Updated: October 9, 2020

What is Kaizen?

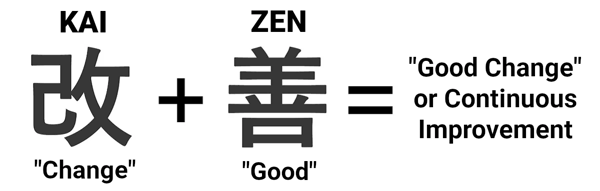

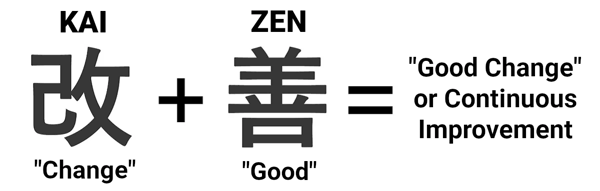

Kaizen, a Sino-Japanese word that means "change for better", is most commonly referred to by lean manufacturers as the practice of "continuous improvement." Kaizen is an approach to manufacturing honed and perfected by many Japanese manufacturers in the 1960s and 1970s that eventually lead to the global rise of Japanese automobile manufacturers and their reputation for quality. Toyota's approach to manufacturing is a prime example of Kaizen in action. Why is Kaizen of interest to lean manufacturers? The phrase "lean manufacturing" defines an approach to manufacturing that focuses on eliminating waste and also improving and focusing on quality.

Why Kaizen, Why Now?

Below, we will outline exactly how your machine shop can implement kaizen. First, let's discuss for a moment why you should even bother with kaizen. Some large American manufacturers have struggled in implementing kaizen. Most famously, General Motors opened NUMMI, an automobile manufacturing plant Fremont, CA, in collaboration with Toyota. Despite the overnight change in quality - by every measurement - General Motors was unable or unwilling to quickly change its entire manufacturing supply chain to adopt the lessons learned at NUMMI.

Many manufacturing and industry experts point to General Motors lack of adoption as one of the primary reasons that eventually led to the company's record-breaking bankruptcy. Recently, the popular This American Life radio show devoted an entire show to the NUMMI experience and is well worth the listen for anyone interested in Kaizen and lean manufacturing.

Most manufacturers and machine shop owners tend to operate their businesses by feast or famine. Either they're drowning in work and can't find enough good help. Or there's no work, and workers are laid off. When the work is overflowing, it's hard to make the argument to devote precious time and resources to kaizen -- in effect, slowing down your processes to examine each manufacturing step in minute detail to look for additional time and cost savings. However, we'd argue that kaizen rigorously and continually applied in your small-to-medium-sized machine shop can actually steer your business away from feast or famine. Implementing kaizen can improve your efficiency and allow your shop to manufacture even more products or parts. And, if you can benchmark manufacturing quality and efficiency, you have a much greater chance of winning supply contracts.

Jump to a particular section:

How to Implement Kaizen

Lean manufacturers can implement Kaizen in two ways: Daily Kaizen and Kaizen Events.

Daily Kaizen

Daily Kaizen embraces the core concept of Kaizen - continuous improvement. Workers and managers empowered and encouraged to continually improve processes are practicing Kaizen on a daily basis. They're continually vigilant and constantly question workflows and production processes. Can a small change today speed up or improve production? Once that change has been implemented are there ripple effects? Can additional changes create a small percentage of improvement - even less than a 1%? If we make this one change to our workflow, will it improve the overall production process?

Over time, if a machine shop practices Daily Kaizen, every aspect of the shop's workflow will be questioned, analyzed, and researched. Those small, teeny-tiny changes and improvements (Daily Kaizen) searched for and implemented on a daily basis lead to efficient and lean manufacturing. By offering a visual dashboard of historical performance of machines in small and medium-sized machine shops, MachineMetrics is a tool that lends itself well to Daily Kaizen and Kaizen events. In addition to machine operators and managers intuitively knowing the performance of their machines, MachineMetrics offers easy-to-understand visual charts and graphics mapping the efficiency and workflow of an entire machine shop and each individual machine.

Kaizen Events

Most small and medium-sized manufacturers that utilize Kaizen use Daily Kaizen to make continuous improvements. However, Kaizen events can also be used to tackle a persistent manufacturing or workflow problem. Kaizen events are akin to the popular hackathons that many digital startups organize. A group of managers and workers organize to study a known problem in the machine shop's manufacturing process and then brainstorm potential solutions. Kaizen events usually follow a similar format:

- Participants identify and quantify a problem in the machine shop

- Brainstorm potential improvements

- Implement improvements, and then measure the new workflow or quality

- Report final results, and then determine any additional changes that can be implemented immediately or gradually related to the initial problem

While Daily Kaizen improvements can lead to long-range improvements in quality and efficiency for machine shops, Kaizen events can be useful too. A team can often brainstorm innovative improvements that might be missed in the daily kaizen process.

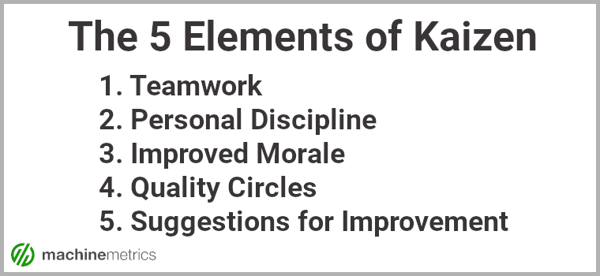

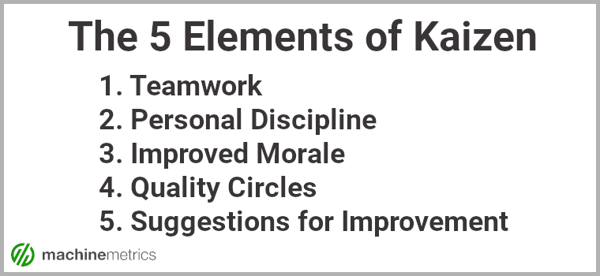

The 5 Elements of Kaizen

Below are the 5 key founding elements of the Kaizen philosophy. In order for Kaizen to be successfully implemented, each of these elements are required:

- Teamwork

- Personal Discipline

- Improved Morale

- Quality Circles

- Suggestions for Improvement

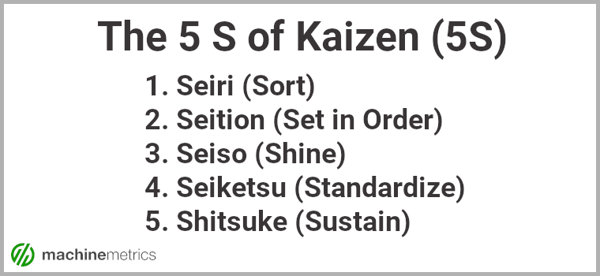

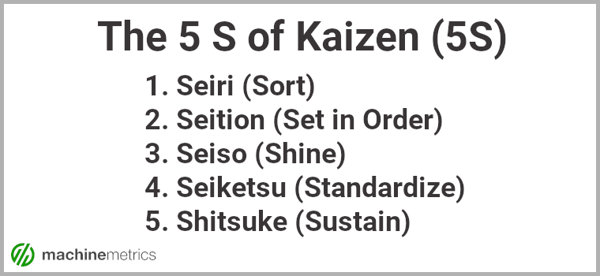

The Five S of Kaizen (5s)

The Five S of Kaizen stress structure, order, cleanliness, standardization, and sustaining of process.

- Seiri (Sort)

- Seition (Set in Order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain)

The First S: Seiri (Sort)

The First S, Seiri has an objective of removing any unnecessary or unsorted objects within the workplace. It stresses a workspace for employees that is removed of any distractions.

The Second S: Seition (Set in Order)

The perfect transition from Seiri, Seition means "to set in order." During this stage, your team organizes all the objects so that they are in their correct place for action. By now, all unnecessary objects are gone and all the tools you need are in the right place.

The Third S: Seiso (Shine)

Seiso urges manufacturers to maintain a clean shop floor. At this stage, not only should a workspace be free of clutter, but also well-organized and properly cleaned.

The Fourth S: Seiketsu (Standardize)

Standardization simply means that the rigorously defined processes that are discovered remain intact and are followed. This means there must be s trict adherence of all employees to the rules and processes outlined.

The Fifth S: Shitsuke (Sustain)

To achieve a successful continuous improvement approach, manufacturers mist retain all the knowledge acquired as well as the processes that are of the highest efficiency. This requires a fair amount of discipline, but the habits will pay dividends.

The Benefits of Kaizen

Cutting Waste

Perhaps the most important element here, finding areas to improve efficiency naturally leads to a reduction in waste. This waste could take many forms including a reduction in scrap parts, less downtime, and less unnecessary motion.

Improved Customer Satisfaction

A Kaizen-led operation will produce products in a more predictable fashion, which means that delivery rates will be higher, resulting in higher satisfaction (and loyalty) among customers.

Higher Productivity

Given the reduction in waste, the operation will naturally be more efficiency, having a higher utilization rate among equipment and staff.

Happier, More Productive Employees

With the first element of Kaizen being teamwork, it is not surprising how important it is for all employees to adopt the Kaizen approach. With such a program in place, all staff is openly contributing to continuous improvement.

Taking the Next Steps Forward with Your Operational Efficiency

Learn how you can leverage the Industrial IoT to take your Kaizen program to the next level and drive even greater operational efficiency:

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments