Efficient software platforms that integrate seamlessly with one another are critical to modern manufacturing. Without them, companies must rely on outdated, archaic, standalone software or manual data collection and analysis that lower productivity and impact competitiveness.

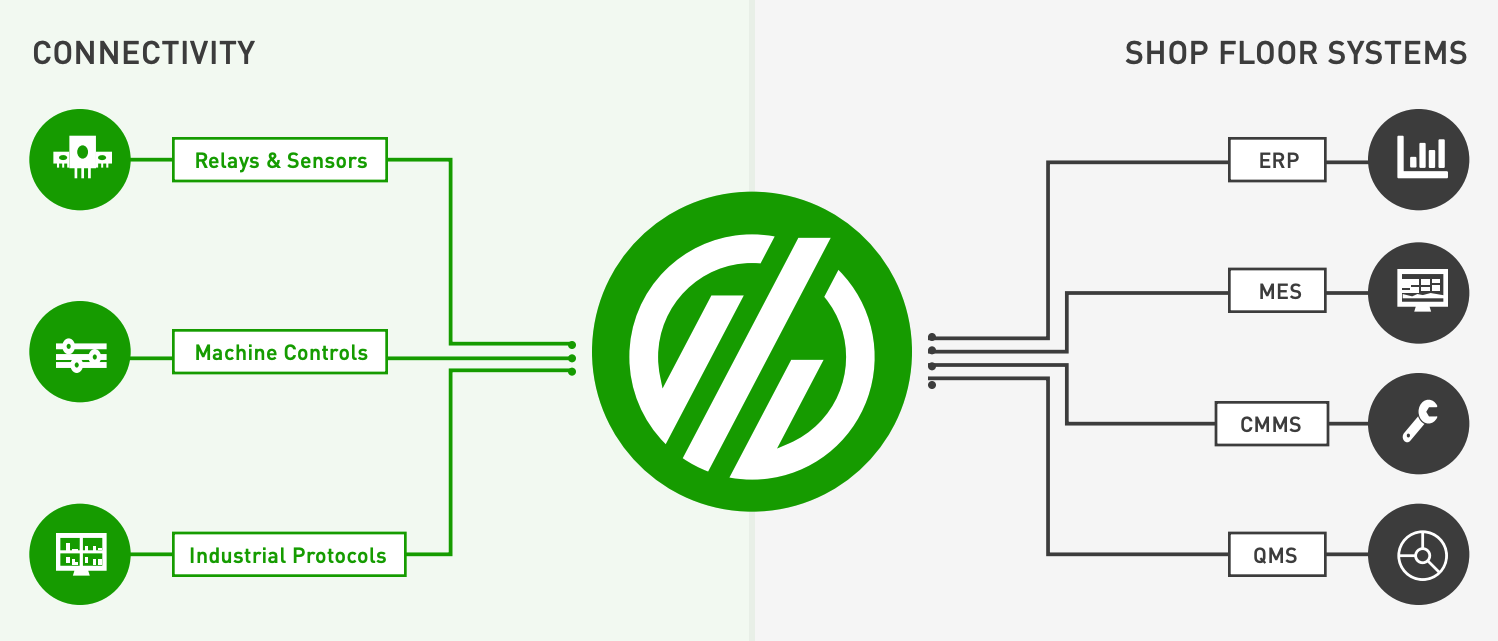

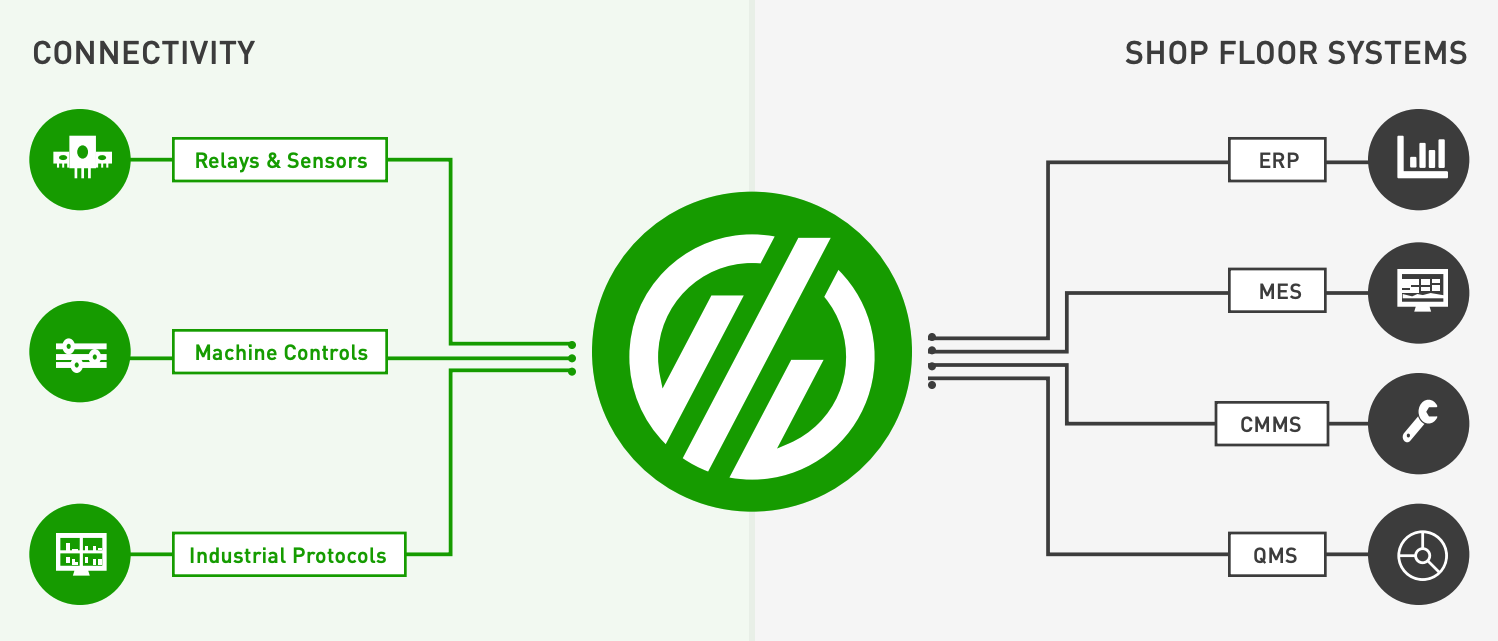

Leveraging the power of your machine data to increase efficiency and reduce costs is crucial to staying competitive today. MachineMetrics’ platform is flexible and can connect directly to other enterprise software such as CMMS and BI tools, supplying these systems with accurate, real-time production data. This data value is enhanced even further when connected to an ERP platform.

Which should you implement first? Here are the benefits of both systems and how adding machine monitoring first can enhance the potential of your ERP.

Machine Monitoring vs. ERP

In today's dynamic manufacturing landscape, two key system implementations often come into play: Machine monitoring and ERP (Enterprise Resource Planning) systems. The first involves collecting, processing, and analyzing production data to offer invaluable insights and enhance operational efficiency and productivity.

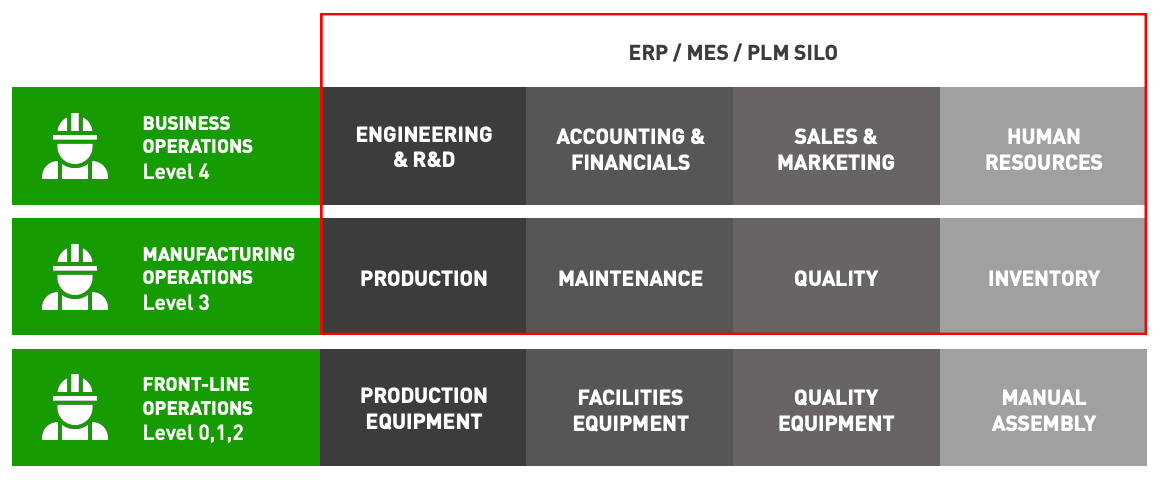

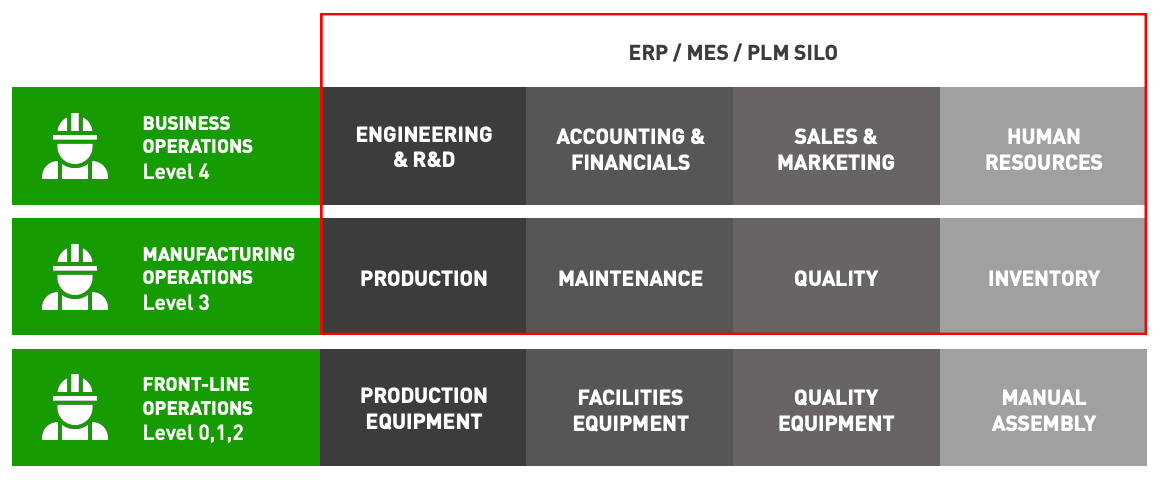

On the other hand, ERP systems manage core business processes across finance, supply chain, and manufacturing. However, legacy ERP and MES systems struggle with capturing data from the many functions that these systems attempt to manage. While financial data may be highly accurate, production data is often inaccurate, delayed, or altogether missing.

Production monitoring platforms ensure that this key source of information reaches the ERP, enabling the core functions of the system to rely on truly accurate production data.

The Benefits of ERP Systems

ERP systems offer a multitude of advantages for manufacturers. Primarily, they facilitate comprehensive oversight of your organization's various operations. They enable easier decision-making and streamline business processes by unifying the data from different departments into one platform.

They can also help you manage inventory better, reducing warehousing costs and out-of-stock instances. Additionally, an ERP system's capacity for accurate forecasting can significantly reduce production lead times. More precise data about customer trends and behaviors will allow you to plan your production cycles more effectively, avoiding waste and improving customer satisfaction.

ERP systems can integrate financial management processes, enabling better cash flow management and forecasting. With this level of operational visibility, you can make more informed decisions, boosting productivity and profitability.

However, ERP systems have a variety of critical failures. Perhaps the most significant failure is the lack of accurate, real-time data from the shop floor. Manual systems are inherently error-prone and subject to bias. This forces people to collect, collate, and analyze the data.

In addition to the time it takes (time that could be better spent operating machines), the data is far less reliable (or altogether nonexistent) compared to automated solutions.

The Need for Actionable Data

Today, accurate and actionable data is more than just valuable—it’s indispensable. Machine analytics shines a spotlight in this regard, offering real-time and historical data on the performance of the shop floor across multiple dimensions.

With MachineMetrics, highly important contextual data, like operational information, can also be captured (without any data entry from operators). This allows users to dive into every dimension of their production, slicing across machines, operators, cells, dates, and operations to analyze part counts, utilization, OEE, speeds + feeds, machine conditions, and more.

The platform enables actionability on this data as well, not only in the form of shop floor dashboards and in-depth reports, but also notifications, workflows, and integrations to ensure your team has the information it needs to make decisions and also to ensure your systems (like ERP) have the accurate data to execute their functions properly.

Starting with Machine Data

Although both ERP and machine monitoring bring significant benefits, it makes sense for most manufacturers to implement machine monitoring first. The rationale is rooted in the transformative power of data.

This data is not just about highlighting what's happening; it's about understanding why it's happening, thus providing actionable insights for significant operational efficiency improvement.

The generated data is a reliable foundation for ERP systems, enabling effective decision-making and strategic planning. When the ERP system comes into play, it can hit the ground running, fortified with accurate, real-time data from inception.

How is MachineMetrics taking your ERP or MES to the next level?

Data Collection and Aggregation

Manual data collection is slow, error-prone, and subject to bias or omission. MachineMetrics automates data collection and standardization so MES/ERP can consume and use the information. The insights generated by a real-time machine data platform let managers make better decisions, take immediate action, and automate processes instead of painstakingly collecting and analyzing data.

Resource Management

How much material, labor, and machines are needed? Can you take on a new customer right now? How many more parts do you need to produce this month? What is the cycle time of the newest process? There are a lot of questions that need to be answered. Accurate production data highlights bottlenecks and capacity constraints to allocate your resources accordingly, and justify adding additional capabilities.

Scheduling and Planning

With a documented record of cycle times, part counts, and quality rejects, planning teams can better project the necessary people and machines to meet expected demand. As the data can be ingested by the scheduling application in real-time, it can be adjusted based on current performance and extenuating circumstances.

Production Performance Analysis

MES/ERP allow managers to carry out work and understand production performance. But the capability is only as good as the data that goes in. Manual data, missing data, or siloed and unstructured data mean that the output of an MES will lack accuracy. Downtime, cycle time, capacity, quality, and other variables can be captured and used in an MES as a true reflection of the factory floor, enabling a digital thread that ties production performance to the bottom-line performance of the business.

The Core of ERP Success

The synergy between an ERP system and machine monitoring cannot be overstated. The former sets the stage by organizing data and making it accessible across the organization, while the latter feeds into it with real-time, machine-level data.

The move to connected factories and data-driven manufacturing is well underway. If you plan to add or upgrade your ERP, consider adding machine monitoring capabilities first. This will deliver more value to your immediate and long-term efforts and help you get your ERP implementation journey on the right foot.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments