Increased competition, shrinking skilled labor availability, and legacy technology solutions create new challenges for manufacturers; companies are looking for ways to manage their production more tightly and control every input and output to maximize production and optimize processes.

Traditional factory monitoring consisted of manual data tracking, calendar-based preventive maintenance, and guesswork. But today, companies looking to enable "smart" manufacturing are turning to automated factory monitoring solutions.

Instead of playing catch up with part goals, wondering why machines are down, or being unsure of the effectiveness of processes, continuous improvement leads can dive into data to better understand where capacity exists, identify bottlenecks, and get notified of any factory downtime events as soon as they happen.

Benefits of Factory Monitoring

As companies seek a competitive advantage, factory monitoring has emerged as critical for continuous improvement. As part of the smart manufacturing movement, manufacturing leaders know they need insights from their production data. But further, they know just how important it is to have real-time, accurate data that can drive action.

Top manufacturers, like Morgan Olson, are deploying factory monitoring solutions that collect and use real-time production data, enable shop floor automation, and optimize processes.

Here are some of the benefits of using an advanced monitoring system:

Data and Alerts are in Real-Time

A monitoring system that provides data from yesterday is far less actionable than one which can provide real-time insights. While primitive manual monitoring solutions have been aided by robust methodologies such as Lean and Six Sigma, real-time data means that operators and managers have access to event and production data as it occurs, allowing them to take action immediately.

Real-time monitoring solutions enable notifications and alerts where and when needed. They can also visualize production performance in real-time so that operators and managers can see if they are meeting production goals for the current shift. This enables operators to intervene quickly and make adjustments that reduce downtime, improve efficiency, and reduce waste.

An example of a MachineMetrics alert sent to a user's cell phone due to a machine downtime event.

An example of a MachineMetrics alert sent to a user's cell phone due to a machine downtime event.

Complete Transparency

The process becomes completely transparent because connected plant assets are unified under a single data platform. Data previously siloed and unavailable between departments and systems is now visible to everyone who needs it.

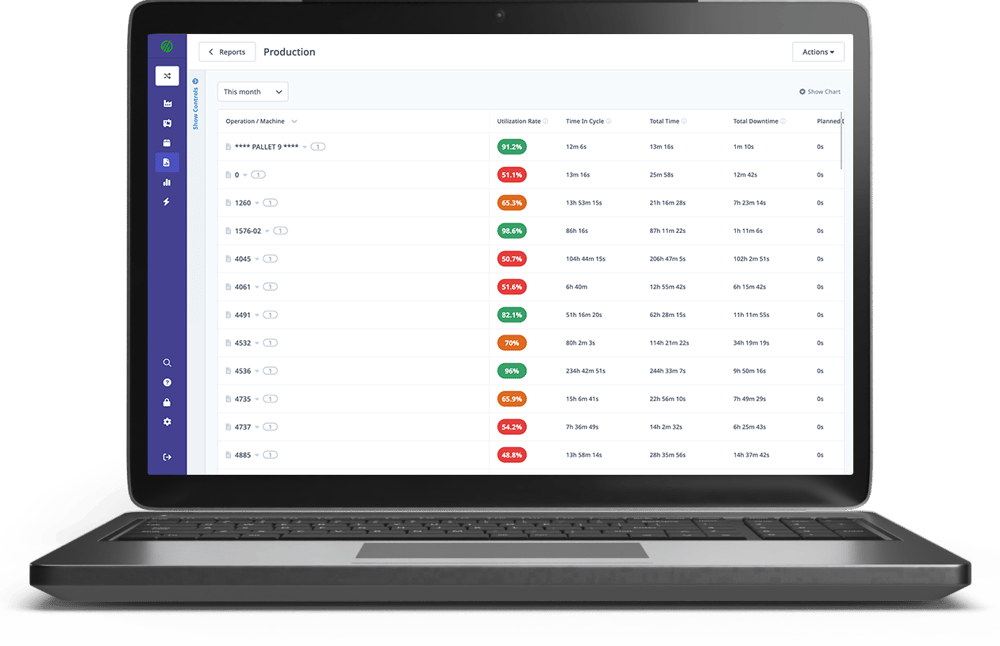

This enables visibility into equipment performance and health, as well as the efficiency of processes. MachineMetrics, a production monitoring platform, surfaces accurate production data from equipment that can ensure key shop floor management systems, like MES and ERP, have accurate and updated part counts and cycle times.

This transparency improves decision-making and increases process efficiency. It enables departments such as supply chain, finance, planning, and maintenance to stay connected to the status of production using a customized dashboard that shows the information relevant to their task or department.

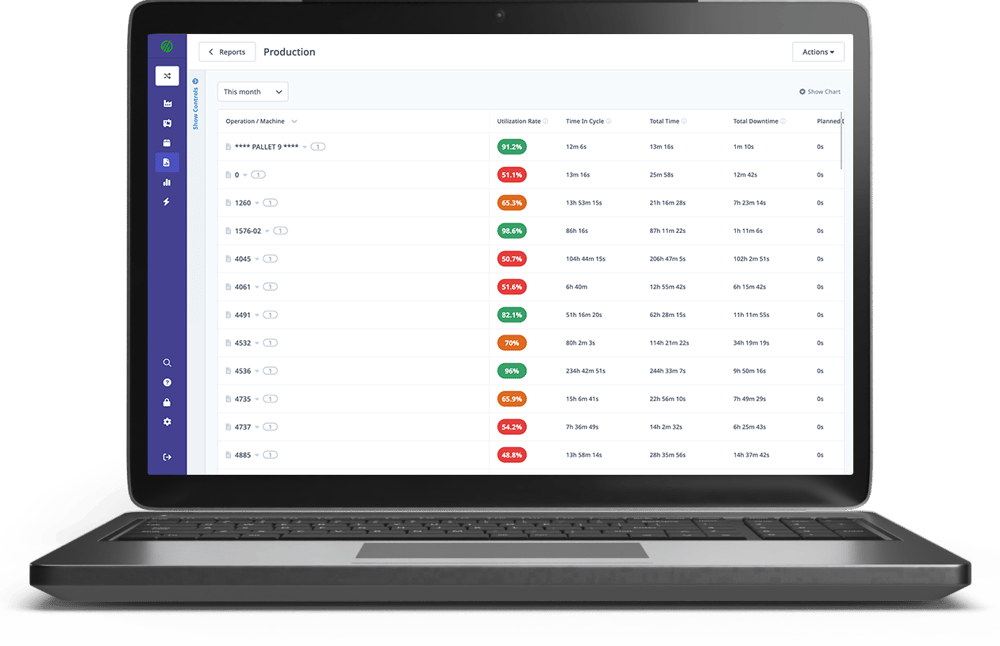

MachineMetrics' report builder allows users to visualize any data points they would like, such as utilization, downtime, cycle time, etc. This data can be filtered and visualized at the operator, machine, cell, or plant level.

MachineMetrics' report builder allows users to visualize any data points they would like, such as utilization, downtime, cycle time, etc. This data can be filtered and visualized at the operator, machine, cell, or plant level.

Keep an Eye on Assets

Factory monitoring allows companies to better manage and optimize their investment in machine assets. With a production monitoring platform like MachineMetrics manufacturers can identify and exploit capacity across their equipment as well as better identify the processes around machines.

Success Story: Learn how Paragon Medical doubled capacity with no additional machines.

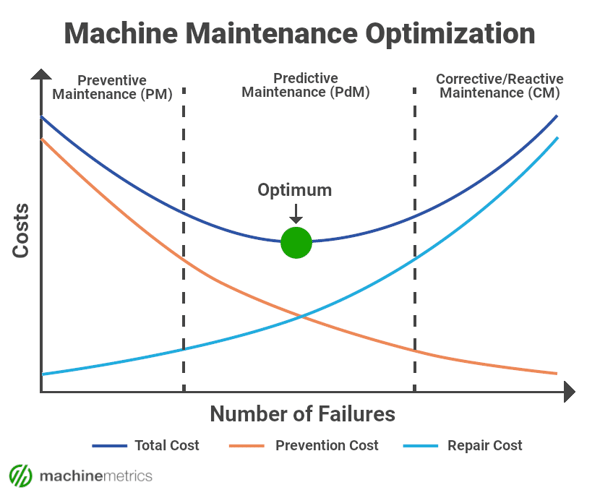

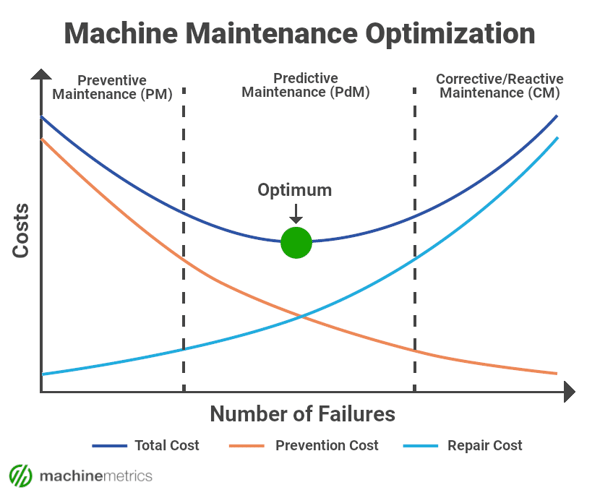

Real-time condition monitoring is also an excellent way to move from preventive to condition-based or predictive maintenance strategies to reduce waste and cost further. Real-time machine diagnostics and conditions, such as vibration on a machine or a certain machine alarm, can enable workflows that notify maintenance of an issue, or automatically create a work order in a CMMS.

This monitoring, in turn, reduces the amount companies need to spend on new machines, allowing them to shuttle CAPEX dollars to cover operational costs or cash flow.

Make Use of Resources

With complete visibility at their fingertips, management can make better use of resources. The same system that monitors machines lends valuable information to understanding and managing the performance of operators. Building accurate work instructions, training effectively, and upskilling workers becomes all the more possible with accurate production data.

The same is true of the supply chain and other resources managing the flow of raw materials. As disruption has altered traditional just-in-time (JIT) strategies, real-time factory monitoring allows supply chains to operate in support of current production needs and alert planners of shortages or bottlenecks.

Enabling Automation with Real-time Monitoring

As manufacturing challenges become more complex, companies are turning to factory monitoring to automate tasks and gain more precise control over processes. Ultimately, manufacturers need accurate production data in order to make better decisions faster, automate low-value tasks, and ensure that management systems are guiding them effectively, rather than stifling continuous improvement.

MachineMetrics is the leading platform to collect, monitor, analyze, and drive action with manufacturing equipment data. Our platform easily captures data from your manufacturing equipment and provides a complete toolkit to drive actionable insights for frontline workers and other factory floor systems that improve the efficiency and quality of production.

Want to see the platform in action? Watch an on-demand video demo.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments