Below is what we will cover in this in-depth article on edge computing in manufacturing. Select a link if you would like to jump to a particular section:

An Introduction to Edge Computing in Manufacturing

The edge computing framework is quickly finding its way into a variety of industries as Internet of Things (IoT) devices become more commonplace. One of the most promising edge computing use cases is in manufacturing, where these new technologies can potentially lead to massive productivity gains.

While IoT is already proving to be a critical enabler on the factory floor, organizations are now looking to enhance the responsiveness of their manufacturing systems further. To achieve this, these organizations are adopting smart manufacturing with edge computing as its main enabler.

Smart manufacturing envisions a future where factory equipment can make autonomous decisions based on what’s happening on the factory floor. Businesses can more easily integrate all steps of the manufacturing process including design, manufacturing, supply chain, and operations. This facilitates greater flexibility and reactivity when participating in competitive markets. Enabling this vision requires a combination of related technologies such as IoT, AI/machine learning, and Edge Computing.

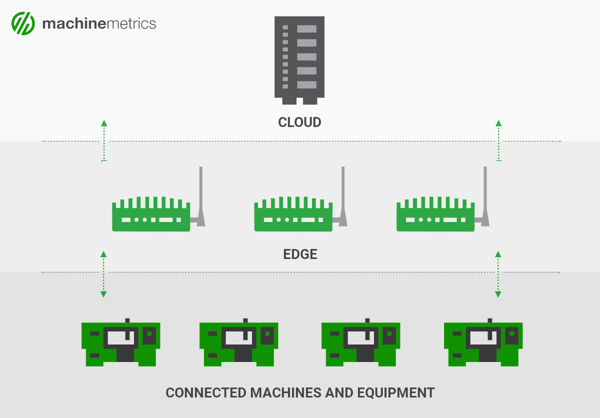

The key advantage of gathering analytics at the edge of the network is the ability to analyze and execute on real-time data without the bandwidth costs that come with sending that data offsite (to the cloud or the data center) for analysis. Manufacturing is time-sensitive in terms of avoiding the production of out-of-spec components, equipment downtime, worker injury, or death. For more complex, longer-term tasks, data can be sent to the cloud and combined with other structured and unstructured forms of data. As a result, the use of these two separate computing frameworks is not mutually exclusive, but rather a symbiotic relationship that leverages the benefits each provides. Below, we dive deeper into use cases and the relationship between cloud and edge in manufacturing.

First, we’ll define the components of an edge computing framework.

What is Edge Computing?

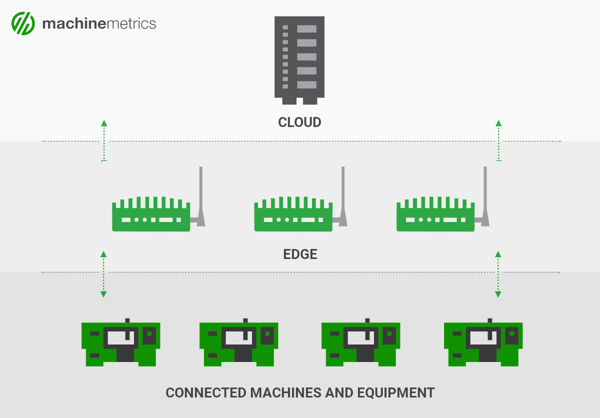

Edge computing is a distributed computing framework which brings computation and data storage closer to the source of the data, thus improving response time and saving bandwidth.

Put simply, edge computing is about taking code that runs in the cloud and running it near or on local devices. Examples include gateway devices (such as MachineMetrics Edge) or even a PC sitting next to IIoT enabled equipment.

With edge computing, less data needs to be transmitted to the cloud. This is particularly useful for collecting high-frequency data that is used to run machine learning algorithms. Since this data can be processed at the edge, it can be acted on immediately. In contrast, if this high-frequency data was to be transmitted to the cloud, processed, and then acted on, there would be a latency effect. Edge computing solves this problem.

To understand edge computing it helps to think of an IoT solution as generally having three components:

- Things like IoT devices, which generate sensor data.

- Insights you extract from this data.

- Actions you perform based on these insights to deliver some sort of value.

With edge computing, you move the insights and actions components from the cloud to the device. In other words, you bring some of the code right into the device, which is used to process and extract insights from the data and perform some action in response to it.

In manufacturing, the things may be machines or equipment on your shop floor. Insights could therefore be real-time machine data. And an example of an action may be a machine pausing operation due to anticipated tool breakage.

What is an Edge Computing Platform?

An edge platforms built for manufacturing allow you collect data from industrial systems like PLCs, Digital Control Systems, sensors, or historians and run applications locally on top of the data, such as event processing, predictive analytics, machine learning models, and more – all in an offline first deployment.

Edge computing platforms manage the applications, devices, and connections that operate on the edge of a network. Here, edge devices and connected equipment (“things”) can communicate and perform tasks at a rate faster than those achieved with pure cloud computing.

Dealing with many edge devices can be a challenging task. A centralized edge management platform alleviates this problem by connecting the many disparate edge devices to ensure proper management of the entire network. For example, with an edge computing platform, manufacturers can push security updates across all edge devices and troubleshoot if necessary.

In one sense, edge computing platforms simply bring the computational resources of a cloud closer to the sources of data. Thus, edge platforms simply do the work of a cloud computing platform, but at the edge. This reduces the strain on cloud computing resources and reduces data latency between the edge device and the equipment. If machine learning and AI are the way of the future, the speed with which data can be stored and analyzed is vital.

What is an Edge device?

Edge devices are equipment that manage the flow of data between a local network and the cloud. They act as a gateway between connected equipment on a local network and the software platform that is used to analyze the data.

In the context of smart manufacturing, edge devices provide more than a link between separate networks. They also include functionality for enhancing IoT security and analytics conversion. To expand on this, edge devices translate otherwise incompatible data (if you had different protocols for example) so that data from different sources can be aggregated and understood in the cloud.

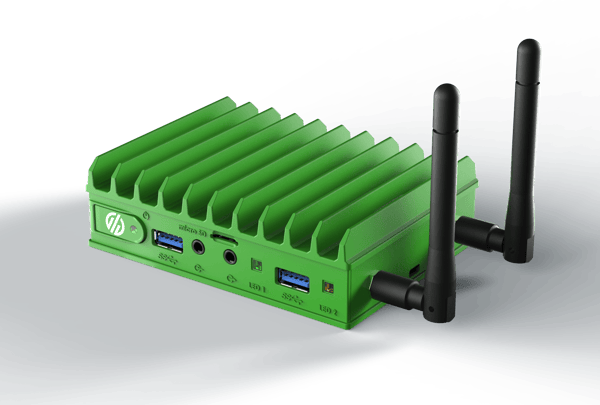

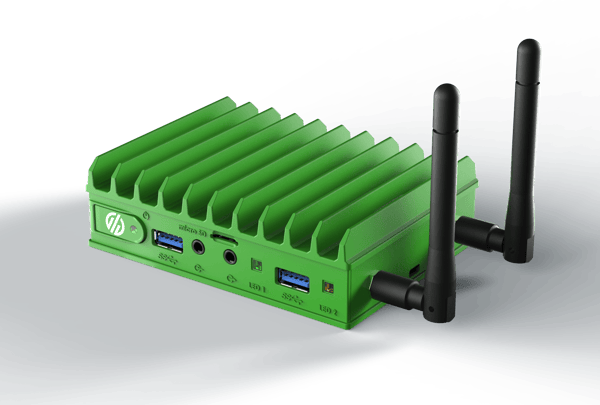

The MachineMetrics Edge easily connects machines to the MachineMetrics cloud service using Wifi, cellular connectivity, or an ethernet connection.

The MachineMetrics Edge easily connects machines to the MachineMetrics cloud service using Wifi, cellular connectivity, or an ethernet connection.

Physical distance with a traditional network means longer transmit times for large data packets. Edge devices permit the data networks coming from the machines to be that much closer to where the data is stored and analyzed. This permits a much faster return of information to the user, which is essential when it comes to use cases like real-time predictive analytics. Edge devices and edge computing are placing more storage and analytic power to consume and act on the data, right at the machine location.

As IoT infrastructures grow in complexity (ie. more plant locations, devices, and networks), the need for data aggregation and processing remains important. However, the challenge is that devices on the edge will suffer from high-latency communication with the cloud computing platform.

This is what edge devices and edge computing platforms work to solve.

The Relationship Between Edge and Cloud

We have a complete article on the difference between edge computing and cloud computing in manufacturing, so we will keep this short.

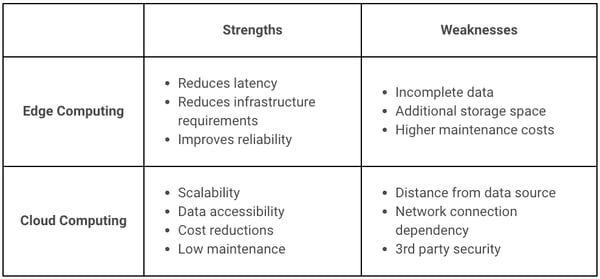

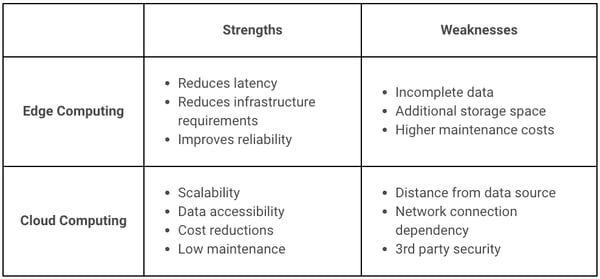

The edge and cloud are two distinct technologies, but they are often used in tandem due to their offsetting strengths. At the heart of the relationship, edge computing processes and takes action on data that is time sensitive, whereas cloud computing aggregates data in a centralized location that will not need to be acted on in a timely manner.

In a complete IIoT infrastructure, manufacturers can use both the edge for real-time data collection, predictive analytics, and autonomous decision-making, and the cloud for aggregate data analysis, benchmarking, and trend analysis.

These benefits and downsides continue:

Edge Computing Use Cases in Manufacturing

Let’s now discuss practical reasons for the use of edge computing in manufacturing. There are a variety of business benefits to ensuring that all networks are properly connected to the cloud while also being able to deliver powerful computing resources at the edge.

- Improved equipment uptime: A failure in a subsystem, component or the impact of running a component in a degraded state, for instance, can be predicted in real time, continually refined as more data is analyzed, and used to enhance operational use and maintenance scheduling.

- Reduced maintenance costs: Enhanced analysis of needed maintenance also means that more repairs can be completed on first visits by giving mechanics detailed instructions about the causes of a problem, what action is needed, and what parts are required—reducing repair cost.

- Lower spare parts inventory: Edge analytics models can be tailored to the requirements of an individual device or system. This might mean reading sensors directly associated with certain components and/or subsystems. Guided by an organization’s desired business value, the edge model can then define how the device or system should be optimally configured to achieve a business goal, making a spare parts inventory vastly more efficient at minimal cost.

- Critical failure prevention: By acquiring, monitoring and analyzing data regarding components, edge analytics can identify a cause before its effect materializes, enabling earlier problem detection and prevention.

- Condition-based monitoring: With the convergence of IT and OT, manufacturers are able to access machine data, allowing them to monitor the condition of their equipment on the shop floor even if they are using legacy equipment.

- New business models: Perhaps most important, edge analytics can help shape new business models to capture new opportunities. For example, it can improve just-in-time parts management systems using self-monitoring analysis that predicts which components will fail and when—triggering parts replacement notifications throughout the value chain. This enables the creation of an “as needed” maintenance schedule, reduces downtime and parts inventory, and results in a more efficient model.

How the Connectivity Landscape in Manufacturing is Changing

We know the point of the industrial IoT is to apply advanced analytics to vast quantities of machine data, all with the aim of reducing unplanned downtime, reducing the overall cost of machine maintenance, and leveraging machine learning capabilities. The cloud has been instrumental in making this kind of massive data acquisition, transfer, and analysis possible.

Edge computing and analytics is simply taking this concept to a new level by reducing the physical distance between the machines and the data processing itself. For companies that are spread over distance and acquiring data from many sources, this proximity helps deal with several realities:

- Connectivity issues related to distance as well as the cost of massive ongoing data transfer to a centralized location.

- Availability of the analytics at an operational level, permitting users at multiple levels to make decisions quickly.

- Availability of the data in real time, for faster (and even autonomous) decision-making

- Ensuring security of the data and the integrity of the network.

All of these realities, when dealt with by edge computing, permit manufacturers to reduce costs and increase efficiency. Additionally, manufacturers can now have a reliable data transfer with few errors and risks to security. Not to mention, this also enables customization and small run manufacturing with the same value a large scale production would experience. With edge computing, all of this is available with flexible and simplified maintenance of all devices.

When data speed is the order of the day and connectivity needs to be solid, the edge will be the solution that manufacturers should look to. Applying AI and machine learning algorithms to visualize, diagnose, and predict problems in real-time is a goal that can be more readily accomplished with proximity, speed, and a solid network. Real-time visualizations and predictive notifications enable your team to take immediate corrective action and keep your machines up and running without fear of missing crucial data.

Industrial manufacturing is on the brink of a revolution thanks to the potential of edge computing. Combined with a new generation of smart IoT edge devices, edge computing applications will completely transform manufacturing in the coming decades to drive better efficiency and productivity while also controlling costs.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments