Key Takeaways:

- Quality assurance ensures that products meet specified standards and customer expectations, playing a vital role in manufacturing.

- Implementing robust QA processes reduces defects, improves product reliability, and enhances customer satisfaction.

- Continuous monitoring and improvement of quality assurance practices are essential for maintaining high standards in production.

What is Quality Assurance?

Quality assurance, or QA, in the context of manufacturing, refers to the processes manufacturers utilize as part of a quality management system to maintain consistent, expected quality levels on the items they produce.

Often paired with quality control, or QC, quality assurance is part of the ecosystem that ensures customers receive quality products devoid of unexpected defects. Quality assurance is the way that manufacturers manage product quality (as opposed to quality verification).

Quality assurance is important in any manufacturing environment, but it is critical for certain types of manufacturers such as those in the automotive industry and high-precision parts suppliers because failure to maintain a high standard of quality could result in injury or death.

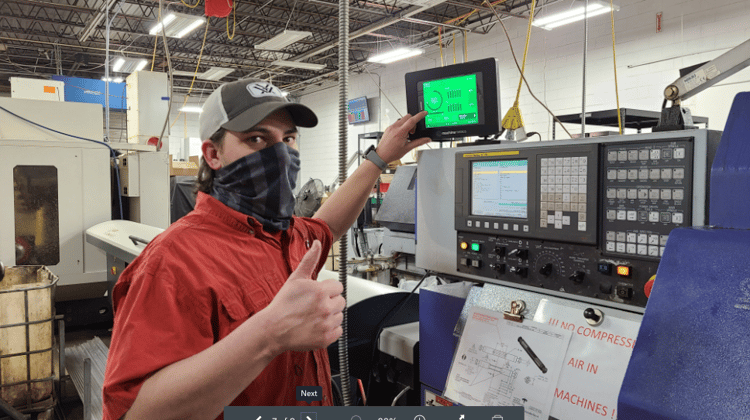

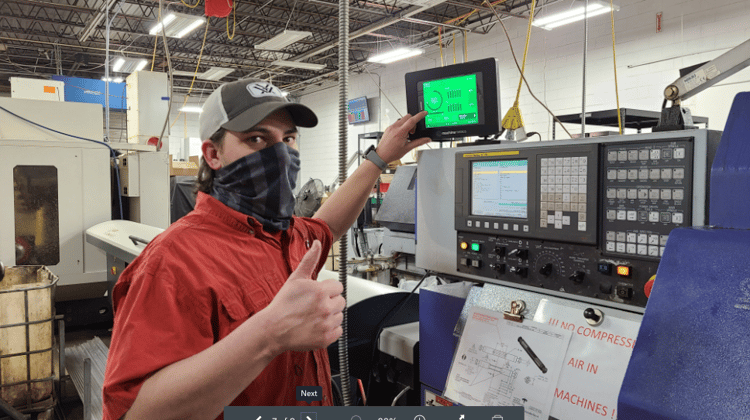

MachineMetrics Operator View tablets are installed at machines as annotation tools for when issues occur. Any scrap parts can be documented and categorized appropriately to monitor production quality.

MachineMetrics Operator View tablets are installed at machines as annotation tools for when issues occur. Any scrap parts can be documented and categorized appropriately to monitor production quality.

The Difference Between Quality Assurance and Quality Control

Quality control is a subset of quality assurance and refers to the reactive components of quality management. QC includes tasks like final product inspections to ensure the manufacturing process resulted in products that achieve the desired standard of quality at an acceptable level of consistency, as defined by the manufacturer. QC in manufacturing also includes testing, walkthroughs, and checkpoint reviews.

On the other hand, quality assurance refers to the proactive components of quality management such as defining processes, team training, and educated tool selection. Auditing, too, is part of quality assurance.

Quality assurance is process-based and proactive while quality control is product-based and reactive. Both components are necessary for an effective quality management system.

The Benefits of Quality Assurance

Quality assurance offers a host of benefits to manufacturers who choose to make it a priority. Three major pros of good quality assurance are:

Cost Savings

Because QA is a proactive component of quality management, good QA leads to the prevention of quality issues. That is to say, because manufacturers do not have to account as much for scrap parts, returns, and other byproducts of poor quality items, they can see substantial cost savings.

Efficiency Boosts

With fewer defective products, manufacturers are able to allot resources such as time, money, and warehouse space not only to creating more quality parts but also to other, lucrative projects. It takes fewer resources to produce quality goods if processes are in place to support the success of that initiative.

Improvements In Customer Satisfaction

Customers receive better products on faster timelines and with greater levels of consistency when manufacturers employ effective quality assurance techniques. With a lower likelihood of receiving a defective product, customers can also see benefits further down the line with greater personalization and innovation since more resources are available for these tasks.

| Case Study: Learn how Carolina Precision used machine monitoring to eliminate paperwork, allowing quality managers to do their jobs more efficiently and resolve quality issues more quickly. Read the full story. |

Quality Assurance Best Practices and Methods

Some aspects of quality assurance are standardized in the ISO 9000. In addition to these standards, manufacturers are encouraged to further develop and employ their own internal standardization practice. Consistency is key. Manufacturers can reduce variability using standard operating procedures (SOPs), keeping equipment in good condition via an effective maintenance strategy, using 5S or 6S strategies, and documenting and using up-to-date formulas for production.

Manufacturers can also encourage a culture of constant improvement, teamwork, and learning. By fostering curiosity and collaboration among teams, manufacturers will reap the rewards of combined ideas and innovations which will, in turn, lead to higher quality production.

Standardizing areas of focus for teams is of vital importance. Manufacturers can utilize well-defined, well-organized planning systems and KPIs to keep teams on track and producing to the best of their abilities.

An example of a good part (top) vs. bad part (second from top). This scrap part was due to a tool breakage, as seen with the broken endmill at the bottom of the image.

An example of a good part (top) vs. bad part (second from top). This scrap part was due to a tool breakage, as seen with the broken endmill at the bottom of the image.

Examples of Quality Assurance in Manufacturing

When a manufacturer uses software and systems to maintain SOPs, plan tasks, and guide organizational improvements using centralized KPIs, they are engaging in quality assurance practices.

Similarly, manufacturers who monitor machine information for anomalies using hardware like the High Frequency Data Collector can be said to be engaging in quality assurance. Poorly maintained machinery can result in slowed production as well as scrap parts. Continuous monitoring can help manufacturers use predictive maintenance techniques (quality assurance) prior to the event where broken-down machinery begins to create sub-par products, causing quality control issues.

Quality Assurance KPIs

Manufacturers who employ quality assurance best practices can consider the following KPIs as part of an overarching quality management plan, ideally fulfilled together:

- Specification compliance

- Low percentage rate of defects (first pass yield)

- Shipping is on-time

- Shipping results in delivery without damage to the product or packaging

- Delivering speedy responses from customer service

Using MachineMetrics for Quality Assurance

Maintaining quality is a constant challenge for manufacturers. Not only is there a cost generated from scrap parts, but an opportunity cost as a result of not creating good parts that can be sold.

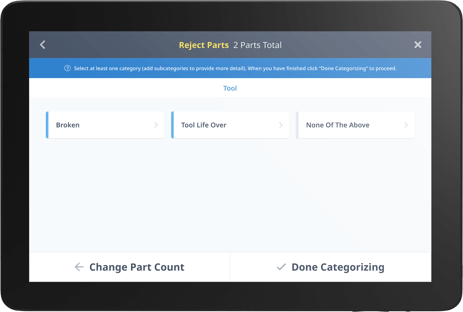

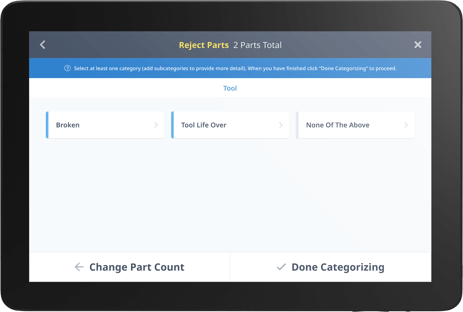

With a solution like MachineMetrics, manufacturers can track when quality issues occur. Operators are able to do this via tablets mounted at machines. Below, you can see the operator view where a rejected part can be categorized:

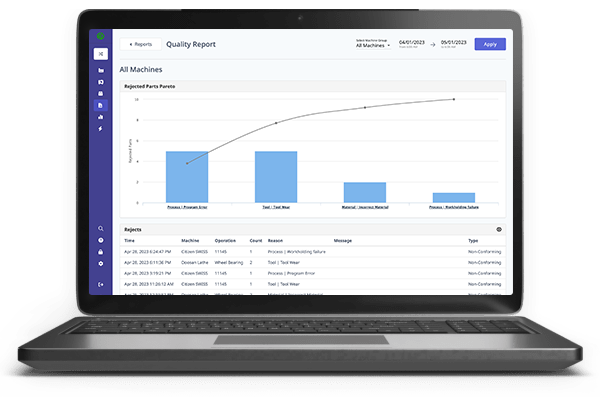

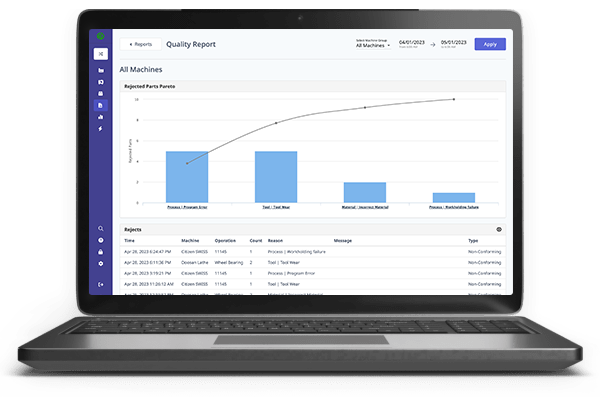

With this scrap data accurately collected, quality managers can review the largest reasons for poor quality via pareto charts and begin making process changes to reduce the amount of scrap generated.

Interested in a real-world use case of ensuring quality by predicting tool failure? Learn how BC Machining deployed MachineMetrics Predictive, enabling them to diagnose, predict, and automatically prevent machine tool failures on their Star CNC machines that lead to broken tools, scrap parts, and costly downtime. Read the case study.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments