Many complex elements are needed to run a modern manufacturing operation. Equipment, raw materials, operators, and supply chain professionals work together to ensure production is on time and made to specifications. Production scheduling is also a critical part of the process, acting as a roadmap for production.

But planning out production in an accurate and effective manner has historically been a challenge. There are many variables at play, not only the internal operations, but also external components like supply chains and changing customer demand.

Production planners need to know what to schedule, when to schedule the work, how much their team can accommodate, how to allocate resources, how much material to procure, etc.

It's simply a lot to manage. With the current status of production planning, there is a lot to improve on. But, where should you start?

What is Manufacturing Production Scheduling?

Production scheduling is a process manufacturers use to plan production timelines and resources. It’s vital for any company with multiple products within one operation. The process involves calculating the resources needed, the order in which tasks will be performed, and the time frame for production. It ensures the manufacturing process is efficient, cost-effective, and produces the highest quality finished goods.

Scheduling can be executed at different detail levels based on the type of product being run and the available resources; for example:

- Batch planning, where a single item is made in bulk.

- Job scheduling for a small number of goods.

- Flow or continuous planning for high-volume goods.

Production scheduling can help businesses avoid stockouts or excess inventory. It also enables them to manage labor capacity and adjust staffing to handle demand fluctuations.

For companies with agile production scheduling processes, the ability to adjust the schedule requirements due to seasonality, rapidly changing consumer tastes, or other disruptions is critical. Changes should be quickly incorporated into the original schedule so everyone is on the same page and no resources are wasted.

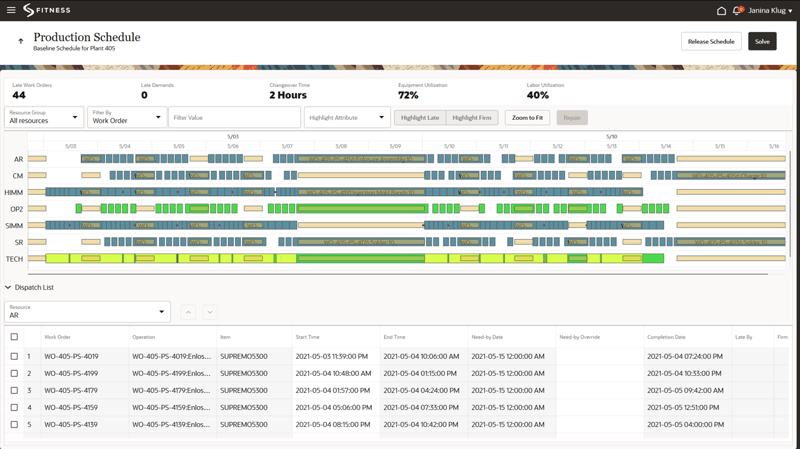

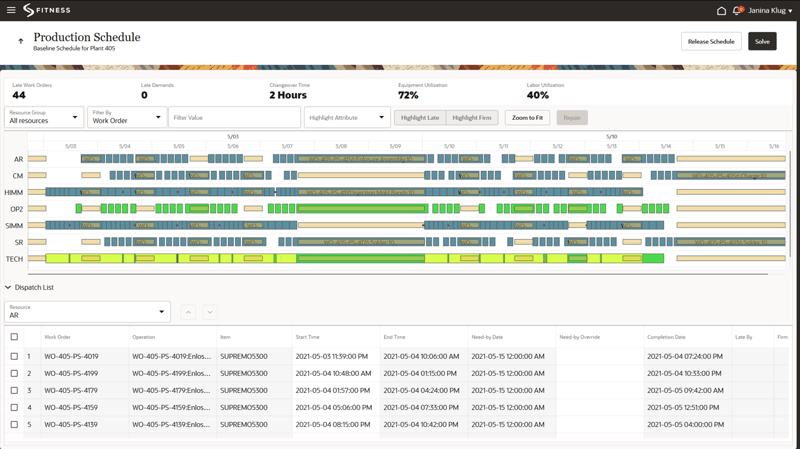

Image Source

Image Source

The Importance of Production Scheduling

Production scheduling provides a high-level roadmap for the entire facility and drills down to the department level for subprocesses and other midstream and downstream operations.

A well-designed master production schedule can minimize downtime, reduce waste, and optimize the use of resources to capture cost savings and increase profitability. It can also help ensure that customer orders are fulfilled on time, increasing customer satisfaction and loyalty.

But there is a major challenge here. With all the variables at play, designing a master production schedule requires meticulous detail as well as accurate historical production data to estimate effectively.

Types of Production Scheduling in Manufacturing

The scheduling process begins with identifying how much raw material is needed and when. It requires solid vendor relationships, agile transportation and logistics, and accurate receipt when they arrive.

Straightforward and predictable production may use static scheduling, which assumes that they’ll be completed once the production steps are laid out in the schedule. All inputs are completed before the scheduled run begins.

Complex production systems will use dynamic scheduling, which requires advanced production software for manufacturing and considers changes that may occur for things like set-up times, workload, resources, new or expedited orders, and other variables.

The product type usually dictates the manufacturing process and, therefore, the type of schedule. While there are many similarities and variations in these methods, the planning and scheduling process includes several basic types of schedules, including the following:

Flow Scheduling

Flow scheduling is used for high-ticket items (such as automobiles and aircraft) with a complex process involving thousands of steps, parts, and assemblies. In flow scheduling, the goal is to plan the schedule to avoid bottlenecks or delays.

Mass Production

Mass production scheduling is used to make many units at a time. Multiple products may be produced in the production facility, but individual machines make only one product each. Scheduling requires the correct direction of materials and resources based on speed and throughput to create the right amount of each product.

Process Manufacturing

Process manufacturing involves the production of goods by following a specific formula. These products include gases, fuels, chemicals, and others. In this type of scheduling, product substitutions aren’t expected. Each production step is a subprocess to bring the final material to tight performance standards.

Batch Manufacturing

Batch scheduling involves the production of goods in groups or batches. It’s commonly used in food and beverage (where recipes are required for consistency) and in manufacturing (where lot consistency based on a formula must be done in large quantities).

Job Scheduling

Job scheduling is also known as project-based scheduling. It plans material and production for a single product or item. Job scheduling is common in CNC machining, where small lots or "lots of one" reflect specific design and performance characteristics.

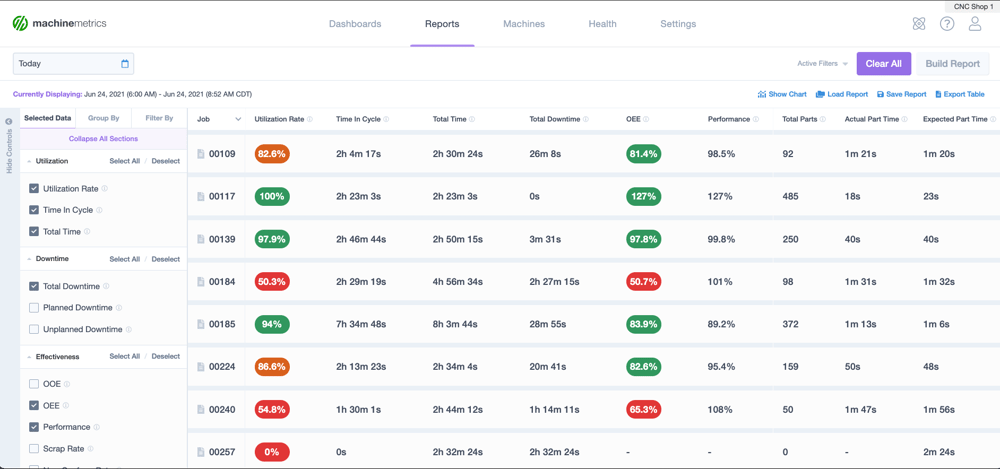

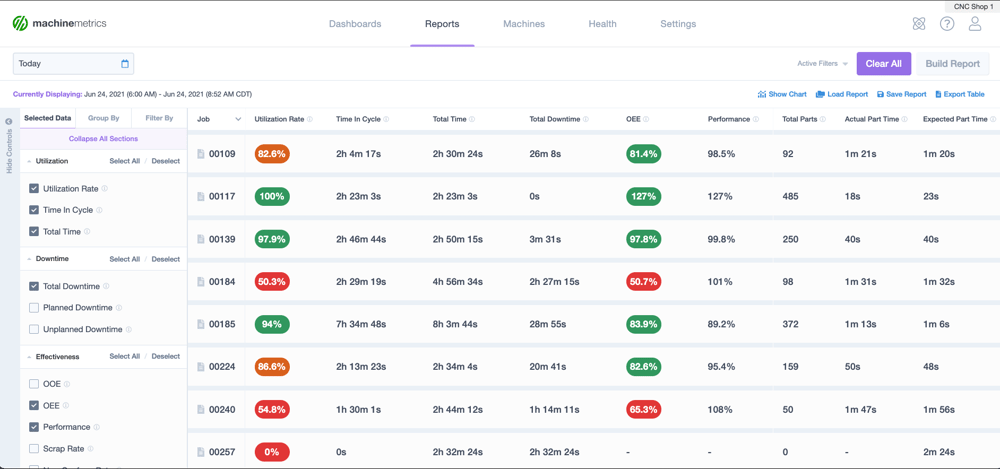

Analyzing data by the job in MachineMetrics.

Analyzing data by the job in MachineMetrics.

Factors to Consider When Creating a Production Schedule

Several factors are critical for success when creating a production schedule. These factors include the availability of resources, production and labor capacity, raw material and component lead time, and the promised delivery date of finished goods to consumers. For companies using dynamic scheduling, unexpected events like machine breakdowns or transportation and logistics delays need to be considered.

Production Planning

This factor calculates and procures raw materials for production. It also uses BOMs to match each manufacturing process with workstations and machines and indicates which supplies should be issued from MRO stores.

Routing

Routing is the "roadmap" stage where the path to be followed is included in the schedule. Not all materials will run on all machines, so matching BOMs to equipment and process capability will determine each product’s path through the factory.

Scheduling

The master production schedule will streamline the inventory process by uniting all aspects of production planning and routing into an efficient timeline.

Execution

Execution is the “action” stage of the production plan. It requires close monitoring and adjustments to ensure the schedule unfolds as planned.

Optimizing Production Scheduling

The proper scheduling technique optimizes factory production flow, minimizes production costs, reduces waste, and improves productivity. Which technique to use will depend on the complexity of the product, the chosen production method, and the market requirements for maintaining service levels. Some of the most common techniques include:

Infinite Capacity Planning

Infinite capacity planning considers all available resources and capabilities, including workforce and work centers. This method is most effective when a company has a small number of SKUs and a high volume. It also works well with no resource constraints or potential bottlenecks.

Finite Capacity Planning

Finite capacity planning considers limitations of a company's resources like staffing, the number of workstations, and the number and type of machines. This method helps avoid schedule conflicts when a machine cannot be scheduled to complete a job due to limited production capacity or if the machine’s size or output doesn’t match a product’s physical characteristics.

Forward Scheduling

Forward scheduling uses a chronology-based schedule for the production line based on receipt of the order. For simple manufacturing operations, this is a viable technique. But it’s ineffective in more complex processes because it doesn’t consider jobs that require extra WIP for sub-processes or resources already committed to other orders.

Backward Scheduling

Backward scheduling "reverse engineers" production requirements and works backward from the due date. It uses established BOMs, work instructions, set-up times, and processing steps to determine when the order for that volume should begin.

Implementing and Managing a Production Schedule

Production schedules must be implemented and managed properly to ensure products are manufactured on time and spec. Advanced scheduling systems also make it easy for managers to spot issues and intervene before they accelerate.

The more data and information are available to the scheduling system, and the more advanced the scheduling software, the more accurate and attainable the schedule becomes. These advanced capabilities are beneficial when multiple SKUs are made at once. Managers and planners can create flexible schedules to adjust to changing demand and other variables.

A production schedule relies on several steps for success:

- Demand Forecasting: Knowing demand by-products will help create an attainable schedule and plan for contingencies.

- Inventory Management: Having the right materials and managing them to prevent stockouts or overages is critical for cash-flow management.

- Resource Planning: Resources may include the amount and type of equipment, understanding what equipment is needed for subprocesses and what is required for finished goods, labor utilization, and more.

- Production Monitoring: Without the ability to accurately monitor production at or near real-time, the system is left open to gaps and errors in performance.

- Agile Response: Responding to unexpected disruptions like power failures or downtime requires accurate, real-time data.

The Role of Technology

As the implementation and management steps above indicate, a solid production schedule requires robust monitoring, protocols, and data. Technology has made those requirements easy to include in any scheduling system.

Production monitoring platforms like MachineMetrics improve the accuracy of production scheduling. Production monitoring, advanced analytics, and machine learning enable schedules to access real-time shop floor data.

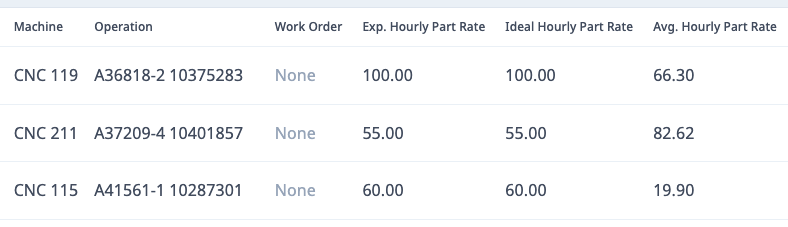

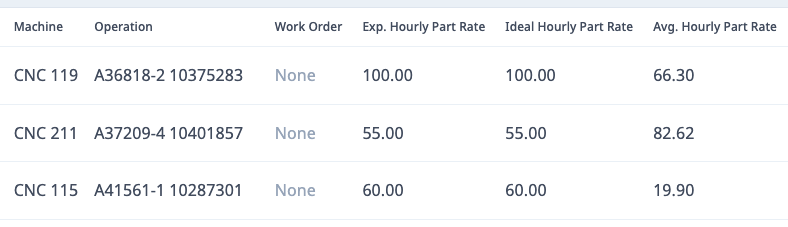

Analyzing hourly part rates in MachineMetrics by each machine.

Analyzing hourly part rates in MachineMetrics by each machine.

Creating and managing a production schedule can be complicated and requires detailed information about everything from the availability of raw materials to the specific machines used. Employing software designed for this purpose can help streamline the process and ensure that the proper steps are taken at the correct times to maximize production efficiency.

But in today's hyper-competitive markets, more than software is needed. By leveraging machine data, production processes can be taken to the next level.

Power Production Scheduling with Machine Data

An advanced machine data platform like MachineMetrics will help you understand what is happening on the shop floor in real-time. MachineMetrics provides insights that drive the optimization of a broad range of factory components, including:

- Operator performance

- Maintenance

- Process improvement

- Production visibility

By digitizing processes, you can zero in on the whole facility and make changes that improve your ability to meet the production schedule. These data insights can be connected seamlessly to scheduling software to operate with the most current conditions and performance data available.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Analyzing data by the job in MachineMetrics.

Analyzing data by the job in MachineMetrics.

Analyzing hourly part rates in MachineMetrics by each machine.

Analyzing hourly part rates in MachineMetrics by each machine.

.gif)

Comments