Key Takeaways:

- Reducing manufacturing scrap involves identifying sources of waste and implementing strategies to minimize defects.

- Improving process control, quality management, and material handling can significantly decrease scrap rates.

- Lowering scrap not only reduces costs but also enhances sustainability and operational efficiency.

Of all the components comprising the cost structure of manufactured goods, material cost is one of the most expensive for almost any industry. Of course, without raw materials and components, there would be no production. But if too much material is rejected for off quality, it can significantly impact a company's profit margins. Even tooling alone can be expensive!

Across industries, rejected material is referred to as scrap. Few things get the attention of management like high scrap rates. The issue is so critical that, similar to labor and equipment utilization, programs to reduce scrap are almost always part of manufacturers’ continuous improvement initiatives.

Manufacturers have to take into consideration scrap rate as opposed to focusing solely on creating maximum output, otherwise, profits will take a significant hit.

But what exactly falls into the category of “scrap” material? And how can managers actively work to reduce the amount of scrap generated? We explore the concept of scrap, how to calculate your scrap rate, and explore strategies to reduce scrap and rework from your operation.

What is Scrap in Manufacturing?

Manufacturing scrap is the unusable material from a manufacturing operation that will be discarded.

Scrap can be subdivided into several categories while used as a general definition for all rejected material. First, there’s scrap that’s rejected in raw material form. It may be due to spoilage, or it may be due to off-specification performance characteristics such as tensile strength or shatter point. This material has had no additional processing or partial processing added to it.

Second, there’s scrap that has been partially processed. Many manufactured goods are produced in stages of a production process, and the failure at any one step can mean that the part must be rejected. This is more expensive than scrapping raw material as the partially finished part has had some value-added labor.

Third, finished goods must be scrapped due to failure to meet specifications. Some can be reworked by adding labor to adjust the part or turn it into something else. Others may require complete scrapping if no rework can be performed.

This is an example of a scrap part. In this case, a tool failure (the broken endmill on the bottom) caused the part to be developed slightly out of spec. With no way to rework this component, this part will have to be scrapped, along with the broken tooling.

This is an example of a scrap part. In this case, a tool failure (the broken endmill on the bottom) caused the part to be developed slightly out of spec. With no way to rework this component, this part will have to be scrapped, along with the broken tooling.

How to Measure Scrap in Manufacturing: Scrap Rate

What is Scrap Rate in Manufacturing?

Scrape rate is a measure of production quality and output that helps manufacturers understand the efficiency of their processes. Whereas a low scrap rate suggests an operation is manufacturing at high efficiency, a high scrap rate may mean that the organization is suffering from quality control issues and a lower level of operational efficiency.

How is Manufacturing Scrap Calculated?

Put most simply, the formula for scrap rate is simply a function of the number of unusable units divided by the number of total units produced. (In theory, this is the opposite of first-pass yield, which looks at the number of usable, or quality units produced divided by the total number of units produced).

Scrap Rate = Unusable Units / Total Units Produced

Applying dollar values to these scrap parts allows manufacturers to engage in a manufacturing scrap analysis to determine the full cost of scrap that the business is incurring.

There is also a more complicated (albeit accurate) method for measuring scrap rate, which takes into consideration additional types of waste to ensure a complete view of the scrap generated. Planning Master suggests incorporating estimates of these wastes to generate a more accurate scrap rate:

- Materials

- Rework time

- Energy

- Handling

- Disposal cost

- Quality assurance cost

Maximize tool life and eliminate scrap

What Causes Scrap in Manufacturing?

Scrap can be caused by a range of factors and is often a result of poor processes. Typically these processes inhibit maintenance, setup, tool quality, and training.

All scrap increases cost, and those that require added labor drive those costs up even more. In complex manufacturing environments, there are many factors that cause scrap and rework, including:

- Improper setup

- Poor equipment maintenance

- Poor tool maintenance

- Poor tool quality

- Operator error

- Training issues

- Manual processes

- Communication errors

- Inefficient procedures

- Poor design change/specification management

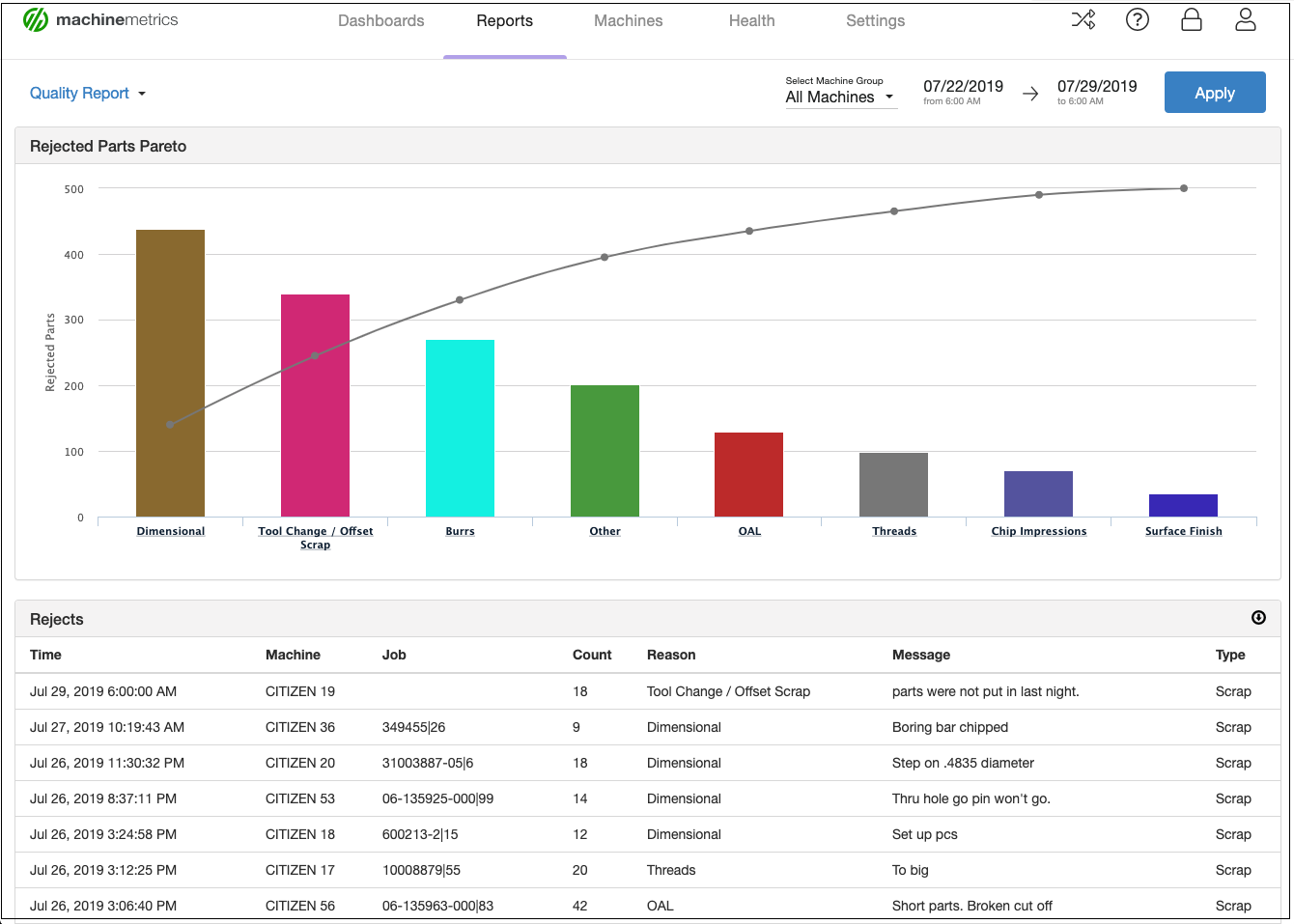

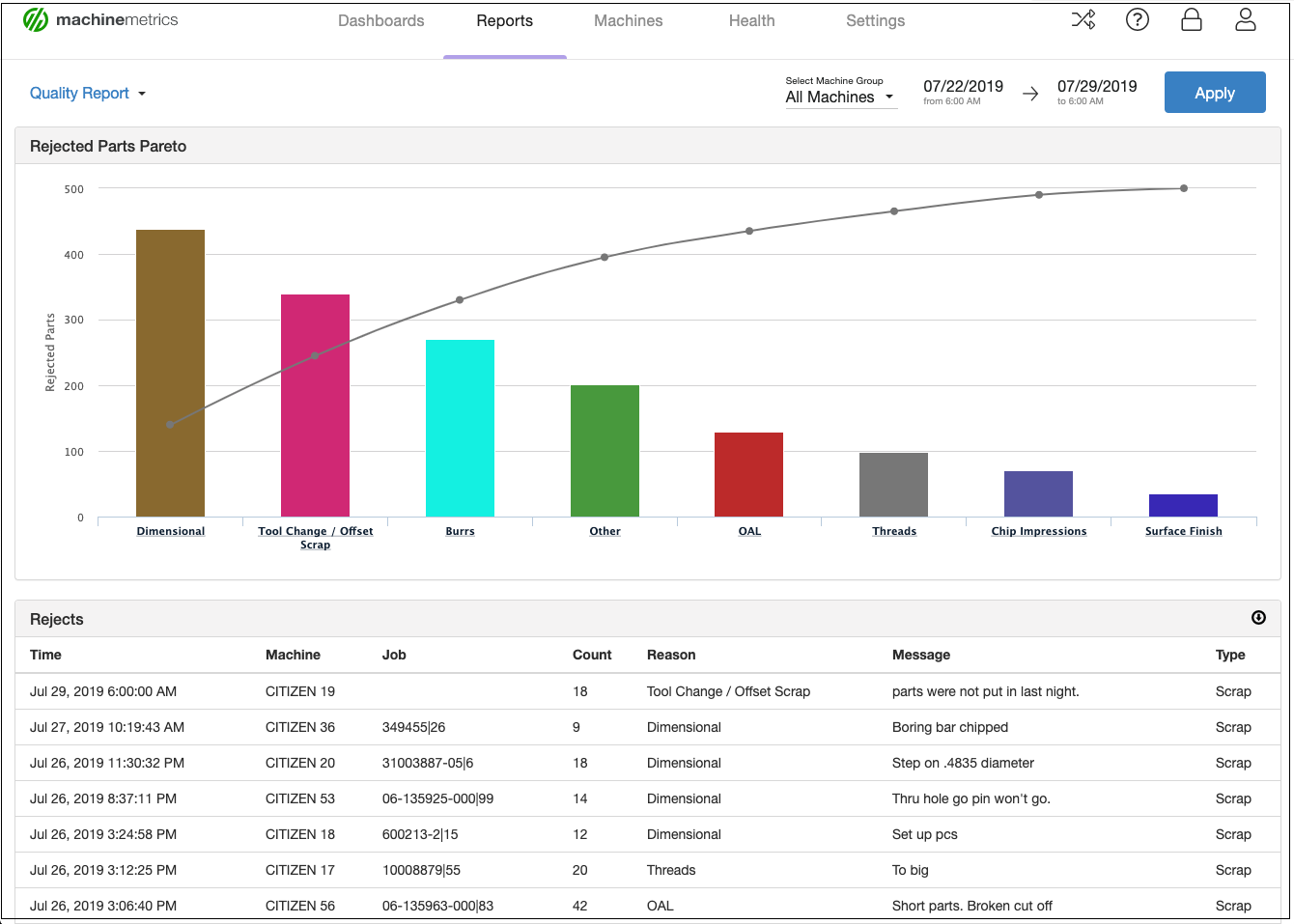

A rejected parts Pareto chart from MachineMetrics visualizes why parts were rejected. This can help quality managers and continuous improvement leaders adjust processes to ensure the most common causes of scrap are mitigated.

A rejected parts Pareto chart from MachineMetrics visualizes why parts were rejected. This can help quality managers and continuous improvement leaders adjust processes to ensure the most common causes of scrap are mitigated.

6 Ways to Reduce Scrap in Manufacturing

Many methodologies, such as Lean and Six Sigma, are designed to help eliminate waste and improve processes in an operation. These methodologies give companies structure and a process for identifying ways to reduce scrap. Scrap reduction techniques include auditing processes, root cause analysis, and other formal procedures to drive change.

There are also many software systems that aid manufacturers in monitoring their processes to ensure higher levels of product quality and reduced waste.

Machine monitoring solutions can be helpful for capturing accurate production data at the machine level to accurately measure the amount of scrap generated.

The key to reducing scrap in manufacturing is buy-in from managers and executives. This can happen as part of a wider continuous improvement initiative or by implementing a dedicated scrap reduction program. Here are six ways to get started:

1. Conduct Process Audits

Many manufacturers' OEE is much lower than they assume. It’s not uncommon for actual OEE to be in the 25-30% range, while managers and executives believe it’s 20-30 points higher. This is because processes veer over time, and control mechanisms to account for and adjust these changes have always been manual.

Conducting process audits is the first step in any scrap reduction process. Without understanding the current process as it occurs, identifying scrap points would prove impossible.

Most scrap will be related to the waste identified in the six big losses:

- Breakdowns

- Setups and adjustments

- Small stops

- Speed reduction

- Startup reduction

- Production rejection

Root cause analysis can be conducted for each type of scrap loss and process changes can be implemented to reduce or eliminate the scrap.

2. Improve Communication and Change Management

Manufacturing is a fast-paced, noisy, and extended process. Communication is sometimes non-existent between upstream and downstream processes, and errors can be compounded as a result. The same is true for hand-written notes and tags, where handwriting quality, lack of clarity, and other shortcomings can impact the next production stage.

Complex bills of materials (BOMs) are also a culprit in communication chains on the production floor. If these must accompany parts, there’s an opportunity for mistakes resulting in scrap. This is true at the floor level, where training may differ from operator to operator in the interpretation of the BOM.

It’s also true when changes to the design or BOM haven’t been communicated or are time-lagged due to manual processes. Accurate communication of changes to the BOM is as critical as having a clear BOM for all production phases.

Case Study: BC Machining virtually eradicated scrap due to tool wear and significantly reduced changeover times, saving $72k per machine.

3. Review Material Sourcing

The quality of a manufacturer depends not only on the quality of material and components used to make goods but also on the quality of material used in production tools. In the case of the former, a rigorous selection of materials such as tensile strength, alloy consistency, and vendor's production methods can make or break a company's quality when those materials are in production.

In the latter case, cutting dies, routing heads, and other hardened tool types must be guaranteed to cut the material they claim to cut. If the performance characteristics of the tool are inferior, scrap can result.

Vendor management, vendor quality auditing, and certification of materials and tools will help lower scrap across the shop floor, contributing to scrap reduction in manufacturing. Changes to those materials, like BOMs and design change notifications, must be meticulously monitored when they’re introduced.

4. Review and Improve Training

Traditional manufacturing in industries such as CNC machining of precision parts relied on years of apprenticeship and training to get an operator up to speed. Much of what operators knew was based on intuition and "feel." The problem with this method is that "feel" isn’t always a good enough tool to prevent scrap.

On the other hand, training new operators in the same unaudited processes with inadequate change management processes and poor material selection puts the load onto the operator's shoulders, meaning the chances of scrap are baked in and all but guaranteed.

In addition to the steps above, operators need access to real-time data and machine health to make decisions and take action. Utilizing software such as MachineMetrics' condition and production monitoring means that operators are still trained on the operation of the equipment and the craftsmanship skills required to produce accurate parts. They’re also trained to monitor and respond to potential scrap events proactively.

5. Document the Right Things

Many manufacturers are drowning in written documents from manual procedures. But when it comes to the most critical aspects of documentation, they’re lacking. Design iterations for active products should always have defined and traceable access. This includes CAD and CAM drawings and any other engineering specifications.

BOMS, quality documents (especially those related to compliance and regulatory authorities), and other critical items should be rigidly structured. They should also take part in an audit process to ensure they’re being completed.

6. Evaluate Maintenance Strategies

As a step up from "if it ain't broke, don't fix it," preventive maintenance strategies have served their purpose. But scrap still occurs at a higher than desirable rate while using preventive methods, and most manufacturers have yet to move beyond them.

This is because manual condition monitoring requires a lot of labor, manual checking, and measurement of temperature, wear, abrasion, and more. Tool-wear and failure may not be detected with a manual preventive maintenance strategy, and data may be omitted through error, bias, or training issues. Traditional maintenance doesn't predict subtle, deeply embedded data such as vibration, oil and lubrication consistency, particulate content, and other factors.

Using MachineMetrics to Reduce Scrap and Rework

MachineMetrics is able to monitor and automate your production operation to reduce scrap and rework, as well as significantly improve processes. MachineMetrics’ best-in-class machine data platform includes production monitoring, condition monitoring, predictive maintenance, and process optimization.

Here are some of the ways MachineMetrics lowers scrap and rework for machine shops, injection molding operations, and other discrete manufacturers:

Workflows, Notifications, and Instructions

All the auditing and process improvement documentation in the world will fall short if created and managed manually. With MachineMetrics, workflows can be built and added to the system using a Triggers and Actions function to customize and automate many factory operations.

Operators can see the actual operation or task and call for support when needed. These alerts to appropriate staff are sent from the machine and go to the right resource to address the problem, whether managers, maintenance, or quality. They’re further aided by work instructions that help them conduct and understand the process undertaken.

Plug-and-play Machine Connectivity

Accurate Documentation

With MachineMetrics, manual document movement can be a thing of the past. When scrap occurs, the system can designate a "why" so that operators, maintenance, and quality managers can understand what happened. This helps drill down to the root cause faster to prevent scrap in the future.

Automated accurate documentation also assists QA teams in understanding the KPIs such as "first pass yield" so that benchmarks can be established or adjusted. Because the data and analysis are real-time, managers and technicians can adjust processes quickly to prevent scrap and rework.

Condition Monitoring

Advanced machine monitoring technology and analytics software from MachineMetrics can help companies move from preventive to predictive maintenance strategies to identify potential scrap and act before it happens.

With automated condition monitoring, machine health is monitored in real-time by collecting machine diagnostics. This is true for mechanical IIoT sensors attached to the machine and high-frequency data detection that predicts part and tool failure before it occurs. Maintenance can be alerted as soon as problems arise, ensuring that equipment runs smoothly and won’t deliver defective parts.

Tool Monitoring

With tool monitoring, settings can be monitored at a level beyond human detection. This includes vibration, temperature, and other variables that precede a tool failure.

The data from these events are analyzed and reported through intuitive manufacturing dashboards and HMIs, so the operator or maintenance tech has true visibility of accurate machine conditions. Combined with high-frequency data analysis, staff can see undetected problems before they occur.

This ensures that inaccurate parts, broken tooling, and other quality issues are prevented and manufacturers do not have to waste any material or tooling.

Getting Started with MachineMetrics

Automating your manufacturing operation with the MachineMetrics Machine Data Platform delivers many benefits, including the reduction of scrap and rework. The insights offered by the platform allow operators and managers to take quick action as soon as it happens, or even before it occurs. The information is contextualized and made available to everyone who needs it via alerts, notifications, and dashboards.

With MachineMetrics, you can optimize processes and have confidence that problems will be proactively addressed using real-time data and advanced analytics. Your documentation will be digital and instantly accessible in its most current and accurate form to prevent the use of outdated information.

Using MachineMetrics to lower scrap is part of the platform's wide range of benefits. Companies can rely on accurate machine and production data to analyze problems, develop faster root cause analysis, and prevent scrap and rework at a level unimaginable a few years ago.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments