When we started MachineMetrics, we identified huge gaps in current manufacturing processes: a lack of real-time production visibility and communication between machine operators and their managers. The promise of Industrial IoT is to gain complete transparency and facilitate the connection between people, machines, and processes. 77% of machine shops have plans to install a machine monitoring system in 2017, the very first step in embracing IoT. However, many companies still struggle to embrace a roadmap to digital advancement and very few shops have actually taken this first step.

When we started MachineMetrics, we identified huge gaps in current manufacturing processes: a lack of real-time production visibility and communication between machine operators and their managers. The promise of Industrial IoT is to gain complete transparency and facilitate the connection between people, machines, and processes. 77% of machine shops have plans to install a machine monitoring system in 2017, the very first step in embracing IoT. However, many companies still struggle to embrace a roadmap to digital advancement and very few shops have actually taken this first step.

MachineMetrics has simplified IoT for the shop floor and is empowering manufacturers to develop their roadmap toward manufacturing excellence. Our machine monitoring solution allows factory workers to make smarter, more confident decisions based on real-time data. We collect data from machine controls and machine operators for the entire production floor and use this data to monitor machine conditions (faults, status, tool utilization), production (OEE & Machine Utilization), work-order status, and downtime reasons that can be auto classified or indicated by the operator with touch screen interfaces mounted at the machine tool. With software that's easy to integrate and simple to use, we're driving manufacturing efficiency by more than 20% on average.

They key for systems like this to be useful is simplicity - both in installation and in use. One gateway is required per site. It can be either purchased from us or downloaded and installed on your own hardware. It includes all the software to connect to most machine types with just an ethernet connection, and isolates machines from the public internet. As MachineMetrics is a cloud application, there are no servers to manage, and no applications to update. All that's required that your machines are on your network and accessible from our gateway. We allow you the option to integrate your own machines or to work with our on-site integration team.

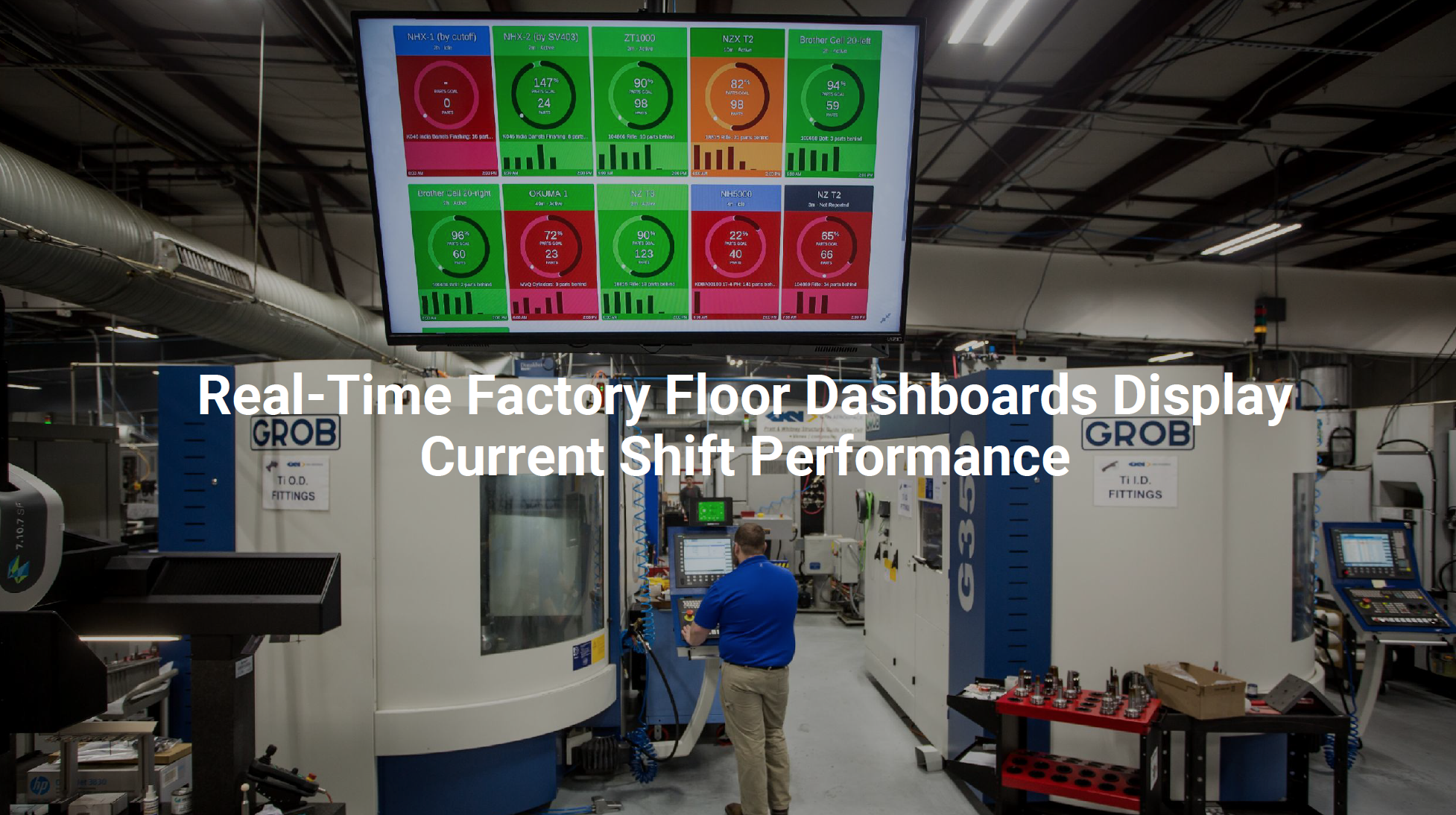

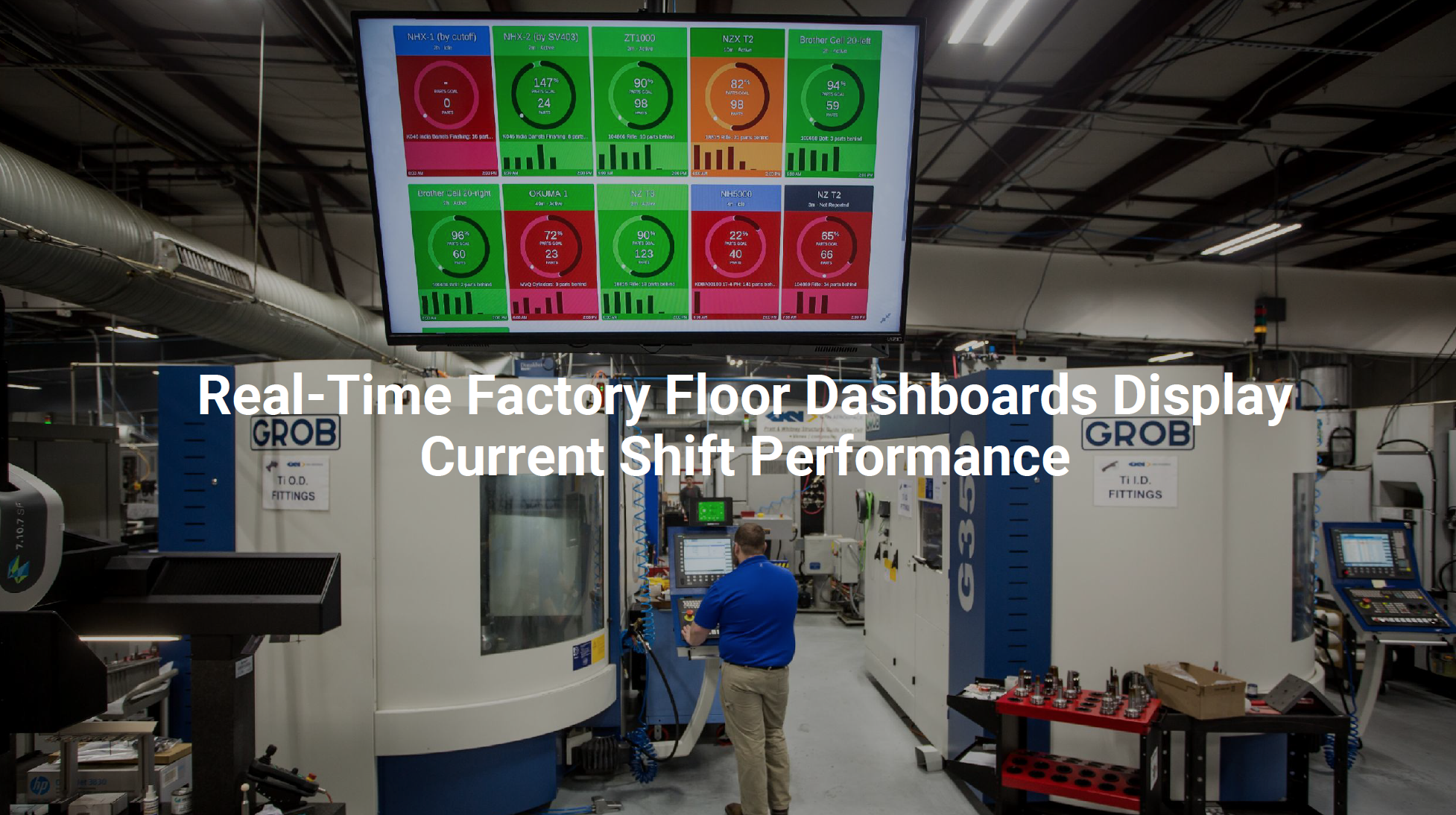

MachineMetrics' cloud-based platform provides real-time dashboards that visualize production data against goals, closing the communication gap between machine operators, managers, and the front office. Our Real-time dashboards are installed in big screen TV's across the shop floor. This data empowers operators to keep their machines running and meeting goals.

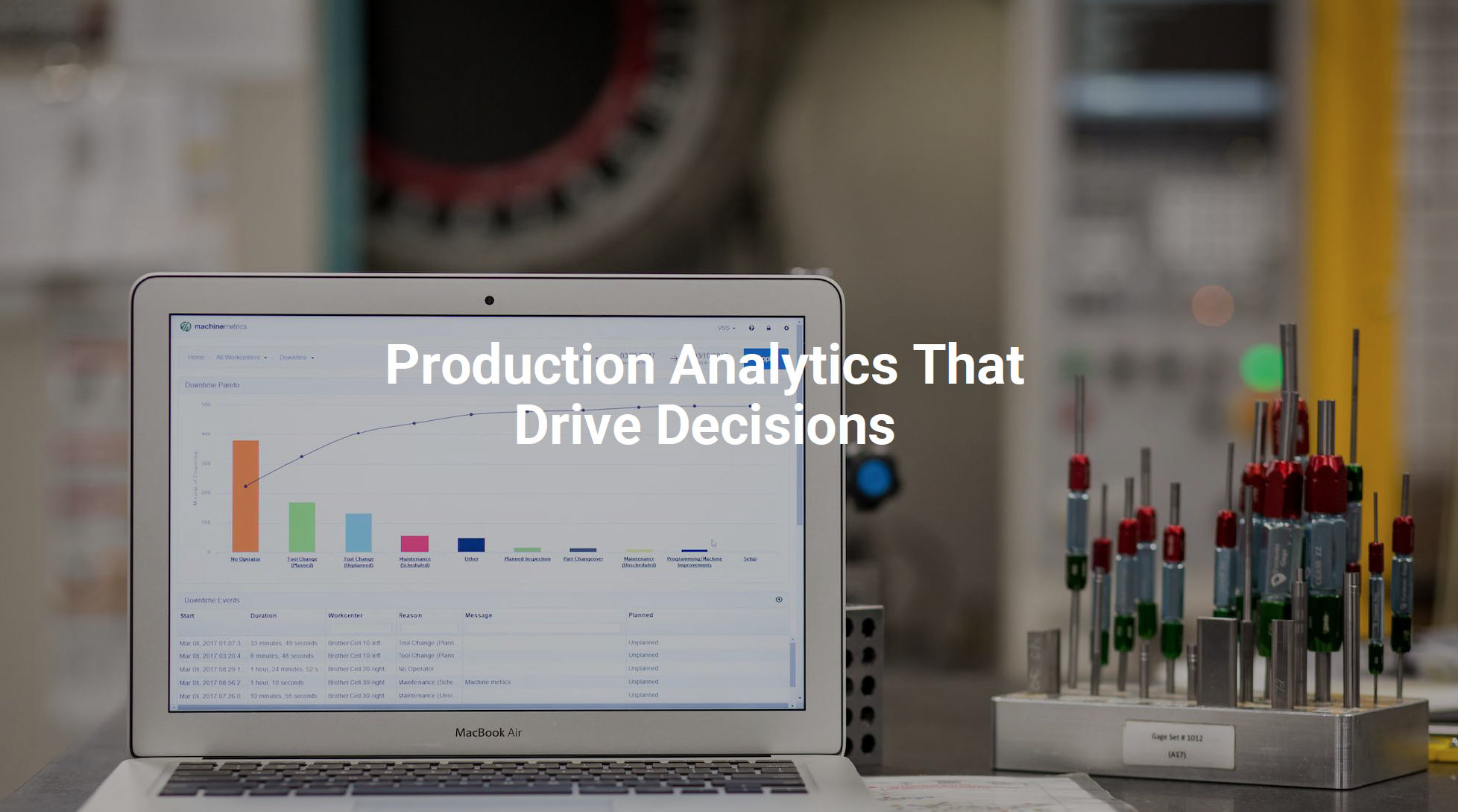

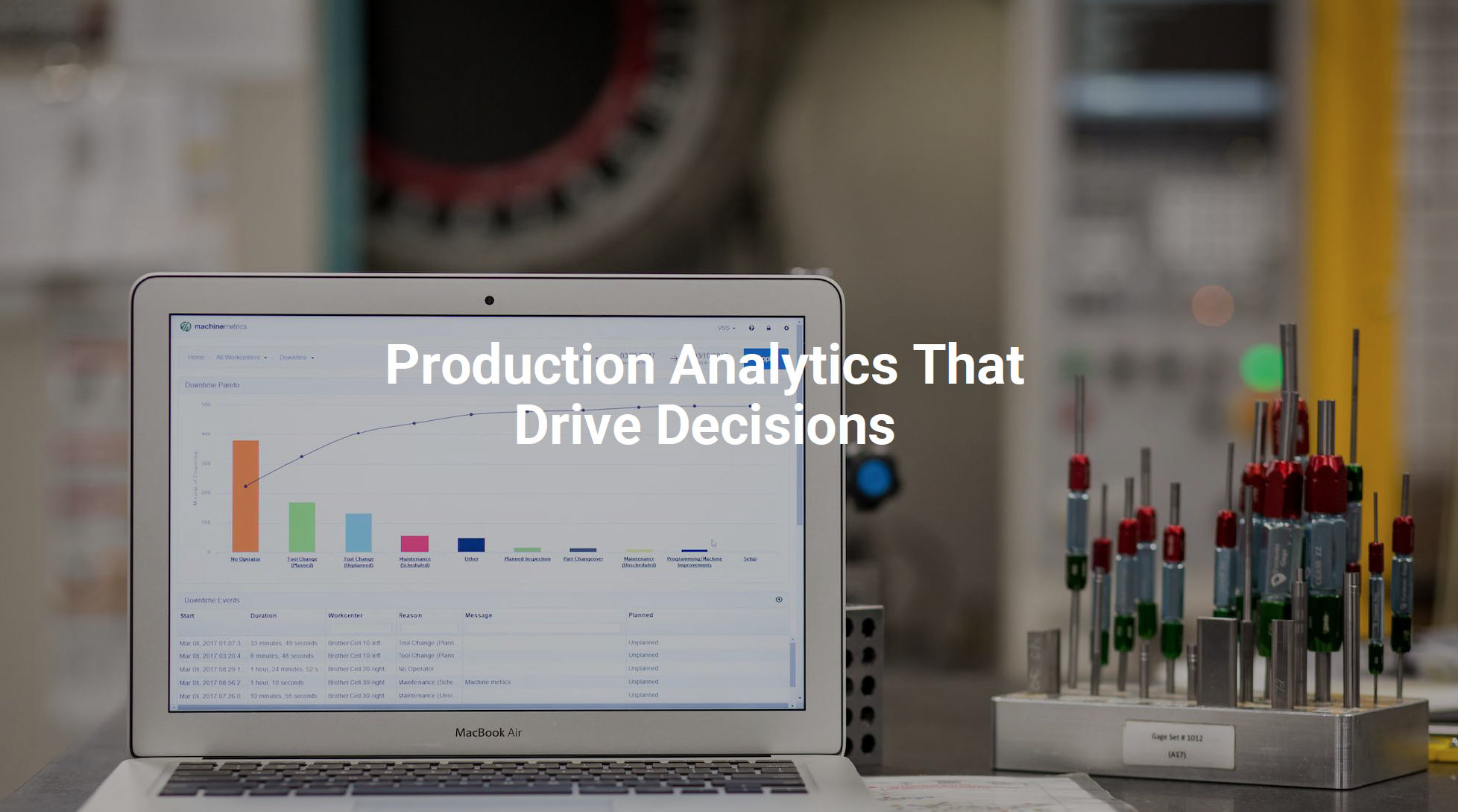

The machine data we collect tells us when the machine is down, and any faults that might have led to it, but the operators are the only ones that know the full context of the machine downtime. Our touchscreen allows for operators to add human-context to this data with touch screen tablet interfaces mounted right at the machine tool. Having a touchscreen at each machine with an intuitive interface that asks the operator to categorize downtime as it's happening allows this information to be made available in real-time to managers in downtime pareto charts. This data empowers operators to keep their machines running and meeting goals.

MachineMetrics provides robust and superior reporting features including better OEE reports, job reports, downtime and quality pareto reports. Real-time OEE is available in various reports including the real-time dashboard, historical reports that can be compared by shift, and when viewing individual job/part reports. Utilization, TEEP and OOE are also measured and visible in historical reports.

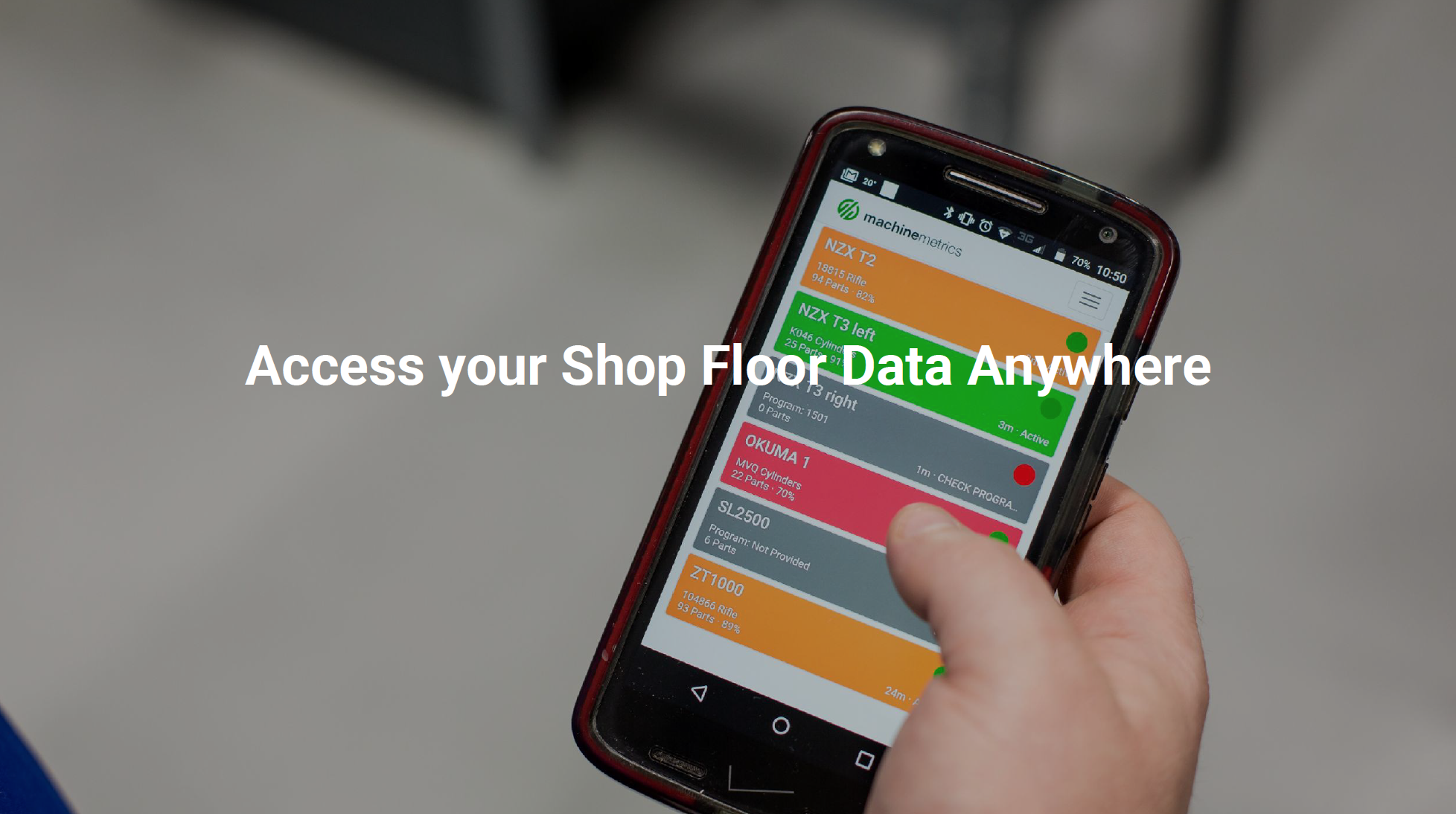

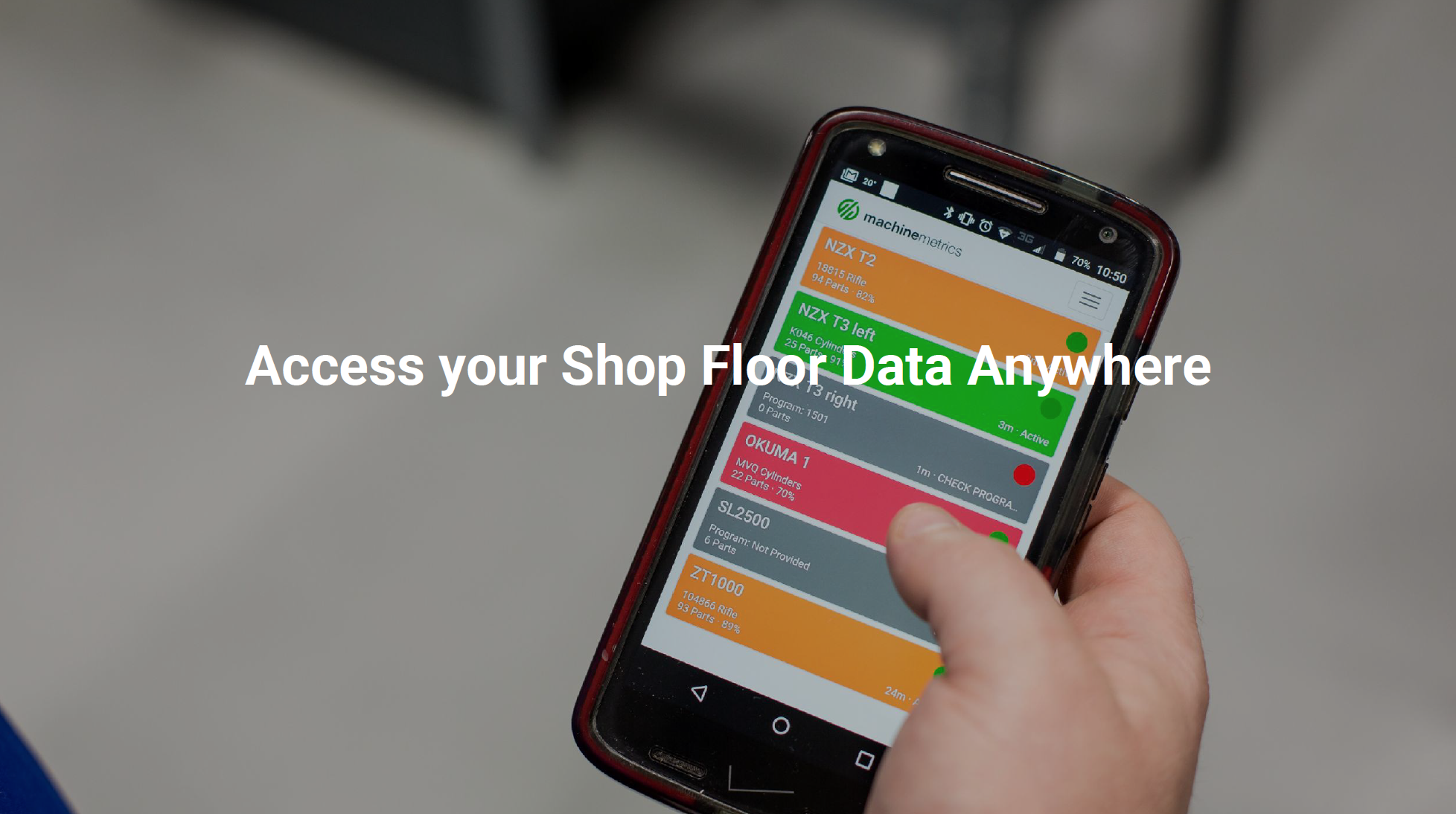

Information such as cycle times, performance, number of parts produced, rejects, downtime reasons, and reject reasons can be reported on for each part operation. This information allows managers to track efficiency and quickly identify production bottlenecks that are related to a specific machining operation and help measure the effect of process improvements. Our mobile friendly software allows you to access your data from anywhere with a secure connection from your mobile phone or home PC without IT support or complicated firewalls and VPNs. We can also roll out new features instantly upon approval.

Because MachineMetrics is cloud-based, there's minimal IT infrastructure is required. We not only provide Full-Time unlimited IT support forever but also every one of our customers has a dedicated customer success manager that, through routine meetings, helps train your team on our software and helps you meet your performance goals.

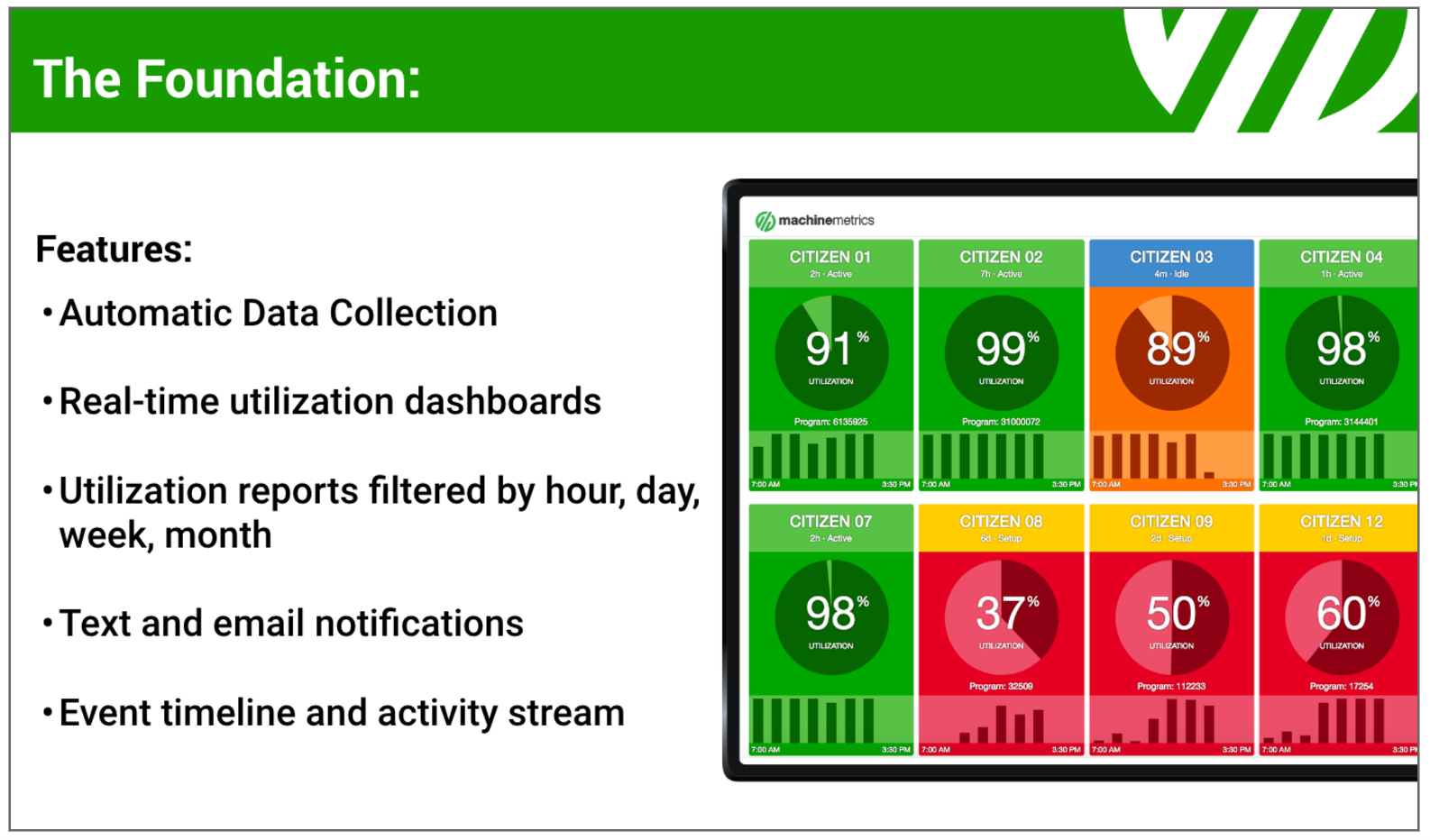

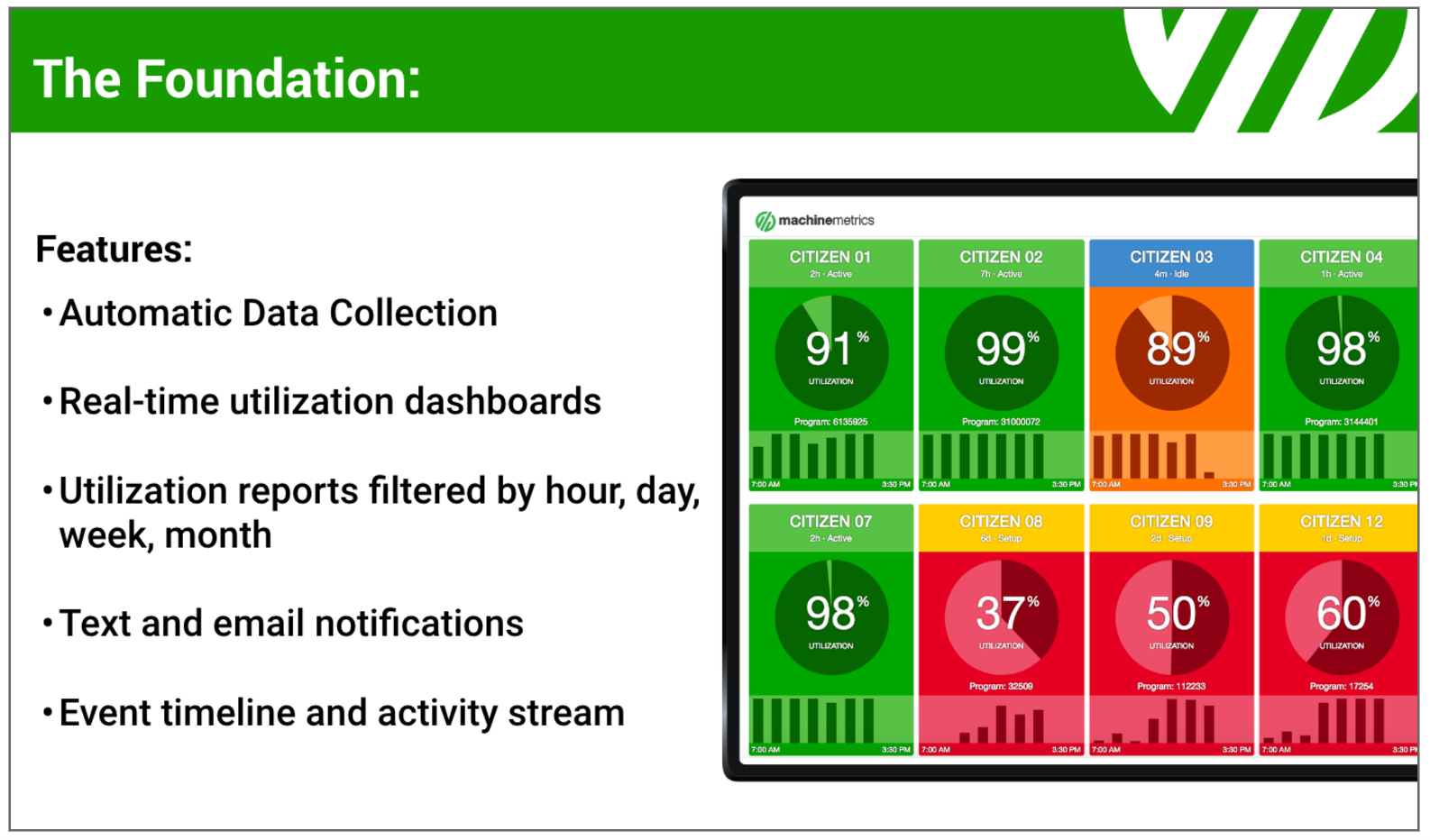

MachineMetrics is available in 2 editions: Our ‘Foundation’ edition allows manufacturers to track utilization rates on their equipment and is a great ‘first step’ into the world of IoT. You’ll receive weekly emails that indicate how your shop performed last week compared with the week before. It’s also a popular option for low volume shops.

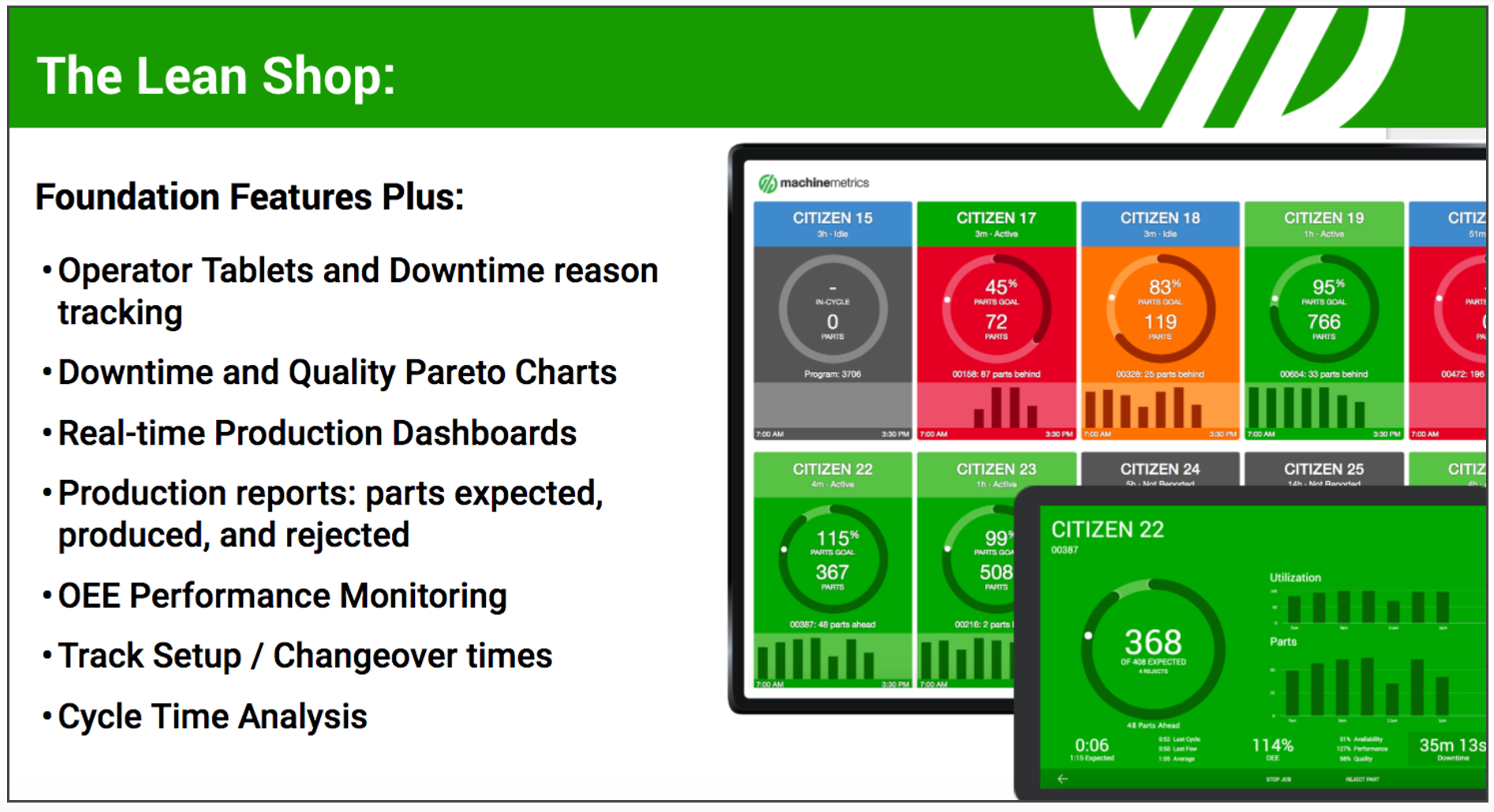

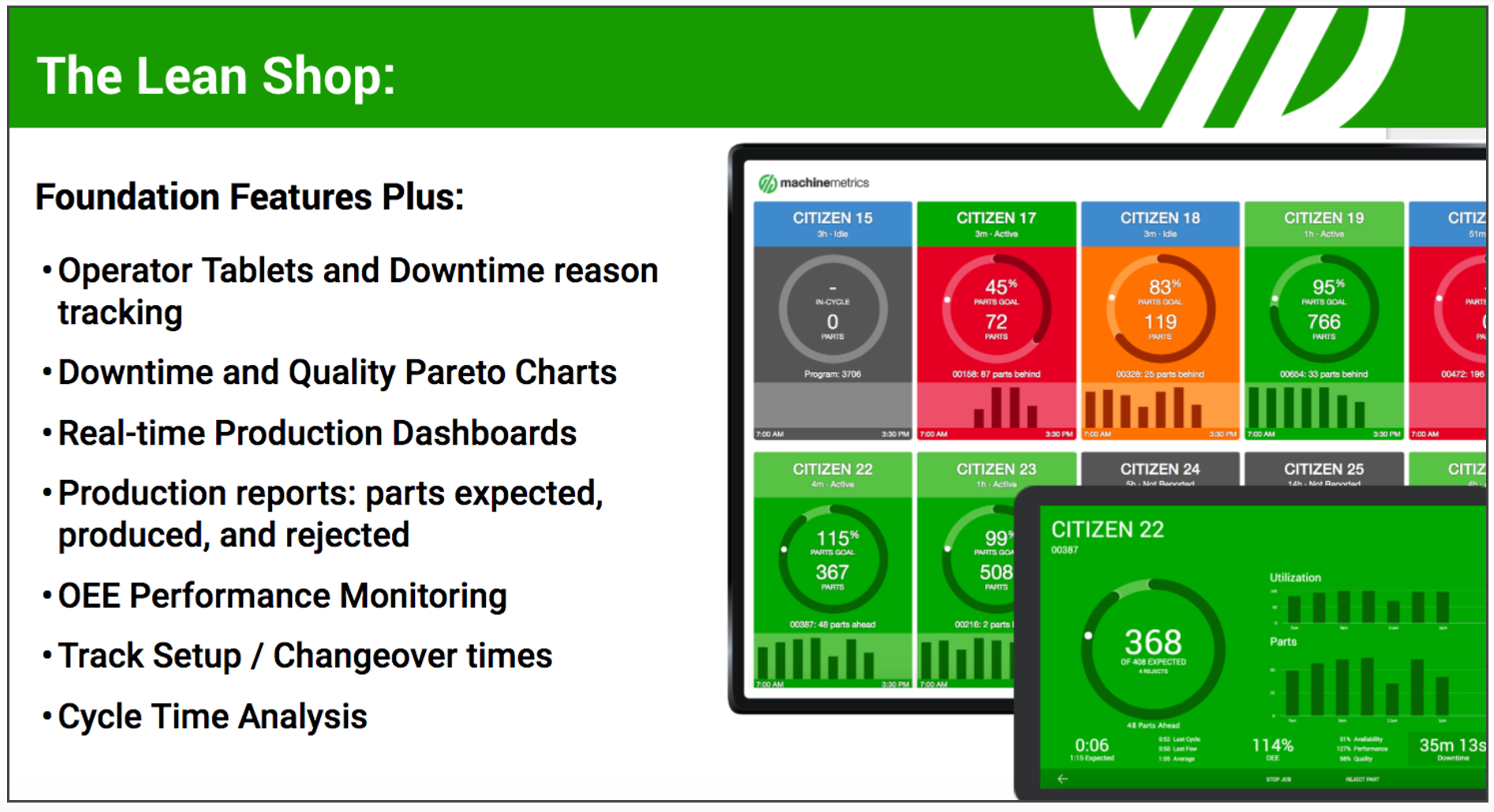

If your team is ready to take full advantage of all our features, our ‘Lean Shop’ edition incorporates all the features from basic but also includes the operator tablet view, downtime reason tracking, downtime and quality pareto charts, real time production dashboard, production reports, OEE Performance monitoring, setup/changeover time tracking, and cycle time analysis

With installing web-enabled shop-wide machine monitoring systems being the first and most important step toward data-driven manufacturing, MachineMetrics is excited to help companies develop a roadmap to digital success and take this initial and crucial step forward into Industry 4.0.

Start monitoring your machines today!

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments