production processes.

- The adoption of IoT in manufacturing enhances machine communication and predictive maintenance capabilities.

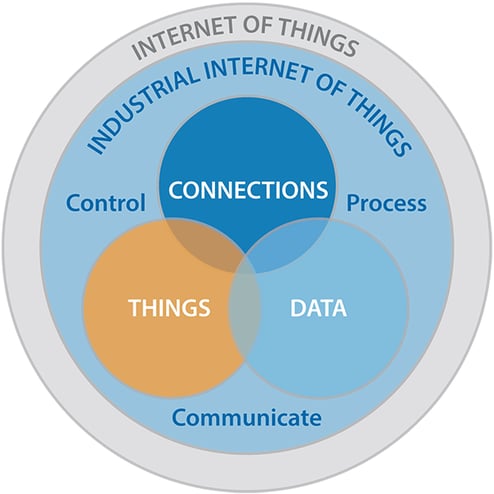

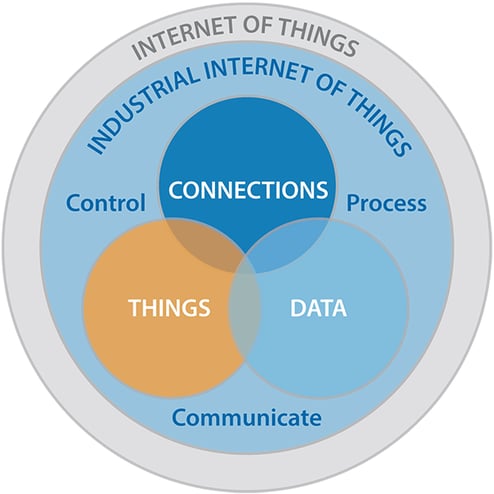

The Internet of Things (IoT) is paving the way for savvy manufacturers to redefine the way they not only manufacture products but how they design those products in the first place.

Call it advanced manufacturing - where automation, connectivity, and the Internet of Things converge with the manufacturing industry.

Advanced manufacturing technology allows companies to deliver more value to customers resulting in a much stronger partnership.

At the heart of these emerging new relationships is the Internet of Things which is driving the development of “smart products” packed with sensors and microchips.

Mix in some built-in software driven intelligence and you’ve got products that not only talk to each other but also communicate with humans in a way that wasn’t even considered only a few years ago.

Advanced manufacturing processes and advanced manufacturing technology are opening up new opportunities on daily basis.

Designing smart products that include online connectivity allows manufacturers, service partners and operators to gather and share product performance information through a digital connection that allows for remote visibility - where various stakeholders can interact with products in real time.

The ability to collect this information lets manufacturers understand what’s going on down on the shop floor - and can even alert them to potential problems before they escalate.

A perfect example is machine monitoring.

The advanced manufacturing technology behind a machine monitoring software system helps manufacturers make faster, more informed decisions based on real-time data.

Monitoring your machines becomes simple.

Leveraging the power of IoT, data is automatically collected from machines and used to provide real-time visualizations and notifications, as well as historical analytics to help factory workers make faster and more informed decisions.

And the benefits of IoT continue once products leave the manufacturing plant.

Advanced manufacturing delivers “smart products” that reach far beyond basic functionality.

Consider a residential indoor air quality monitor:

Until the Internet of Things came along, homeowners pretty much had a couple of simple considerations where it concerned the air in their homes: was it too hot or too cold?

The decision became one where the heating and air conditioning system dictated by air temperature.

Today an indoor air quality monitor allows you to determine the health of the air you’re breathing by tracking airborne particles. It can send the data recorded about the air quality right to your smartphone so you have the latest information.

By monitoring particles in the air, total VOC, carbon dioxide, temperature, humidity, and more, an air quality monitor can store and update the data every five minutes for the most current information.

Without IoT, this wouldn’t be possible. In fact, the product would likely never be created!

When manufacturers are able to establish a secure, reliable connection to their products as well as a platform to rapidly develop applications for optimizing their operation and maintenance, everyone benefits.

And, as manufacturers continue exploring the potential of the Internet of Things, new opportunities to engage customers beyond the purchase will present themselves.

Want to listen to your machines?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments