One of the biggest problems manufacturers face is downtime. This problem is exacerbated by the fact that most manufacturers are unaware of what is causing the downtime across their plant. Fortunately, connected technology and Cloud computing platforms have have the ability to connect, collect, and analyze data and generate automatic user-friendly reports.

With machine monitoring, manufacturers are able to see the amount, impact, and causes of machine downtime in order to take steps towards reducing it. Within this article, we discuss how connected solutions can give managers and operators a real-time view of the shop floor and provide accurate information to reduce downtime.

We Don’t Know What We Don’t Know

Most manufacturers are aware they are losing time and money because of downtime. However, many manufacturers can not accurately answer the following questions.

We have discussed in greater detail the downside of manual data collection, and it is quite obvious that manufactures benefit dramatically from automated data collection systems. We can quickly summarize this.

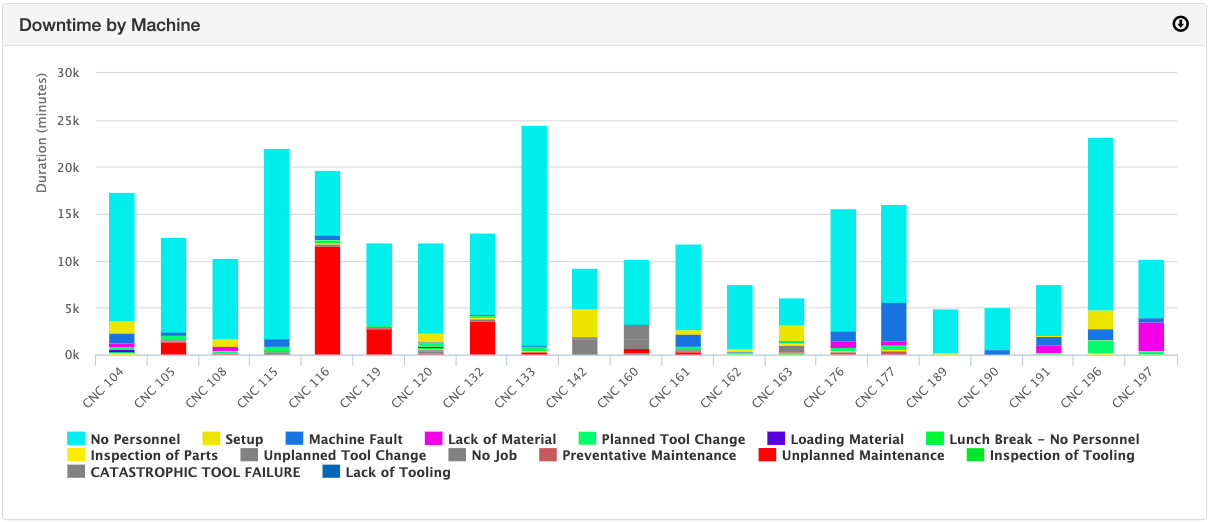

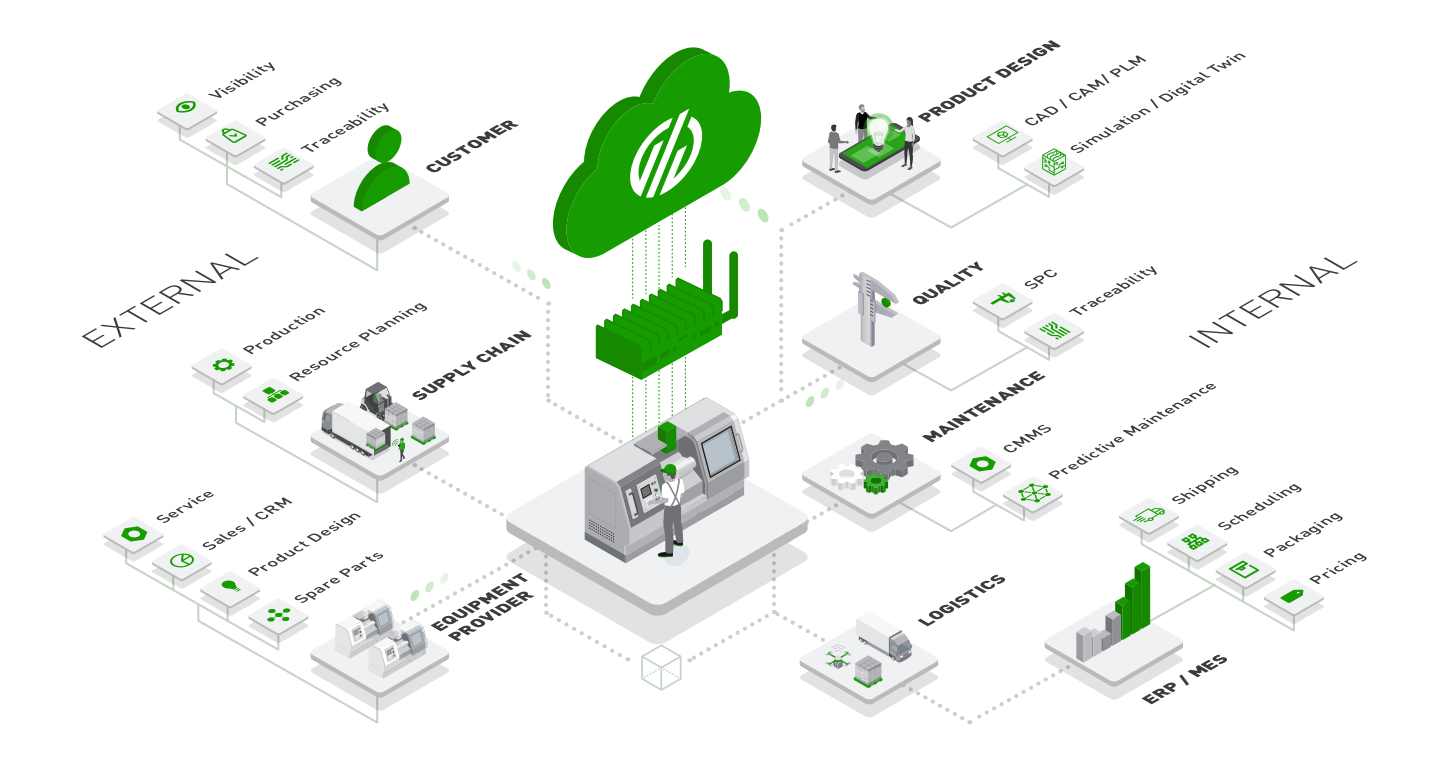

Platform software should connect equipment and people to gain a full perspective about what is happening on the shop floor in real-time. Traditional or manual documentation takes time between reporting the data, analyzing it, and extracting useful information to improve, correct, or even know that downtime occurred. Operators might also be busy, tired, overworked, monitoring multiple machines, etc. which leads to inaccurate reports or reports not being filed. MachineMetrics offers the ability to autoamtically colect real-time data from manufacturing equipment as well as contextual data from operators, via tablets placed at each machine.

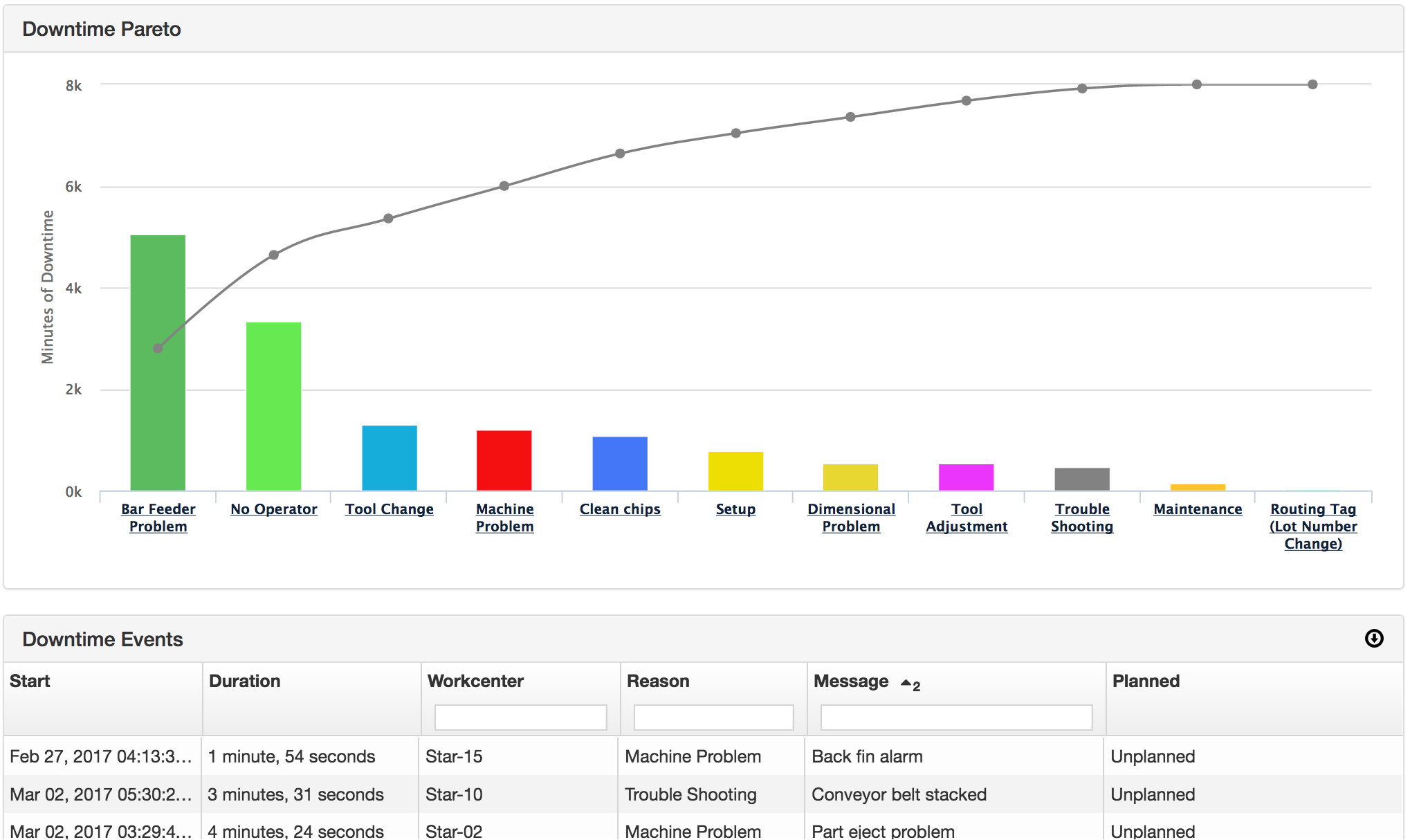

An operator can easily document the reason for a downtime event using a tablet placed at the Machine. This key contextual data provides insight into the top reasons why your shop is experiencing downtime events.

An operator can easily document the reason for a downtime event using a tablet placed at the Machine. This key contextual data provides insight into the top reasons why your shop is experiencing downtime events.

Manufacturing is becoming faster than ever before. A simple error not noticed for a few minutes could represent thousands of dollars of materials and production time that is wasted. Real-time machine monitoring is increasingly important to reducing scrap, mitigating downtime, and keeping up with the competition.

We Can’t Act on What We Don’t Know

Research shows that the average rate of machine utilization is far lower than manufacturers expect. To increase machine utilization, key stakeholders including operators, technicians, and managers need accurate real-time production data. Making decisions without data leads to decisions based on gut instinct, resulting in increased problems, failures, and frustrations.

Due to the time consumed in manual documentation, and not to mention the inaccuracy of the data, finding root causes of downtime is difficult. Tracking machines with a machien monitoring solution can provide accurate data for managers to make informed decisions towards meeting production goals.

Data collected and processed by these real-time and interactive tools makes it quick and easy to determine machine utilization rates and how to improve them. Acting on production with accurate data lets decision-makers attack the largest root causes of manufacturing downtimes and lags in performance.

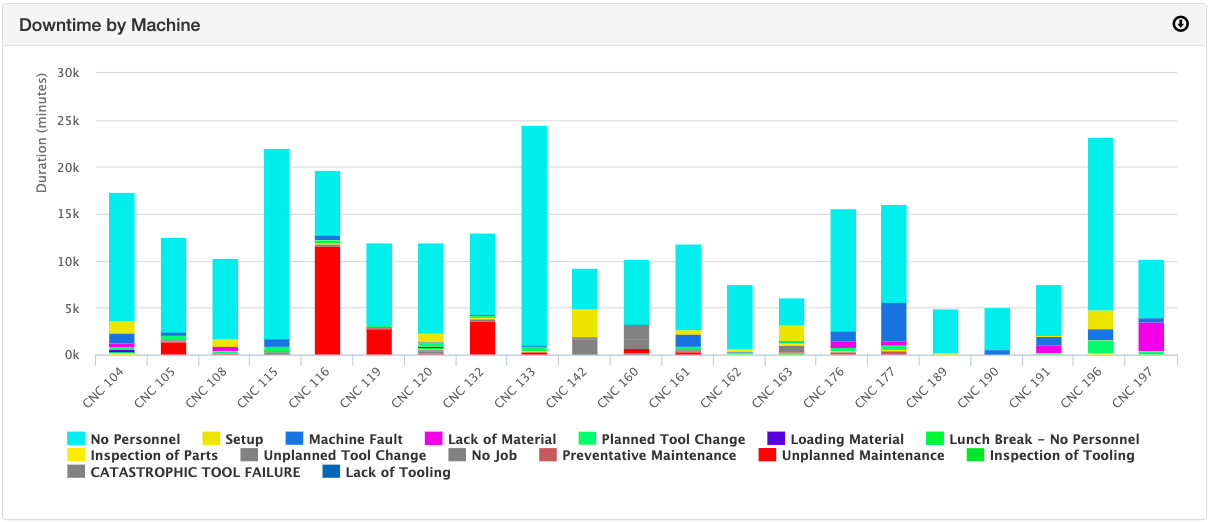

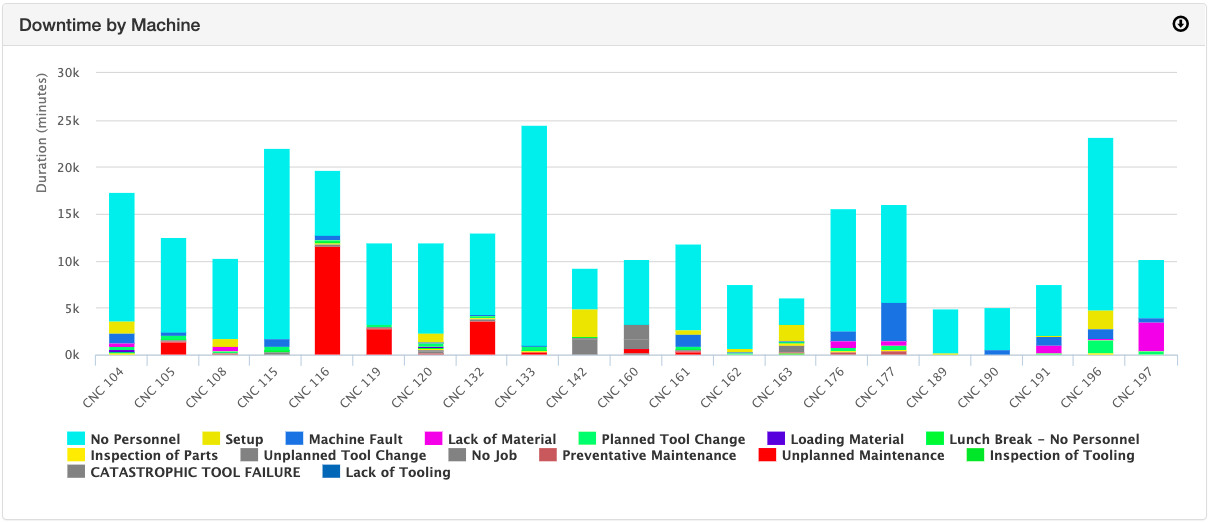

This out-of-the-box report from MachineMetrics shows the downtime reasons for each individual machine, but the data can also be aggregated across all machine for a complete view of the most egregious downtime reasons.

We Won’t Know Until We Search

The introduction of connected shop floor technology alone improves communication and provides an accurate depiction of what is happening on the shop floor. In fact, most MachineMetrics customers see a 20% in productivity by simply integrating real-time machine monitoring without making any other changes.

This helps manufacturers get to value fast so they can begin solving problems and optimizing processes rather than focusing on building a solution. When searching for a solution, remember the more time and disruption a system needs to integrate, train, and operate all add to the total cost of ownership (TCO).

Also, keep in mind that legacy equipment does not necessarily need the most advanced sensor packages. Basic sensors, on/off monitoring, and a simple I/O adapter can provide much of the data needed to find your top causes of downtime or performance problems.

To gain deep visibility into the shop floor, search for flexible plug-and-play software that doesn’t remove the operators from the process. Operators provide an essential layer of detail to complement machine data.

These real-time, tracking, analyzing, reporting solutions are able to connect new and old machines with workers to make sure managers are informed about how much downtime is happening, what causes it, and how it affects all aspects of production. Solutions should connect, collect, analyze, and report machine downtime with non-disruptive, easy to integrate, flexible, and user-friendly hardware and software.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments