Updated February 25, 2021

What is Industry 4.0?

Industry 4.0, also known as the Fourth Industrial Revolution, or 4IR, is an all-encompassing term to refer to the way computers, data and automation are evolving and coming together to change the way work happens, and in particular, manufacturing.

Building on the third industrial revolution that included the creation of the PC and the internet, Industry 4.0 takes technology to the next evolution by blurring the lines between the digital and physical worlds. Elements such as automation, AI, IoT, and more are becoming more and more prevalent. While industrial revolutions of the past were essentially about the advancement of technology, Industry 4.0 is more about the evolution of tech and its impact on everyday lives.

Why Industry 4.0 Matters

Whereas industrial changes and technological advancement in the past might have been characterized as creating problems as much as it solved some, Industry 4.0 is about taking what exists and improving upon it. So while technology such as large scale computing and data acquisition isn’t new, applying the 4.0 layer of cloud computing means that data that was previously retained in silos can now be shared across many levels of an organization, and around the world.

Moving away from traditional manufacturing, Industry 4.0 can reduce the strain from so many of the challenges the industry currently faces, including having to compete in a global marketplace with its concomitant volatility, shorten production cycles of increasingly complex products, allowing the ability to review and analyze data, resulting in valuable insights. Trends that change are no longer worrisome as companies are able to engage in course correction with maximum flexibility and minimal cost, and predictive maintenance creates more efficiency and a stronger bottom line.

Since Industry 4.0 isn’t just about advancing tech but actually evolving it, economic indicators become focused on innovation, rather than creation. A company can innovate and create a new business model —from the initial idea to implementation—on a much faster cycle than in the past.

Rather than eliminating the need for human interaction, as some aspects of previous industrial revolutions did, Industry 4.0 is innovating on tech to put the customer first. Faster to market, on-demand production and easier customization levels ensure customer satisfaction on a whole new level. Even people who will be working with machines that have been improved by the IoT or robotics and automation will find their lot improved as repetitive simple tasks will be eliminated in favor of working on problem solving or innovating.

What is Driving the Move Towards Industry 4.0?

There are a couple of needs that are driving manufacturers to embrace Industry 4.0.

First, and most valuable, is the customer. Their wants and needs are constantly changing, as is their demand for product sooner, cheaper and still using less resources than in the past. In addition, customization is the name of the game, which was costly and inefficient in previous evolutions of technology but which, with Industry 4.0, can become the norm. 3D printing, for example, can allow short run, quick turn around production on a highly customized item, at a marginally higher cost than a full production would be.

Next is the data itself: the ability to acquire and analyze the quantities of historic data that manufacturers produce constantly is usable intelligence to allow for demand, production and maintenance planning. Increasing efficiency and productivity, while at the same time guaranteeing a high end product quality, is all good for the health of a manufacturer.

Finally, the ability to leverage cloud computing and connectivity means that the constraints of the global market are virtually nil. Distance and differing time zones are no longer an issue when workers at all levels can access the data they need, from supply chain resourcing through production and shipping, in real time, displayed in ways that are material to any given user.

The Evolution of Manufacturing

Manufacturing has changed substantially since its humble beginnings. There have been four major technological advances that align with each of the four Industrial Revolutions

The First Industrial Revolution

This is when manufacturing turned towards tools and machinery. Popular technology of this era—which happened from the late 1700’s to the early 1800’s—included the power loom, carding machine, spinning mule, and spinning jenny. Water was used to power equipment such as the power loom, and this trend progressed to its high-powered counterpart, steam. Steam engines became popular for a variety of use cases during this time. This is in contrast to the manual human labor and animal labor that was used prior to this Revolution.

The Second Industrial Revolution

From the late 1800s to the early 1900s, the Second Industrial Revolution marked a period of rapid technological advancements that led to increased industrialization and standardization due to a need for interchangeable parts to support such growth. This is when the production line as we know it came into existence. Popular technology and major advancements included electrical power, telephones, steel, and the first modern ship.

The Third Industrial Revolution

The Third Industrial Revolution is sometimes called the Digital Revolution thanks to the rapid adoption of digital electronics. Microprocessors, PCs, cellphones, and the internet all were major technologies during the Third Industrial Revolution which occurred in the latter part of the 20th century. This marked the beginning of the Information Age.

The Fourth Industrial Revolution

Automation is the big differentiator in the Fourth Industrial Revolution (Industry 4.0). Machine-to-machine communication and IoT technology have resulted in smart factories, smart sensors, predictive maintenance using machine data and machine learning, and additive manufacturing all have come from the Fourth Industrial Revolution. This period removes humans from the loop where applicable. Many experts consider this to be our current place in history.

The Fifth Industrial Revolution

Some experts believe we are now on the other side of Industry 4.0 and are instead on the cusp of the Fifth Industrial Revolution (Industry 5.0). While disagreements remain, 5IR places great importance on human intelligence. It’s during this Industrial Revolution that humans and machines must ultimately work together to achieve progress. An example of what could be considered budding 5IR technology is Elon Musk’s Neuralink or MachineMetrics’ Operator Dashboards, which overlay human context with machine data for better, more accurate ML analysis.

How to Successfully Implement Industry 4.0 Solutions

There are three key ways to ensure that implementing Industry 4.0—and in particular IoT integration on the factory floor—in your manufacturing environment goes off without too much difficulty:

- Make sure that you are not getting stuck with the 20/60/20 rule of change management. This is where 20% of your workforce is firmly on board with your plans, 60% are going along with it but are skeptical and 20% are not happy about it all. While 100% acceptance in any change management plan isn’t likely at the best of times, that last 20%, when it comes to integrating industrial IoT, can be difficult to ignore. One way you can improve on the 60% is to acknowledge those who are change averse and see if you can dig down as to why, and get into some discussion about that bigger picture. Including people can help to make them feel that they have a stake in the changes. In addition, investing in training is the single best way to offset discomfort over the longer term. If people understand the WHY and the HOW, they’ll be happier to come along for the ride.

- Make the switch to proactive maintenance. Before Industry 4.0 and lack of machine connectivity, big data and cloud based analytics, maintenance was by default reactive. There was some ability to plan maintenance thanks to historical patterns but, overall, the standard style was to wait for failure before fixing a problem. With solid data analysis, manufacturers can leverage Industry 4.0 to not only predict patterns and trends for the purposes of scheduling maintenance and production efficient times, but can also reach a stage of autonomous detection, self-correction or repair by machines.

- Share you data but protect it too. One of the big advantages of Industry 4.0 is the ability to share data in real-time, even with third party suppliers. If they can see what your demand looks like, they can better forecast to provision you adequately. With that sharing comes a need to ensure that your data is secure. Cybersecurity is a core pillar when it comes to Industry 4.0, with cloud based data storage, management and wireless connectivity. Getting that set up from the beginning will ensure that you don’t have a downstream problem that will require a retrofitted solution.

Benefits of Industry 4.0

Improved Efficiency And Productivity

When you take the human out of the loop, you also remove human inefficiencies and inaccuracies. With better resource allocation that is based on numbers, fewer resources are needed to maintain optimal levels of productivity. Downtime becomes less frequent when data and machine learning come together for predictive and prescriptive maintenance, keeping machines in top shape while without sacrificing warehouse space for an oversupply of unnecessary spare parts or engaging in regularly-scheduled downtime.

Improved Agility

When decisions are based on numbers which can also be changed at will to view alternate scenarios, manufacturers reap the rewards of a massive boost in agility. With numbers to back decisions, it’s possible to quickly pivot as opportunities arise, even opening opportunities for one-off production runs if supplies for forecasted demand have already been met.

More Money

This comes from a variety of factors. Increased efficiency and productivity mean maximized outputs. Sensor data used for predictive maintenance lowers downtime as well as scrap. Better resource planning means less overhead for upfront materials spend, warehouse space (which can also be optimized using ML), and overall lower operating costs with increased revenue potential.

Challenges of Industry 4.0

Disparate, Overwhelming Pools of Data

Manufacturers are often inundated in more data than they can reasonably use. The usefulness of this data is depleted by a lack of in-house talent (or external service) that understands how to clean and organize the data—the right data—to answer business questions. Many manufacturers came into Industry 4.0 expecting data solutions to be plug-and-play and for them all to work harmoniously together. Especially early adopters have often been sad to find out that their data was in an array of different formats that did not work together and there was no one-click button that pulled all of the data to answer whatever question they had at that moment. Data normalization engines and low-code ML environments now resolve some of these issues, turning citizen data science into a boon for businesses that use and allow it, but many manufacturers still have data warehouses full of information with no way to use it.

Scarcity of Talent

While there are many talented individuals in the world, specific types of talent are more in demand now than ever, and supply can’t seem to keep up with demand. In-house data scientists have been a luxury over the last decade, and even those companies who have hired one often find that they are a bottleneck, because they are severely overburdened. Data scientists have largely had a name-your-price option in recent times due to the extreme disparity in supply and demand. Data analysts as well as low-code ML environments have made the process of deploying new algorithms much faster and simpler, but there continues to be a shortage of experts in the field of data science.

Company Culture Lash Back

Major digital transformations can be stressful for employees. Lack of change management procedures have left many companies in chaos as well as many employees afraid that they will lose their jobs to AI or to a robot (although this does not align with the outlook of Industry 5.0). Breaking down silos and requiring interdepartmental cooperation can cause tensions where there was once competition. Company culture has to evolve into an open, innovative, and collaborative place for the benefits of Industry 4.0 to be fully realized, and quick, data-based action instead of long deliberation ultimately wins out in the modern business environment.

Industry 4.0 Technologies

What are the solutions and technologies arriving as part of Industry 4.0 innovations? We have a complete article on 4IR technologies, but here is a quick summary of the top 10:

Big Data & Analytics

This is the massive amount of data collected using sensors, tracking pixels, surveys, and any other data stream, where this data is stored, and the means through which it is analyzed such as using edge computing and machine learning.

Autonomous Robots

These are robots that work on their own, without human input. Using ML, these robots can make on-the-fly decisions and corrections to carry out the tasks they are programmed for.

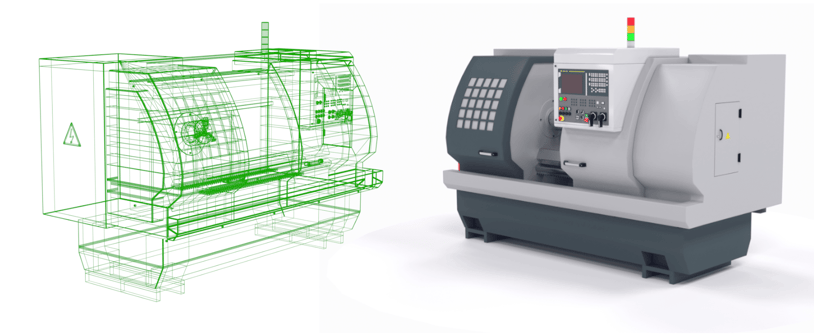

Simulation/Digital Twins

This is a digital version of a system, such as a factory’s production floor. Through the use of sensors on manufacturing equipment and similar digital devices, businesses can see a virtual “twin” of a system that they can then use for analysis, testing, etc.

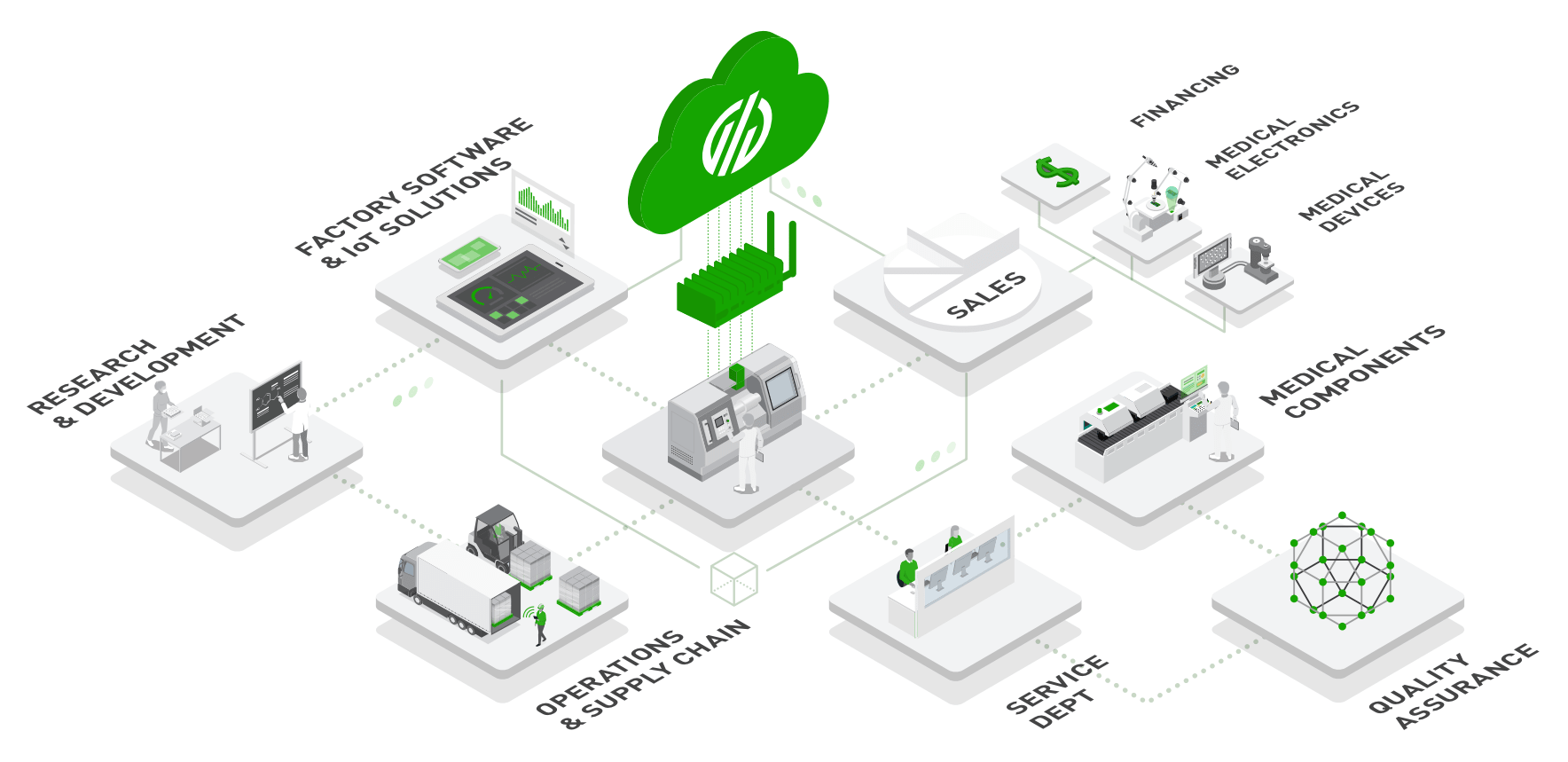

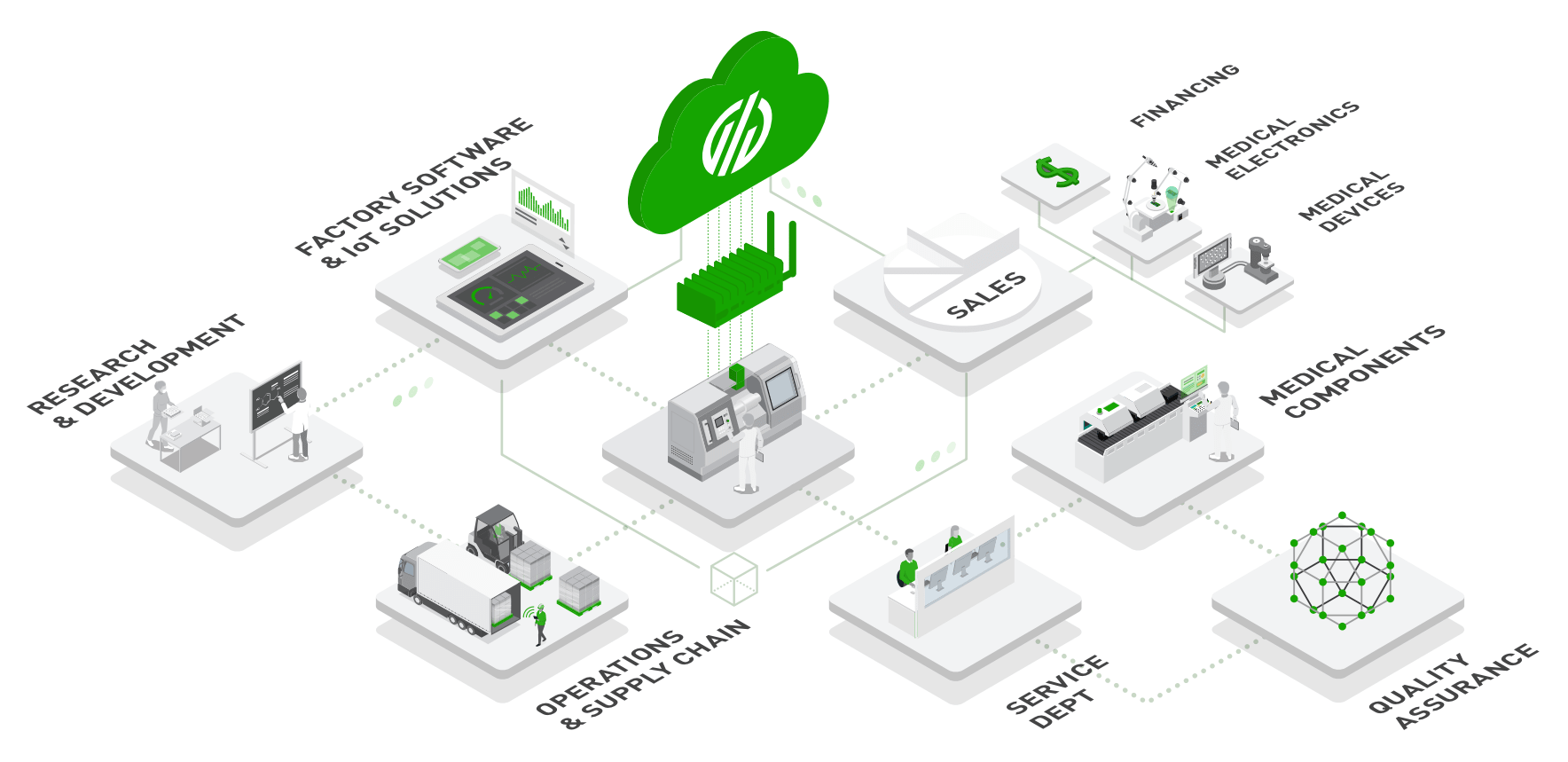

Horizontal and Vertical Systems

This refers to the connectedness of every aspect of a system, both horizontally and vertically, such as departments working together across facilities as well as machine data sharing and interaction between differing levels of seniority.

Industrial IoT (IIoT)

This is any IoT device used in an industrial setting such as a smart HVAC control or a manufacturing machine sensor. The MachineMetrics IIoT Platform transforms your shop floor data from insights into actions with powerful apps that reduce machine downtime, increase your throughput, and maximize profitability driven by your manufacturing equipment.

Cybersecurity Technology

Cybersecurity is critical in IR4 because the influx of machines means an increased number of security vulnerabilities that must be protected.

The Cloud

This is offsite accessible information storage that is usually reached via the internet. It doesn’t require local hardware and can be leveraged by manufacturers to access computer resources on-demand without having to actively manage those resources.

Additive Manufacturing

This is manufacturing that doesn’t take things away through cutting, grinding, etc., but instead adds material to create an object. 3D printing is the most prominent example.

Artificial Intelligence

AI refers to machines that are able to learn and reach conclusions on their own based on forming connections using training data and continuous prediction opportunities.

Augmented Reality

AR refers to the overlay of information on the physical world. Notable examples include Snapchat filters and Pokémon Go, but many use cases exist in the business world as well, especially as it pertains to training and maintenance.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments