Key Takeaways:

- Lean manufacturing focuses on minimizing waste while maximizing value to improve overall efficiency.

- The five key steps to implement lean include identifying value, mapping the value stream, creating flow, establishing pull, and seeking perfection.

- Embracing lean manufacturing can enhance productivity, reduce costs, and improve quality across production processes.

For those in manufacturing, soaring customer expectations of reliable quality and rapid delivery are forcing them to operate more efficiently.

Queue up lean management - doing more with less.

The core lean manufacturing definition boils down to this: It's a concept that focuses on continually being on the lookout for and eliminating steps in the process that cost you time, money, materials, and don't contribute value to your customer.

Here’s a 5-step plan to put you on the road to lean success…

Step 1: Go Lean For The Right Reasons

Some companies view lean manufacturing as a necessary evil - one they must somehow fake their way through in order to impress customers. Big mistake. Today’s customers are savvy and can quickly see through this facade.

A successful lean production implementation depends on a commitment to make continual, lasting improvements in your manufacturing processes.

The driving force behind adopting lean principles should be an objective to create value through eliminating waste.

The right philosophical approach will set the foundation for success.

Step 2: Get Everybody To Buy In

Bringing change to an organization takes time - even when times are good.

The adoption of lean principles means instilling a mindset of continuous improvement throughout your company and continually seeking ways to improve work flow and value output.

This new culture requires everyone in your organization to be engaged in the process and be kept abreast of the progress.

To encourage participation, set up a clear channel of communications to share productivity gains so you can build momentum and support.

Step 3: Devise An Implementation Plan

An important step when implementing a lean strategy is to establish a plan of action.

Start by identifying the obvious areas you need to address. Do you have delivery issues? Problems with lead times? Maybe your downtime has increased?

Your plan - complete with attainable targets - will allow you to show those in upper management and those on the shop floor how you are progressing and reaching your milestones as planned so you can continue to garner support.

Having a plan is essential for keeping you and your team on track for increased productivity.

Step 4: Just do it!

Don’t overthink your decision to start implementing lean manufacturing principles.

After careful planning, start small by directing your efforts at one product line so you can demonstrate proof of concept prior to a broad-scale rollout.

The best way to get lean is to act that way. Get started so you can build on your efforts and results.

Create a follow up system that will allow you to evaluate the changes you made to ensure you’re moving forward and not falling back into old habits.

Step 5: Be Sure To Have Lean Tools to Accurately Measure Your Results

One sure way to accurately measure Overall Equipment Effectiveness (OEE) is to implement a system for measuring your lean production management.

All too often, companies make manufacturing quality improvements that only fix the symptoms of inefficient production methods rather than the root cause.

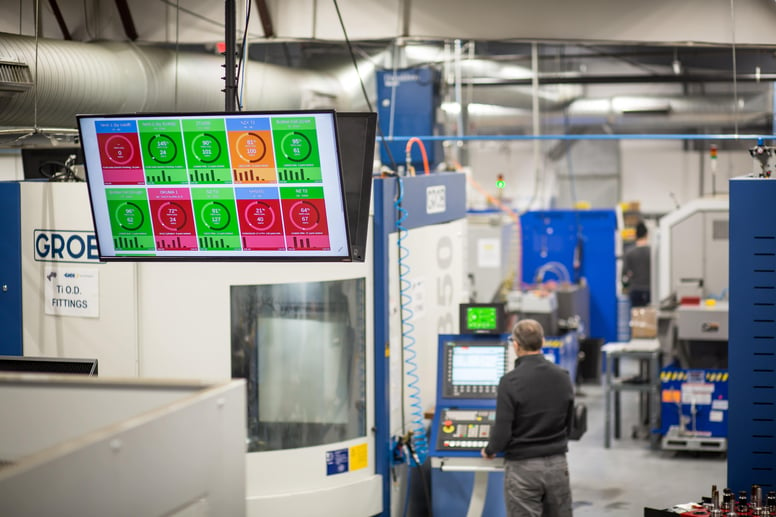

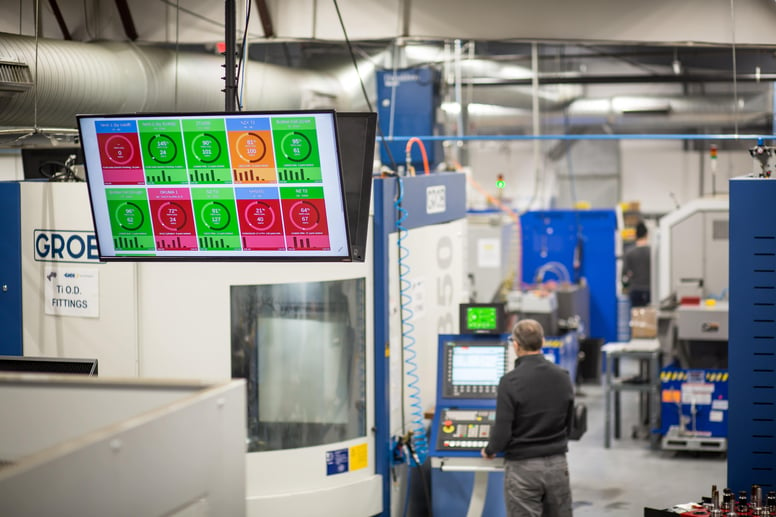

Create a “visual” shop with displays and controls used throughout your manufacturing plant that makes the state and condition of manufacturing processes easily accessible and clear to everyone. Lean manufacturing tools such as machine monitoring software give you accurate data on downtime and slow cycles that you can use to make practical decisions.

Today's competitive global environment demands lean efficiency.

Not only will you will benefit from a business culture focused on mutual problem solving, this type of an environment empowers and encourages all team members to contribute to quality operations which results in the optimum customer value needed for competitive advantage in the modern marketplace.

Learn how Wiscon Products enabled their lean manufacturing program with machine monitoring in a recent case study.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments