At the end of the day manufacturing is all about numbers. While some companies are still manually reporting data, others are adopting new autonomous technology to improve production throughput. However, with many companies failing to reach desired ROIs with new technology, it is time to check the numbers and understand what affects manufacturing throughput. The following presents how to find pain points and solutions to increase production throughput and drive key manufacturing metrics.

Strategies to Increase Manufacturing Throughput

1. Inspect Your Workflow

Start by knowing what data is being collected and why. When it is all about the numbers remember - garbage in, garbage out. If you are inputting bad, not enough, or even old data, you can’t expect a valuable output. To better understand manufacturing throughput, create a map of your workflow including labor, equipment, processes, and how they work together. This workflow map should also include where data will carry the most value, or indicate throughput effectors (areas and/or processes with the greatest effect on production throughput).

2. Identify Bottlenecks

A well-defined workflow should make finding bottlenecks relatively easy. Finding and streamlining bottlenecks via a bottleneck analysis, might be as simple as improving communication between both machines and workers. In many cases, workers might already know where and why a bottleneck exists. If not, it is important to collect machine data to find the bottleneck's root cause. Some bottlenecks are from a lack of knowledge about equipment cycle times.

Cycle efficiency can be improved by adjusting the depth of cut, speed rates, and feed rates to reduce bottlenecks. However, it is important to know safe operating specifications. Operating within a safe operating range prevents extraneous wear and tear, or mitigates machine maintenance according to use, to prevent bottlenecks caused by downtime.

Success Story: How an OEE Director increased capacity by millions using production data to identify and reduce bottlenecks.

3. Reduce Equipment Downtime

Maintaining proper maintenance reduces downtime. It can be easy to find the cost associated with downtime and how it affects ROI. This relatively easy to calculate cost is often why many companies start a digital transformation plan based on preventative maintenance.

Maintaining proper maintenance reduces downtime. It can be easy to find the cost associated with downtime and how it affects ROI. This relatively easy to calculate cost is often why many companies start a digital transformation plan based on preventative maintenance.

Finding better ways of documenting and tracking maintenance can be a good way to start small, find throughput effectors, and make informed decisions on scaling or adopting new technology. Using technology with reminders, real-time notifications, and alerts will keep machines running and help reduce downtime, and rejected parts.

4. Reduce Rejected Parts

Scrapping or reworking parts hinders manufacturing throughput. Monitoring machines more accurately can provide preventative maintenance, but monitoring production can find rejected parts faster. Combining preventative maintenance and quality control data can predict errors to fix problems before they start to improve throughput.

Using your workflow will determine where quality control is needed. If inspection is too far downstream, more scrap parts might be made before an error is detected. Depending on where the controls are located, more reject parts might be produced before the line is stopped or the error is fixed. Workers should be made aware of workflow and where quality control is needed so they understand why inspection or checking gages is so important.

Case Study: BC Machining virtually eradicated scrap due to tool wear and significantly reduced changeover times, saving $72k per machine.

5. Improve Training Programs

Proper training and management is another common throughput effector. Employees that understand the entire production and why things are done certain ways can help them see how mistakes create delays and ripple effects. Education can also help employees make changes that might save time downstream or reduce process and setup times. Workers aware of the big picture are more likely to observe ways to improve their work station, eliminate extraneous steps, and more.

There are often two parts to education. First, educate workers. Second, have management listen to educated workers. Companies should have an effective way for experienced, knowledgeable workers to communicate ideas. While connecting machines provides data, your workers also collect data and observe patterns everyday. If you don’t have a good communication system or relationship with them, you are losing some great data points and observations. This real-world information might target the largest throughput effectors without spending a dime on new equipment.

6. Manage Labor Efficiently

While workers should be well trained, understand production, know what effects downstream, and effects production throughput, limiting what workers do can increase efficiency. As the assembly line has proven many years ago, workers dedicated to specific parts or tasks can increase production throughput.

Dedicated workers with limited production responsibilities can set up parts and perform processes faster while reducing time in change-overs, checking instructions, reading prints, or performing inspections. Dedicated workers require less training to get up and running too. However, companies should still encourage continuous education to promote flexible workers able to create the type of value mentioned in the previous section; Training.

7. Leverage Factory Automation

Automation has become the focus of many companies to improve manufacturing throughput. However, many attempts to connect machines, integrate new technology, or scale holistic platforms are failing to meet expected manufacturing throughput and ROI. Throwing automation and technology at problems without understanding the previous key points mentioned will likely fail. Information on your specific production throughput effectors is important to knowing…

- What data do you need?

- Where do you need data from?

- Where does it need to go?

- How often do you need to receive data?

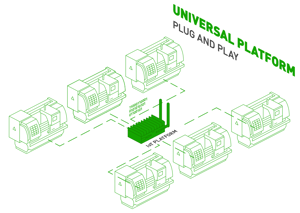

The answers to these questions will help you understand what type of automation solution you need. To find successful automation solutions look for products that offer different ways to communicate or present data. If the end user doesn’t understand what is behind the data that technology provides, it leads to failure. Technology must also be flexible and customizable to your production goals, or it will not deliver the best value for your investment. Solutions claiming to be a one-size-fits-all, or a more horizontal approach often fails to gain expected ROI.

For the greatest value, technology should be able to operate horizontally, but must be capable of focusing on your specific verticals. Additionally, automation solutions should deliver customizable hybrid solutions at the Edge and Cloud, while being flexible and customizable to focus on your specific objectives and throughput effectors.

Software as service (SaaS) and flexible hardware often provides customizable dashboards and micro-services that offer companies quick efficient monitoring and control of production and manufacturing throughput. Real-time visibility into machine and job performance alone has shown to improve efficiency by 20%. In one example, MachineMetrics helped Carolina Precision Manufacturing, a small-diameter, close-tolerance CNC Swiss turned parts manufacturer, save over $1.5 million in their first year with machine monitoring.

Software as service (SaaS) and flexible hardware often provides customizable dashboards and micro-services that offer companies quick efficient monitoring and control of production and manufacturing throughput. Real-time visibility into machine and job performance alone has shown to improve efficiency by 20%. In one example, MachineMetrics helped Carolina Precision Manufacturing, a small-diameter, close-tolerance CNC Swiss turned parts manufacturer, save over $1.5 million in their first year with machine monitoring.

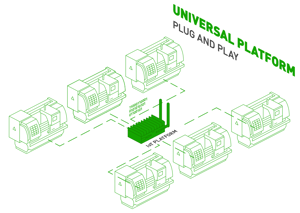

Customizable, flexible solutions do have downfalls. One of the reasons new technology fails to add perceived value or desired ROIs is development and integration time. Custom solutions can have long integration times, disrupt production, and may require additional training hours for workers. To increase value and manufacturing throughput, quick integration is necessary. Look for solutions with plug-and-play technology able to eliminate time-consuming data tag mapping and data standardization.

Driving Greater Manufacturing Throughput Going Forward

At the end of the day, manufacturing is a simple game of numbers, calculating how much we can manage to produce with the limited resources at our disposal. This places a huge amount of importance on being able to understand the "numbers" behind manufacturing.

Production data must be gathered in an accurate fashion that allows decision-makers to easily interpret it. Manufacturing throughput is a result of many variables within a shop floor and beyond, but without a clear understanding of how production is performing there will be no way to improve it.

Our suggestion? Begin collecting manufacturing data as soon as possible so that you can track part counts, downtimes, and more to develop a clear picture of costs, wastes, and production throughput. And if you are interested in automating data collection, standardizing the vast amounts of unique data into one model, and making it visible and actionable in pre-built reports, reach out to our team today.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Maintaining proper maintenance reduces downtime. It can be easy to find the cost associated with downtime and how it affects ROI. This relatively easy to calculate cost is often why many companies start a digital transformation plan based on preventative maintenance.

Maintaining proper maintenance reduces downtime. It can be easy to find the cost associated with downtime and how it affects ROI. This relatively easy to calculate cost is often why many companies start a digital transformation plan based on preventative maintenance.

Software as service (SaaS) and flexible hardware often provides customizable dashboards and micro-services that offer companies quick efficient monitoring and control of production and manufacturing throughput. Real-time visibility into machine and job performance alone has shown to

Software as service (SaaS) and flexible hardware often provides customizable dashboards and micro-services that offer companies quick efficient monitoring and control of production and manufacturing throughput. Real-time visibility into machine and job performance alone has shown to

.gif)

Comments