The Blurring of IT and OT Leads to Operational Visibility

Information technology (IT) has been a critical component in the success of manufacturing companies for decades. With it, companies have improved processes and added automation that tapped into the best technology available.

But technology is on the move, and the extensibility of data from the machinery and equipment that runs industrial control systems in the form of operational technology, or OT, has caught up with IT systems.

Combined with the Industrial Internet of Things (II0T), the ability to collect data and control physical devices on industrial equipment has revolutionized the concept of manufacturing, enabling deep visibility across operations.

Within this article, we explain the concepts of IT and OT, and discuss the primary differences among IT vs. OT systems, devices, and security.

What is Operational Technology?

Operational technology refers to the collection of hardware and software used to control physical devices. It can be configured to trigger, control, monitor, and send data to an IT system.

As manufacturing OEM equipment changed over the decades to include more embedded technology, automation, and monitoring capabilities, operational technology has changed too. In the past, manufacturing equipment often used mechanical means to adjust devices and run manual counters for monitoring.

Data acquisition usually needed to be manually entered into other systems for analysis, creating a time delay and opening the door for error. Most early OT systems such as Manufacturing Execution Systems (MES), Supervisory Control and Data Acquisition (SCADA), and others weren’t networked. The few with digital capability often used proprietary protocols in a closed system, making data siloed and reducing its value.

| Legacy systems that manufacturers have long relied on to manage their operations, such as MES and ERP, are ill-equipped to meet their needs due to bloated and unspecialized capabilities, rigid architectures that stifle innovation, and an over-reliance on manual data entry and processes. Read our latest report: The Death of MES and the Rise of Data-Driven Manufacturing Automation |

As advances have been made in computing, advanced OT systems have helped OT devices become linked in a complex network of computer systems that monitor events. With IIoT and the broader Industry 4.0 technologies, OT and IT lines are working to create highly accurate factory monitoring systems.

Today, OT networks allow companies to use edge devices and IoT sensors to control physical devices and monitor equipment at the spindle, machine, shift, or factory level.

This real-time capability allows advanced software platforms to analyze data much faster than human operators could, and at a far higher degree of accuracy. These platforms are highly configurable and can work with user-defined configurations and parameters.

What is Information Technology?

Information technology refers to an extensive collection of data storage devices like servers and software, network hardware such as cables and switches, and communication devices and protocols.

IT networks and IT devices work together to store, control, and deliver information, typically handling data for business applications. ERP and MRP systems are examples of software used in IT. These types of software work at the macro level to control plans, calculations, and other high-level functions used to make business decisions or manage industrial processes from a coordinated level.

Because these systems are hardware intensive, they’re expensive to maintain. And because they focused on allowing a “roadway” for handling information and not analyzing it, data from financial programs, ERP, and MRP were often siloed. In addition, the system suffered from interoperability issues.

Today, most companies use cloud-based networks, reducing the cost and training required to manage systems. But security concerns, fear of adoption, or lack of resources mean that there are still many legacy or hybrid cloud/in-house systems out there.

What's the Difference Between IT and OT?

The primary difference between IT and OT is how data is used. IT is more focused on broad business needs. This means it deals with transactions, voice communication, data storage – often in unstructured databases – and other meta-level data needs.

By contrast, OT deals with machine-driven data meant to be consumed in real-time at the user or manager level. This data comes from the control of physical devices through digital technologies such as software with advanced analytics engines dedicated to optimizing processes.

The essential relationship of IT and OT is like that of a water system. IT serves as a reservoir to hold the water and deliver it through massive infrastructures of pipes to towns, businesses, and other holding facilities. OT is the collection of pressure pumps, faucets, pressure gauges, and other systems that work at the device level to deliver the water in the format needed for end-use.

IT vs. OT Device Specification

Early IT interaction with machines was primarily used to gather data in a one-way manner. Data was collected and sent to in-house servers to be accessed by programs like ERP systems. As machine automation grew, the heavy use of programmable logic controllers (PLC) meant that there was often some degree of interaction with a programmed device that triggered an action. But monitoring was limited to capturing - and not controlling - machines.

These devices, like PLCs, required on-site or PC-based programming and often used closed communications protocols limiting the use of other devices on the network. IT devices were also limited by a trunk and node system that capped the number of PLCs.

The MachineMetrics Edge device connects to a PLC to collect data, standardize the information, and send it to the cloud. This is an example of the overlap of OT and IT, as the operational technology data can now be consumed in cloud-based applications, such as an ERP or MES. MachineMetrics helps to bridge this gap, ensuring complete visibility of the shop floor.

The MachineMetrics Edge device connects to a PLC to collect data, standardize the information, and send it to the cloud. This is an example of the overlap of OT and IT, as the operational technology data can now be consumed in cloud-based applications, such as an ERP or MES. MachineMetrics helps to bridge this gap, ensuring complete visibility of the shop floor.

Adopting the EtherNet/IP protocol and creating open-source protocols such as DeviceNet and ControlNet meant that OT devices from different vendors could be configured to allow faster, real-time data collection.

This device transformation has advanced, along with IIoT technology, the move to cloud-based IT, and the arrival of Big Data through AI and ML to bring IT and OT closer together. Now, rather than two systems that can’t effectively operate and communicate together, IT and OT are best viewed as “layers.” These layers consist of business functions and machine data layers, with OT working with IIoT technologies.

As they’re meant to move data without other requirements, IT devices are often more straightforward to maintain than OT devices. They may also have a shorter lifespan and operate with standard OS systems such as Windows or Linux.

OT devices have specific purposes for control and data acquisition. Because they’re critical to safety and machine condition, they’re very reliable and can operate around the clock for many years without failure or replacement. OT devices are also smaller and more modular to integrate into a production machine. They may also be ruggedized to withstand heat, moisture, vibration, and other wear and tear that IT devices cannot handle.

Most OT devices have a variety of network interfaces and communication protocols not used in IT. This includes Modbus, CIP, and Profinet. This variety allows them to work with most of today’s IoT applications seamlessly.

What are the Main Distinctions Between IT and OT?

IT focuses on the fact that there is data, and OT focuses on what it means and how it can optimally drive connected assets. Other critical distinctions between IT and OT include:

- Device Maturity: The technology for IT devices is long-established. It’s simpler and easier to manufacture. OT devices represent a constantly changing collection that works to keep pace with new advances in digital technologies. As this cross-field communication requirement between the two increases, it will be critical for IT teams and OT departments to work together to program a converged system for optimization.

- Cost: Many companies with legacy IT networks balk at the expense of another CAPEX undertaking that carries with it a significant learning curve for new technology. Having invested in cables, servicers, fiber, and skillsets, some are wary of the move to the cloud, much less OT and industrial IoT. But entry costs to both OT devices and industrial IoT platforms have dropped significantly. And when combined with productivity gains and lower total cost of ownership over time, the ROI for cloud-based machine monitoring devices and platforms is considerably lower than long-term maintenance of traditional IT.

- Data Management: OT focuses on the processing of data in real-time. Because it’s centered on machine status and condition, it includes different data types like monitoring data, control and data acquisition, and supervisory data. IT focuses on transactional data that may consist of office communication, video processing, and large chunks of unstructured data.

- Safety: If an IT device fails, the most significant effect is data loss that could affect the business. However, because OT monitors physical assets, it can help prevent costly catastrophic machine failure.

IT vs. OT Security Threats

IT has always been security conscious, and companies have invested a lot in securing their networks. These concerns were multiplied when businesses began to move IT functionality to the cloud. However, cloud-based security has become significantly more robust. Today, the greatest threat to the IT side is the same as when networks were in-house; passwords, access, and authorization protocols are a more significant threat to cloud-based data than attacks.

OT began as disconnected from the outside world. But with the rise of IoT in the Fourth Industrial Revolution, OT devices became more vulnerable to external attack. Many OT security initiatives focus on the application layer to control access. In contrast, IT looks to secure enterprise data to protect employee safety and ensure the continuous operation of connected assets.

Security threats will continue, challenging OT teams with more advanced attacks. But as lines blur in IT and OT, many of the security changes will be designed in layers with different protocols to protect different system levels.

What is IT and OT Convergence?

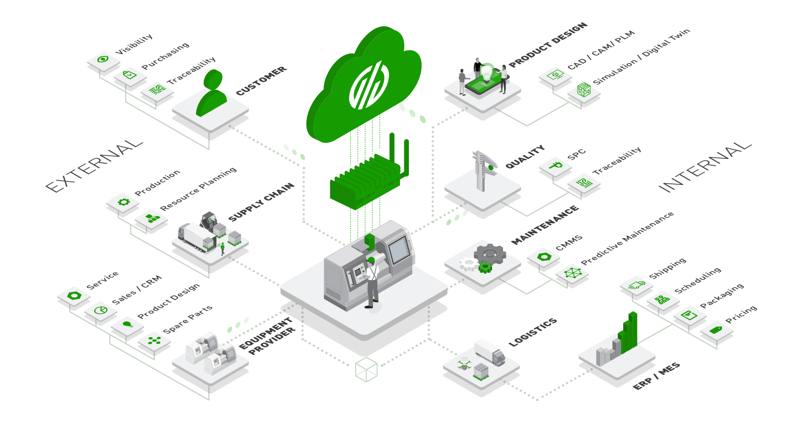

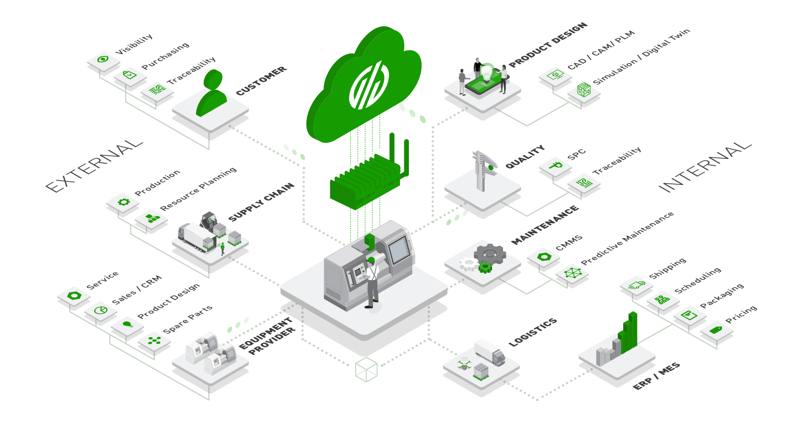

IT and OT convergence represent a unified system that offers comprehensive data management, monitoring, and control. With agnostic and open device and IoT platforms like MachineMetrics, companies can leverage the best of their assets without additional costly infrastructure.

Such systems can work with legacy IT for in-house or cloud-based platforms. Monitoring and controlling industrial assets at the operational level feed data to the enterprise level IT functionality, and both benefit from advanced analytics, AI, and machine learning algorithms.

The result is a streamlined system offering a single version of truth for companies utilizing IIoT technology. Efficiency, inventory control, supply chain, quality, and other critical functions for production are optimized for the most efficient process using real-time data.

How Does IoT Bring IT and OT Closer Together?

The introduction of industrial IoT offers the chance to bring the machine and factory-focused functions of OT together with the enterprise functionality of IT. It’s best thought of as a bridge, linking the two with devices and data generated at the edge.

Because IoT technology is flexible in design and function, devices such as those offered by MachineMetrics can fit analog equipment and newer OEM equipment. This means companies can link system acquisition costs and measure ROI together rather than choose an either/or.

IoT also bridges Information Technology and Operational Technology with the lure of interoperability. APIs and flexible software mean data is un-siloed and available to all users.

Benefits of IT and OT Convergence

Combining these two data management systems has many advantages, including:

- Real-Time Data: Perhaps the most significant advantage is that companies converging information technology and operational technology with IoT will have actionable insights from real-time data.

- Decision-making: With IT and OT convergence, decision-making becomes sharper and faster. Advanced IoT systems’ advanced analytics can even offer predictive and prescriptive suggestions or drive autonomous or semi-autonomous machine control.

- Scalability: As more companies move to the cloud, IT functionality becomes more affordable. Because OT and IoT produce and handle massive amounts of data, cloud-based IT storage can be added to analyze and return the data in a cost-efficient system. However, legacy in-house systems may be swamped by data as they struggle to add capacity.

- Improved Business Processes: Manufacturing Operations always seek to improve processes. But IT and OT convergence with powerful IoT analytics mean that all business processes can be improved across the enterprise.

- Capacity: Companies adopting IoT have improved efficiency. This “hidden capacity” lowers operating costs, improves margins, and mitigates the need for additional CAPEX equipment.

IT and OT Convergence with MachineMetrics

MachineMetrics Machine Data platform allows companies to bridge the gap between IT and OT. Real-time-production monitoring, condition monitoring, and other machine-centric data are driven by powerful analytics, enabling you to optimize processes at the shop floor and enterprise level.

The autonomously collected data can be used to support existing IT systems and/or legacy solutions, like MES and ERP, ensuring that these critical systems are taking advantage of accurate production data.

Contact MachineMetrics to learn how we can help you bring your IT and OT systems together with a best-in-class IoT platform:

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments