Key Takeaways:

- OEE (Overall Equipment Effectiveness), OOE (Overall Operations Effectiveness), and TEEP (Total Effective Equipment Performance) are key metrics for evaluating equipment efficiency.

- Understanding and improving these metrics can significantly boost production performance and equipment utilization.

- Each metric offers a different perspective, helping manufacturers identify areas for improvement in equipment and operations.

In last week’s blog post, we discussed Overall Equipment Effectiveness (OEE), the most commonly used manufacturing metric to understand, measure, and improve current performance. To review, OEE is measured by combining a machine’s performance, availability, and quality. In this way, OEE helps you to identify potential losses and understand where your process is falling short. But OEE alone is just the first step to fully understanding your performance.

Today we will explore two other important and related metrics to help round out your continuous improvement strategy: Overall Operations Effectiveness (OOE) and Total Effective Equipment Performance (TEEP).

OEE, OOE, and TEEP major Differences

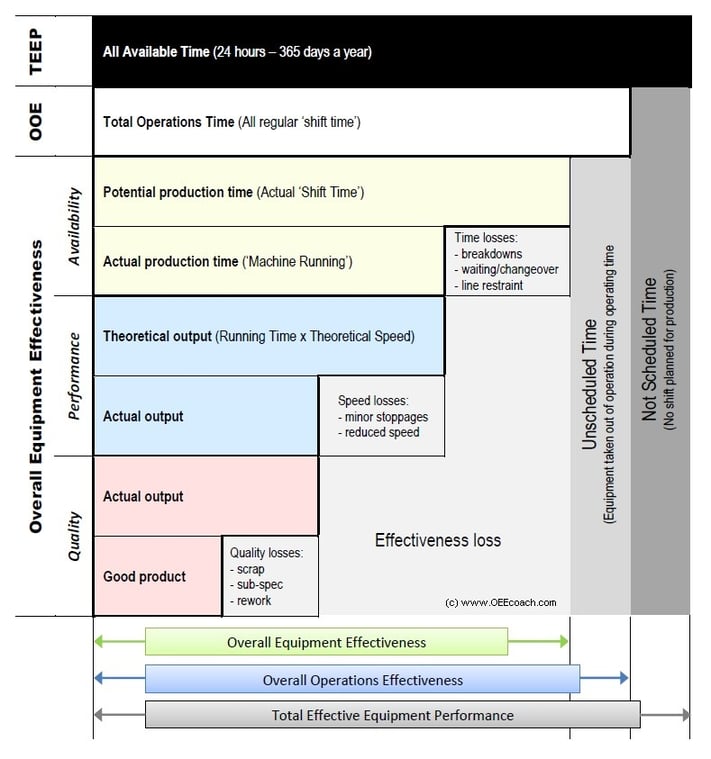

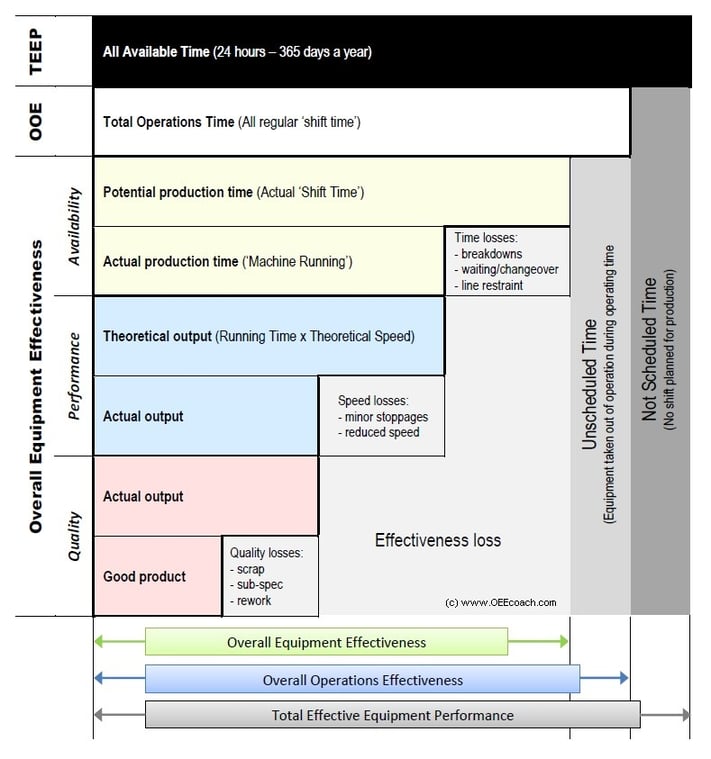

The major differentiator between these three metrics is in how you define Availability. At their core, the goal of each of these metrics is to determine how much good product was made versus how much could have been made. Deciding which metric to use is really dependent on the time frame you consider. To better illustrate this, let’s think about a year’s production on your shop floor. Should your production be based on 365 days and 24 hrs each day? Or perhaps you should only look at the times when you had a shift scheduled? Or maybe you only want to look at the scheduled shifts the time you actually ran? Clearly there are different ways to think about your Availability and this requires different metrics to address each timeframe.

Again, the main difference between OEE, OOE and TEEP is the time or Availability that is used in each calculation.

In other words, the only changing variable between these three calculations is the maximum time that you define as available for a machine to run. OEE, OOE, and TEEP all take availability, performance and quality into account. Here is a more detailed look at the calculations for both OOE and TEEP :

Total Effective Equipment Performance (TEEP) considers maximum time to be All Available Time – that is 24 hours, 365 days a year.

Therefore, TEEP = Performance x Quality x Availability (where Availability = Actual Production Time / All Time).

Overall Operations Effectiveness (OOE) takes unscheduled time into account, looking at Total Operations Time as the maximum.

Performance x Quality x Availability (where Availability = Actual Production Time / Operating Time)

Overall Equipment Effectiveness (OEE) only considers scheduled time. If a machine is down due to maintenance, and it’s not scheduled for work, OEE ignores this time.

Performance x Quality x Availability (where Availability = Actual Production Time / Scheduled Time)

Here's a useful image from our friends at OEE Coach (www.oeecoach.com) that best illustrates this difference:

For example, your company is trying to determine whether or not they need to purchase new equipment in order to meet your production demands. You will first need to confirm that you in fact need the additional capacity. Depending on how you define time, needs to identify how much room there is to increase capacity in order to decide whether to focus on getting more from current equipment or to purchase new equipment.TEEP shows how much potential you have to increase production output with your current equipment. In many cases, reclaiming potential production output is a faster and less expensive alternative to purchasing new equipment.

The importance of understanding OEE, OOE, and TEEP is essential so you can accurately forecast, plan and schedule production. Regardless of what the numbers are, if they have been consistent, you can now, with a high degree of accuracy, schedule what you can manufacture for your customers. Once you understand these measures, you can then begin to look at each of the loss categories, speed, quality, operational and planned, and use the appropriate reliability tool to reduce the losses.

MachineMetrics is the only machine monitoring software that can help you gather the data to reliably measure OEE, OOE, and TEEP. So what are you waiting for?

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments