As the individual in charge of ensuring your manufacturing process runs efficiently, it’s your responsibility to stay on top of every factor that impacts your organization’s production process.

Although CNC machine monitoring can be a powerful ally when it comes to ensuring everything operates smoothly on the shop floor, it can be a double edged sword.

Optimal productivity isn’t a given simply because you implement a system to monitor your CNC machines.

In order to leverage the full capability of your MES, you need to stay alert and open to ways to improve its effectiveness.

Here are five common CNC machine monitoring mistakes that can result in the unnecessary loss of efficiency:

1.) Underestimating the power of your CNC monitoring system

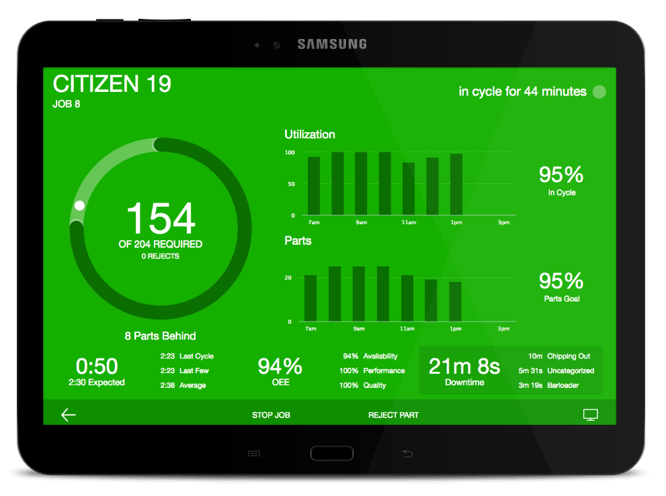

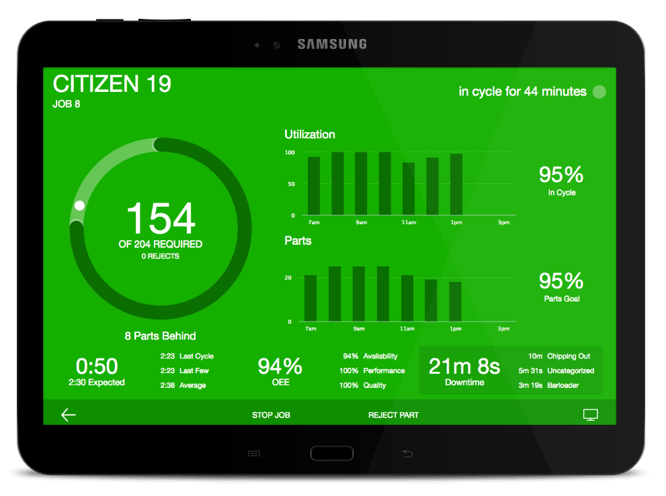

Your monitoring system is a watchdog. But it’s also a beacon that can point the way to additional productivity enhancements - IF you’re proactively looking for them. Many companies with powerful monitoring systems underutilize them never realizing the full potential. Data visualization is only the first half of what manufacturing execution system should offer. While real-time dashboards are a vital tool in offering a window into production, if you aren’t using your reporting and analytics tools, then you haven’t begun to solve for the problems confronting your shop.

MachineMetrics' scorecard report provides a full shop-floor view of OEE for each job broken down by shift. It also shows the dollar amount that any given job is behind.

2. Not scheduling regular, monthly reviews

Due to the repetitive nature of the manufacturing process, it’s easy to lapse into a “business as usual” mindset and assume things are running smoothly on the shop floor. Regular monthly or quarterly reviews of the information your monitoring system is generating can help you to see how much your shop floor has improved, how much money you have saved thanks to reduced downtime, as well as help you to set new benchmarks and goals for the coming months.

3. Over-relying on human input to detect problems

To ensure your CNC machine monitoring system operates at maximum efficiency, it’s important to remove the “human” element wherever possible. As long as data is being entered in manually, it’s impossible to ever fully and completely avoid human error. While many machine events require an operator to categorize them, some downtime events - such as tool changeovers or part changeovers - can be categorized automatically from machine data by the MachineMetrics rules engine. Make certain that you have automated the recording of as many events as your manufacturing execution system will allow. Minimizing manual input will help maximize the reliability of your system.

4. Assuming a previous job setup will run smoothly

It’s easy to think that because a job has run before, it’s simply a matter of setting it up the same way and flicking a switch. However, just because a job ran flawlessly in the past, is no guarantee it will continue to do so. Different machine events can and will occur. Every recurring job could still produce new data and potentially new challenges. You also never know when you will discover new ways to improve a job and reduce the amount of anticipated production time it should take. MachineMetrics clients have discovered ways of shaving hundreds of hours off of recurring jobs.

5. Not Monitoring Your Monitoring System

You’ve installed your CNC machine monitoring system, but if you haven’t instilled it into the culture of your shop floor, you’re going to have a hard time seeing the changes you want to see. Make sure that your operators are fully trained in how to to incorporate your MES into their daily efforts. Be sure to let them know it’s not there to monitor them and their performance, but to act as their eyes and ears. In keeping with the canine metaphors, it’s not your watchdog, it’s their best friend!

By adopting a philosophy where nothing is taken for granted and everything is constantly reviewed, you’ll be in a position to stay on top of issues - before they have a chance to impact your business.

Click on the button below to learn more about MachineMetrics machine monitoring software and how you can start transforming your shop floor today!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments