For decades manufacturers have used data as a way to gain a competitive edge. Perhaps the biggest change today is how data is collected. Some companies have technicians walking around the plant checking gauges, filling out forms, and writing down operation and maintenance history for machines. All tedious, error-prone, and inacurate methods of collecting and using data to drive decision-making. However, with the proliferation of IoT devices and sensors, connected equipment and operations are changing how manufacturers take advantage of data and analytics.

Companies have started transitioning to digital software and connected devices to reduce labor associated with manual data collection and documentation. Compared to manual data collection methods, these technologies also increase fidelity that amplifies the power of analytics and leads to more accurate models. The following will present the benefits and use cases for predictive analytics in manufacturing.

The Maturity of Analytics in Manufacturing

Also known as the Manufacturing Analytics Journey, there are several stages that manufacturers go through as they strive towards predictive and prescriptive strategies.

Step 1: Data

Collecting data for descriptive analytics establishes a baseline to answer what happened.

Step 2: Information

Processing this data into diagnostic analytics to answer why something happened effectively turns data into information. A manufacturing analytics solution can be used to enable this.

Step 3: Understanding

Once enough information is collected a better understanding of processes can be achieved and statistical models can forecast what could happen in the future by using predictive analytics.

Step 4: Knowledge

As more accurate models are produced, data is transitioned into knowledge and prescriptive analytics will answer what should be done.

While it might be tempting to connect everything and run through these steps, it is important to establish clear goals and set baselines to monitor performance improvements. Know what data, and how much data is needed to transition from descriptive to prescriptive analytics. When starting this journey it will be beneficial to establish a single platform for any data collected. Additionally, make sure all stakeholders - whether devices, people, or vendors - have proper access to this platform.

Real-time data and monitoring can offer high fidelity which will help establish baselines, achieve N-values, and alert stakeholders to changes faster than manual or devices that are not connected. These steps take time, but each step offers its own benefits. One of the biggest benefits of using analytics is the ability to predict what will happen to a high degree of accuracy.

Benefits and Use Case of Predictive Analytics for Manufacturers

Connected real-time devices are able to collect more data points. This can help predict how much time or how many pieces can be produced before a failure. Traditional maintenance plans may suggest when to replace parts or perform maintenance based on average estimates, not necessarily when it is needed. Predicting failures with data and manufacturing analytics reduces unplanned downtime, and can eliminate unnecessary and expensive maintenance service.

Predictive Maintenance Analytics

Use Case: Reduce downtime, tool failure, and maintenance demands

There are many benefits in this one term; predictive maintenance. First, is that collecting data can help predict when maintenance is needed, not assumed. This increases the equipment’s uptime, giving managers a chance to plan needed maintenance or make necessary adjustments before a failure occurs.

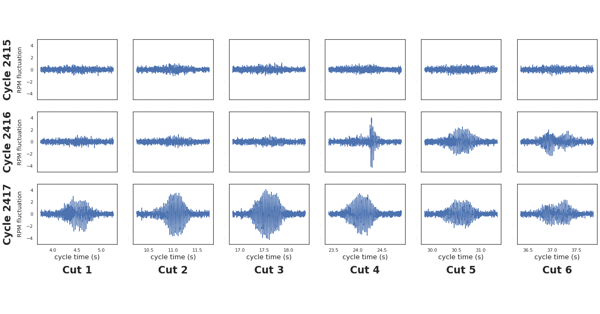

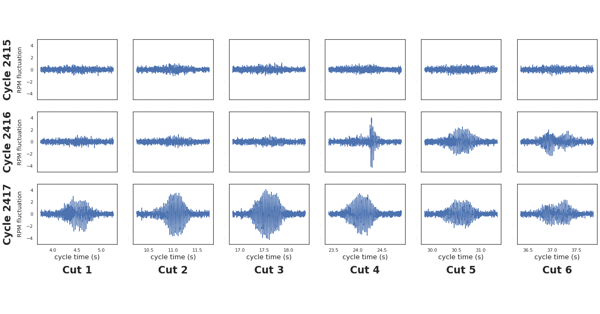

Predictive analytics becomes increasingly accurate as more data is collected and correlations are made. In one example, tool failure was found to occur as the equipment’s amperage increased. Tracking amperage was difficult, but spindle load data could be provided by turning on a feature in the equipment’s software dashboard.

Researchers were able to prove that there was over an 80% correlation between increased spindle load and transducer amperage. By monitoring the easier and more cost-effective spindle load, it was possible to predict how many parts could be made from the time of the increased load until tool failure. For this example, the parts to failure range was 1 to 68. Depending on the amount of increased load it could be possible to reduce this range further. Correlating data and noticing patterns expands what is possible through analytics to quality and decision making.

Measuring the spindle speed to identify impending tool failure. Using data like this, it's possible to build algorithms that automatically detect failure, and give you the ability to prevent it.

Measuring the spindle speed to identify impending tool failure. Using data like this, it's possible to build algorithms that automatically detect failure, and give you the ability to prevent it.

Quality Analytics

Use Case: Alerts to quality issues, minimize scrap

By tracking performance it is possible to be notified when processes are out of tolerance or may yield quality concerns. Being able to stop or adjust a process earlier can greatly reduce or eliminate material waste or rework. In one example a pneumatic cylinder would drift over time. By the time workers noticed and adjusted it, about 1,000 units were made and hours of production was scrapped. Predicting maintenance and quality issues earlier can add value to applications that involve materials with unstable prices or market fluctuations.

Predicting Demand Analytics

Use Case: Identifying and utilizing KPI and ERP

Tracking individual processes and overall lead times offers insight into material and production demands. As connected abilities expand, manufacturing KPI will be identified that will increase the ability, value, and accuracy of software tools such as ERP. Additionally, in applications where material prices may greatly be affected by politics, natural disasters, etc., using data to predict consumption rates and shipping can offer great benefits in streamlining supply chain management. Predicting volume, timelines, and market demand will help manage economics and cost for new equipment, products, or processes.

Workforce Analytics

Use Case: Predicting education and workforce demands

In fluctuating markets, predictive demand analytics can even be used to manage labor and talent acquisition more effectively. One of the biggest concerns is the Skills Gap in manufacturing. Expanding data from the process, to plant, to the planet, manufacturers may predict what skills and labor will be needed in the future. This lets companies work more effectively with educators, post jobs earlier, or upskill or reskill the current workforce to meet labor needs.

The Future of Predictive Analytics in the Manufacturing Industry

Future Use Case: Remote Maintenance of Tools

Using technology and analytics turns data into knowledge. As connectivity expands there is a trend moving toward increased remote and mobile asset tracking and monitoring. The ability to deliver high fidelity data will increase remote and mobile diagnostic analytics. This trend will reduce the need for field technicians. With high-confidence remote diagnostics, it may also be possible to give maintenance recommendations or information to operators that are on location to further reduce the need for field technicians.

Future Use Case: Risk and Insurance Assessments

With an increased ability to track and monitor equipment, analytics may increase subscriptions, insurance policies, or warranties. Connected devices may lead to more flexible equipment. For example, subscriptions give OEMs the ability to add or take away features, data tracking, and software remotely. As demand changes, so can the subscription and features.

Additionally, diagnostic analytics could change how far or what insurance policies and warranties cover. Manufacturing analytics and connected technology can prove or disprove operator, equipment, or design errors. Math has been an effective way to explain, understand, and compete. Future successes in manufacturing might be whoever has the most accurate and expansive knowledge of digital models and analytics.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments