Updated: January 21, 2021

Here’s what we will cover in this in-depth article on cloud computing in manufacturing:

An Introduction to Cloud Computing in Manufacturing

Cloud computing is deepening its presence in manufacturing as manufacturers and OEMs increasingly rely on data to guide their decisions. Data collection itself has become more of an expectation than an anomaly on the factory floor. Between IoT-connected industrial machinery, operator interfaces, supplier data, demand forecasting, and a host of other data streams, many businesses find themselves inundated with more data than they know how to utilize. Even best-in-class businesses average about 50% data usage for decision-making, with laggards hitting only 30%.

A major limiting factor to utilizing collected data has been the sheer power it can take to analyze and derive meaning from such vast swaths of data. Many companies who may have installed data collection devices started their analytics journey with in-house data scientists on in-house machines, but have quickly become overwhelmed. Data storage, data backups, offsite backups, data security, on top of the hardware to effectively and quickly use machine learning techniques to derive the most in-depth and accurate insights—these things quickly add up, both in time and money spent.

That’s where the cloud excels. The cloud offers practically limitless data storage at a fraction of the cost of in-house storage. Despite a (now eroding) popular belief, data left with a reputable cloud provider is safer from harm than on an in-house server. Because it is a major factor of their entire business model, not an addition or an aside as it would be in most businesses contemplating using in-house data storage, cloud platforms tend to have more sophisticated storage and deeper protections than those that would be achieved on-site by most businesses. Cloud providers agree to maintain a certain level of security, stay apprised of any known security risks as they evolve, and many can insure businesses against the possibility of a data breach. In terms of physical safety, cloud providers tend to maintain higher redundancy (including off-site copies at another facility in case of fire, flood, or other natural or man-made disasters), so the risk of data loss is notably reduced.

As for computing power, sharing hardware resources using the cloud can afford businesses exponentially more computing power per dollar than in-house machines. Manufacturers are able to gain access to hugely expensive hardware by sharing resources with others over the internet. This enables deep analysis and the use of even complex machine learning techniques on vast amounts of data without bogging down decision-making due to slow hardware. Cloud computing is generally pennies on the dollar compared to buying (and maintaining) in-house equipment with notably higher uptime and ease of use.

For all its benefits which we will cover in more depth in a later portion of this article, there remains one important question to be answered: What is the cloud? The question still rolls around the minds of many who may have a vague notion but haven’t seen it spelled out. Let’s define exactly what the cloud means, especially within the context of manufacturing.

What is Cloud Computing?

Cloud computing is a way to access computer resources on-demand without having to actively manage those resources. Access is usually made via the internet. The types of resources available with cloud computing include computing power and data storage. It’s like having nearly limitless hard drives, GPUs, and CPUs, all of which are well-maintained and up-to-date for a low price that can be accessed from nearly anywhere with better security and uptime than local machines, all without having to hire additional IT staff, buy any equipment, or change any infrastructure as the business scales.

Put simply, cloud computing is about gaining access to top-of-the-line computer resources for a reasonable cost. The business model works for cloud providers because they get increasing ROI on their high-tech offerings the more people they can serve effectively. Basically, everyone wins.

Cloud computing works well alongside edge computing. Cloud computing can take high-frequency data and collect long-term stores of it— far more than would be realistically feasible on-site. It then enables deep analysis of this data that would be too resource-intensive for edge computing scenarios. The combination of the technologies makes for data-led real-time decisions as well as long-term strategic analysis and decision-making.

To understand edge computing it helps to think of an IoT solution as generally having three components:

- Things like IoT devices, which generate sensor data.

- Insights you extract from this data.

- Actions you perform based on these insights to deliver some sort of value.

With cloud computing, you move the insights and actions components from within the manufacturing facility into higher-powered hardware at another location, usually via the internet, but sometimes via satellite or another transmission method. In other words, you can send your data away for storage or analysis so you can act on insights derived from it at a later date.

What is a Cloud Computing Platform?

A Cloud Computing Platform is a solution for offering cloud computing services. One of the most well known cloud platforms available is Amazon Web Services (AWS).

Cloud computing platforms handle workloads that would be too intensive, time-consuming, or (in some scenarios) sensitive to perform using on-site equipment. In an edge computing scenario, high-frequency machine data could be analyzed by edge computing devices to derive real-time insights that can be acted upon immediately—like shutting off a machine with a detected security hazard—while cloud computing can handle the full streams of data that would be too large a burden for an edge system, allowing for storage and deeper insights that can then be passed back down into the manufacturing system, oftentimes even driving responses generated from edge devices.

MachineMetrics is an AWS Industrial Software Competency Partner to ensure the most secure, high-performing, resilient, and efficient cloud infrastructure for industry applications.

Benefits and Use Cases of Cloud Computing in Manufacturing

Many are aware of the affordable data storage solutions presented via the cloud. What you may not know is the flexibility, single-source of truth, customization, and advanced analytical benefits cloud platforms bring to the table for both manufacturers and OEMs.

Starting with OEMs, the journey to building optimized equipment or IIoT hardware which can withstand the harsh environments of factory floors begins with data collection. The data collection process, in this case, focuses on how machines perform in specific environments. The industrial cloud provides a platform for collecting machine data from any and all IoT-enabled equipment your enterprise has ever sold, without running out of space.

The cloud serves as a platform to aggregate these big data sets and to develop advanced algorithms to analyze them. As an OEM, you can then choose to use the insight to develop remote servicing plans, or Data-as-a-Service packages to assist end-users to optimize the use of their equipment. Yet again, cost creeps into the picture.

The cost associated with a cloud solution that never runs out of space is considerably less than what it costs to operate individual on-premise storage facilities. The purchase of a high-performing on premise storage system could cost $100,000, not including the recurrent costs for maintaining the system. On the other hand, a cloud subscription plan would cost many times less and have no overhead costs from upgrades and further enhancements.

The Cloud Platform built for manufacturing brings the best of both worlds to every OEM. These include infinite storage space and a high performing platform for aggregating data, remote machine monitoring, and every IIoT computing requirement your enterprise may need.

From the perspective of a manufacturer, the Cloud offers limitless data storage for tracking production history, getting visibility into operations remotely, and building advanced algorithms to detect machine failures before they happen.

In addition to the above benefits, manufacturers will also experience the below advantages:

Flexibility

Manufacturing activities fluctuate according to customer demand. These fluctuations mean a flexible storage and computing system is required to ensure optimal data collection, analytics, and operations. Cloud platforms offer this resource flexibility to you when adding more production capacity to your shop floor. It also provides a centralized storage location for the multiple facilities you intend to digitize.

Data Security

Digitization brings with it cybersecurity threats that can lead to downtime and data theft. A well-built cloud platform integrates the use of enterprise-grade security management systems to protect your data and reduce security threats.

Backup and Recovery

Data collection and management systems are nearly infallible but not completely. Thus, when errors or incidents that lead to data loss occur it is important that a backup and recovery solution is in place. With the right cloud platform, your machine data stays secure and backed-up against complete data loss.

Automated Upgrades

One feature of Cloud computing is the upgrades and new features that come as part of the package. This includes new applications, security certificates, and communication protocols that are added with every technology upgrade at no additional cost.

Enhanced Customer Support

What many cloud service providers fail to mention, is the learning curve that comes with using new technology. To quickly get started and reap the benefits of the industrial cloud, customer support may be required. Look to vendors that not only have the technology you need, but can help you successfully implement a cloud computing strategy.

The Cloud, The Edge, or Both?

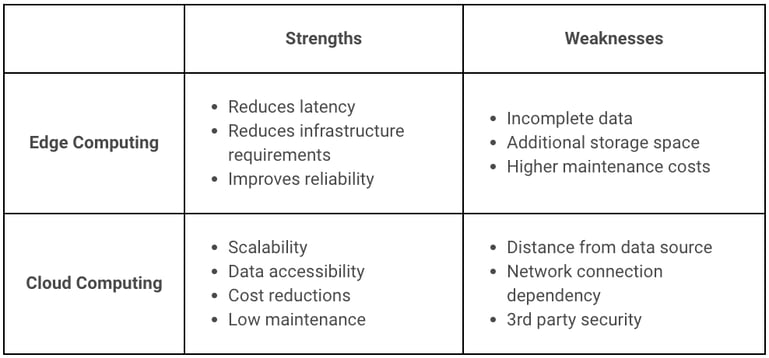

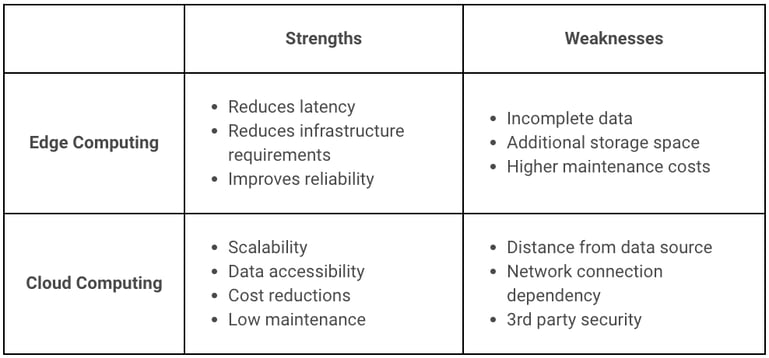

We have a complete article on the difference between cloud computing and edge computing in manufacturing, so we will keep this short.

The cloud and edge are two distinct technologies, but they are often used in tandem due to their offsetting strengths. At the heart of the relationship, edge computing processes and takes action on data that is time sensitive, whereas cloud computing aggregates data in a centralized location that will not need to be acted on in a timely manner.

In a complete IIoT infrastructure, manufacturers can use both the edge for real-time data collection, predictive analytics, and autonomous decision-making, and the cloud for aggregate data analysis, benchmarking, and trend analysis.

These benefits and downsides continue:

How the Connectivity Landscape in Manufacturing is Changing

We know the point of the Industrial IoT is to apply advanced analytics to vast quantities of machine data, all with the aim of reducing unplanned downtime, reducing the overall cost of machine maintenance, and leveraging machine learning capabilities to drive continuous improvement initiatives. The cloud has been instrumental in making this kind of massive data acquisition, transfer, and analysis possible.

While edge computing and analytics take data-led decision-making to a new level of speed and real-time accuracy by reducing the physical distance between the machines and the data processing itself, cloud computing still holds a steady place for long-term storage and deep analysis. For companies that are acquiring data from many sources, the cloud helps:

- Centralize data between machines or even facilities for long-term strategic analysis

- Availability of the analytics to a broader range of businesses and users because information can easily be accessed remotely, as well as by multiple users at the same time

- Availability of computer resources for faster decision-making using even advanced analysis techniques such as those sometimes seen with AI and ML as well as completely scalable storage

- Data security both in terms of breach of privacy and physical protection so that investments in data collection drive positive action with a lower risk of loss or of reputational harm

All of these realities, when dealt with by cloud computing, permit manufacturers to reduce costs and increase efficiency. Cloud computing enables even small run manufacturing with the same value a large scale production would experience. With cloud computing, all of this is available without the need for in-house maintenance or management of the computing devices.

When reaching insights are needed, the cloud is the solution manufacturers should look to. Applying AI and machine learning algorithms to visualize, diagnose, and predict problems is a goal that can be more readily accomplished with affordable, scalable computing resources available. Predictive insights enable teams to create long-term strategies that can evolve with the data as well as allow for quick pivoting when data begins to point toward a different solution. Long-term storage of large libraries of historical data means that your team never has to worry about missing crucial data sources when unforeseen chances for analysis arise.

Industrial manufacturing is on the brink of a revolution thanks to the potential of cloud computing, especially when combined with edge computing. In conjunction with a new generation of smart IoT edge devices, cloud computing applications will completely transform manufacturing in the coming decades to drive better efficiency and productivity while also controlling costs.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments