Updated April 23, 2021

How to Improve OEE and Boost Plant Productivity

In manufacturing terminology, OEE stands for Overall Equipment Efficiency. Measuring OEE is considered a best practice among manufacturers who seek to understand where losses may be occurring in their business as well as a method to gauge productivity improvement over time and in a standardized way.

Whether you have been tracking OEE with a OEE software solution to automatically collect and calculate data, you use a manual paper-based approach to track metrics on spreadsheets, or you are unsure of your shop's OEE entirely, this article is meant as a guide for understanding what OEE is, general lean methodologies around increasing OEE, and actionable strategies to drive greater productivity on the shop floor.

There is also a real-world case study to showcase how manufacturers can use data to analyze shop floor performance and improve OEE.

Skip to any section:

What Exactly is OEE?

OEE, or Overall Equipment Effectiveness, is a measurement of productivity that can be broken down into three main parts; Quality, Performance, and Availability. As the most important metric in manufacturing (at least in regards to productivity), measuring OEE is incredibly important for manufacturers, as it gives them a KPI to better understand the percentage of operating time that a plant has been truly productive. ie. Making as many quality parts as possible within a given time frame.

Let's break out each of the components of an OEE score:

- Quality: Quality refers to what percentage of parts produced meet or exceed quality standards, e.g. “Good Parts”

- Performance: Performance is a measurement of production speed that considers any activity that leads to lost time. Performance is often gauged by comparing ideal cycle times to actual cycle times.

- Availability: Measuring availability, in OEE terms, means tracking the frequency and duration of downtime and stops, whether planned or unplanned. By ideal standards, manufacturers will suffer no stop time in order to get a 100% result in availability. Some formulas only take into consideration planned productive time and fully productive time to get a better gauge of how efficient actual work-time is without skewing results with stop time that was both intended and expected.

Understanding Your OEE Score

Each of these three factors is gauged on a scale from zero to 100 percent. Achieving 100% is a lofty, perfect-world goal that is unrealistic. In fact, to be considered world-class, discrete manufacturers need only achieve 85% OEE, though this is no simple task. Average companies usually score around 60%.

How To Calculate OEE

As a measurement of productivity, the simplified calculation for OEE is as follows:

OEE = (Good Count × Ideal Cycle Time) / Planned Production Time

A more effective measurement takes into consideration the combined production metrics of availability, performance, and quality, helping a manufacturer understand in which area they are experiencing losses. This way, a manufacturer is able to see how much time is actually used productively out of the total time allotted for production.

The calculation would then be:

Availability x Performance x Quality = Overall Equipment Effectiveness

How each metric is calculated:

- Availability = Run Time / Planned Production Time

- Performance = (Ideal Cycle Time x Total Count) / Run Time

- Quality = Good Count / Total Count

| Metric |

January |

February |

March |

| Availability |

81% |

84% |

87% |

| Performance |

82% |

85% |

90% |

| Quality |

82% |

85% |

86% |

| OEE (A x P x Q) |

54.5% |

60.7% |

67.3% |

The Top Manufacturing Improvement Methodologies Driving OEE Gains

As one might expect, OEE goes hand-in-hand with all of the major manufacturing efficiency philosophies and systems. All of the most commonly-used systems and methodologies take into consideration OEE when benchmarking success, eliminating waste, and mapping future improvements.

Six Sigma

Six Sigma seeks to improve the processes which underpin the business of manufacturing. A primary way of doing this under Six Sigma principles is by reducing variability, e.g. implementing efficient, effective, consistent business processes wherever possible. Alongside reducing variability, Six Sigma also prioritizes the reduction or elimination of defects.

Lean Manufacturing

This is actually the birthplace of OEE. Lean manufacturing focuses on the full utilization of resources to eliminate waste and enable manufacturers to do more with less. Familiar concepts associated with lean manufacturing include value stream mapping and Kaizen, or continuous improvement.

Theory of Constraints (TOC)

This philosophy is essentially the manufacturing management version of “a chain is only as strong as its weakest link.” TOC seeks to find the constraints that limit progress, growth, and efficiency, e.g. the weakest link. In this system, users are guided to find and exploit these constraints, altering the rest of the organization’s processes and eventually alleviating the constraints. Constraints generally include things like people, policies, and equipment.

7 Actionable Strategies for Improving OEE Across Your Plant

Below we outline many useful strategies manufacturers can use to improve OEE. Each offers a different approach to better understanding the nature of your equipment usage and identifying where your most egregious losses are. After all, improving OEE can be solved in a myriad of ways, from identifying bottlenecks, developing better workflows, improving maintenance programs, reducing machine downtimes, introducing automation, etc.

Prioritize Mission-Critical Assets

By focusing attention on the equipment and assets that have a ripple effect when they fail to function properly, OEE improvements can then extend up and down the value chain with only efforts put forth to that single machine. In this regard, the machine is the heart of your operation. It's imperative that machines are well taken care of via a cost-effective maintenance program that ensures they can remaining running as much as possible.

Use IIoT for Real-Time Data Collection

Connected manufacturing equipment and smart factories use connected devices to capture and analyze data in real-time, often with the help of edge computing capabilities. These types of devices offer valuable information on OEE in the moment, but collected data can also be combined and analyzed to derive deeper insights that can bolster OEE moving forward.

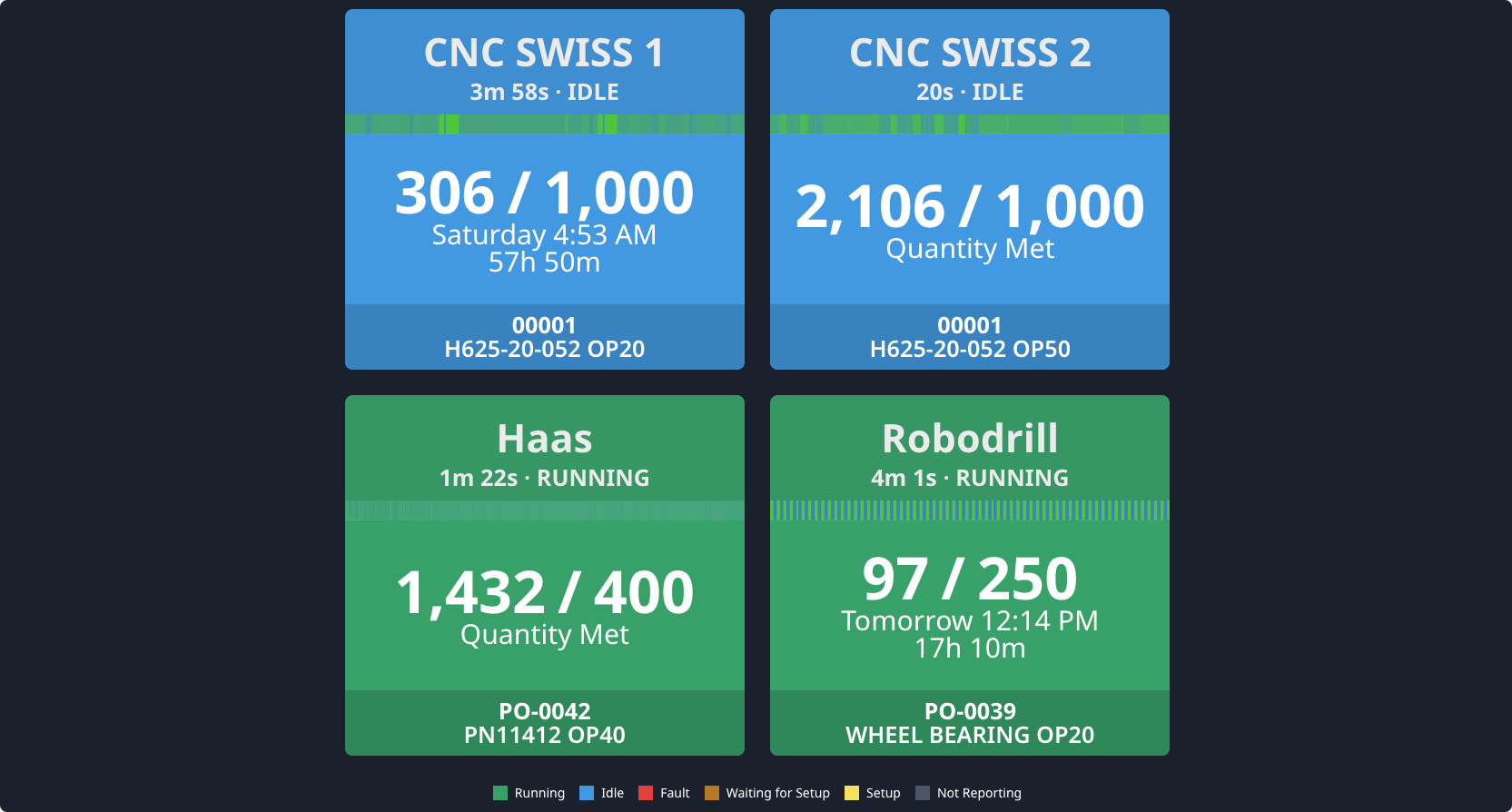

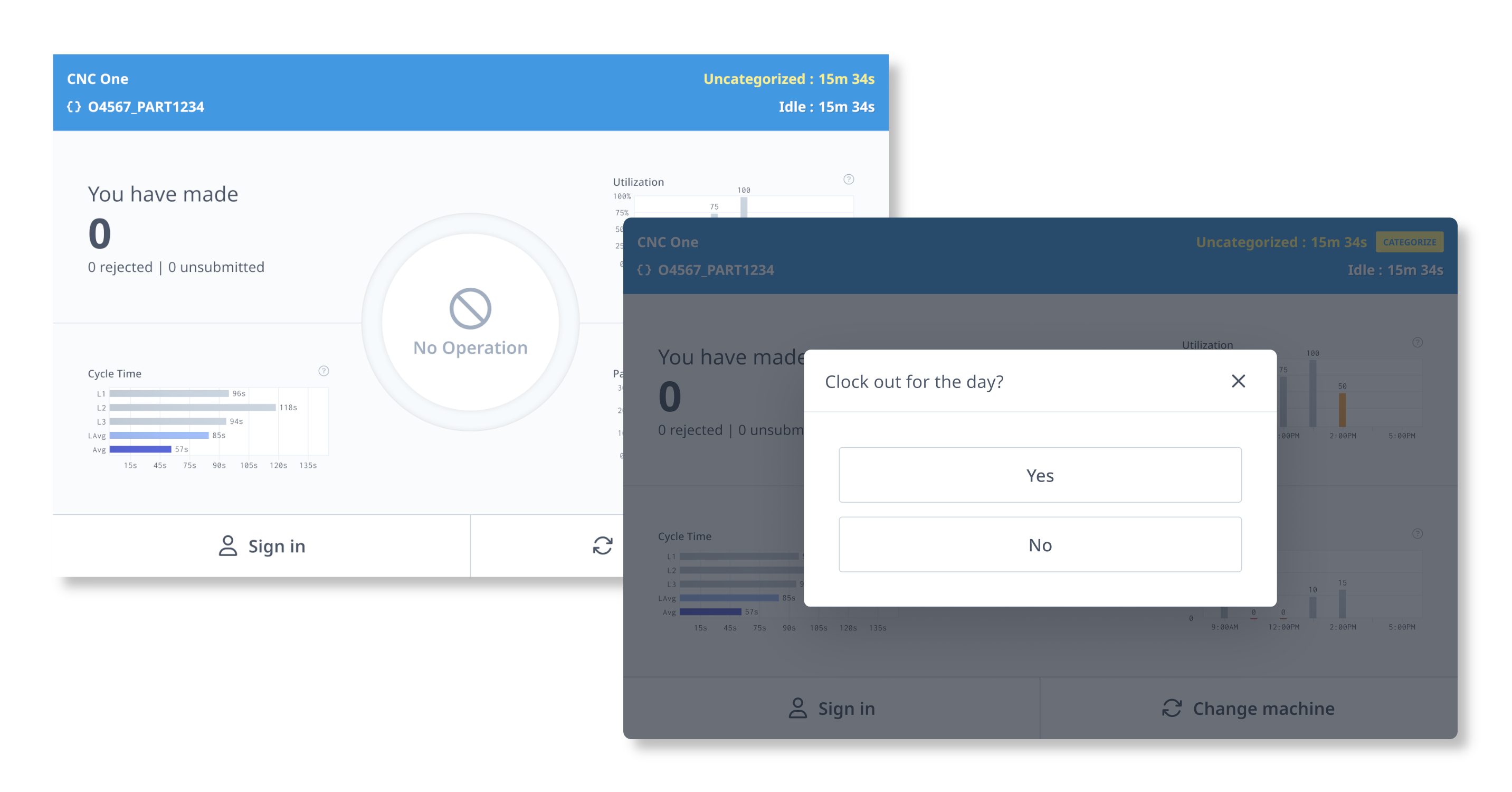

Plug-and-play Machine Connectivity

Collecting machine and operator data in real-time and contextualizing it for use across the operation provides an immediate boost to productivity based on visible accountability, via production reports, OEE dashboards, and historical data. Both operators and managers can easily see where they stand when it comes to production goals, as well as identify any machines that are falling behind or experiencing downtime events.

Without the real-time, accurate production data, manufacturers are forced to deal with inaccurate, paper-based data that will be delayed and far less useful in solving problems and making decisions on the shop floor.

Really Grasp OEE And Its Origination Points

OEE seems simple on the surface but can be quite complex. Frequently, OEE issues stem back to earlier issues that only surface during a later stage of production. This can even extend back to procurement processes which impact supplier quality which can alter machine effectiveness, and so forth. To get to the root of OEE, you need to first understand the “gears,” so to say, of OEE itself and how they drive one another.

Not All Value Is Equal

What makes a huge difference in one business adds little value to another. It’s important to adapt OEE formulas to where the real value lies in your business, else skewed results (and skewed optimizations) will lead to underwhelming results when and where it matters.

For example, there will be a major difference between the levers in a high mix low volume production versus a high volume low mix production. Furthermore, while a medical device manufacturer may have extremely strict standards for good quality parts, other manufacturers may not. As you can imagine, manufacturers must use good business judgment when making decisions on which metrics are the most important to focus on improving.

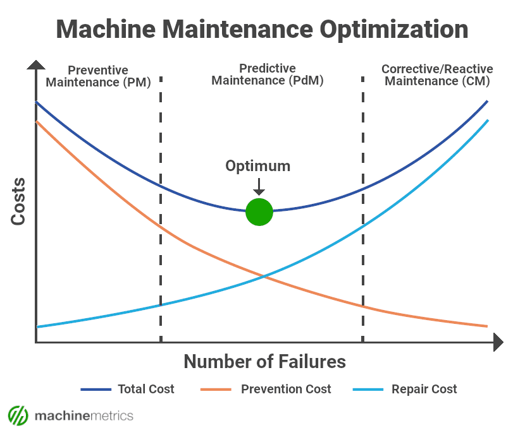

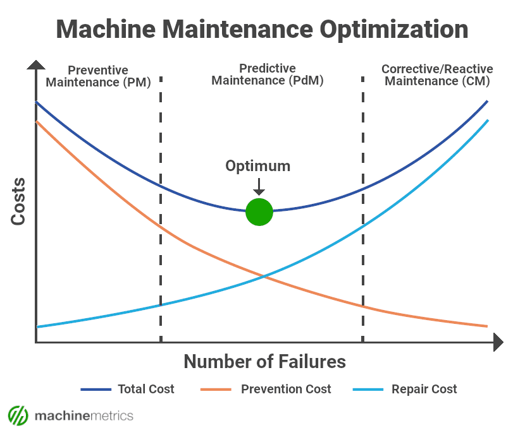

Smart Maintenance

Ensuring machines can stay running during planned production time is a major component of OEE (availability). This is why a strong maintenance program is integral, helping manufacturers find the sweet spot between unnecessary and expensive preventative maintenance measures, and downtime-inducing reactive maintenance.

Advanced maintenance teams will move toward a predictive maintenance strategy that allows them to identify impending machine failures and fix the problem before it occurs, while at the same time ensuring they are not over-maintaining their equipment to the point that the costs outweigh the benefits.

Pay Attention To Your Environment

How do the conditions surrounding your machinery affect their performance? Excess debris, grease, oil, fumes, vibrations, dust, and even poor lighting can all impact equipment OEE as well as factors that can be attributed to factory workers. If you can’t see what you’re doing very well, then you’re probably going to move slower than if you could.

Seamless Integrations

Connecting systems for seamless information and insights is critical to bolstering OEE. Once manufacturers are monitoring their machinery and operations to automatically collect data, they can integrate with other systems to develop efficiencies.

There is an unlimited number of use cases created by integrating different systems. The most important part is having the foundation be built upon the data closest to production; machines and operators on the shop floor.

MachineMetrics is extensible in that it collects this production data in real-time and can feed the information into other systems for analysis and automation. That way, other management systems such as CMMS, MES, and ERP can leverage accurate, real-time production data.

For example, a machine condition that hits a given predefined threshold can trigger a work order in a CMMS and automatically notify a maintenance team member.

Case Study: Increasing OEE 30% by Identifying Bottlenecks

Avalign Technologies is a medical device manufacturer with facilities across the United States. They were having trouble tracking OEE and monitoring machine downtime. This resulted in many problems, including poor machine performance, unclear standard operating procedures, and production bottlenecks.

In this video co-produced by AWS, OEE Director Matt Townsend discusses how he was able to get instant visibility into shop floor performance resulting in a 25-30% increase in OEE, a more effectively leveraged workforce, millions of dollars in increased capacity (without additional equipment), and increased throughput via the reduction of bottlenecks.

Watch the video case study!

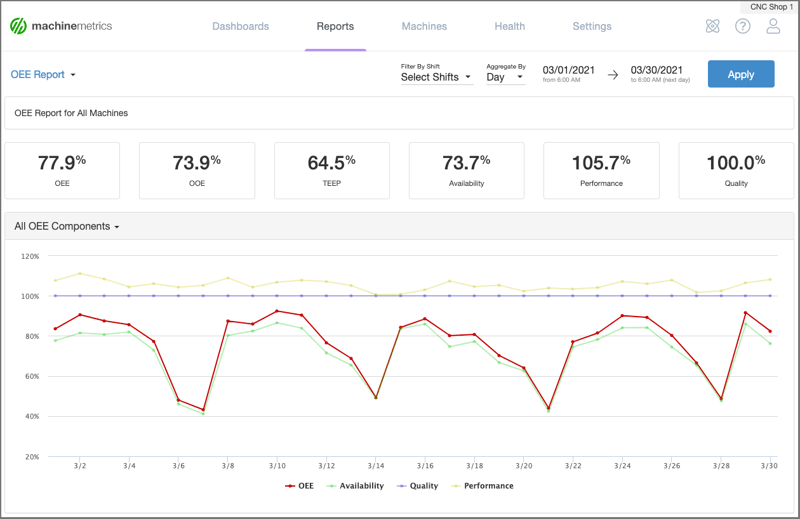

Using MachineMetrics to Track and Improve OEE

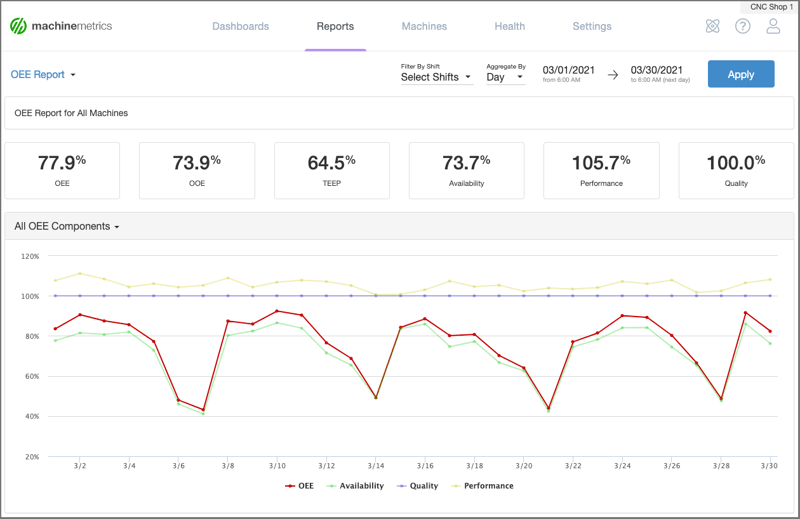

With MachineMetrics, production data is at your fingertips, ready to be used for making on-the-fly decisions, analyze historical data, or enabling automation. The accurate, contextualized data can help you benchmark OEE and measure improvements based on any process changes you have engaged in.

In line with our plug-and-play solution, MachineMetrics comes with an out-of-the-box OEE report for instant visibility across Availability, Performance, and Quality.

Production data is aggregated to easily track your organization's OEE, or drill down to specific shifts and machines.

Production data is aggregated to easily track your organization's OEE, or drill down to specific shifts and machines.

On top of the pre-built OEE report, users can create an OEE report in the Production Report Builder to add additional layers of customization, ensuring that the data you are paying attention to is the most relevant for you operation.

Here's a short video demonstrating how to build the OEE report in the Production Report Builder:

Interested in how MachineMetrics can help you track and improve your OEE? Book a demo with our team today.

Track and Improve Your OEE Today

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments