This article is part of a series discussing the value of machine data for every level of an organization, including the machine level, plant level, and enterprise level. The MachineMetrics platform's flexible and extensible nature enables users to get started quickly while ensuring they can get accurate production data everywhere it needs to be, both horizontally across their shop floor operations, as well as vertically to support management and the enterprise as a whole.

Other articles in this series:

- Machine Level Insights:

- Harnessing Machine-Level Insights with MachineMetrics [You're Currently Reading]

- Plant Level Insights:

- Enterprise Level Insights:

The Foundation of Machine Monitoring

Monitoring and analyzing machines in real-time yields valuable information that facilitates informed decision-making processes at the shop floor level. Machine analytics opens new horizons for operational efficiency, productivity, and continuous improvement.

Machine analytics, such as those provided by MachineMetrics, serve as the fundamental layer of data generation within a manufacturing operation. By delivering precise, real-time data on machine performance, these platforms ensure that shop floor production runs smoothly.

Bridging Data and Decision-Making

Integrating machine analytics platforms into manufacturing operations effectively bridges the gap between raw data and strategic decision-making. Machine analytics is the first step toward data-driven management strategies that streamline operations and enhance efficiency.

These insights can include:

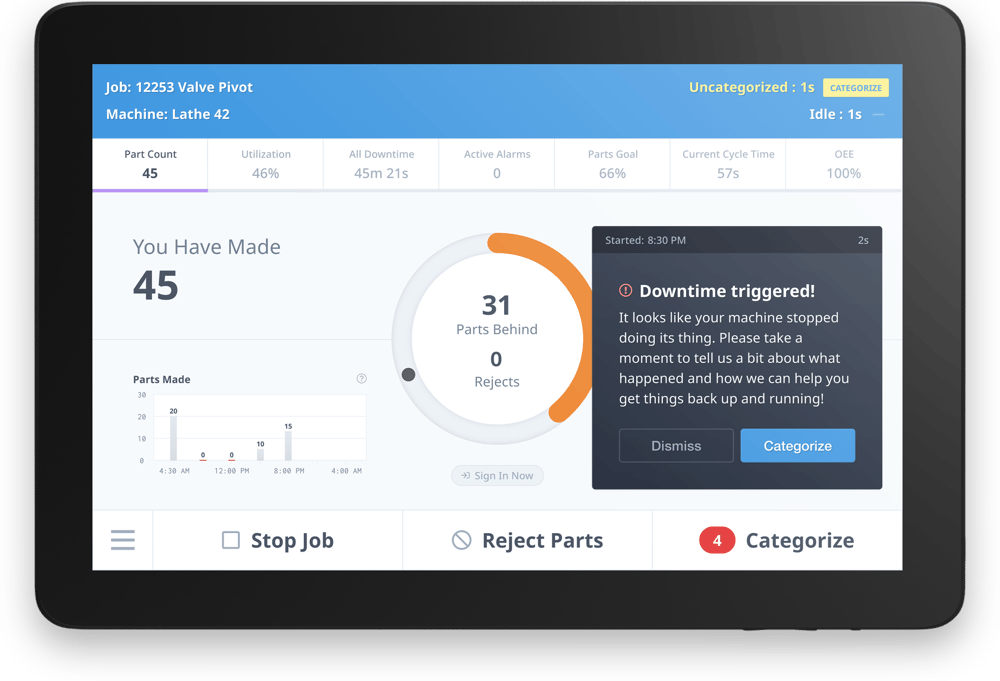

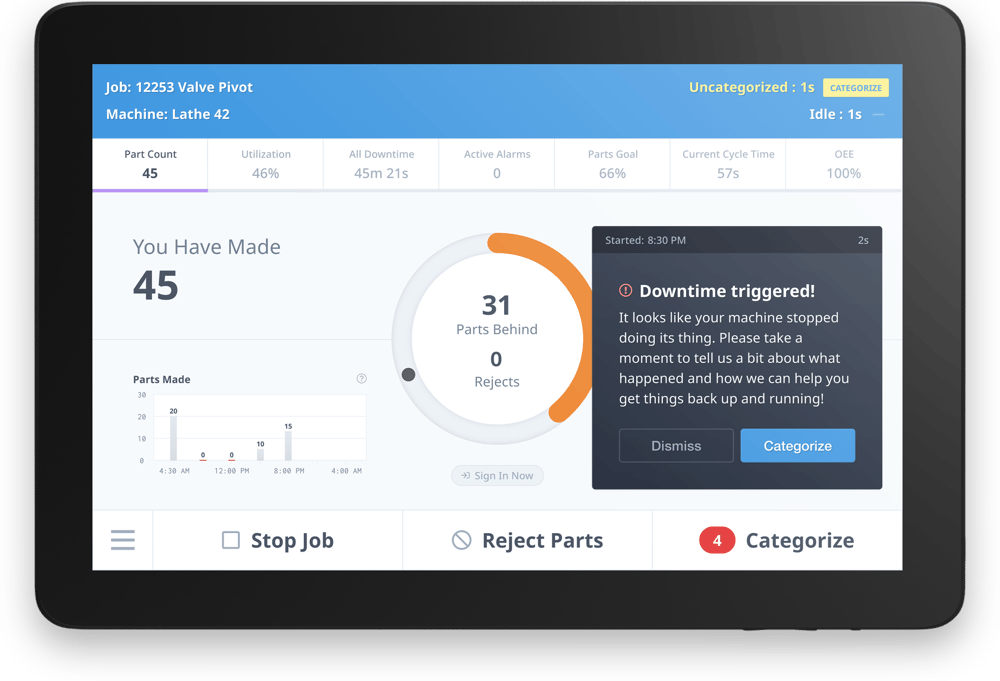

- Part Counts: Accurate part counts from machines provide a measurement of how effectively operators are managing their machines, and provide a gauge of the percent of work they have completed for the day.

- Downtime Events: With visible dashboards ont he shop floor, red tiles indicate to the shop floor that a machine is down, so that the operator or manager can take action quickly.

- Machine Conditions: Key triggers can be set up in MachineMetrics to alert managers or maintenance teams. These can be set up based on different insights within the data, from a certain downtime event to a specific machine condition that indicates failure.

These are only a few examples of how analytical insights are used to bridge data and decision-making. Such insights, distilled from data collected directly from production machines, provide important real-time intel to frontline workers.

A Catalyst for Continuous Improvement

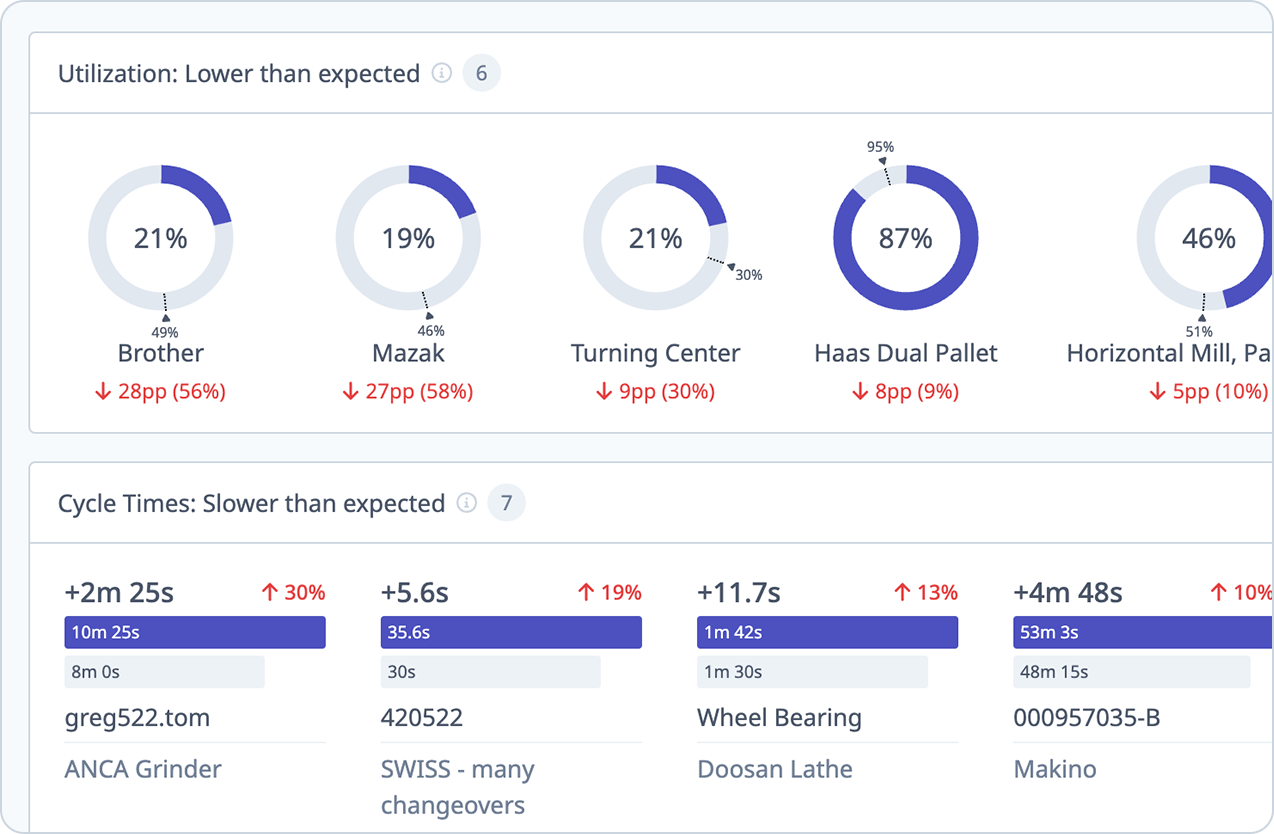

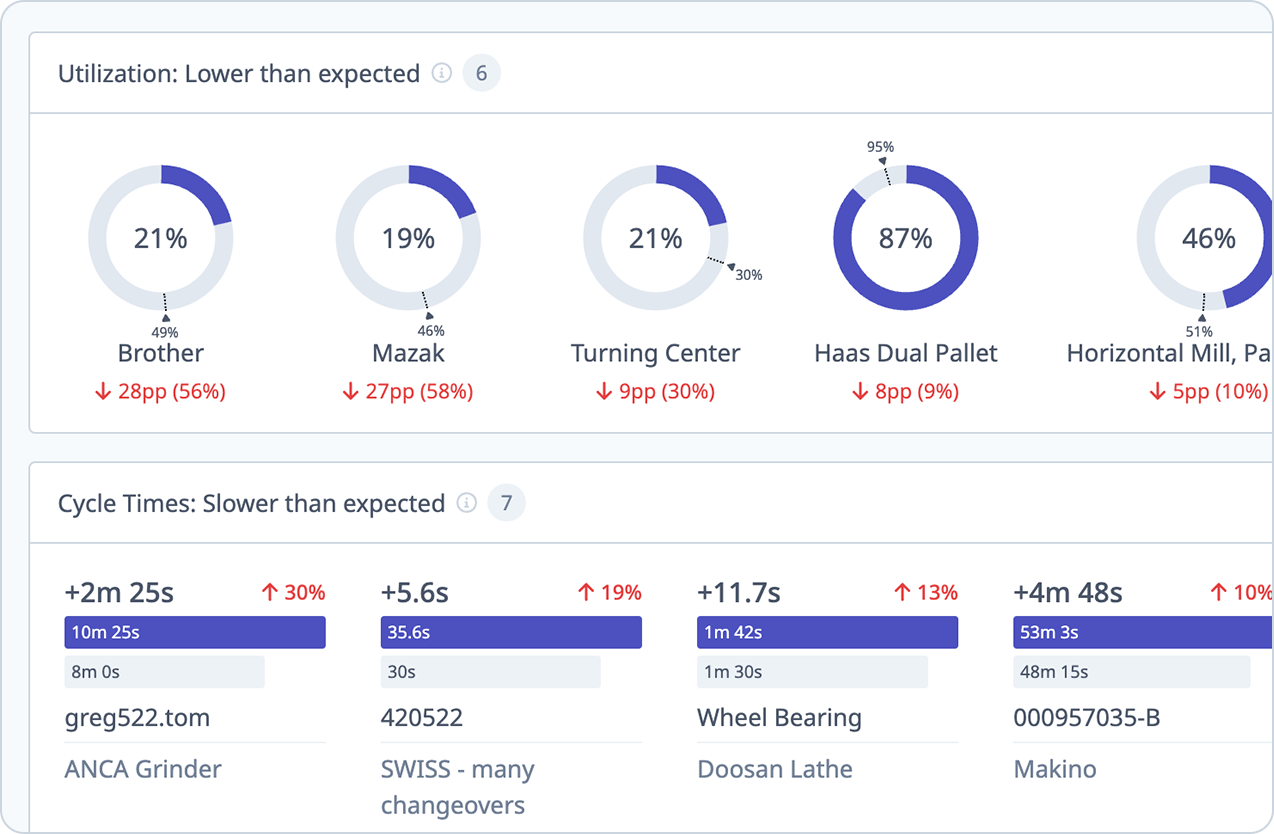

The insights yielded by machine analytics are more than just operational snapshots; they are the catalysts for ongoing improvements within the manufacturing process. As each machine's performance data is continually monitored and analyzed, patterns and trends emerge. These insights can predict future performance, optimize machine utilization, and identify potential issues before they become significant problems.

This is where MachineMetrics shines. By enabling predictive and preventative decision-making, MachineMetrics fosters an environment of continuous improvement. It also helps to continuously establish a benchmark of machine-level performance.

For each machine and operation, a benchmark is established based on historical data. This benchmark can be used to understand how current utilization rates and cycle times hold up to the expected performance.

How Machine Insights Drive Visibility

In the labyrinth of modern manufacturing processes, visibility guides operational efficiency and informs decision-making. At the center of this visibility lies machine-level insights driven by sophisticated platforms like MachineMetrics, vital in enhancing transparency and understanding of the production process.

Machine insights provide a granular view of every operational aspect, from machine utilization to productivity, performance, and potential failures. This wealth of real-time information can effectively reveal the operational realities on the factory floor.

This advanced predictive analytics capability significantly heightens operational visibility and encourages proactive rather than reactive management.

Operators, too, benefit from increased visibility. With intuitive dashboards, customized views of what the operator needs to see are at their fingertips. They can contextualize, respond, or call for help as each machine requires.

With platforms like MachineMetrics, manufacturers can peel back the layers of their operations, gaining an unobstructed view of their processes and using this clarity to inform more intelligent, data-driven decisions.

Get the Most Out of Your Machines

Analytical insights are valuable components of every manufacturer's toolbox, and it all starts at the machine level. The MachineMetrics Production Monitoring platform provides these critical analytics and empowers other enterprise systems. These capabilities drive machine-level decision-making and enable the early detection of issues before they can negatively affect production.

This article is part of a series discussing the value of machine data for every level of an organization, including the machine level, plant level, and enterprise level. The MachineMetrics platform's flexible and extensible nature enables users to get started quickly while ensuring they can get accurate production data everywhere it needs to be, both horizontally across their shop floor operations, as well as vertically to support management and the enterprise as a whole.

Other articles in this series:

- Machine Level Insights:

- Harnessing Machine-Level Insights with MachineMetrics [You're Currently Reading]

- Plant Level Insights:

- Enterprise Level Insights:

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments